Filling the hole

It works today but will it work tomorrow

At some time when working on your truck you will find the need to add or modify wiring. The use of insulated terminals/splices would be the most common connectors that you would be working with. Yes there are plenty of other connectors out there like Weather pack, Packard 56, not insulated, and so on, all requiring their own and separate crimping tools and step to put them together.

I was helping a friend the other day figuring out why the tail lights on the old trailer he bought where not working right. I think we ran into a lot of the common mistakes that people make from twisting wires together & taping it up with electrical tape, putting the bear wire under a screw for a ground, the quick wire taps used, and so on. They all worked the day it was put together but with time, vibration and weather they failed in the end. If they would have taken the time to do the wiring terminals/splices correctly the problems that we ran into would not have happened.

One process of terminals/ splices that little information is commonly known is how to figure multiple wire termination and chousing the right size terminal/splice to use. When splicing two wires the same size together itís easy just pick the splice color for that wire size. But when your putting more than one wire in a terminal or one end of a splice you need to figure out what size is needed, to small and all the wires will not fit and to large and the crimp will be loose and not be a good connection.

There are two way of calculating wire area (kcmil) thousand circular mils or (mm2) square millimeter, both are just a way to figure how much area a wire will take up. In the chart and calculation below Iím using (mm2) area for the process.

In the two pictures below I think you can find enough information on how to figure out the right size terminal/splice to use in your wiring projects. Thereís no way to give you the answer for every situation and different wire sizes, you need to calculate each multiple wire termination. But the examples should give you a starting point. May all your terminations be good and not cause problems down the road.

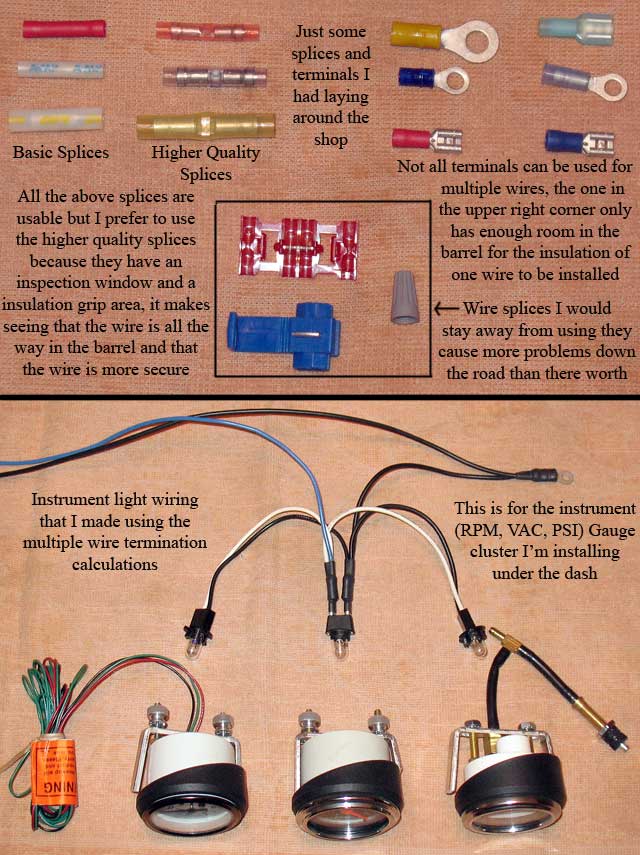

Just a picture of some of the terminals/ splices that I had laying around the shop and wiring Iíve been doing for the instrument cluster going under the dash. You find the quick tap splices everywhere (in the box below) I personally would not use them, they can cut the wire strand when being installed and corrosion is a problem if in a wet environment.

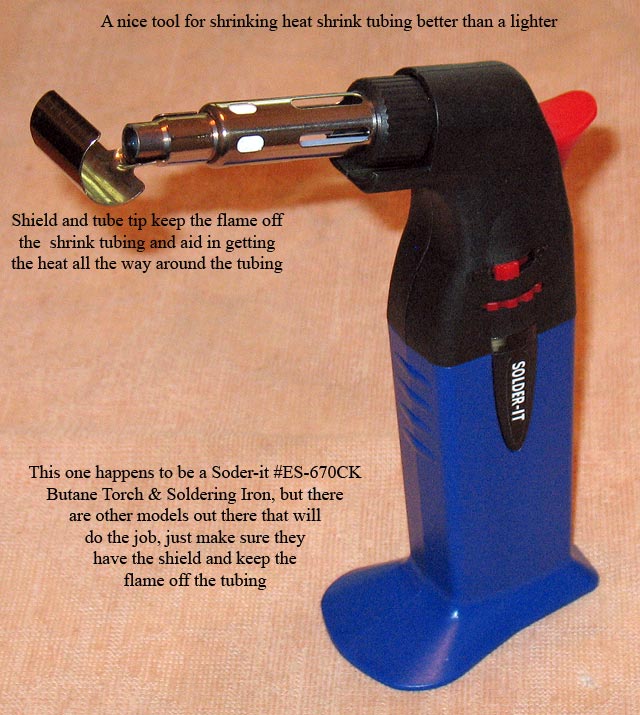

Heat shrink tubing is a nice finishing touch to add to terminals/splices giving added insulation/protection and help preventing water from getting into the splice causing possible corrosion. Iíve used a lighter to shrink the tubing but you always run into the problem of melting/burning the tubing. Thereís some handy butane torches out there that do a good job of concentrating the heat and not burning the tubing. If you get one just look for one with the shield and tube to concentrate the heat and prevent burning.

Just passing on some information and tips that might help you out with a wiring project.

Body and paint update

Not a lot done since the last update just some block sanding, the color and clear coat should be laid down next week. Where somewhat behind anticipated schedule but with the weather delays and the holiday season it isnít too bad.

Happy New Year