|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Harmonic balancer questions

I'll start this off by saying: I know the purpose of a harmonic balancer, but that's as far as my knolwedge goes.

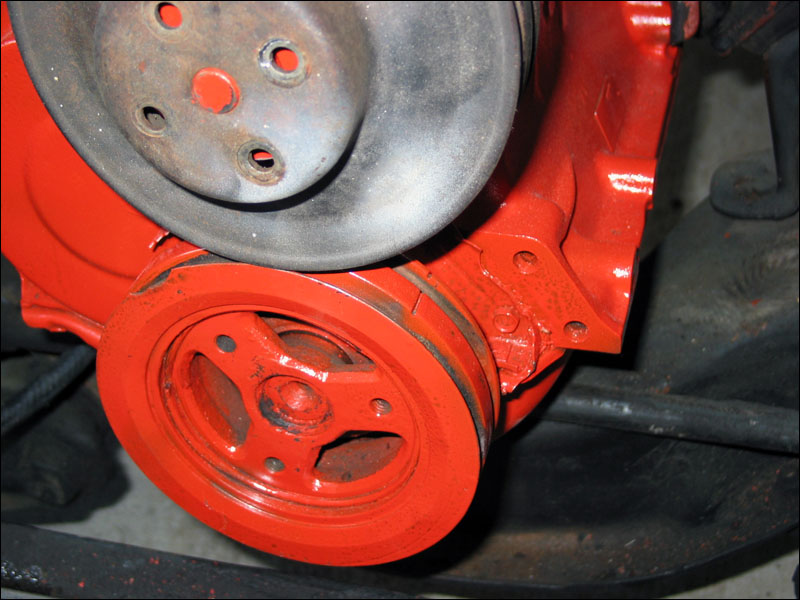

In an effort to "better" my truck and restore the original engine, I swapped my L6 this weekend. I solved most of my problems - like removing the threaded oil pressure tube someone loc-tite'd into the block, swapping heat sensors, removing various parts, doing a partial rebuild on my carb and installing a new clutch. I'm having one big issue though - the spacing o nthe new harmonic balancer is different and I need to use the old one or something. I'd like to know: Should I just go to a junkyard and find a new alternator and fan assembly or should I yank off the existing harmonic balancer? What can the veterans tell me about doing this process the right way? So you see what I'm talking about, I have pictures! I will show you the differences and whatnot. This is the HB on the new motor, notice the gap between the belt grooves; it's about 3/4" wide:  This is the old harmonic balancer, buried underneath that gunk, you'll see the gap is about 1/8" wide between grooves:  If I use the fan assembly the "new" motor came with, the HB and fan pulley don't line up at all. See:  Not to mention - the bolts for my my cooling fan assembly don't fit on the "new" engine parts. Bottom line: I'm either looking at : 1) Hitting a junkyard to find a proper cooling fan assembly, proper alternator or alternator pulley and finding a way to space out the cooling fan pulley from the motor or 2) Removing the "new" harmonic balancer and popping on the old one. Do I have other options? What do you suggest? Does anyone have tips (for future reference) on things to watch out for while pulling an harmonic balancer? What is the general process? Should I rent/borrow a puller from the local parts store? TIA.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Dec 2001

Location: Redding,CA...USA

Posts: 4,736

|

It looks like the new balancer is not on all of the way. I hate pressed on dampers. No real way of seating them with out beating them to death. If it is on all of the way..you can shim out the water pump pulley. They actually make shims for it.

__________________

It's called "drag racing" if they called it "tic..tic..WHAM!..BANG! F*&K!!!", they'd have to keep the magazines under the counter with the other men's publications click the clicky to join the site.... http://67-72chevytrucks.com/vboard/payments.php 67 lwb..first hotrod in 25 years..540 best ET is 9.45 @ 141.44 Anderson,CA |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: Feb 2002

Location: Tucson, AZ USA

Posts: 7,504

|

I don't have a lot of experience with 250s, but I heard they are not tapped on the nose of the crank to accept an HB bolt. Therefore a harmonic balancer installer tool can't work. If you were taking the engine down to be machined, a shop could drill and tap the crank just like a 292 and SBC, but it's too late for that now, I guess.

Like BigJim says, the best you can do is tap it on further with a dead blow hammer (if it's not home yet) or shim out the waterpump pulley to match. There is a lot of latitude in the waterpump set-up. On my latest 292 I had to have a shop press a 2-groove pulley onto the alternator snout and use the forward groove to match up with all other pulleys. By the way that's a strange looking valve cover on the new engine. What year is it from? Also I wouldn't trust a used harmonic balancer. The rubber can rot and get distorted from the dead blow process (or just years of constant use) and the outer inertia ring can go out -of -true in relation to the inner hub. A new one is good insurance and a lot less likely to launch itself thru the radiator or "walk" off kilter. Good luck.

