|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

This one is for the FAQ section.

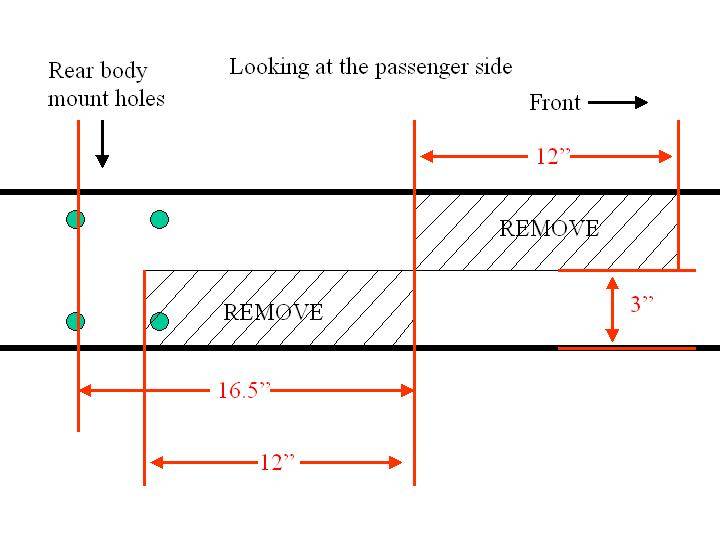

N2TRUX asked if I would combine my posts about my adventure into shortening my LWB frame into a SWB frame along with all the pics into one post, so here it goes!! Background: I bought a sweet 68 LWB in Feb 2004. Spent about 3 months worth of evenings and weekends rebuilding the front and rear suspensions, adding front disc brakes, cleaning and sprucing up the interior, installed a new 350, new exhaust, new rally wheels and tires, and a lot of detail work and cleaning! I had driven the truck a total of about 5 times when a drunk sideswiped me on Mothers Day. As I started to disassemble the now crunched parts, I found myself going beyond what was damaged, until I was left with a bare frame!! After a close inspection of the frame, I found it to be bent in two different places. I decided then and there that I would set out to build what I had always wanted ...... a 68 SWB two wheel drive! SWB frames are not that easy to find around here, and if one is found, it takes a small fortune to become the new owner. So, after picking a few peoples brains, looking at some photos on ebfabmans website (www.ebfabman.com) , I decided to shorten a “new” replacement frame. I picked up a good 72 rolling chassis cheap in Denver (also had a good 3.08 5 lug rear that I needed!) for $150. So here we go!! I started out by supporting the frame rails front and rear with jackstands. Then, I used a small floor jack under the crossmember that the rear trailing arms bolt to, and a jack under the manual trans crossmember. Just enough lift to support the two, but not bring them off the floor. To do this job, 12" needs to be taken out of the middle of the frame, and 8" taken off the rear. LWB frames are 199 1/4" long end-to-end, while SWB frames are 179 1/4". So we need to remove 20" total. First, I laid out my cut marks. One thing I kept in mind is that I did not want to destroy the serial number that is stamped on the frame rails. That could lead to trouble. I decided that I liked the stepped cut that ebfabman shows on his site. But I have a pet peave about using 90° corners where structure stability is involved, that being the corner could be a potential starting point for a crack. Not that it will happen, but I want to avoid that at any expense. I plan on driving this truck a lot, with my 1 and 4 year old kids, and driving it for a long time. In the drawing below, I used the old rear body mount bracket holes as the reference point for measuring. In particular, I used the upper rear hole on each side.  From the upper rear hole, measure forward 4 ½". Make a mark, and using a square, draw a vertical line. From that line, measure forward 12" and mark. Then from that mark, measure forward another 12". Now, find the center of the frame rail top to bottom. They are about 6" tall, so the center should be 3". Make a mark at the front and rear lines, then draw a straight line front to rear connecting all three vertical lines. The idea is to remove a 3" tall x 12" long section of frame rail from the upper front and lower rear of this area. Not only does this leave the serial number intact (if yours is stamped in the same area as mine), but is offers a perfect “stair step” area that will join together nicely, making for an easy way to align the front and rear frame rails, and it makes a very stout joint once completed. To radius the corners, I used one of those plastic templates that has various sized holes in it. But a roll of electrical tape would do in a pinch. Just be sure they are all made in the same spot in the corners so they will line up later without large gaps. **DON’T FORGET TO REMOVE THE FUEL AND BRAKE LINES BEFORE CUTTING!!!!** I used a plasma cutter for all the cuts, but an oxy/acetylene will do just as well. To make the straight cut um, well, straight, I clamped a piece of 1/8" thick flat bar onto the frame, using the tip of the plasma cutter as a guide so that the tip could drag along the edge of the flat bar and the hole in the plasma torch tip would be right on top of the line. MEASURE TWICE, CUT ONCE!!!! Dress all the cut areas with a grinder, then follow up with a 60 grit grinding disc or flapper wheel to make the cuts nice and smooth. Be sure to add a slight bevel around the cuts too. This makes for a nicer fit and better welds. Have someone help you at this point, and pull the two halves together. You will want a good supply of C-clamps (4 to 6 at least), and some large Vise Grips would be handy as well. Clamp as needed to mate the halves together, so that the rails are even top and bottom, and side to side. I also used a come along to help pull the halves together, and to hold them tight when I went to tack them together. But first, be sure the frame is square before tack welding anything. Pick various points on the frame that are consistent side to side, such as any of the many holes on top the frame. Measure front to rear, as well as measuring across (ex: right front to left rear) then swap sides, but measure from the same holes across from one another. You want that sucker square before you commit to welding. The further it is out of square, the more likely it will want to “dog-track” down the road. And we don’t want that!! I would say that a tolerance of no more than 1/8" would be acceptable. Here is a EXCELLENT reference for doing this project!  