|

|

|

|

|

#1 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Working Man's Burbon

I bought this Suburban because I needed to haul sheet goods (plywood and such) and my S10 Blazer wasn't cutting it when it rained. Which in my part of Oregon is fairly frequent. It fit my prerequisites: pre 1975 no DEQ, Presentable from the outside, interior must not be too nice (I don't want to send all my time worrying about when I was going to screw it up.), reliable enough to be a daily driver. After several months I settled on this one.

The pros: starts and stops well, has been converted to disc brakes, every thing is there except the windshield washer tank. Low amount of rust for the price, I like the wheels. The con's: Leaks inside (PO said it didn't) has a 305 (PO said it was a 350), PURPLE, (PO painted it), terrible exhaust system (looks as if it came off the PO's Chevelle racecar. Short Flow Masters 90ed down in front of the swing arm cross member. IT IS LOUD! I'm good with loud if it's fast. This not. Plus they torched the frame to get the headers to fit.). Window felts and rear gate seals are all shot. When your coasting it sounds like riding in the dump box of a gravel truck. The handling is terrible. It has front and rear air bags tee-ed to single valves. Had a 1980\90's? Covette steering column with the key knocked out so the wheel would move in and out 3 to 4 inches. The dash has been hacked for a DIN radio, &$%#%%$ kids!! After some looking and parking in the rain we have determined that drip rail seal has failed (after only 49 YEARS). So one thing lead to another and now I'm deep into Project Waterproof. Ah yes, waterproofing, something people with lesser cars, in brighter places never think about. At this point I must confess that this is the first time I have ever shared a project with the world. I humbly beg for your patience and forgiveness as this is a new trick for an old dog.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#2 |

|

The Older Generation

Join Date: Aug 2006

Location: Montezuma, Iowa

Posts: 25,657

|

Re: Working Man's Burbon

-

Looks good. Sealing up one of these old rigs can be a daunting task for sure. I just went through the same thing with the '67 Panel Truck.... I had to weld in some patches in the bottom corners of the windshield opening. LockDoc

__________________

Leon Locksmith, Specializing In Antique Trucks, Automobiles, & Motorcycles (My Dually Pickup Project Thread) http://67-72chevytrucks.com/vboard/s...d.php?t=829820 - |

|

|

|

|

|

#3 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

Thanks LockDoc. I was surprised that with the streams I had running out of the kick panels that the windshield channel is in as good of shape as it is. Some small holes I'll fix with long strand, then renew the seam sealer and the windshield will be good to go.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#4 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

As you can see now I've got in the steering wheel and column replaced. I scored the wheel off Craigs list. This lady liked the shape of it, had it hand painted and it had been hanging on the wall of her art gallery for the last 30 plus years since. Perfect condition GMC! Score 40 bucks. I got the column without the upper bearing, but a good signal switch from a nice guy in Vancouver. New bearing and slid it in and then the trouble started. The shifter was very stiff so out it came. It took me 5 hours to beat it back into submission. The slide bearing on the lower end had rusted badly underneath and caused the bearing to swell and with no clearance it couldn't move. It's like butter now. Plus the wheel doesn't move in and out. Man talk about disconcerting. I never realized how often I pull on the wheel.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: Working Man's Burbon

HO455, welcome to the board! Looking forward to the updates on your Suburban.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Oct 2004

Location: Milwaukee, WI

Posts: 403

|

Re: Working Man's Burbon

__________________

Steven 69 Chevy C10 Suburban 350 700R4 w/Disc brakes on all four corners  2017 50th Anniversary Camaro SS 2004 Chevy Impala LS 2016 Chevy Malibu LT |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2012

Location: molalla or

Posts: 90

|

Re: Working Man's Burbon

Iam out in Molalla and in the process of redoing my burb if you need help or parts

|

|

|

|

|

|

#8 | |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

Quote:

It has been a busy couple days working on the WMB. I drilled 1 inch holes to allow me to spray Por15 into the sills and other void spaces in an attempt to slow the rust. The drip rail sealant had failed so long ago that the panel above the windshield had rust holes into the cab. I drilled two holes by the mirror and one on the passenger side A pillar. I was able to get the spray wand down the driver side A pillar with the wires for the taillights, but not the passenger side with no wires??? The holes felt the same size, but the angles were different and the spray nozzle just would not go down the inside of the pillar. Basically it was 3 days of prep for 3 hours of spraying. I don't believe that I have achieved the 100% coverage that I would like but hopefully that I have cover the worst areas. I'm pretty sure I will be putting a second coat on just for some more peace of mind. This is the first time I have tried this process and it generally went as expected. I haven't been able to get a good close look at it yet and that will have to wait until later this week. But a quick look into the rear hatch showed pretty fair coverage. Obviously there are some areas that I will never be able to inspect. I am hoping that the Por15 will run down to the places the water ran to and give those areas protection. The photos show some of the holes if you look closely.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 Last edited by HO455; 02-23-2016 at 12:27 AM. Reason: Forgot the last sentence. |

|

|

|

|

|

|

#9 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

In addition I have traded the raised cowl hood for a stocker that fits the way it is supposed to. The cowl hood was a real mess.