__________________

Every 25 years I like to rebuild that 292, whether it needs it or not. |

|

|

|

|

|

#4 | |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Quote:

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. Last edited by shifty; 03-15-2005 at 03:01 PM. |

|

|

|

|

|

|

#5 | |

|

Senior Member

Join Date: Feb 2002

Location: Tucson, AZ USA

Posts: 7,504

|

Quote:

Definately you want a new HB. If you can drill and tap the crankshaft snout for 1/2" x 20NF x 2-1/2" you'll be way ahead of the game. As far as carb heat issue, I live in Tucson where I've never needed it. I know you have a winter in GA so you may need it there. I run an orange '68 C/10 Stepside Chevy w/ L6 292 bored @ .030-over [296 actual CI], Badger pistons, moly rings, stock rods w/ ARP fasteners, 1.84 Intake valves (for a 305 V8), Crane cam, Rhoads lifters, hi-vol oil pump, Centerforce 2 clutch, Clifford headers (refurbished after 250,000 miles on my last engine) exhaust is 1-7/8" dual pipes -- w/ crossover-- thru turbo mufflers exiting stock configuration, Offy intake, Holley 4160/8007 390 CFM 4Bbl carb [+50cc accel pump]. K&N 12" aircleaner. '72 Chevy-type gas pedal and Lokar throttle cable. Stock points distributor w/ Mallory voltmaster coil. SM 465 4-speed, Straight driveline to 3.73 Posi in 12 bolt rear. Tires are 235/85R16LT Dunlops. Autometer tach and water temp, Mooneyes vacuum, Stewart Warner oil pressure gauges. Into the third year of the original engine rebuild project, 600 miles on "new" engine and currently having teething problems with manifold and carb set-up. (28 year old Holley). Good luck on your L6.

__________________

Every 25 years I like to rebuild that 292, whether it needs it or not. Last edited by '68OrangeSunshine; 03-16-2005 at 04:03 AM. |

|

|

|

|

|

|

#6 | |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Okay - if I get the water pump spacers, I still have a problem: I need to buy a new fan assembly and alternator pulley, because neither of these parts match. That sucks

The valve cover is from another truck - I want to say it came off a Jeep, but also possibly off a C20 - I can find out for sure, gimme a bit. Here are the details on the engine that were given to me. I bought it from someone advertising on Craigslist and, subsequently on eBay: Quote:

http://cgi.ebay.com/ebaymotors/ws/eB...spagename=WDVW Let me email the guy and I'll find out for sure where the valve cover came from.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

|

#7 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

I think a new harmonic balancer is relatively cheap for this 250 L6. Maybe I should look into that...probably means another couple of days of waiting to get it up and running again.

This engine swap is taking forever!!! I don't know how to get the old HB off and put on the new one. There are no bolts holding it on - and it looks like there is some kind of rubber, gasket or permatex sealer squishing out from the back side of the current HB. I also don't know how to true up the HB so it's spinning correctly either.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#8 |

|

Cantankerous Geezer

Join Date: Aug 2002

Location: Bel Aire, KS

Posts: 6,264

|

What I will recommend is to get a NEW balancer. The rubber gets old and hard, causing the head to spin and the balancer not to balance correctly.

Also, get a balancer puller/installer and a 7/16-20 tap. Pull the balancer, then drill and tap the crank snout. You will probably have to jack up the engine to drill. Go to the parts store and get a balancer bolt and washer for a small block. Use the balancer installer to seat the balancer, is should go on straight that way. I alos use anti-sieze on the crank snout.

__________________

Fred There is no such thing as too much cam...just not enough engine.

|

|

|

|

|

|

#9 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Okay, I bought a new HB assembly from NAPA. They also had something called a "harmonic balancer sleeve". Is that necessary to put the new one on?

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: Feb 2002

Location: Tucson, AZ USA

Posts: 7,504

|

Quote:

To me that sounds like keeping the same stale toast and replacing the peanut butter. With some early vintage stuff, that's all you can do. There's a company called "Damper Doctor" formerly Damper Dudes that specializes in obso HBs. If you're pulling the HB in the pix, you set 3 bolts in the 3 holes in the inner ring thru the 3 slots on the harmonic balancer puller tool -- a loan item at most parts store chains -- set up the long threaded rod point-first in the conical taper at the end of the cranksnout and slowly twist off. Use lots of light machine oil or 30 weight.

__________________

Every 25 years I like to rebuild that 292, whether it needs it or not. Last edited by '68OrangeSunshine; 03-16-2005 at 04:13 AM. |

|

|

|

|

|

|

#11 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Update: the HB sleeve is simply a metal ring that sometimes wears out.

