Update. So I got the engine pretty much ready to go. I decided to take the heads in and have them cleaned and change out the valve seals for some new ones also had matching edelbrock springs put in for the cam (edl 5802). I did some bowl blending and minor porting for the last few weeks and had a performance valve job done and angle milled. Why so much work for just a 305? Well if you pull the short block out of the picture everything else put on is good for another engine

but I have it put together for about $400 1/4 that being clutch and flywheel.

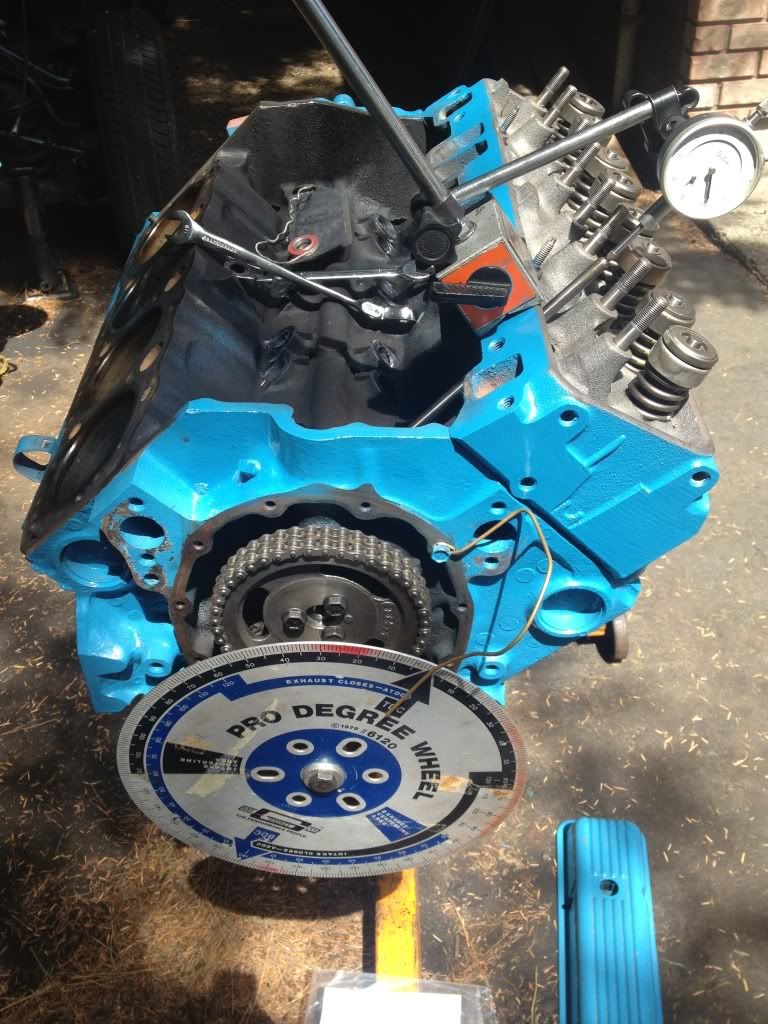

I'm degreeing the cam here, I use the intake centerline method. The summit 1102 cam calls for a 107* intake centerline and I came up with 108* which accounting for inaccuracies in such that you can be a degree or two off on the crankshaft when you turn it. Either It's good enough.

As I was getting the lifters ready I lubed the lifter bores with leftover cam lube. The summit kit gives you plenty which is a good thing. Another thing to note is that when you do this before installing lifters put the engine in final position so I put it on number 1 firing position, this makes it so that you don't wipe your grease off your cam. Just a thing I like to do. I haven't tightened down the rockers yet as one of them was kinda screws inside with a big raised ding. It pays to look at the details. Even if your engine is a used slightly worn 305 being half assed together.