The line along the fenders had a 3/8" bow on each side. Both sides were bowed to the passenger side. The front edge of the drivers side was 1/2" farther out than it was supposed to be. And the body line along the top was at least a 1/4" low on the drivers side but OK on the passenger side. The stocker has some surface rust and was the victim of a carb fire in the past. Plus I had to remove the hood ornament, but it was delivered for free. The line along the fenders had a 3/8" bow on each side. Both sides were bowed to the passenger side. The front edge of the drivers side was 1/2" farther out than it was supposed to be. And the body line along the top was at least a 1/4" low on the drivers side but OK on the passenger side. The stocker has some surface rust and was the victim of a carb fire in the past. Plus I had to remove the hood ornament, but it was delivered for free.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#10 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Thank you.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: Working Man's Burbon

Bet that was a stomach crunch work out! Well done!

|

|

|

|

|

|

#12 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Man I think it was hardest on my neck muscles. Thanks for the reply.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#13 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

While under the WMB doing the mounts I noticed the fenders had no bolts (and thus no shims) in the bottom inside location. I had noticed that sometimes the door hit the fender when you opened it. I had hoped the new body and core support mounts would solve the problem. I started on the passenger side by loosening the fender and wheel well so I could align the fender to the door. This is when I found that in addition to the fenders lower back bolt, 4 of the bolts in the wheel well were missing, as were the 2 bolts that go perpendicular to the chassis into the upper part of the core support. Plus the bolt that goes forward into to the upper grille piece was backed out 1/4" (and no shims) . No wonder the fender moved around! The PO said he had replaced the fenders with aftermarket units. It took me 2.5 hours to get the fender aligned with the door, shimmed up and locked down. Then it was off to the other side where I found only 2 bolts in the wheel well missing along with one stripped out. All the core support bolts were there, but the bolt to the grille was also loose and needing shims. After fighting with the bottom inside bolt and shim pack for at least 30 minutes I realized there must be a bigger issue. I just could not get the shims to work right, every other time I moved the fender and tried to snug it up it would twist all wrong and I would have to back the bolt off and try again. So I removed all the bolts on the rear portion of the fender and pried it out to see what the issue was. See the photo for a better idea of what I am trying to explain. At some time in the past a sliver of metal got pulled out of the hole for the bottom bolt and this would not allow the shims to sit flat thus causing the fender to twist when the bolt was tightened. OK, over the years things happen, maybe the reason this fine rig has had the fenders, hood, and grille replaced was possibly there was an unauthorized contact with an immovable object at some some point, however that was never discussed during the transaction. Moving on, I was able to make a wood block to hold the fender out far enough to get a rotary grinder in and remove the sliver. Now we are to the place where my head wants to explode. It would have been a 30 second job with a 4" grinder when the fender was off! Not 10 minutes with the rotary gringer on your back underneath it with no good angle to get at it and your shirt neck open to catch the metal silvers. But I guess they figured there was no reason to fix it since they weren't going to put the bolt back in. ÀAAAAAAAAARRRRRRRRGGGGGGGGG! Some peoples children.

I tried to find solace in the fact that since I had access to the area I could Por15 as much as I could reach. Did that and spent the rest of the day scuff sanding the under side of the hood. The next day (had to let the Por-15 dry) with that bolt issue solved, I found I that I had a new issue. The reason there were 2 bolts on this fender were missing is that the fender holes didn't line up with the wheel well holes, I'm pretty sure this also caused the other bolt to be stripped. (If it doesn't fit, force it) so I got things as close as possible and drilled new holes. I ended up having to move the door around to get the body lines to line up in a reasonable fashion. Basically I had to split the difference to minimize the misalignments at the crease below the wing window and the lower crease between the wheel wells. The aftermarket driver's side fender lines are not as good as the passenger side lines. Then more fun times trashing my fingers sanding the hood, but now its ready. I also pulled what was left of the grille out for disposal. I tried to find solace in the fact that since I had access to the area I could Por15 as much as I could reach. Did that and spent the rest of the day scuff sanding the under side of the hood. The next day (had to let the Por-15 dry) with that bolt issue solved, I found I that I had a new issue. The reason there were 2 bolts on this fender were missing is that the fender holes didn't line up with the wheel well holes, I'm pretty sure this also caused the other bolt to be stripped. (If it doesn't fit, force it) so I got things as close as possible and drilled new holes. I ended up having to move the door around to get the body lines to line up in a reasonable fashion. Basically I had to split the difference to minimize the misalignments at the crease below the wing window and the lower crease between the wheel wells. The aftermarket driver's side fender lines are not as good as the passenger side lines. Then more fun times trashing my fingers sanding the hood, but now its ready. I also pulled what was left of the grille out for disposal.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#14 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

