|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

1971-72 C10 Cable Throttle Install

Ever since my original gas pedal wore out and I switched to an aluminum racing pedal, Iíve been struggling to obtain the smooth pedal operation I was after. Recently I noticed a few members had installed the 1971-72 C10 cable throttle in their 60-66 trucks. Further research showed this to be a very popular swap with the 67-70 crowd as well.

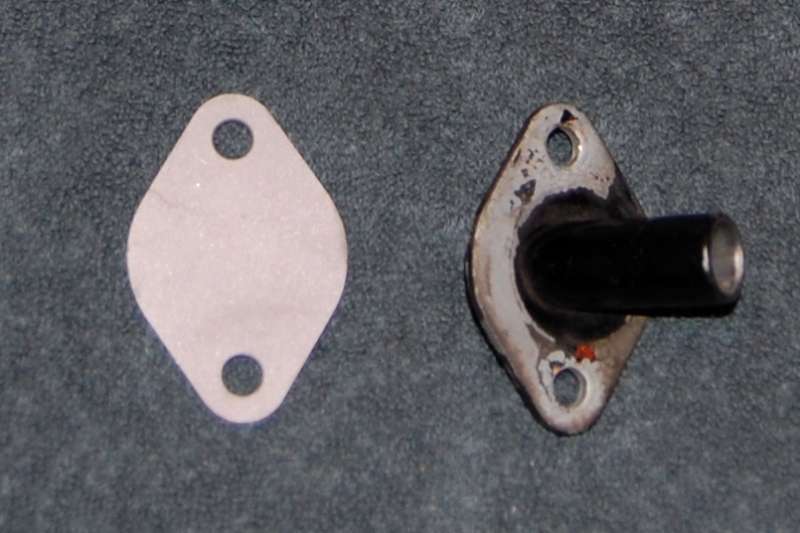

Other than 2 photographs another member posted, there wasnít much helpful information available. When I finally decided to install the cable throttle in my 1960 GMC I took a few pictures that may prove helpful to others wanting to do the same swap. First up I removed the pedal, firewall pivot, and all the linkage up to the carburetor. The nutserts in the floor were plugged with silicone sealant followed by a pair of 1/4x20 button head Allen screws. Using the bellcrank pivot mount as a template, a block off plate (the same thickness as the pivot plate) was fabricated to cover the pivot hole:  This is what the complete 71-72 pedal assembly looks like before modifications:  The upper chunk was quickly unbolted and the trusty Dremel tool was called on to slice off the attaching bracket, level with the top of the plastic firewall anchor:  After further study I could find no reason to retain the ear on the upper left side, so it was sliced off and the remaining part angled to more closely match the other side:   Early test fittings indicated the right side of the plastic mount should be ground flat to match the angle of the firewall. This picture is out of sequence because it shows all three mounting bolts, but itís the only one showing where the plastic mount was modified:  The complete assembly was test fit numerous times looking for the best fit at the firewall, the most comfortable pedal position, and level alignment. (Some of the pictures appear to lean to the left, but thatís because I didnít have the camera level on the seat). Once the location was established, the upper right hole was marked with a 17/64 transfer punch (the next size up from ľĒ). It was a tight slip fit to keep alignment accurate. That hole alone was drilled to ľĒ, and the complete pedal assembly reattached to the firewall. The allowed a precise final alignment before marking the other two mounting holes. With the pedal where it belonged, the top of the bellcrank needed to move about ĹĒ to the left. It was clamped in the bench vise at the point indicated by the arrow, and given a gentle nudge with an 18Ē adjustable wrench. Bolted back in place, the upper cable hole was marked with a 5/32Ē transfer punch directly through the cable restraint bushing:  And finally the cable hole was drilled out to ĹĒ.  To help insure the cable hole came out square and level, I started out by making a template/guide. I applied a length of 2Ē masking tape to one of my wifeís cutting boards. A ĹĒ square was marked and cut out freehand with an Xacto knife.  It was lined up and stuck over the 1/2Ē hole:

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#2 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: 1971-72 C10 Cable Throttle Install

There was less to remove than I expected, and the corners were quickly squared up with a small triangle file. It occurred to me I have a 400 grit stone in my stash, so I checked and sure enough it is exactly ĹĒ square. So I used it for a go/no go gauge until it slipped through. Now I have a nice 400 grit polish on the edges of the opening.

