Oh ok . Its not a " real" blow-thru . lol

I've got a Carb Shop Carb with a few unique tricks on it . I use a power valve set-up that uses air pressure from an on-board air system . A turbo car doesnt need the fuel during vacuum and it will actually hurt spool . So you need a PV that opens in boost . CSU carbs have a very good BRPV that works with fuel pressure from the bowls to push on the diaphragm and is adjustable . C&S uses hat pressure through the main body to the power valve cavity . A standard PV can have problems opening because fuel bowl pressure is higher than the pressure it can get though the baseplate .

I reference mine through the side of the main body and into the PV cavity . The PV spring is taken off and put on the outside and has a spring retainer to hold the spring . Now the spring holds the PV closed and the only way it will open is when I tell it to . I use a boost switch to open a solenoid at the pressure I want .

I could go on for hours about this , but I'll stop short . lol But it works very well . Just food for thought ..... I have 68/70 jetting with .081 pvcrs and my 750 Holley supports over 1000hp .

The other big advantage to using a PV deal like this is ... you can keep them closed on the transbrake while building boost . I open my PVs at 6psi and the truck leaves on 7psi .

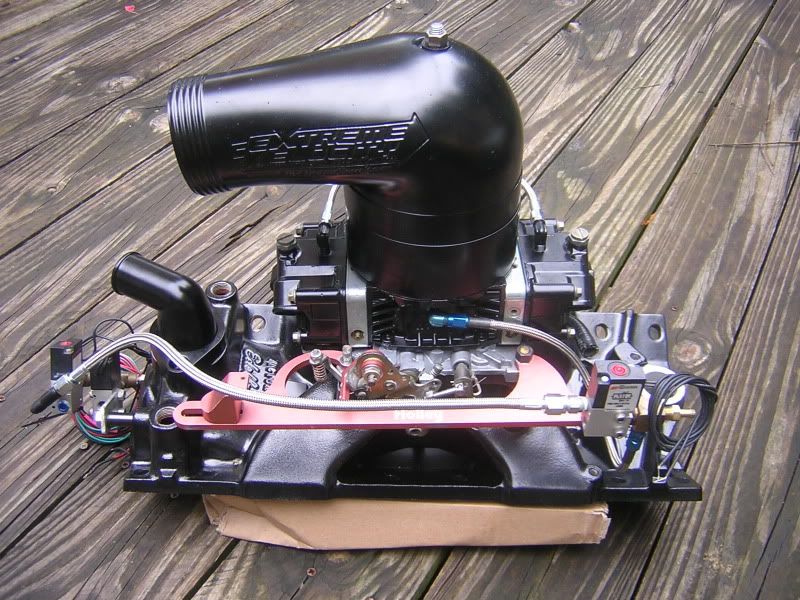

Got a pic of my blow-thru . Just had it powder coated . The solenoids on the front of the manifold is for the boost controller . I just tee into that for the air source . ( 40psi from on-board air )

Sorry for the long post .