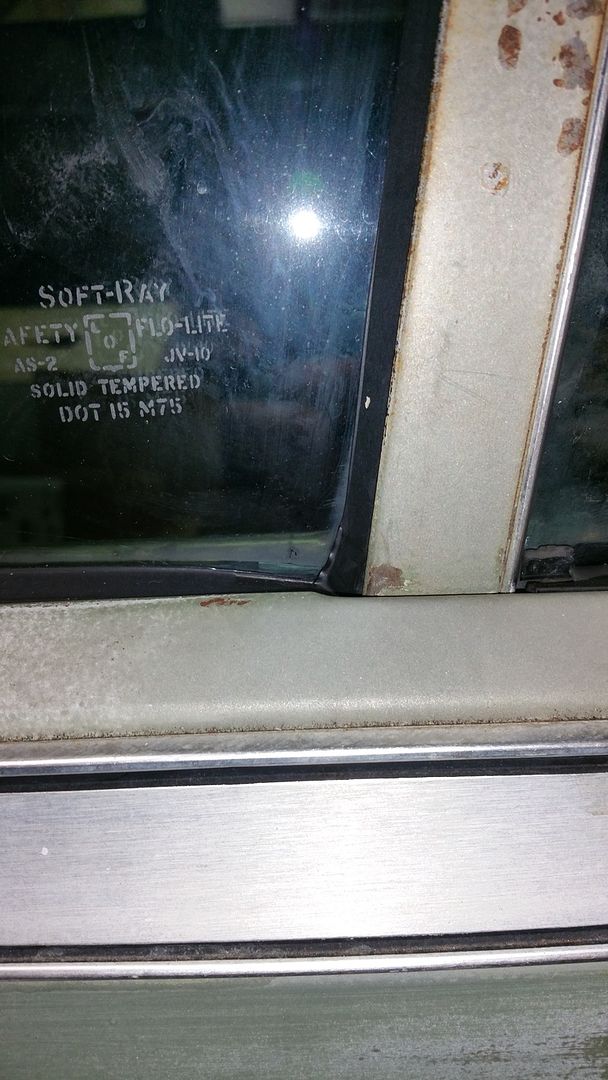

Re: Working Man's Burbon Rear 1/4 windows (fixed)

The WMB has been on the back burner for a month or so, but I am back on it. The rear door fixed window seal was falling down inside the door so it needed to be replaced. (No photo as I was wayyyy out of focus). The gap was big enough to drop a dime through not to mention the river of water through the door when it rained. The first photo is of the drivers side which isn't as bad. To remove the glass I took the door panel off, rolled the window down, and carefully removed the inner and outer wipers to give more room. Then the 2 screws at the bottom of the felt track/window divider were removed. Then I removed the screw on the top of the window frame that goes down into the felt track/window divider. Carefully wiggle the divider away from the fixed window. The glass would not budge when i tried to pull it out. I then used a single edge razor blade and a small hooked seal remover to cut and pull the seal away from the glass. The glass still would not budge until I had broken the seal between the glass and rubber seal all around the window inside and out. I did manage to avoid damaging the window tint on the passenger side (yet to see if I will be that lucky on the drivers side.). After getting the glass out I now see why the seal had deformed the way it has. The window seal sits on a metal piece that doesn't go the full length of the seal. (Last photo with gray circle). I am thinking about putting a piece of shim stock in to prevent this from reoccurring. The process is slightly different on the drivers side. The screw that holds the top of the divider goes up through a tab in the divider, then up into the frame. I am still arguing with that screw at this time. It may get ugly with voices being raised and blood may be spilled. More to follow.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#15 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,860

|

Re: Working Man's Burbon

I'm getting ready to replace my windows and seals. Where did you get the small window seals? Thanks for the pictures!

