A typical day might look something like this:

times 20.

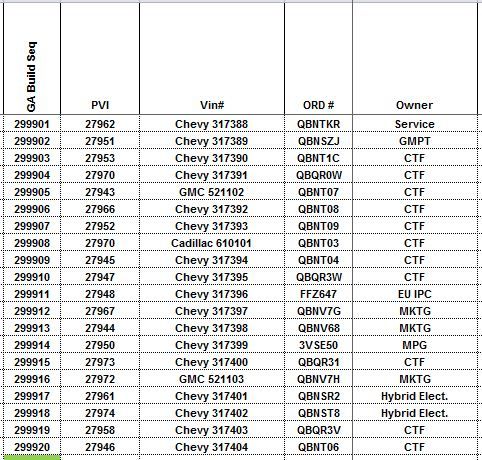

Orders are received at the plant in batches by Order Number. The PVI, or Primary Vehicle Indicator, is assigned to each Order Number in a sequence and the VIN is assigned.

The PVI's are then often shuffled before being broadcast to the floor. Once that order is settled and the build sequence is set then the build sheets and build manifests are printed and distributed.

Note that the VINs are incrementing up one for one (more or less) within a vehicle nameplate, with other nameplates interjected at some interval (one GMC every nine vehicles, one Cadillac every 20 vehicles, for example).

Also be aware that the VINs are independent between each final assembly location. For example, you could have a 1965 Pontiac Lemans hardtop built in Fremont, VIN 237375

Z123456, and a 1965 Pontiac GTO hardtop built in Pontiac Michigan, VIN 237375

P123456, the only distinction being the plant code, and in no relation to each other time wise. In this case the Pontiac vehicle was built in November of 1964 whereas it took Fremont until March of '65 to hit the same number.

K