Baby its cold outside

A cold front has moved in dropping temps into the 20’s kind of early for this time of year. Where’s the global warming when you need it (yes a bad joke depending on your opinion --- O well). Time to head down and pick up some kerosene for the garage heater. A good day to stay warm inside and generate this post.

Installed the front fender close to its final position to help set the door and fender lower mounting bracket. I measured across the hood and added the gap on both sides and cut a board to this length. Marked the center of the fire wall and the board just cut and clamped the board in place to figure out how far outboard the fender needed to be shimmed out board (you can see the board clamped to the fire wall in the picture below). Along with the cowl in position this should get the fender close to the final outboard position dividing any shimming between both sides of the cab (there will still need to be some fine tuning of the shims on final installation, but it should be close). With a four foot straight edge laid between the cab corner and onto the fender adjusted the fender and door to be in line.

I’m lucky the garage floor is really close to level and with the cab on my stand the cab floor is really close to level. This makes it easy when checking the rear cab pillar at being 90 DEG to the floor and with the door rear edge gap set all the door body lines are level.

Yes there are problems with the door fit to the cab and front fender to the door is not an exact perfect fit and some of the problems I might just have to live with concerning fit and fair. Will talk later on how I’m going to correct them and what ones I’m going to live with (I have them all written down so not forget to check them).

Was able to save the lower fender mounting bracket from the old pillar. Used a long bolt with a bushing to help locate the mounting bracket with the fender set in position. The bushing is used so on final installation I still have up and down & forward and aft adjustment capabilities.

I think the pictures speak for them selves before welding and after welding lower pillar repair panel. If it ever needs to be repaired or taken apart the next guy can cuss me out it’s welded in solid.

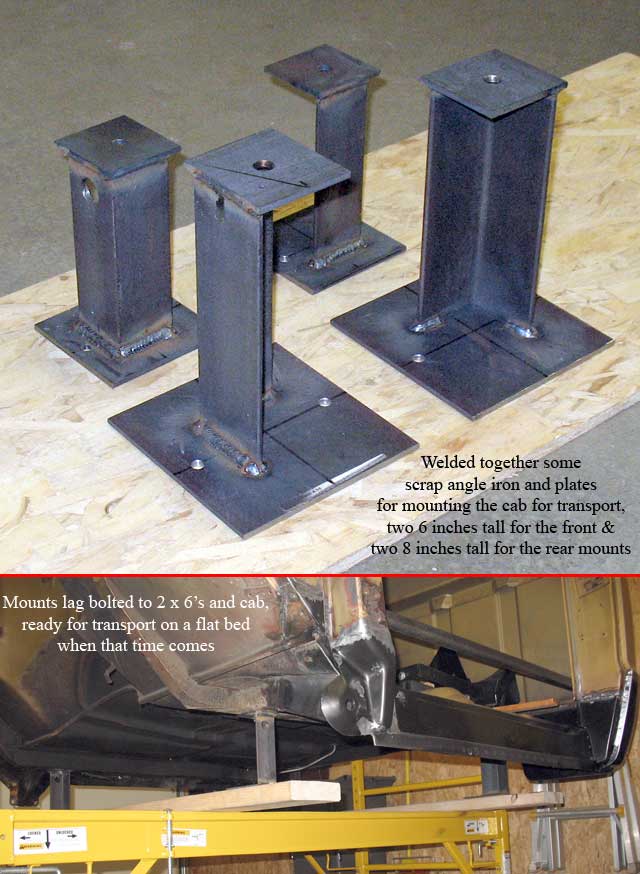

I have a small 4 foot x 8 foot flat bed trailer that I’m planning on using to transport the cab to the sandblaster and to the painter when that time comes. Made some cab mounts out of scrap angle iron & plates and along with some 2 x 6’s I now have a way to load the cab on the flat bed without damaging it.

That time of the year has come, stay warm & healthy and enjoy your build