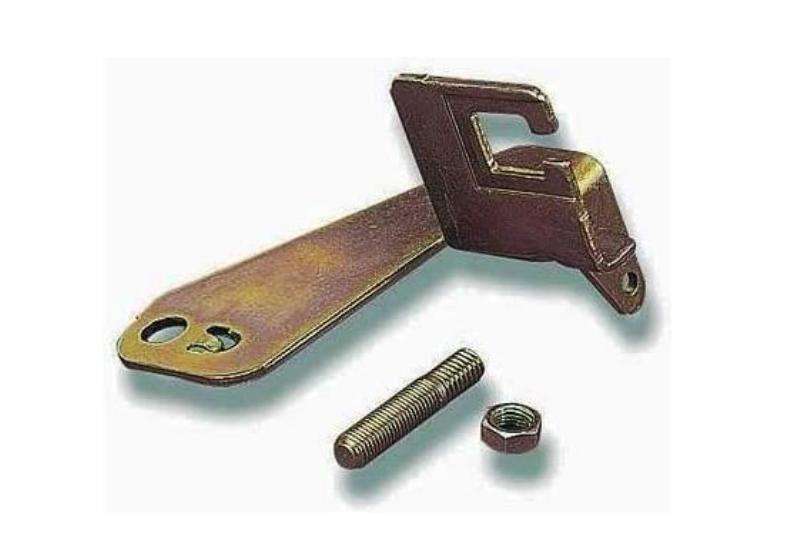

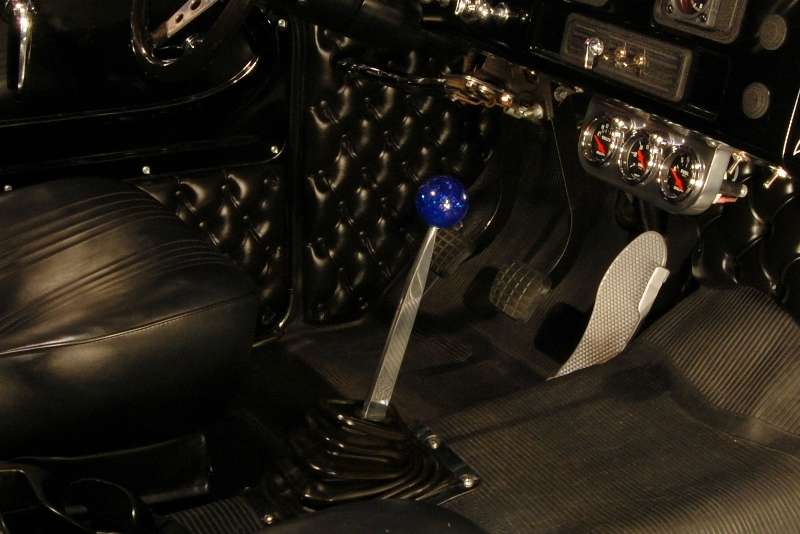

After vacuuming up the last of the mess the cable was slipped in place and the pedal assembly installed. The cable remained loose until the carb connections were complete to allow for best routing. Engine Connections A ball stud was added to the side of the Edelbrock carburetor linkage as I had previously been using the large hole in the forward position. I didnít have a bracket available to mount the forward end of the throttle cable. I looked through everything Edelbrock had to offer and didnít find anything that looked suitable. A couple more hours of internet searching turned up this Holley/GM bracket. Holley part number 20-44:  This turned out to not be the best available choice because it needed modification to fit my particular installation. Subsequently I discovered Holley part number 20-88 which would have bolted to the outboard stud on my Edelbrock carb and saved me at least 2 hours of wasted time:  Hereís what the engine side looks like all back together. This one shows the mounting bolts for the gas pedal support, the cable attachment, and the block off plate for the old linkage pivot:  And this is the best shot I can get of the engine brackets. The new bracket moved the anchor for the throttle return springs back almost an inch and a half stretching them too tight. So I added a high tech adjustable return spring connector (a piece of dog chain). Once I dial in the correct length Iíll have my kid whip up something a little fancier looking. Obviously I need to wash my engine again.  And hereís a shot of the finished install from the driverís seat after everything was connected. The gas pedal is just about centered half way between the brake pedal and the transmission hump. I donít really want the eye drawn to the shiny silver mounting nuts so Iím going to etch prime and paint them gloss black:  Here are before and after shots from the passenger side:   Compared to the previous aluminum pedal the newer version is certainly unimportant looking, but it does work much better. Itís very smooth, provides a more precise response from the engine than the old setup, and allows a more natural positioning of the foot. To add a little sparkle 71-72 clutch and brake pedal pads and stainless trim were installed. These items fit perfectly with no modifications to the pedals:  The interior changes from start to finish took longer to write up and take pictures of than it did to perform the actual modifications. Compressed into actual working time it probably took less than a couple of hours to do the whole conversion. Final notes - the standard 1972 350 cable is actually several inches too long for my application requiring a pretty severe corkscrew routing between the firewall and the carburetor. Apparently my engine is closer to the firewall than a stock 71-72 C10. The 4x4 version is shorter, but I donít know by how much. It might have been a more suitable