sqrlnts and NASTY-LSX, thanks and thanks for checking in.

I've been sidetracked with some winter preparation projects around the house and shop.

One project being gathering fire wood. My old work horse for nearly 30 years has been an Willys truck I put together. It'll be getting some cab work done to it when the Chevy is done.

Some time back once I finished the steering column and I used the universal joints and a solid "D" shaft in between I've been troubled with the idea of the solid shaft.

What stands out for many people is the idea of a front on collision, the possibility of the steering box being shoved back thus the solid shaft, then the steering column being forced back in the drivers chest, not a good thought.

Well ok, I understand safety concerns but I've never been one to build unsafe stuff, but on the other hand, if I have no choice in a matter, I will continue to build one way or another.

My true issue with the solid shaft between the steering box and the steering column has to do with body vs cab flex. I know that while driving, the distance between the cab/column and the steering gear box will change, but the solid shaft will not. Something has to give, I feared the u joints to the splined shafts will give and become loose over time.

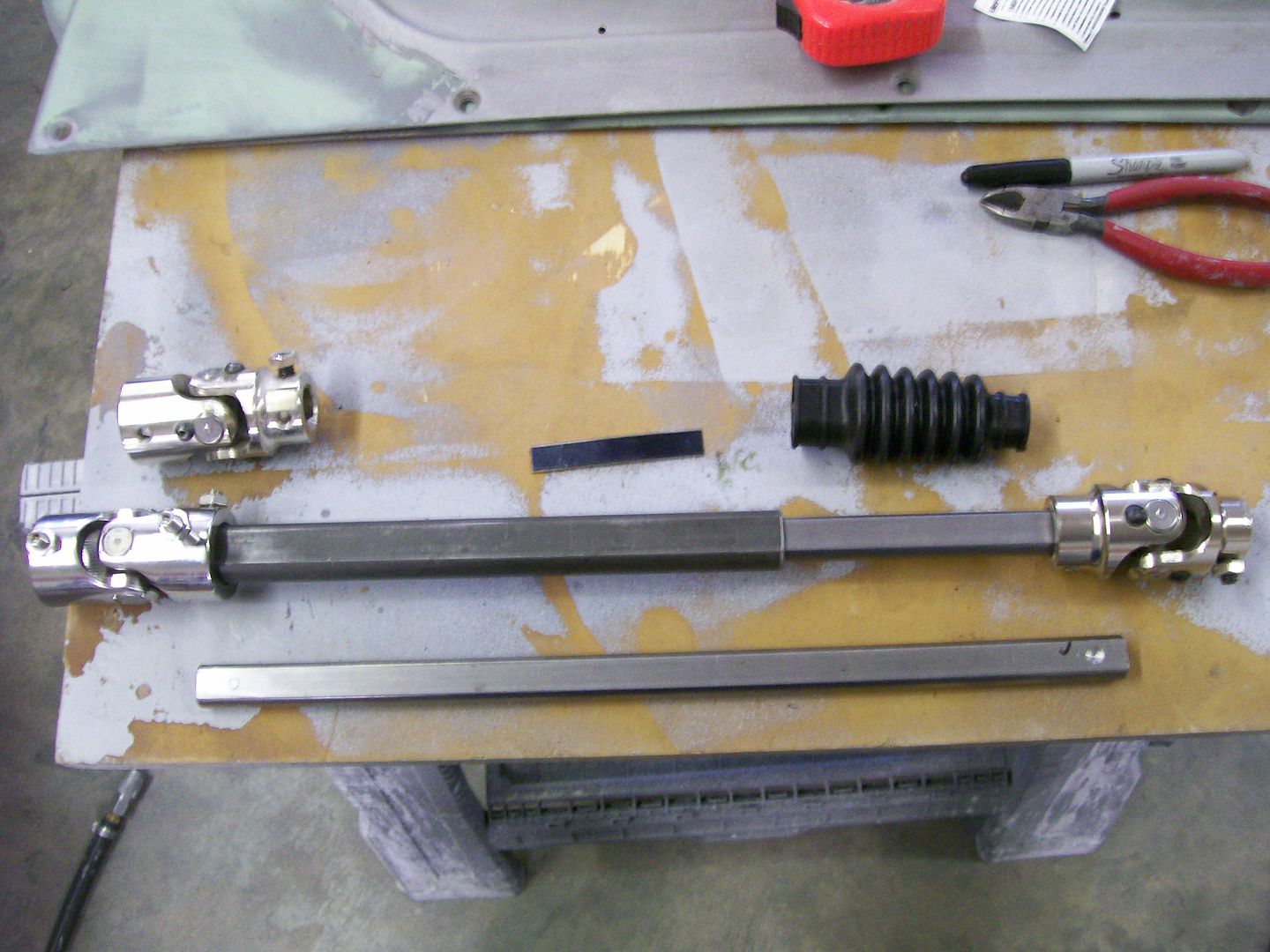

For those with 3 u joints, yours will flex at the middle u joint so I figure these concerns are already taken care of. For mine, as I was going through the catalog I found a telescopic "D" shaft set up, just what I wanted.

I had to cut it to length and get a different u joint for the column end but it's exactly what I was looking for. It comes with the rubber boot, it has about 4 1/2 inches to collapse and it will flex as needed for normal driving.

Since it has a 3/4" ID-OD fit there could be a slight sloppiness over time or perhaps a chattery vibration. The makers machined a flat spot into the inner shaft, this machined area allows the short piece of bent spring steel to fit in as you assemble the two shafts. This spring steel basically keeps tension between the inner and outer shafts so there will be no slop or chattery vibration.

I just wanted to make mention of this product, I think it may be a good way to go.