It has kept me busy!

Things don't always work the way you planned. Before the ends were folded, the bottom piece could never be test fit into the opening. Now with the ends folded, it was slipped over the bottom of the lift gate and it bolted into the opening. With the upper bead detail aligned, the lower was considerably off kilter. Slightly off on the contour, I guess.

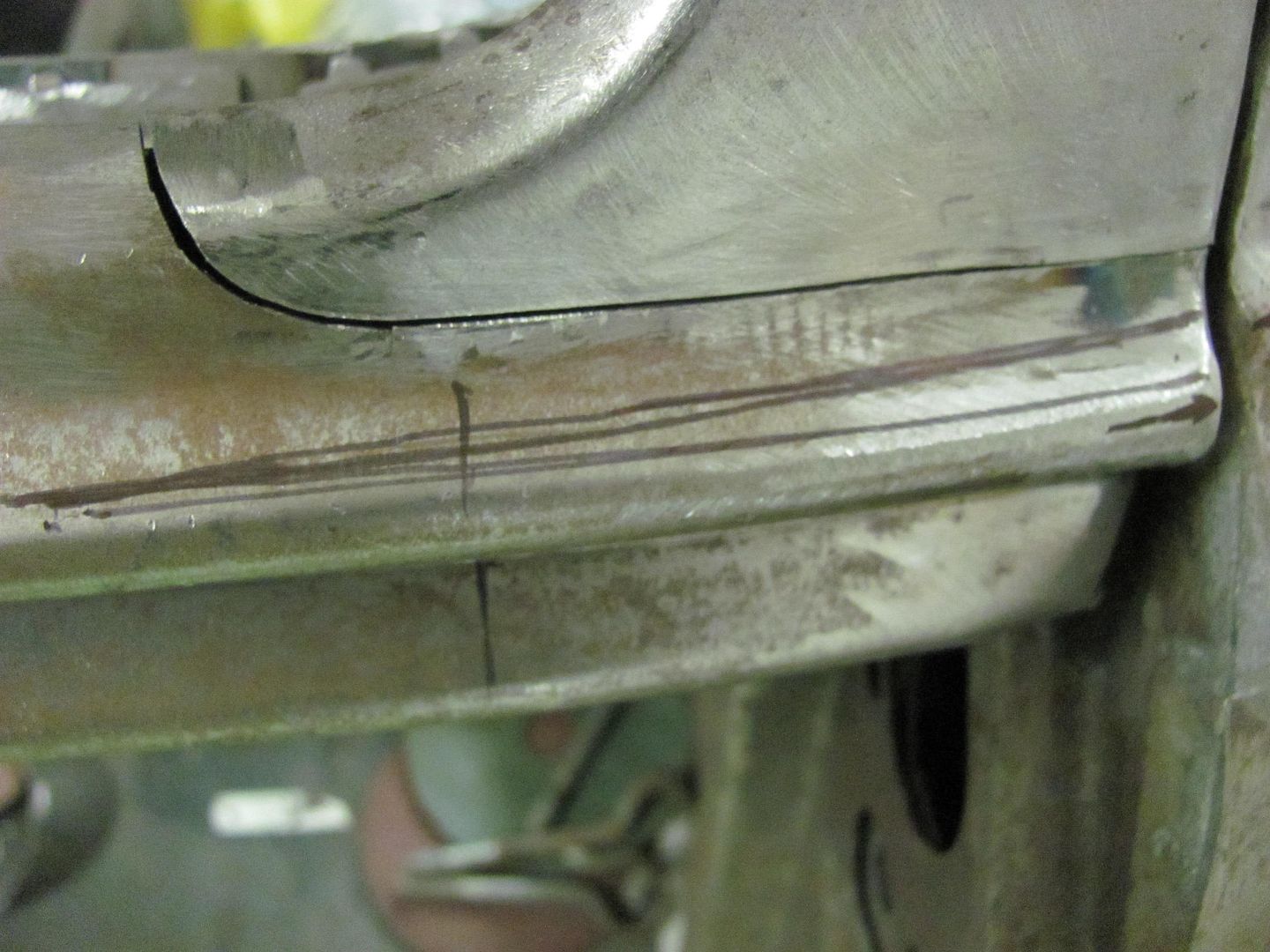

The patch piece was marked off on both ends to bring the lower bead detail up into the car for better alignment...