I don't have an HB puller and don't know how to put the new one on. I'm kinda dumb. I don't know what this "snout" is that everyone keeps talking about. Can someone explain this a little better? I have a threading kit, but ... How do I keep the drill perfectly straight so the hole isn't crooked or at an angle? How do I press the new one?

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Feb 2002

Location: Tucson, AZ USA

Posts: 7,504

|

The "snout" of the crank is the front end that's machined for a woodruff key -- what the HB goes onto.

If you want to have a retaining bolt on the snout of your 250, the best thing would be to have a machine shop do it. If the crank is still installed in the engine and the engine is still in the truck, this is difficult. You would at least have to pull the radiator. Since the factory never tapped stock 250 cranks, maybe all this hot rod stuff isn't necessary. There is a shadetree trick involving baking the new HB to expand the metal, and also chilling the snout end of the crank ( with ice or Freon) then tapping the hot HB on with a deadblow hammer. I've never done this, so I can't advise further on temps or techniques. No clue what that process does to the elastomeric sleeve (rubber part) -- it kinda scares me. Another danger is that continued thumping on the crank end is not good for the crank bearings and journals. Good news is that this series of L6 has 7 journals, V8s only have 4. To remove an existing HB, you can "rent" a gear/HB puller set from a neighborhood auto parts store. Instructions are illustrated in the '68 Chevy Truck Chassis Service manual or equivalent, Haynes, Chilton's etc. To install an HB with a special tool [and it's different from above], the crank shaft end ("snout") must be drilled and tapped to accept the threaded end of the tool. Tool has a thrust bearing which spins along with the threaded bolt and doesn't cause the HB to be torqued off alignment with the woodruff keyway. It goes on slow but steady, avoiding bearing damage. Are you familiar with the forums?: www.inliners.org www.stovebolt.com There may be a lot more archival stuff and FAQs on this subject. Also a much deeper pool of old L6 lore. Hope this helps.

__________________

Every 25 years I like to rebuild that 292, whether it needs it or not. |

|

|

|

|

|

#13 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

You can buy a balancer puller set for under 20 bucks at any parts store.

To install the new one, start it on by hand and then use a big hammer and a piece of 2x4 wood to protect the balancer from the hammer's impact. That's the way they've been installed for over 40 years now, and it still works. A bolt and an install tool would be better, but the GM engineers didn't think the 250 needed a tapped hole in the crank. We used the wood block and hammer trick at the dealership to install them, so even Mr Goodwrench does it. I had to replace the balancer beside the road on my 70 truck because it came apart at speed. My local AutoZone stocks the balancer for 50 something bucks. I had to buy a hammer and a puller set there too. All told, it cost me 90 bucks and half an hour of time beside the road replacing it.

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

|

|

|

#14 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Thanks again, guys. I'll report back either today or tomorrow with new on how it goes. I've had the new HB in my car ready to go on, weather here in GA hasn't been permitting the replacement. The engine swap is 95% done now, just gotta replace the starter, get this new HB on, put on the flashing plate and pan onto the back of the bell housing and setup the dizzy I pulled off an '81 Monte Carlo.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#15 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

....distributor out of an 81 Monte Carlo....Are you sure it was an inline engine engine, not a V6 in that Monte?

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

|

|

|

#16 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

I am not certain - this thing came with the motor I just bought. The guy said I would love it and it runs like a champ

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#17 |

|

It's just a check engine lamp.

Join Date: Apr 2001

Location: Melbourne, FL

Posts: 311

|

I went through the EXACT same thing you are going through. I would advise against drilling the crank while still in the truck. You aren't able to drill the crank straight with the engine still in the truck. Trust me.

About the only thing you can do, is to beat it on with a hammer. I tried that with mine, but couldn't get it on all the way. It's parked right now, since I'm in FL. If you have an engine hoist, then pull the engine and drill the crank for the bolt. Good luck. John

__________________

Active Inliner---bigchevy66 68 SWB Stepside 250 L6/3 on the floor/ Hedman headers, HEI, MSD 6A box, K&N filter, Offy intake and Edelbrock 600cfm 4 barrel Soon to have: WC T-5 five speed 66 SWB Stepside-undergoing restoration |

|

|

|

|

|

#18 |

|

Hittin E-Z Street on Mud Tires

Join Date: Nov 2004

Location: Greenville, SC

Posts: 23,090

|

On more little tip. Do what Tx said, but when you are hitting on the HB don't hit anything outside of the squished rubber. Basically, do not hit the outside metal ring. That is the part of the balancer that is "balanced." If you move it it may cause your motor to vibrate, but whack all you want on the inner metal piece. I changed the balancer on my 250 years ago and it wasn't too hard. Just a tip.

