|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: Dec 2005

Location: TN

Posts: 204

|

Building your own control arms

Ok guys, what are you guys using to build your own control arms. What kinda cross shafts? Tubing? Balljoints/Uniballs?

|

|

|

|

|

#2 |

|

Registered User

Join Date: Sep 2005

Location: spokane, washington

Posts: 302

|

Re: Building your own control arms

tubing i have heard of people using

1" d.o.m. tube. thickness on the wall ??? |

|

|

|

|

#3 |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

there are various things to make them out of. i was curious myself awhile back and asked a guy who builds arms and spindles from scratch, decently often.. he told me i could easily use seamed tubing at .188 wall, 1.25 OD for uppers and 1.50 OD for lowers, or if i went with DOM, i could easily use 1.25 OD .125 wall for uppers and 1.50 x .125 for lowers and I'd have absolutely no problems.

Since I am jigged for nissan arms and about to build a buddy a set of yota arms with uni balls.. i'm going to be doing my personal arms and his arms out of .125 wall DOM. |

|

|

|

|

#4 | |

|

just can't cover up my redneck

Join Date: May 2004

Location: Columbus OH

Posts: 11,414

|

Re: Building your own control arms

Quote:

|

|

|

|

|

|

#5 | |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

Quote:

the tensile strength of .125 DOM is 70 or 75k psi.. do you see our trucks reaching that? nowhere near it. |

|

|

|

|

|

#6 |

|

Seņor Member

Join Date: May 2002

Location: Edge of the world

Posts: 5,367

|

Re: Building your own control arms

I believe LONGHAIR was making a general point about product liability, not about your choice if tubing.

Having said that... I disagree. I've got to be on the road with his work too. Maybe he's an expert welder. But if not...

__________________

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jan 2007

Location: San Jose

Posts: 847

|

Re: Building your own control arms

Exactly, engineering safety aspect is usually 4:1. So lets say said part fails at 100psi, engineering would spec it at 400psi fail point. Either way, if you trust your friend, no worries, if you dont have them sign that "for off road only" disclaimer. Have fun guys, and please post pics of said contol arms when finished!

Last edited by PrerunnerRob; 12-17-2007 at 08:18 PM. |

|

|

|

|

#8 | |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

Quote:

So I am perfectly fine with my welding abilities if the DOT is too. Here are some random welds on random things throughout the shop, if it makes any difference to debate on the tube not failing, but my welds.

|

|

|

|

|

|

#9 |

|

Account Suspended

Join Date: Jun 2000

Location: over yonder

Posts: 14,270

|

Re: Building your own control arms

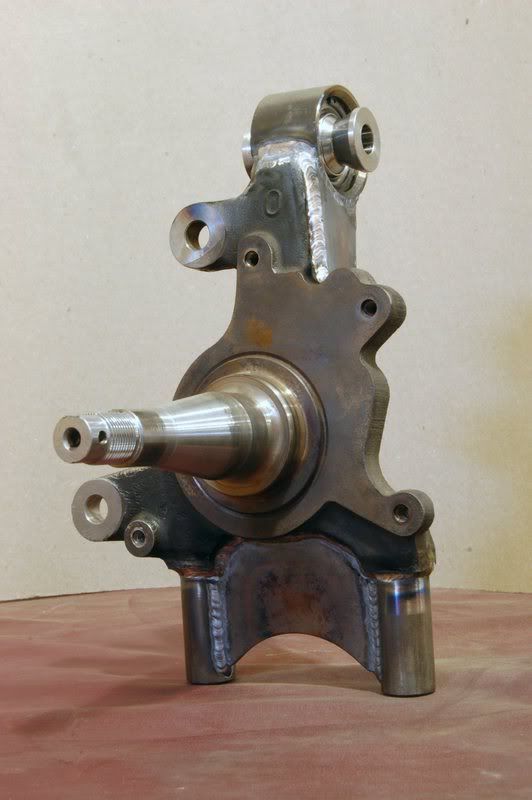

i'd like to see some of those scratch built spindles that were referred to earlier.

post pics. |

|

|

|

|

#10 |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

I will find you some pics in a bit when I get back from some errands. The guy I was talking about has made 3" drop spindles for a tundra or a titan (i forget which needed em) from scratch.. the yota spindle he builds to eliminate bumpsteer on 20's, uses the factory center section.

|

|

|

|

|

#11 |

|

Formerly ADHDCARGUY

Join Date: Mar 2005

Location: DUNCANVILLE, TX

Posts: 1,213

|

Re: Building your own control arms

UuuuuH, nice welds!

__________________

Jay 67CHEVY SWB,355, built 700r, 5/7,9",posi 3.50,REAR BAGS,HOOSIERS, A/C. 54CHEVY - BURB, beginning construction(well, i gotta take it apart first!) 36FORD PU - WAITING 38CHEVY - 2DR SD,CHASSIS FINISHED 46CHEVY - BURB - waiting |

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2005

Location: Modesto, Ca

Posts: 225

|

Re: Building your own control arms

For my arms I use 1 1/8" DOM .250 wall.