choice, but OEM versions are claimed to no longer be available. In order to keep the cable level with the throttle linkage I added an Adel clamp to the kick down bracket which also removed any strain from the factory cable/bracket attaching grommet. Installing the cable grommet into the square carburetor bracket hole was a nightmare. If I ever have to do it again I will modify the bracket first, angling the square entrance slot to more closely resemble the factory GM approach as shown on this Monte Carlo bracket:  After the first test drive with the new cable setup I knew this upgrade was a smart investment. What an unbelievable difference. I would have made the change years ago had I known how much of an improvement it was going to make. It is smooth as glass and extremely precise. The final minor adjustment was increasing throttle spring tension by one notch. The cruise control worked perfectly requiring no adjustment at all. Having been a mechanical linkage guy for the last 45 years Iím surprised how delighted I am with the results of this conversion. Iíll be recommending cable gas pedals from now on.

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Nov 2009

Location: Galt, Calif

Posts: 2,437

|

Re: 1971-72 C10 Cable Throttle Install

One question remains,,? Whats with the 30 cents up on the firewall....? As usual great write up Mark..

__________________

`64 C10 vortec 350/350/373 posi `69 RS/SS 350/350/308 `37 Ford 406/350/324 traclock `68 Dart 370/904/323 suregrip |

|

|

|

|

|

#4 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: 1971-72 C10 Cable Throttle Install

Those coins are examples of my JB Weld mania. I've been using coins and JB Weld to close sheet metal holes since the 1970's. Unless the back side with the coin can be seen, the repairs are undetectable.

Here's the write up: http://67-72chevytrucks.com/vboard/s...highlight=warp

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

I'm needing to do this on my 1960 'Burb.

I have a few questions....on the carb, what bracket are you using? I see you talking about the Holley GM Bracket is what you used, but I'm not seeing that bracket in the picture(s) or I'm missing something. A google search for a 1971 pedal brings up an Edelbrock 8036 Chevy Throttle Bracket. Will that give me the connections at the manifold for the carb? If I'm not mistaken, I'm seeing that in your picture with one of the legs not installed....guessing it's the connection for cruise. I'll likely have more questions once I start this, but I have to find the pedal and then get the engine installed. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2009

Location: Burbank, CA

Posts: 3,619

|

Re: 1971-72 C10 Cable Throttle Install

that's a creative way of decreasing the return spring tension

|

|

|

|

|

|

#7 |

|

1965 Chevy C10, 2005 4.8L/4l60

Join Date: Aug 2004

Location: DFW Texas

Posts: 8,546

|

Re: 1971-72 C10 Cable Throttle Install

I need to do this on my truck!!