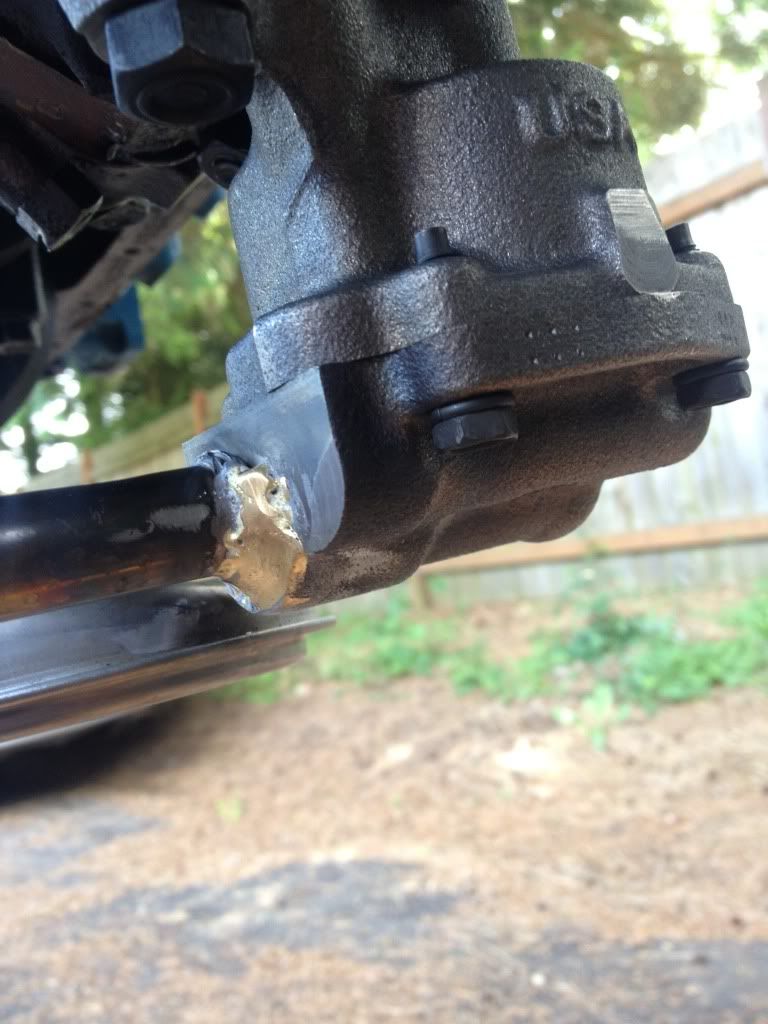

Another detail. I like to braze my pickup tubes to the oil pump. This is a summit brand pump but its really just a melling m55 in a plain summit box. When you braze take the relief spring out as well and then let it cool slowly. I improvised at school and threw it in a rod oven and that worked fine. Also past couple years they haven't done so great in cleaning up their castings such as edges and passages. Carb cleaner and a dremal to radius edges.

Here it is together if you look closely at heat passages I used some coke can tin to block off the heat riser passages to the intake. I never have really had much issue with cold starts or winter weather here in wash with a proper tuned carb. I never use a choke either although I will hook it up and use it on this engine with my 650 demon. Not the carb that's on it now. That's my nice $75 Craigslist Barry grant gold claw. Goes on my red truck when I don't care about how much gas I use haha. I put some pull tabs on the heat riser blockers if I want to pull them out if winter starting gets that much worse. Worth a try anyways. Also LOL I re used the intake gaskets haha.

Btw girlfriends jewelry cleaner is great for getting air bubbles out of lifters while they soak in oil haha. Shhh don't tell her btw

Also summit lifters look like reman or repro oem style lifters. They have a good crown but surface finish on the swirl is kinda rough for my liking but if anything wipes out then I'm sure summit will replace and I will use different lifters. But for now I think they will do. Also use leftover cam lube on the bottom of the lifters before install.

This week I'm going to try and get the firewall painted and the trans mounted and my clutch pedals in as well. Also cutout the trans tunnel for the big hump floor.

Keep tuned guys! More progress to come in the coming weeks. Just got done with this quarter of school so I have more time on my hands to get things done. The cheap way of coarse but hey do it right and cheap is ok

Posted via Mobile Device