I think I figured it out. I took photo's from each step of the process, so I'll post them here for future reference. If you notice something out of whack, please don't hesitate to let me know.

Apologies if this should have been posted in the dedicated Suspension forum.

- Spring in and drop spindle on.

- Dust shield on.

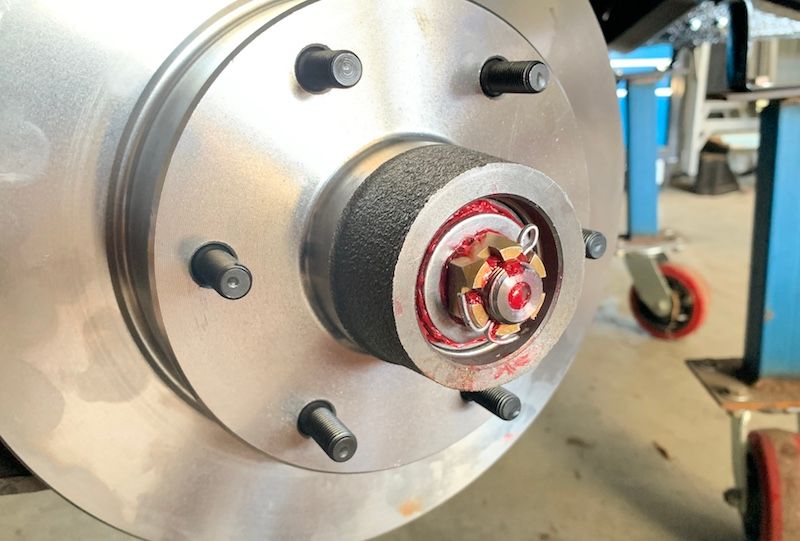

- Small rubber gasket. This was the part I was unsure of. It's the only place I could think of for it to go.

- Bearings greased and installed, along with seal.

- Outer bearing, keyed washer, and nut in place. Pin in. Spins great.

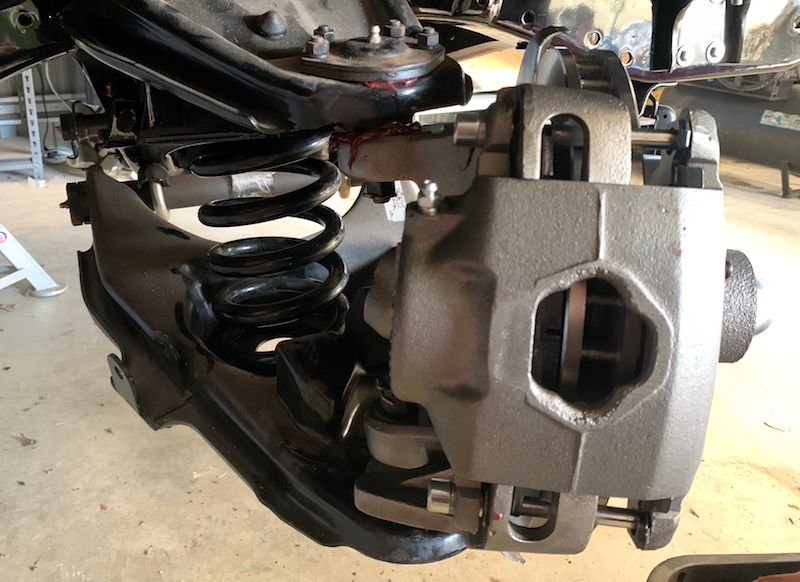

- Then on to the pads, using the anti rattle clip/retainer. This also took me a while to figure out. This is the only place I could make it work. Hope it's not wrong.

- All buttoned in and looking good.

The only issue I've come across is that the outer pad (the one without a retainer clip) is a little wobbly, and unless I hold it in place, it contacts the disc when spinning. The bolts that run through it lock down in place, but as you can see in the next photo, the hole in the pad back is larger than the bolt. This is where the movement comes from.

I'm wondering if this hole should have a some kind of bushing in it? Or will the issue sort itself out once the brake system finished and properly bled? This is my first time installing a disc conversion by myself, so I'm not sure what's what.

Thanks for your time.