For a larger copy of this, click here: http://67-72chevytrucks.com/gallery/.../framedims.jpg Once you are sure the frame is square, place about a half-dozen tack welds on each side. Re-measure again to ensure it is square, then start welding! Now, this is not a job for a 110volt welder. A GOOD knowledge of welding is needed, as is a good welder. I used my Miller 210 MIG welder, .035" wire, heat setting 3, wire speed of 35. When welding, make several short welds. Do not try to weld the entire length at once. That might create too much heat, and increase the chance of blowing a hole or two, not to mention warpage. I use piece of 1/8" x 1.5" x 6" copper flat bar as a backing under the weld area. The weld won’t stick to the copper, so no holes are blown in through the metal. And it also acts as a heat sink. Take your time here! Don’t weld so much at a time that you warp the rails. That is the point of no return, so do it right the first time! Allow the weld to cool naturally, do not try to speed up the process by spraying water or compressed air on the weld area. That’s a trick an experienced body man will use to shrink metal. Don’t want that here. Once cool, grind all welds smooth. Dress with a 60 grit disc or flapper wheel. Again, check the frame for squareness. If it tweaked a little during welding, you might be able to tweak it back with a come along or a porta-power. But hopefully it didn’t move at all! Now we need to reinforce the frame at the weld areas to provide extra strength. Do this inside the rails, as it is not easily seen if some leans down and takes a peek under your truck. I made the “fish plates”, the long skinny shaped pieces, out of 1/4" mild steel plate. Make them long enough that they extend front and rear AT LEAST the length of the removed section, which is 12". I made mine 14" so that they would overlap a bit. They are also 5" tall, but could be anywhere from 4" to 5" tall. Next I wanted to support the short welds the run from the outer edge of the fish plate down (or up) to the inside corner of the rail, and from the inside corner of the rail to the outer lip of the rail. I used one of the notches that was cut out, and cut 4 pieces that were 2" wide. Lay them over the remaining welds and mark them where they need to be cut in order to lay flat against the frame against the fish plates, and also mark them so that they set close to flush with the inner lip.  You are almost done!! Move to the rear of the frame, measure forward 8", use a square and draw a line on all three sides of each rail, and cut off the ends of the frame rails. Dress the welds like you did earlier. Remove the forward-most pair of bed mounts. They are no longer needed. There is one setting on the frame in the lower right of this pic. The left one is already gone. The rear cab mounts can now be reinstalled back onto the frame. Measure 12" back from the original rear holes and make a mark. Using a square, draw a verticle line at that mark. Now measure down from the top of the frame to the center of the top original hole. Make a mark at that measurement on the vertical line you just drew. Measure 12" back from the original front hole and repeat as above. Remember, the top of the bracket needs to set .150" above the top of the frame rail, a touch more than 1/8". Drill the holes to 7/16". You can use Grade 5 fasteners here. I suppose Grade 8 wouldn't hurt anything, but may be overkill for their purpose.   Now, stand back and look what you have just done: Next it’s off to the sandblaster. I just have to decide if I want to powdercoat it ($$$) or paint it. We’ll see........ Well, there you have it. This took me three evenings to do, a total of about 10 hours. I have been asked why the hell I am doing this, why not just buy one? Well, like I said before, they are not easy to find around here. Sure, I could have driven a few hundred miles to get a cherry one. But you gotta admit, there is a huge fun factor in doing this kind of stuff yourself! I anyone has any questions, just send me a PM and I’ll do my best to answer them.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE Last edited by augie; 04-10-2011 at 01:50 PM. |

|

|

|

|

#2 | |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Quote:

But, in the meantime....... Since 12" was removed from the middle, the rear cab mount will need to be moved back the same amount.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

|

#3 | |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Quote:

I am not sure how the mod will work with a leaf spring truck. Hopefully someone will read this and jump in. Thanks for the comments!!