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Feb 2009

Location: Southern Oregon

Posts: 1,352

|

Re: Working Man's Burbon

Thanks again for another great write up on the quarter window. Lots of great info in this thread!

__________________

1967 C10 Suburban 454/TH400/3.07's An Average Joe and His 'Burb: http://67-72chevytrucks.com/vboard/s...d.php?t=775843 |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Dec 2011

Location: Earth, NJ

Posts: 479

|

Re: Working Man's Burbon

|

|

|

|

|

|

#18 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

Thanks for the encouraging words. I have ordered my window seals from Dan's Classic Chevrolet here in Portland. I will update as to what brand when I have them in hand. I won't reinstall the glass until the paint is sprayed. I am still debating if it is worth the effort to fab a support for the lower part of the seal.

I have spent the last day realigning the passenger side fender and doors. I was unable to get the door to open without touching the fender. The aftermarket fender holes did not line up correctly, so I had to grind the bottom back one, both of the upper back ones and both of the holes through the inner fender well had to be ovalled out. In addition at the front of the fender it hit the bottom of the core support which prevented me from moving the fender forward to increase the gap between it and the door. I was unable to determine if the fender was made wrong or if the frame/core support was tweaked so I split the difference and cut and bent the inner part of the fender (photo #1) for more clearance and I shimmed the core support up (photo #2). The interfering parts of the fender and core support needed to move a 1/2" so the fender could be shifted to clear the door. Shimming the core support up meant that the bolt was now too short. Which became something of an issue as 7/16-14 bolts are not available at Ace hardware or the big box stores. I had to wait until Monday for Winks Hardware to open so I could get a new 3" long bolt to be able to reattach the core support. The third picture shows the final result. The wow just below center is from the fender not being a straight line. After getting the fender set up I went through and readjusted the doors and then tightened the fender down. When doing the doors remember the bolts that attach the hinge to the cab allow the door to move up and down (photo #4) and the bolts that attach the hinge to the door allow the door to move in and out from the cab. There is no adjustment to move the door forward or back in the cab. Removing the latch plate before starting to adjust the door can save you some time as the door can be moved by the latch when you close the door and you won't see any change in the gaps. Short of major door disassembly and reconstruction the best you can do is to try and balance the gaps around the door. For example if I wanted consistent door gaps on my third door I would have to remove and reposition the window frame on the door. After your satisfied with the gaps reinstall the latch plate making sure it doesn't rub on the door when closing. You may have to shim the plate to prevent it from rubbing like I did (last photo). Good luck and if your like me you may have to go to the store and buy a six pack of patience.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#19 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon 1\4 windows.

I've gotten back to the rear fixed quarter windows. Since last time I posted about the window I have discovered some old damage to the lower frame of the window. I looks as something was dropped and dented the frame. I don't believe the glass was broken due to the fact the channel for the seal is so distorted and I would expect that someone would of straightened it to make it easier to put the seal back in. It looks like they drilled a hole and used a slide hammer to pull it out part of the dent and just filled the rest with old school pink Bondo. In addition to this there is a crack from the lower rear corner of the frame which may have been caused by this. So I now have even more reasons to pull this window out. The divider on the drivers side has a screw that goes up through a tab to hold the top of the divider in place. Mine was rusted to the point that the Phillips head stripped and I was unable to remove the screw. My next try involved using a left handed drill bit to get it out. This didn't work either and now I have a nice left handed Mac drill bit with only one cutting point.

