|

|

|

|

|

#1 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

A different approach to a LWB to SWB conversion

Since I needed to pull the bed on my 1970 C20 to do cab corners, I decided to make it a short bed too. My approach is different than the conversions I see most doing on this site. As a metal shaper, we are taught to plan out our cuts and splices to ease fabrication, save time, and avoid frustration later on. So I came up with a better idea to make cuts and seams easier to do and keep the original paint, well most of it. Here is my plan:

Before:  First remove the bed. I just cut all 8 bolts and unplugged the rear harness.  Remove 8" from rear of frame rails and move the slot on top forward too.  Then remove the front most bed mounting bracket.   Then remove the front rivet of the second bracket and swing out of way. Then mark the cut. I went from the front rivet hole of the front bracket to the front rivet hole of the second brackets.  Then I unbolted the trailing arms from the crossmember, removed all rivets from crossmember and slid it forward 12". I welded in place. Then I cut the frame rails.  To be continued...

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Oct 2014

Location: Mesa AZ (Near Phoenix)

Posts: 2,302

|

Re: A different approach to a LWB to SWB conversion

Interesting.

More than one way to skin a cat.

__________________

"Life is too short to drive a boring vehicle". Later, Wayne

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Sep 2014

Location: meridian, idaho

Posts: 95

|

Re: A different approach to a LWB to SWB conversion

I shortened the frame right behind the cab just like you did. The only difference was I put a 2" step notch. Sure makes it easier if you dont want to pull the cab off.

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Sep 2014

Location: meridian, idaho

Posts: 95

|

Re: A different approach to a LWB to SWB conversion

My cut behind the cab

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

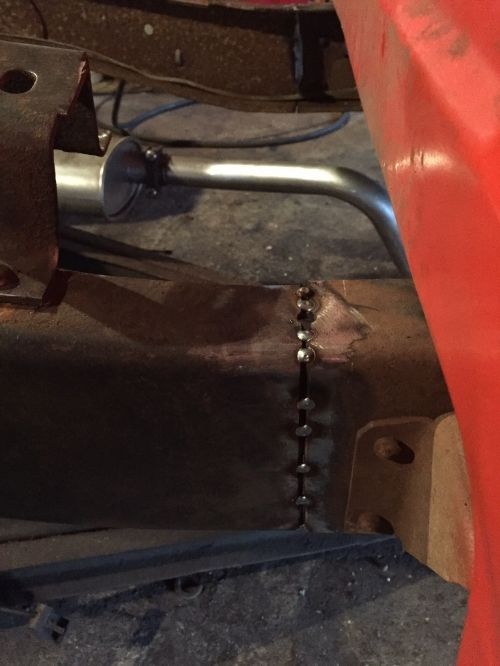

Then I carefully aligned the rails and tack welded them together.

Next did a full penn weld and ground it down so it could be tested. Then swung the bed mounts back.   Cut the front drive shaft down, exhaust, and brake line.  Then drove it out to take a look and the new profile.  Next comes the bed...

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#6 | |

|

The Older Generation

Join Date: Aug 2006

Location: Montezuma, Iowa

Posts: 25,626

|

Re: A different approach to a LWB to SWB conversion

Quote:

95% of the people that read your thread are not going to have a clue what a penn weld is (including me) and what you mean by being "tested". I did a Google search for "penn weld" and not much came up. Also wondering if you plated the inside of the frame at all. Just personal preference I guess, but I would never use a straight cut to shorten a frame. Thanks, LockDoc

__________________

Leon Locksmith, Specializing In Antique Trucks, Automobiles, & Motorcycles (My Dually Pickup Project Thread) http://67-72chevytrucks.com/vboard/s...d.php?t=829820 - |

|

|

|

|

|

|

#7 | |

|

C/10 junkie

Join Date: Nov 2010

Location: Stockton Ca

Posts: 9,093

|

Re: A different approach to a LWB to SWB conversion

Quote:

Great work btw

__________________

Shawn 70 LWB C10 current driver/project http://67-72chevytrucks.com/vboard/s...d.php?t=663051 68 SWB C10 Work in progress.....SOLD http://67-72chevytrucks.com/vboard/s...d.php?t=559520 72 LWB C10 Sold 71 LWB C10 Sold 68 LWB C10 CST Sold http://youtu.be/kbB0QrBIs9k My mom always had the best advice. It was just a tad late. After a fall that involved blood, she'd say....."Careful!"

|

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

95% of the people will not like my frame since I am not added any fish plate. A full penetration weld is just that, the weld bead is the full thickness of the material. This is done by beveling the rails and leaving a small gap before welding. Once welded, you will have a raised bead on both sides of the rail.

I then ground down the weld so it could be tested. A machine like an ultrasound and jelly is used to look for and air gaps or disturbances in the metal. Also, grinding the weld smooth avoids any stress spots or sharp edges. If the weld was not 100%, I would add a brake formed channel to fit inside the rail. This is much better than a fish plate or boxing plate. Now, off to the bed. I completely disassembled the bed and cut down the floor pan. 12" off the front and 7.5" off the rear.  I drilled new front and rear mounting holes in the pan and bolted it to the frame. You can see it still looks factory.  For the rear, I saved the rear cross sill and put it back on the frame and under the pan.  Then I started to tip over the 1/2" of floor pan I saved when I cut 7.5" off.  Once fully tipped, I plug welded the pan back down to the cross sill. The floor is now a SWB pan and no splicing like all others I have seen here. I saved over 10' of weld and kept my original paint.     Now off to the bed sides....

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Nov 2010

Location: Carlsbad, CA

Posts: 1,584

|

Re: A different approach to a LWB to SWB conversion

Interesting. Looking forward to seeing how you do the bed.

__________________

- Jim - My Daily Driver is a 1969 Chevrolet Custom/20 Fleetside 350/TH400/Eaton H052 4.10 and its Project thread is here http://67-72chevytrucks.com/vboard/s...d.php?t=456911 |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jun 2014

Location: Glendale, Arizna

Posts: 1,642

|

Re: A different approach to a LWB to SWB conversion

I'm planning something similar, but planning on removing the rear cab mounts then do a short "Z" like you did but going to the underside of the frame towards the cab, going between the top and bottom row of rivets that hold the rear cab bracket on so that the bracket can be reinstalled into those two holes (still located as before) and then simply drill those two lower holes right through the bracket and add the two other bolts.

Still, your's will be more than strong enough. People over-look the fact that when you cut BEHIND the rear suspension cross-member on coil spring trucks that most of the stress is actually AHEAD of the rear suspension cross-member. Accelerating, braking, all goes into the cross-member. Only time the rear section of frame behind the suspension cross-member sees much stress is when you are towing. Think of it as a tow-bar LOL. Ignore the static, you are very good at what you do.

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: A different approach to a LWB to SWB conversion

Nice work... does that frame need any more reinforcement in the weld area? I see a lot of people use a plate behind it.

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2014

Location: Spring Hill Kansas

Posts: 209

|

Re: A different approach to a LWB to SWB conversion

penn weld is a full penetration weld. tested would mean that a certified weld inspector would check the weld for full penetration using some method of testing

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

No. I didn't see the need to flatten the pan where the bulk head bolt down. I will just re drill the bolts between the ribs of the pan.

I am aiming to keep as much of the original paint and rust as possible. I do not want two huge weld seam on the sides of the bed. I can't keep the original paint or finish the weld that way. It would surely require bondo and new paint with that cut down method.

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Feb 2011

Location: Modesto, CA

Posts: 2,189

|

Re: A different approach to a LWB to SWB conversion

Quote:

|

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jun 2012

Location: springfield mo

Posts: 3,075

|

Re: A different approach to a LWB to SWB conversion

I'm pretty much amazed so far. I'm looking forward to the bed work

__________________

United States Marine Corps 2000-2011 Iraq and Afghanistan veteran Just living life now and enjoying it and my wife, daughter and son

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

For the front of the bed I scribe two lines. My cut line at 11 1/8" and my tipping line at 12". More pictures as I go....