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

|

#4 | |

|

its all about the +6 inches

Join Date: Jan 2001

Location: Hilliard Ohio

Posts: 2,693

|

Quote:

I forgot to mention...that is some FINE work you have done there. I hear about ppl making LWB frames into SWB frames, and it makes me shudder. I've seen the results of crappy work, and I have to say, if they were to follow this thread, and learn to weld as good as what your welding apears to be, then there shouldn't have any problems. Awsome job. Last edited by Longhorn Man; 10-17-2004 at 07:50 PM. |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Oct 2004

Location: Oklahoma

Posts: 261

|

What is the problems when one gets when using a frame from another truck? I mean with the vin numbers not matching the cab?

What is the technique called he used here? Is it the z notch? |

|

|

|

|

#6 |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

My best friend is a state trooper here in Colorado. He said, at least in Colorado, as long as I didn't deface or remove the VIN numbers stamped on the frame, and if I told the buyer (if I were to ever sell it) that the frame had been replaced and modified, there would be no issue. He said the biggest problem would be in defacing or trying to change the VIN on the frame to something else.

I call it the step notch, but "Z" or "S" I suppose would work too

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

#7 |

|

Registered User

Join Date: Oct 2004

Location: Oklahoma

Posts: 261

|

in your opinion is the step notch or the traditional slant ( / ) notch more effective?

|

|

|

|

|

#8 |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Step notch over a slant or 90 degree cut anyday. It is 1] easier to align and 2] stronger.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

#9 |

|

Registered User

Join Date: Oct 2004

Location: Oklahoma

Posts: 261

|

Are you going back with a steel bed or wood? If steel are you going to cut down a long bed?

|

|

|

|

|

#10 |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

I'm gonna build a wood floor bed. I bought new 6' bedsides to do it with. If I were to do a steel floor, I would have either cut down the original one or bought a flat sheet of 16 gauge.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

#11 |

|

Senior Member

Join Date: Sep 2004

Location: CANADA

Posts: 1,681

|

rick......the frame looks like it was repaired from rust and not cut down to me.

Or the frame is splicied together because it was bent some where.Like two frame cut and welded together.I have heard of this being done to repair the back of the frame due to bent rear rails.some people do this instead of swaping the whole frame because they only have to pull the box off and cut and weld instead of messing with the cab and wiring.I would replace the frame or cut and shortin it right as this tread shows.Just my $0.02 The box floor can be cut down.i read a write up in Classic trucks about a year ago on it.not sure what month but the mag was from late 2003 or earily 2004 . |

|

|

|

|

#12 | |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Quote:

If I can just find a little time to get the cab corners and rockers on, that should motivate me to get the cab back on the frame and start pre-assembly!!!

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

|

#13 | |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Quote:

At the very least, I would have someone with good welding skills remove those plates and do it right! It could be cut with a sawsall, you would just need to drill a large enough hole in the corners to get the blade into to finish the cuts front to back. Personally, it looks a little scary to me ..... I would fix it before I drove it too much.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

|

|

#14 |

|

Next project: 1970 K10

Join Date: Feb 2004

Location: Fort Collins, Colo 80524

Posts: 6,685

|

Re: How to shorten a LWB frame

For those with leaf spring frames, I think we have been able to determine that there should be no issues with shortening a LWB leaf frame. Since the main cut is done under the cab, the rear suspension would remain in place just as the coil suspension would. So measure, cut, roll forward, weld. Then get the right measurements for the driveshaft as usual.

__________________

Bob 1970 Chevy K10 LWB "Goldie" 350/TH350 next project!! 1981 Chevy C10 LWB 355/TH350 - My son's truck LS SWAP FORUM! Tons of LS swap info here! PLEASE CLICK HERE TO SUPPORT THE GREATEST BOARD ON THE NET! CLICK HERE FOR THE FAQ INDEX by KRUE |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|