But the head did come off and I was able to remove the divider and slide it past the glass to remove the fixed window. On the other side I had a hard time getting the old rubber seal to come free, but since I had ordered new seals I carefully cut it loose with a razor knife. Since then I have learned that the seals I ordered are made wrong and may or may not work (more on this later). Before I started on this side I took a thin putty knife and worked it between the seal and the glass and the seal and the frame all the way around at the same time I sprayed liquid wrench in the gap. After letting it sit for 30 minutes I very carefully worked the seal away from the glass on the front edge. I then pulled it to the side so the glass could be worked free and slid forward without damage to the seal as I may have to reuse it. At first the glass would not budget. By going around the glass again with the thin "flexible" putty knife I was able get the glass to move forward in the seal about a quarter of an inch. I then went around the seal with the putty knife to loosen its hold on the door. After 2 times around seal I managed to get the seal to move by prying the rear edge forward. Once it moved the glass and seal slid right out. With the glass out of the way I was able to easily remove up the old Bondo, which for the most part just popped off as it had been absorbing moisture from the back through the hole left over from the slide hammer. After spot welding the crack to prevent it from growing, I began the repair by enlarging the hole to get rid of the wasted metal around it. I checked the area for high spots, which I tapped down along with straightening the distortion to the seal channel. Then I sanded the area around the hole inside the door. To fill the hole I used short strand fiberglass putty to give me a water proof seal before I used Evercoat Rage Ultra (what a goofy name for a great putty) to finish filling the area. When I was laying the short strand down I made sure that the area around the hole inside the door was smoothed out to get a good grip on the metal. Some light sanding with 80 grit followed by 150 and then a second coat and more sanding. But the head did come off and I was able to remove the divider and slide it past the glass to remove the fixed window. On the other side I had a hard time getting the old rubber seal to come free, but since I had ordered new seals I carefully cut it loose with a razor knife. Since then I have learned that the seals I ordered are made wrong and may or may not work (more on this later). Before I started on this side I took a thin putty knife and worked it between the seal and the glass and the seal and the frame all the way around at the same time I sprayed liquid wrench in the gap. After letting it sit for 30 minutes I very carefully worked the seal away from the glass on the front edge. I then pulled it to the side so the glass could be worked free and slid forward without damage to the seal as I may have to reuse it. At first the glass would not budget. By going around the glass again with the thin "flexible" putty knife I was able get the glass to move forward in the seal about a quarter of an inch. I then went around the seal with the putty knife to loosen its hold on the door. After 2 times around seal I managed to get the seal to move by prying the rear edge forward. Once it moved the glass and seal slid right out. With the glass out of the way I was able to easily remove up the old Bondo, which for the most part just popped off as it had been absorbing moisture from the back through the hole left over from the slide hammer. After spot welding the crack to prevent it from growing, I began the repair by enlarging the hole to get rid of the wasted metal around it. I checked the area for high spots, which I tapped down along with straightening the distortion to the seal channel. Then I sanded the area around the hole inside the door. To fill the hole I used short strand fiberglass putty to give me a water proof seal before I used Evercoat Rage Ultra (what a goofy name for a great putty) to finish filling the area. When I was laying the short strand down I made sure that the area around the hole inside the door was smoothed out to get a good grip on the metal. Some light sanding with 80 grit followed by 150 and then a second coat and more sanding.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Dec 2011

Location: Earth, NJ

Posts: 479

|

Re: Working Man's Burbon 1\4 windows.

Too short on the bottom? If so, I learned that too. I took pictures of the issue, but I haven't sent them in. I think the GM seals were also this way because the new seals pulled into the channel just like the ones that I took out. I was going to talk about getting new ones, but I have so much to do I didn't bother. As it is Precision wants me to try a 3rd set of dooor weather strips on my vehicle since the originals weren't made right, and I wasn't impressed with the re-tooling, so I think they made more changes

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Dec 2011

Location: Earth, NJ

Posts: 479

|

Re: Working Man's Burbon

This is the top of the window, correct length

This is the bottom of the window, too short  So once you put the seal on the window it does funny things to it. It's not even across the bottom    So this is what it does when iit is installed

Last edited by notchbackgta; 05-05-2016 at 09:54 AM. |

|

|

|

|

|

#22 |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,860

|

Re: Working Man's Burbon

Thanks!

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

#23 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

It looks as if the current batch of seals may have a different problem. The lengths looked fine on the ones I saw but they were laid out wrong. See my crude drawing to understand. It isn't a mirror image but something different with the thin side on wrong side and the angles backwards.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

|

#24 | |

|

Registered User

Join Date: Dec 2011

Location: Earth, NJ

Posts: 479

|

Re: Working Man's Burbon

Quote:

|

|

|

|

|

|

|

#25 |

|

Post Whore

Join Date: Feb 2016

Location: Portland Oregon

Posts: 11,301

|

Re: Working Man's Burbon

The guys at Dan's Classic Chevrolet have been talking to Prescion and it seems that they were confused about how the seal actually fit in the frame. Prescion was checking to see if it was a bad batch or worse. At best it will be six months at best before the correct seals are available. Here are some more photos of my old one.

__________________

Thanks to Bob and Jeanie and everyone else at Superior Performance for all their great help.  RIP Bob Parks. 1967 Burban (the WMB),1988 S10 Blazer (the Stink10 II),1969 GTO (the Goat), 1970 Javelin, 1952 F2 Ford OHC six 4X4, 29 Model A, 72 Firebird (the DBP Bird). 85 Alfa Romeo If it breaks I didn't want it in the first place The WMB repair thread http://67-72chevytrucks.com/vboard/s...d.php?t=698377 |

|

|

|

|

| Bookmarks |

|

|