|

|

|

#1 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Is this the right way

Is this the right way gm did the bolts on the idler arm support and the steering gear

|

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Re: Is this the right way

Pic 2

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Re: Is this the right way

Steering gear pic 1

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Re: Is this the right way

Steering gear pic2

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Re: Is this the right way

Pic 3

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2012

Location: Gig harbor washington

Posts: 246

|

Re: Is this the right way

Pic 4

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Feb 2007

Location: Laughlin,Nv

Posts: 141

|

Re: Is this the right way

idler bolts go in the other way around, steering box is right , I always put a flat washer under nuts on idler arm

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Apr 2011

Location: Mustang, Oklahoma

Posts: 2,806

|

Re: Is this the right way

On steering gear. Bolt w/lock washer through inside of frame into threaded steering gear. On idler bolt through inside of frame, idler bracket, lock washer, nut. Your nylock nut will do fine.

__________________

Dan <---(my name) 67 SWB C10 project "GEORGIA"-59 Brookwood 2dr wag...Next project-03 Tahoe 4x4 5.3 family ride-07 Hondur Accord, commuter car |

|

|

|

|

|

#10 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

Re: Is this the right way

You've done nice finish work on your parts. Invest in bulk flat washers so you don't chew the finish off as you torque your idler arm down. Always use a flat washer to protect your finish under lock nuts.

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Dec 2012

Location: Virginia

Posts: 233

|

Re: Is this the right way

Not trying to hijack thread but OP may be curious to but I have always wondered.

Does using a flat washer under a lock washer negate the effect of the lock washer? Thats the point of the lock washer to dig in and bite but a flat washer underneath can slide on surface an come loose, correct? NEVERMIND I just reread and he is using lock nuts....but still wndering cause Ive seen flat washers under lock washers. |

|

|

|

|

|

#12 | |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

Re: Is this the right way

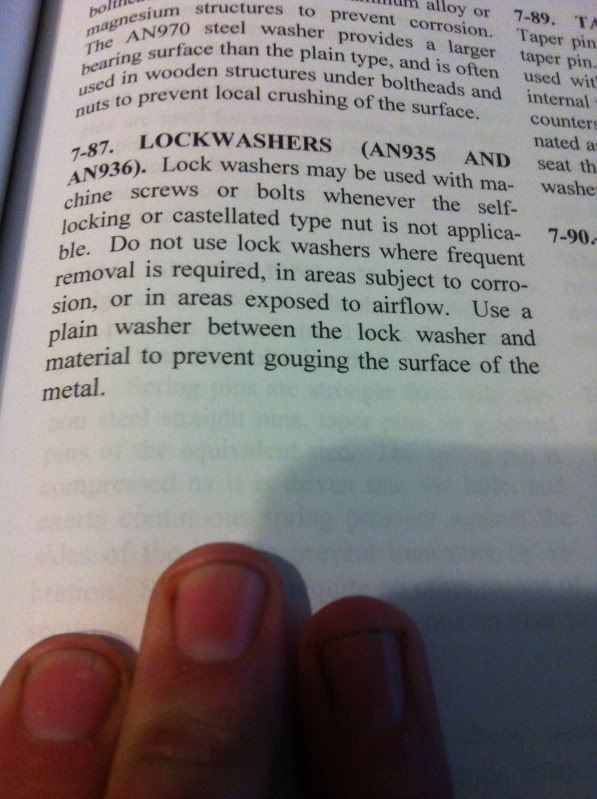

Quote:

Always use a flat washer beneath a lock washer to protect your part finish. Give me a little rambling here to add validity to my answer. My formal education was in aircraft maintenance about 20 years ago. Every repair to all airplanes is done in accordance with the 43.13. That's a giant book of acceptable methods and practices. It covers everything from proper way to bend a cotter key to corrosion prevention. I've worn out several of these books over the years (Amazon is a good source to buy them from). This is the legal bible of all aircraft repairs. If you do a repair by this book and get dragged into court after a crash, you're on solid ground.  Now, according to said bible (read the last sentence above my fingers)....  The reason we did it this way on airplanes is to protect the integrity of whatever corrosion measure had been applied to the part, whether anodizing, paint, etc. a lock washer that digs in will compromise the surface finish and invite corrosion down the road. The original poster has apparently spent a good bit of effort to apply a slick finish to his parts. The flat washer will protect that finish. The last thing we want is to have traces of rust underneath the nut in six months. I can only speculate why auto manufacturers often assemble our trucks with a lock washer straight into the part. I'm guessing its simply a matter of economics and speed of assembly. Planes aren't built quickly, nor cheaply. If it takes a few extra cents to buy a washer and a few extra seconds to stick it in place beneath the lock washer, it's not a problem. Do it right, and do it to last for the long haul. I'm sure some readers will equate aircraft methods to old truck methods the same as apples to oranges, but I strongly feel that they are sound general practices to use. I can't recommend the book too highly. Every single fastener or wiring connector or routing, looming, hoses, lines, drilling holes, or filing off burrs is covered thoroughly in the book.

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|