__________________

Please become a site supporting vendor to advertise a business in your signature. you can do so here |

|

|

|

|

#13 |

|

Registered User

Join Date: Dec 2005

Location: TN

Posts: 204

|

Re: Building your own control arms

What do you guys use for cross-shafts and ball joint mounts. I was also thinking about uniballs

|

|

|

|

|

#14 | |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

Quote:

The uniballs are great, I like using them, but only effective with a misalignment spacer. (I have seen ppl try to use a 1" bolt with a 1" uniball and ***** it gets no movement) As for the person who asked about bump steer.. the problem with the bump steer lies within the design of the spindle, due to steering mounting point. it goes deeper then I even possibly understand. If I need info on a yota, i go straight to max. as for bump steering all over the road. It doesnt bump steer that bad. It does have some, yes.. but it feels like driving a focus in the wind on the highway.. when you hit bumps, you feel it. Its a problem he's aware of and says he's fine with it. So he'll get his arms. <-- this paragraph was wrote thinking the people who mentioned bump steer, knowing knew that yota's do have bump steer when on 20's.. as for my arms causing bump steer, they will no. they are jigged off stock mounting points. so the yota arms i will be building, will cause the truck the same bump steer as stockers would on 20's.. he knows to mount them in stock location just using tabs instead of the crossshaft.. that lies on him and he is a smart dude.. and i'm only an hr away to go help if needed Last edited by Bagged Nissan; 12-23-2007 at 08:48 AM. |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Aug 2002

Location: Valley Center KS

Posts: 3,524

|

Re: Building your own control arms

I made control arms for my jeep grand cherokee rock crawler. I used 2" .250" wall DOM tubing. I also used Johnny Joints for the frame mount, and stock style rubber bushings for the axle mounts. It worked extremely well, with tons of articulation....if my shocks were longer it would have scored well over 1000 on the RTI ramp...but only a 971 since I had too short or shocks. They were that big of tubing, not for driving loads, but for impact loads of landing on rocks and other obstacles.

|

|

|

|

|

#16 |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

here is acouple pics of a titan spindle that max built. cost at 1250 for the pair.

and here are acouple for a yota be built.   This is a f150 desert runner that got built at his shop.. and this truck is no 'all show no go' truck.

|

|

|

|

|

#17 |

|

Account Suspended

Join Date: Jun 2000

Location: over yonder

Posts: 14,270

|

Re: Building your own control arms

$1,250 for welded cast ... no thanks

|

|

|

|

|

#18 |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

you can weld cast if you know how to weld cast and it will last the life of whatever its on. there are also different kinds of cast. the only spindles in that list that are cast, is the center sections of the yota's.. the rest are made from scratch with various metals from tubing to sheet.

you can hate all you want, i'll email max this thread and let him come thump ya with his knowledge and why your comment about him welding to cast means nothing.. you also have to realize why he makes the yota spindles, I dont expect you to considering this site doesnt deal with that stuff.. there is a lot more to the custom world then bolting on a pair of mcgaughty spindles when you want to fix problems that some vehicles have. |

|

|

|

|

#19 | |

|

Account Suspended

Join Date: Jun 2000

Location: over yonder

Posts: 14,270

|

Re: Building your own control arms

Quote:

Never did I say anything derogatory concerning his ability to weld, so I am kinda confused on where you took anything I said as "hating" geesh ... you kid's need to learn to lighten up and not be so defensive ...

Last edited by Shane; 12-23-2007 at 03:09 PM. |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Mar 2006

Location: Kansas

Posts: 865

|

Re: Building your own control arms

I think the main point that was missed earlier wasn't about your ability to weld or the quality of materials you are using. it was for your well being! We live in a world full of lawyers who are all looking for someone to sue. It doesn't matter if you build the part right, or wrong. A lawyer will look at them as another method to collect more money. This is why product liability insurance exists. I believe everyone was telling you to make sure your back is covered.

|

|

|

|

|

#21 |

|

3DrDwn--the 'burb not the band

Join Date: Jan 2007

Location: missoula, mt

Posts: 598

|

Re: Building your own control arms

May I assume we're talking Max Fish of Bio Kustoms?

if so what I've seen of his work is extremely well engineered. And it looks cool 2. Josh

__________________

Slo and Lo that is the tempo. '72 burb build page here: http://67-72chevytrucks.com/vboard/s...d.php?t=259256 '89 GMC Dually crew build page coming soon. 88  4x4 crew DD 4x4 crew DDduallys past/present pics here: http://67-72chevytrucks.com/vboard/s...46#post4001246 89 1 ton Dually rear flip kit install here: http://67-72chevytrucks.com/vboard/s...d.php?t=354327 |

|

|

|

|

#22 | |

|

the fab shack

Join Date: Feb 2007

Location: hell

Posts: 66

|

Re: Building your own control arms

Quote:

If you want spindles for your chevy, they make lifted spindles for 2 wd's out there, check some of the offroad companies. If you are serious about having Max do you a pair, goto streetsourcemag.com click on forums, then the 'ask max' section and ask him what he'd charge. |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jul 2005

Location: Riverside CA

Posts: 860

|

Re: Building your own control arms

max is a god in the mini world. too bad his prices dont meet the average mini truckers budget.

|

|

|

|

|

#24 |

|

It's just a check engine lamp.

Join Date: Apr 2001

Location: Melbourne, FL

Posts: 311

|

Re: Building your own control arms

No offense guys, but I was really hoping to see some info on "building your own control arms". It's nice to see that people are concerned with the legal aspect of this topic, but I think that "Bagged Nissan" understands what he's getting himself into. Can we please not beat a dead horse anymore. I just want to see more custom control arms. Thanks. bigchevy66

__________________

Active Inliner---bigchevy66 68 SWB Stepside 250 L6/3 on the floor/ Hedman headers, HEI, MSD 6A box, K&N filter, Offy intake and Edelbrock 600cfm 4 barrel Soon to have: WC T-5 five speed 66 SWB Stepside-undergoing restoration |

|

|

|

|

#25 |

|

Registered User

Join Date: Dec 2007

Location: Hemet, Ca

Posts: 4

|

Re: Building your own control arms

^^^ Yeah I agree... ha ha.

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|