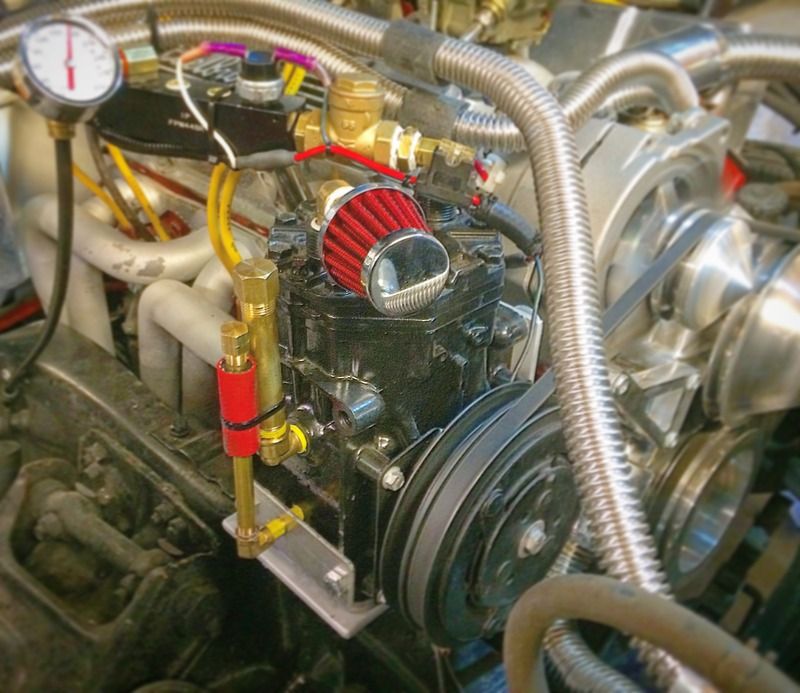

I was able to get everything hooked up yesterday. The distribution block that came with the compressor leaked everywhere. I spent a lot of time redoing every connection. I use pfte paste on all of my connections, but the pump gets too hot and it melted it all out so I wound up having to resort to old fashioned Teflon tape. Once I had all of the wiring and leaks sealed up I ran it up to 180lbs. At 150lbs, it started puking oil out of the dipstick...bad. I tried calling the company that modified it, but they were closed, so eventually I just capped the dipstick tube and that seems to have fixed it.

It is a lot faster than the electric pumps. I can fill 10gal from 0 to 180 in about 90 seconds at idle...a lot faster if I hammer the throttle. I was planning to get a 200psi switch, but as quick as it fills, I think I'll actually be okay with the 170. It recovers from airing up in about 20 seconds. If I can get my overnight bleed out taken care of, I'll be in really good shape.