__________________

Jesse James 1967 C10 SWB Stepside: 350/700R4/3.73 1965 Ford Mustang: 289/T5-5spd/3.25 Trac-Loc 1968 Pontiac Firebird: Project Fire Chicken! 2015 Silverado Double Cab 5.3L Z71 2001 Jeep Wrangler Sport 4.0L 5spd 2020 Chevrolet Equinox Premium 2.0L Turbo 2011 Mustang V6 ~ Wife's ride  American Born, Country by the Grace of God  1967 CST Shop Truck Rebuild! My 1967 C-10 Build Thread My Vintage Air A/C Install Project "On a Dime" Trying my hand at Home Renovation! 1965 Mustang Modifications! |

|

|

|

|

|

#19 |

|

State of Confusion!

Join Date: Jul 2002

Location: Gulfport, MS USA

Posts: 47,216

|

One other note...It looks the balancer you have on the one engine came from the latemodel integrated head sixes. I was told the spacing between the first to pulley groves is firter apart. To get the bracket to line up would require the late model integrated head brackest which are a bit different than ours since the use the head for mounting and our years use the block. I can't tell totally from the view, but that seems to be some of your trub to me. Like you though I am new at some of this stuff. If I still had the 82, I'd show the difference between my 70 and 82's 6 banger.

__________________

Bill 1970 Chevy Custom/10 LWB Fleetside 2010 Toyota Tacoma PreRunner SR5 Double Cab - DD Member of Louisiana Classic Truck Club (LCTC) Bill's Gallery Life isn't tied with a bow, but it's still a gift. Live simply. Love generously. Care deeply. Speak kindly. Leave the rest to God! |

|

|

|

|

|

#20 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

Okay, final two questions:

I managed to pound the new HB in place. I kept all of my hammer strokes in the center ring and it went on tough enough that I don't think it's coming off again. Is it possible to pound it on too far? For all of the belts to align perfectly, it looks like it needs to come out roughly 1/16" - 1/8" or so. The HB came with two small crescent-shaped items. One is about the size of half a nickel (but twice as thick) and the other is nearly the same height but twice as wide. What the heck are these for?. Are you sposta put them on the HB to balance it out, if needed? I got an 8-bolt aftermarket water pump and a new temp gauge for around 20 bucks. All I need is two gaskets and to roughly set the timing. Should turn over the engine for the "first" time tomorrow! (can't wait...) I only pounded on the inside of the HB, so ... I'm hoping I did everything right. I hope I didn't do anything to toss it out of balance.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Dec 2001

Location: Redding,CA...USA

Posts: 4,736

|

those sound like the woodruff keys..they go into the crank snout. They keep the timing gear and H/B from spinning on the crank. No you can not drive it on to far.

__________________

It's called "drag racing" if they called it "tic..tic..WHAM!..BANG! F*&K!!!", they'd have to keep the magazines under the counter with the other men's publications click the clicky to join the site.... http://67-72chevytrucks.com/vboard/payments.php 67 lwb..first hotrod in 25 years..540 best ET is 9.45 @ 141.44 Anderson,CA |

|

|

|

|

|

#22 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

I really didn't see any place that these woodruff keys would fit

Is it safe to pull the HB out 1/8" from where it currently rests? Either I tapped the outer ring and that made the alignment off or ... I tapped it in farther than it needed to go.

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#23 |

|

Senior Member

Join Date: Dec 2001

Location: Redding,CA...USA

Posts: 4,736

|

B4 I did that I would shim the crank pulley with a washer or two. It needs to set flush with the crank gear to seal properly. It could be the thrust bearings are worn out too. See if the crankshaft will move forward the .125" that its out now.

__________________

It's called "drag racing" if they called it "tic..tic..WHAM!..BANG! F*&K!!!", they'd have to keep the magazines under the counter with the other men's publications click the clicky to join the site.... http://67-72chevytrucks.com/vboard/payments.php 67 lwb..first hotrod in 25 years..540 best ET is 9.45 @ 141.44 Anderson,CA |

|

|

|

|

|

#24 |

|

Questionable

Join Date: Mar 2005

Location: Atlanta

Posts: 13,373

|

thanks, bigjim. will give all this a shot tomorrow morning.

i know none of the other pulleys will move in towards the engine, so options are limited. The only thing that can move is the HB or something it's connected to at this point. These last couple of things with my engine swap are really starting to piss me off. I just want my truck to be running again!!!

__________________

If I've got anything up for grabs, it'll be here: 7-hole gauge cluster for a 67-72 p/u FREE (link) I can't check the forum daily. If I don't reply to you within 24 hours, drop me a PM! I'm (hopefully) still alive and will reply faster to a PM. |

|

|

|

|

|

#25 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

There is no crank pulley to shim on one of these inline 6 engines.

Take your balancer puller and pull it back the amount needed to line up the grooves and make the belt align properly. I've knocked them on too far before myself. Stuff like this is perfectly normal when working on old trucks like this. Don't get frustrated. Besides, it builds character.

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

|

|

| Bookmarks |

|

|