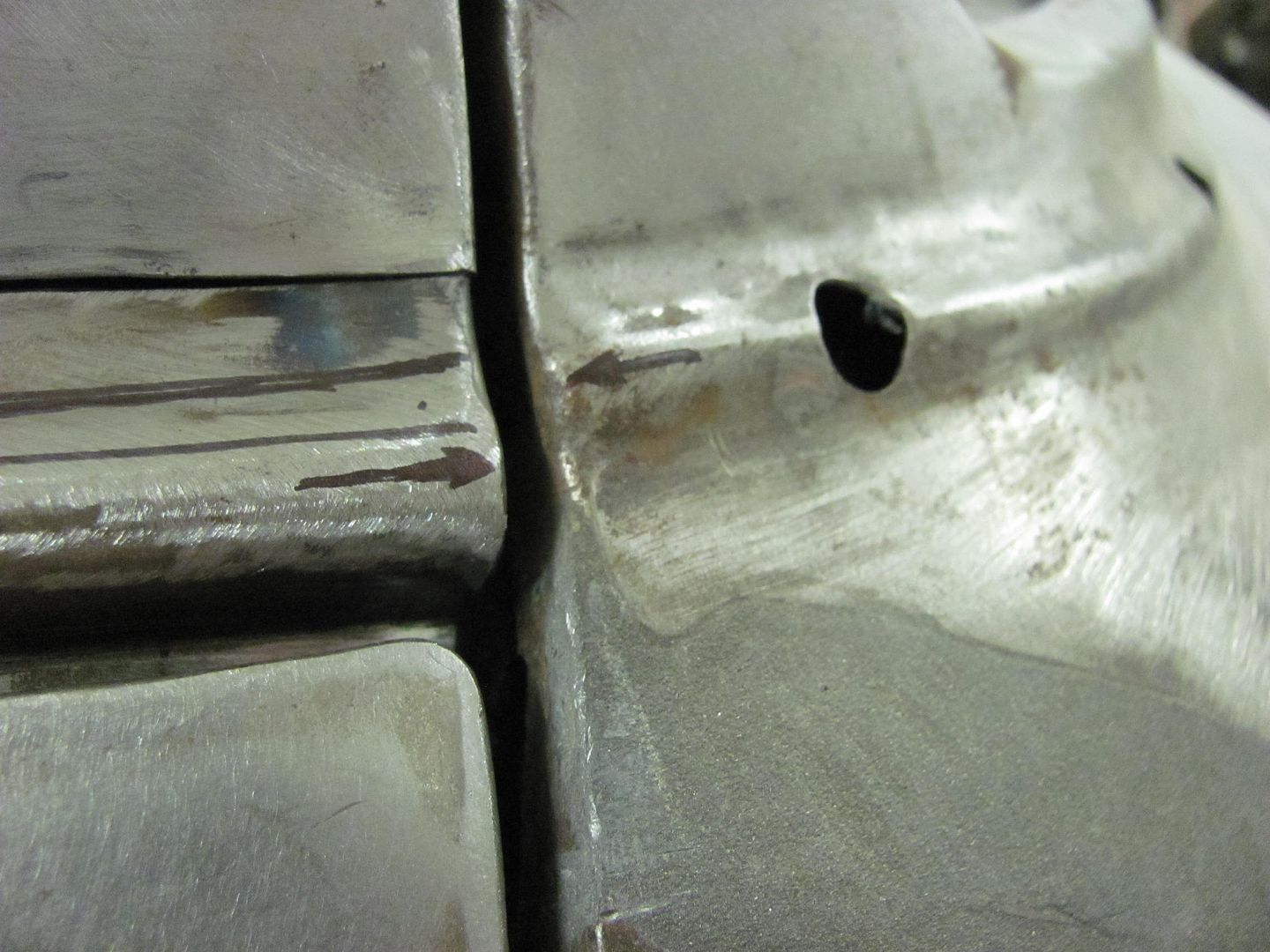

Here's the driver's side after cutting and welding, shows a much better alignment. Good weld penetration on the inside, the seam at the end will be finished after folding onto the lift gate..

We may be able to save this yet..