__________________

Clyde65 Rebuild of Clyde http://67-72chevytrucks.com/vboard/s...84#post8338184 69 Aristocrat Lo Liner build http://67-72chevytrucks.com/vboard/s...84#post7561684    support our troops! |

|

|

|

|

|

#8 |

|

64-66 CHEVY JUNKIE

Join Date: Apr 2007

Location: Cypress ,Texas

Posts: 1,516

|

Re: 1971-72 C10 Cable Throttle Install

Thanks for the detailed write up markeb01, it helped me to to do this to my truck. For the carb bracket I went with the BTO piece and a second bracket from bto to attach the 4l60 shift cable.

__________________

1966 C-10 Fleetside LWB, 350 Lt1 4l60-E 2008 Silverado Crew Cab, 4.8 4l60-E 1998 GMC Yukon 4x4 L-31 Vortec, 4l60-E 2017 GMC Serra 4x4 5.3 Vortec, 4l60-E  Do It In A Chevrolet Do It In A Chevrolet

|

|

|

|

|

|

#9 |

|

64-66 CHEVY JUNKIE

Join Date: Apr 2007

Location: Cypress ,Texas

Posts: 1,516

|

Re: 1971-72 C10 Cable Throttle Install

Some Pics

__________________

1966 C-10 Fleetside LWB, 350 Lt1 4l60-E 2008 Silverado Crew Cab, 4.8 4l60-E 1998 GMC Yukon 4x4 L-31 Vortec, 4l60-E 2017 GMC Serra 4x4 5.3 Vortec, 4l60-E  Do It In A Chevrolet Do It In A Chevrolet

|

|

|

|

|

|

#10 |

|

64-66 CHEVY JUNKIE

Join Date: Apr 2007

Location: Cypress ,Texas

Posts: 1,516

|

Re: 1971-72 C10 Cable Throttle Install

Works Great. .

__________________

1966 C-10 Fleetside LWB, 350 Lt1 4l60-E 2008 Silverado Crew Cab, 4.8 4l60-E 1998 GMC Yukon 4x4 L-31 Vortec, 4l60-E 2017 GMC Serra 4x4 5.3 Vortec, 4l60-E  Do It In A Chevrolet Do It In A Chevrolet

|

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Quote:

I'm also curious what tools, if anything special, I'll need when I visit the salvage yard to rob a pedal/cable. One more thing, Mark mentions cable being too long, is it hard to shorten one if these cables? I have a friend who is very into bicycling and bulls his own bikes and shifting cables, wonder if he'd have tools to do bicycle cables and if they'd somewhat work on throttle cables. Guess I'll have to compare. I'll post a few pics when I start going with my swap as well. |

|

|

|

|

|

|

#12 |

|

64-66 CHEVY JUNKIE

Join Date: Apr 2007

Location: Cypress ,Texas

Posts: 1,516

|

Re: 1971-72 C10 Cable Throttle Install

Bow Tie Overdrive..

__________________

1966 C-10 Fleetside LWB, 350 Lt1 4l60-E 2008 Silverado Crew Cab, 4.8 4l60-E 1998 GMC Yukon 4x4 L-31 Vortec, 4l60-E 2017 GMC Serra 4x4 5.3 Vortec, 4l60-E  Do It In A Chevrolet Do It In A Chevrolet

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Good to know!

Back to the pedal, just left savage yard. Of course the one 71 they had was already gone. Question...Will the mid 70's pedal assembly work? The guy at salvage yard said it would but the arm need bent because the firewall is different angle. Thoughts? Looks the same otherwise. |

|

|

|

|

|

#14 | |

|

64-66 CHEVY JUNKIE

Join Date: Apr 2007

Location: Cypress ,Texas

Posts: 1,516

|

Re: 1971-72 C10 Cable Throttle Install

Quote:

__________________

1966 C-10 Fleetside LWB, 350 Lt1 4l60-E 2008 Silverado Crew Cab, 4.8 4l60-E 1998 GMC Yukon 4x4 L-31 Vortec, 4l60-E 2017 GMC Serra 4x4 5.3 Vortec, 4l60-E  Do It In A Chevrolet Do It In A Chevrolet

|

|

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Is the '98 truck peddle the same as the mid 70's? Also, with the '81 cable what was the length like? Salvage yard wants $20 for the peddle and $20 for a cable. Just curious if it matters which year. I'm excited to finally make headway in this dept. Also, did you have to bend the arm on the '98 peddle?