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Nov 2007

Location: Indianapolis

Posts: 1,161

|

Re: A different approach to a LWB to SWB conversion

looks like very nice work. waiting for more pics

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Dec 2014

Location: Plainfield il.

Posts: 643

|

Re: A different approach to a LWB to SWB conversion

Looks great! You work wonders with metal and it sure is fun to watch.

|

|

|

|

|

|

#19 |

|

C/10 junkie

Join Date: Nov 2010

Location: Stockton Ca

Posts: 9,093

|

Re: A different approach to a LWB to SWB conversion

This is great info for when I shorten mine

__________________

Shawn 70 LWB C10 current driver/project http://67-72chevytrucks.com/vboard/s...d.php?t=663051 68 SWB C10 Work in progress.....SOLD http://67-72chevytrucks.com/vboard/s...d.php?t=559520 72 LWB C10 Sold 71 LWB C10 Sold 68 LWB C10 CST Sold http://youtu.be/kbB0QrBIs9k My mom always had the best advice. It was just a tad late. After a fall that involved blood, she'd say....."Careful!"

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Dec 2010

Location: livingston co.mi

Posts: 2,464

|

Re: A different approach to a LWB to SWB conversion

Some good ideas

__________________

California 65 GTO---Texas 64 burb 283 ---Oklahoma 67 CST SWB BBW wood bed 327 2004r---New Mexico 72 k10 350 350 auto---Georga 72 short step project |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Mar 2014

Location: Las Vegas Nevada

Posts: 93

|

Re: A different approach to a LWB to SWB conversion

Nice

__________________

72 K10 |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Jul 2010

Location: South Dakota

Posts: 4,093

|

Re: A different approach to a LWB to SWB conversion

Looks great.

__________________

1969 Chevy c20(Miss Hackjob) |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

The bulkhead will just bolt to the floor pan something like this. I will drill holes on the lows of the pan.

Here are my scribe lines on the front of the bed side. One for cutting and one for tipping over the edge.  I will tip the edge over just like the factory did here.  If I wanted to, I could just weld the bed side back together right at the edge. But I don't want to burn the paint if I don't have to.  Once I cut the extra material off, I started to tip over the inner panel. Again no welding here.  And started to tip over the outer bed skin.  With the inner panel fully tipped, I slid the end cap in place to see my progress.   Test fit is looking good. I just need to complete tipping the outer skin to the end cap, spot weld back together and add the front bed pocket to finish up this corner.  100% of the original paint save and 17' of weld avoided so far.

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Feb 2008

Location: Tacoma Washington

Posts: 890

|

Re: A different approach to a LWB to SWB conversion

I'm kind of curious how your frame will do without fish plating it. You have two brittle lines running up your frame. Fish plating spreads that stress over multiple areas. It's not a matter of whether the weld is completely penetrated, it's the stress on the toes of the weld. Without heat treating, those toes will be weaker than the weld or the unheated frame.

Jeff

__________________

I know a guy who's addicted to brake fluid. He says he can stop any time. 72 K10 396 75 Cj5 MPI 350 Chev 67 Chevelle 396, 4 speed 74 FXE 08 Tahoe |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Dec 2014

Location: Coal City, IL

Posts: 695

|

Re: A different approach to a LWB to SWB conversion

I understand everyone's concern about the frame. I have been doing this for nearly 30 years now and have never had a weld crack, even on some very high horsepower trucks. Remember, this is a C20 and the frame rail is about 50% thicker than a C10 frame.

Skinning the rail with a channel that fits inside would be insurance that everyone can see and understand. Welding is still mysterious to most and not trusted with your life. I am a unlimited thickness certified welder. The frame will stay as is. All others please add fish plates and not follow my example here.

__________________

Tony Nicholas @ Midwest Metal Masters 1953 Chevy 3100 392 Hemi w/727 & 9” Ford 1985 Chevy C/10 6.0L 4L80 373 locker |

|

|

|

|

| Bookmarks |

|

|