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Picked up a pedal assembly today, guess it's out of an '83. Looks to be somewhat of a cross between the two posted above. I'll get pics later and show how it goes...

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Made some progress on mine today. Like I said the pedal assembly is out of an 83 c10. I cut off all the excess that the OP cut. I then trimmed the plastic up to make it narrower and I cut the raised portion of the right side rear, so it sits flat against the slightly angled fire wall.

My pedal seems a bit different than both of the others, but it'll work as well. At this point the only question I have that I need to figure out is do I bend the upper portion of the rod to the left or if I try to twist the flat part where the cable attaches to the arm so it can exit the angled part of fire wall straight on. It seems to me that if I go through the angled portion it would be straighter shot to carb. Problem is I don't have the engine/carb I'll be using in the vehicle yet do i might hold off on creating this hole. Thanks for all of the help, especially Chris! |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2017

Location: Wichita

Posts: 639

|

Re: 1971-72 C10 Cable Throttle Install

Neighbor looked at the possible mounting locations and his opinion was that if I did it on the angle I could possibly run into a binding situation. Guess I'll try the flat surface and bend the arm to the left. I'll post pics when I get that done.

I might also look into seeing if I can successfully shorten the salvage yard cable. If that works then I might try a new one and see if I can shorten that as well. Worse case I'm out $17. |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Mar 2010

Location: thomastown mississippi

Posts: 1,261

|

Re: 1971-72 C10 Cable Throttle Install

Remember that Mark bent his arm to the left (inside view) so as to get the cable / arm assy to line up with the flat part of the firewall.

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2014

Location: Comfort, TX

Posts: 142

|

Re: 1971-72 C10 Cable Throttle Install

Will this work with a Rochester 4G on a SBC? Iíve swapped engines from 250-6 to a 283 with the Rochester, and Iíve engineered the original rod linkage to work, but it leaves the pedal pretty far off the floor at idle and thatís necessary for full throttle floor pedal....

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2011

Location: Tulare, CA

Posts: 734

|

Re: 1971-72 C10 Cable Throttle Install

It should work fine on a Quadrajet Carb. You may have to move the throttle cable attachment closer to the pivot point on the throttle shaft so less stroke of the cable will yield more movement on the throttle plates. My truck had an Edelbrock (AFB) carb on it when I bought it so I can't give you any specifics for a Quadrajet carb. Also if your truck is an automatic you might want to consider finishing off the look by retrofitting a 73 up brake pedal in it.

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Mar 2014

Location: Tulsa OK

Posts: 96

|

Re: 1971-72 C10 Cable Throttle Install

Good info here. Has anybody thought about using the later model pedal that mounts on the firewall but running the rod through the factory firewall pivot, which would alleviate the need to add the triangular bracket on the firewall? I know the rod may need bending to accomplish this and the two rods may be different sizes but going that route would keep the factory firewall penetration and mount, while removing the floor mounted pedal pivot and putting it on the firewall, which is the overall goal. Then the rod would penetrate the firewall in the factory location and you wouldn’t have to drill a whole for a cable. Thoughts?

|

|

|

|

|

|

#23 |

|

Moderator

Join Date: Aug 2011

Location: China Spring, TX

Posts: 7,280

|

Re: 1971-72 C10 Cable Throttle Install

I think you should try it and take pics along the way.

Besides even the next generation trucks are going the cable way - http://67-72chevytrucks.com/vboard/s...d.php?t=746099

__________________

Master Chief, US Navy, Retired 1964 C10 Step-side Short Bed - In Progress 2009 2500HD Duramax LTZ 1948 GMC Panel 1956 Big Window Stepside 1953 5 Window Chevy Stepside 1932 Coupe New Seat Foam for Bench Seats? Last edited by The Rocknrod; 05-26-2019 at 05:20 PM. |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|