|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#201 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

So, I ended up taking my steering gear, intermediate shaft and coupler to the shop, because nothing fitted together. they fixed it and I picked it up yesterday, but didn't have time yet to put it in.

In the mean time I have been taking my truck apart, because there were a couple of things bothering me. first of all my left header runs against the lover control arm. the right side is fine, but left sits to low. So I thought of putting in new engine mounts, perhaps that would lift the engine a bit. I don't need much, half an inch would do the trick. but ofcourse to get to the engine mounts, the headers had to come off and while in the process of removing them I spotted some wiring which was routed wrongly. Also I was not happy the way I did the plumming of the brake lines and where the brake distributor was sitting. So BigMike, I stole your idea and did almost the same setup you have. I first had to weld a bracket, paint it and it turned out ok. but for the life of me, how do you get the lines to go straight and looking clean...because if you look at the brake lines for the front...pff, very messy..but at this stage I just can't care less and it will have to do for the DMV check in hopefully two weeks?

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#202 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

I had bought some new engine mounts a while ago and thought I'd put them in to see if it would solve my header problem.

the left header rubs against the lower control arm even after trimming it a bit. So I used a engine lift (or hoist?) and a jack underneath the oil pan just to be sure and raised the engine 1,5". the first thing I noticed was that the right engine mount was missing the bolt connecting the mount to the cross member bracket.. the second disturbing thing was that with the exception of 1, the rest of the bolts were loose enough to use just my fingers to unscrew them. I then turned my attention to the engine mount bracket on the right side which was...well...how shall I put this nicely: BUTCHERED by the PO.. to get clearance for the header on the right side. Seeing I still need that clearance I desided to weld in a reinforcement. Now I'm not a master welder nor a crafted metal worker, so be kind judging the finished product. butchered mount bracket  reinforcement   Of course I have no idea of this will work because I don't have my new engine mounts in yet, why not you ask? because the NEW mounts I bought at LMC had both damaged threads (??) for the center bolt.. so my pal took them along to his work where he has the UNC/UNF etc. thread repair kit. I should have them back on Friday. Next thing I tackled was the fuel pump. seeing I only run on LPG, or propane for short. I decided to take out the pump and close off the hole. a lot of muck was stuck behind it and the pump push rod even had corrosion on it...So I cleaned it out as good as possible, but for sure I'll put in engine flush oil and see if I can get some more crap out. fuel pump mounting plate dirty  fuel pump mounting plate clean  fuel pump mounting plate welded up  fuel pump mounting plate installed

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#203 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

I just found this build thread, and read through all of it. Wow! What an adventure you've had so far. I am not sure I would have been able to keep going through all of that, especially all the brake issues. Well done! I'm subscribed, and look forward to seeing how it continues to come together.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#204 | |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Quote:

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

|

#205 |

|

Registered User

Join Date: Dec 2013

Location: Purmerend, Netherlands

Posts: 1,657

|

Re: 1969 Custom/10 clean up

With small steps forward, you are comming there in the end...

Question: Why not built your own enginemounts, then there are no more issues with headers I think? You can built them as you like.

__________________

Cheers!! Kees. 1959 Chevy Fleetside Longbed My build: http://67-72chevytrucks.com/vboard/s...d.php?t=643426 Kool Guyz CC Instagram: _King_Kustom_ |

|

|

|

|

|

#206 | |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Quote:

But if I may ask, how much harm would it do if I raised the engine with a 1/2"? and regarding the angle of the engine-tranny vs driveshaft to differantial, what do I have to take into consideration?

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

|

#207 |

|

Registered User

Join Date: Dec 2013

Location: Purmerend, Netherlands

Posts: 1,657

|

Re: 1969 Custom/10 clean up

Well Steve, easy

You have to measure with the engine at the new hight, how your angle is working out. Maybe try to put some woodblocks under the existing mounts and transmount to see if you have enough room. If so, measure the angle at the joints at the trannie and the axle, that way you know if you're still at the right angle. If you are around the 3 degrees, you'll be okay. Keep in mind that you both do the enginemounts and transmount to get the angle right again, if else, you've got to twist the axle for the right angle... Hope you understand my explanation? PM me for good ol' Dutch if not

__________________

Cheers!! Kees. 1959 Chevy Fleetside Longbed My build: http://67-72chevytrucks.com/vboard/s...d.php?t=643426 Kool Guyz CC Instagram: _King_Kustom_ |

|

|

|

|

|

#208 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Well Kees, the new engine mounts and raising the transmission tail by 2mm (ehh 1/10th of an inch) fixed it, so the header clears the control arm now.

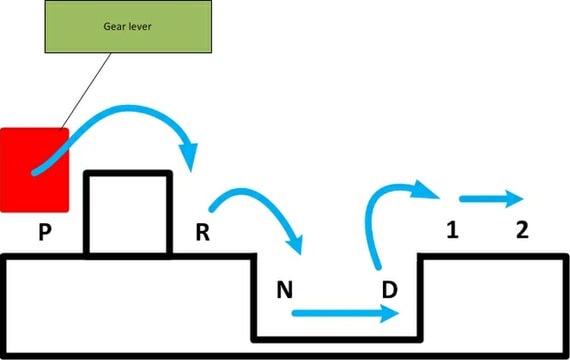

having tackled that problem I set out to fix another, the leaking transmission. Pulled of the transmission pan and I don't know what the PO has been doing, but he welded up three holes? and the pan looks pretty beat up, but I decided to leave it like that..just replacing the seal and sprayed it with heat resistant clear coat     then finished my doorpanels, we made them from a thin kind of plywood, I decided to paint them black.  and now a dumb question to which I think I know the answer, but I want to be sure. what is the correct position for this lever when in PARK position? picture nr 1:  or picture number 2?  I assume picture nr 2? but I don't know what the lever plate holding thing is called, so I don't know what to google for..

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod Last edited by Steve-W; 11-29-2015 at 07:44 PM. |

|

|

|

|

|

#209 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

I don't know the answer on the park lever, since my truck is in pieces, and I can't check. That door panel turned out very nice!

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#210 |

|

Registered User

Join Date: Dec 2013

Location: Purmerend, Netherlands

Posts: 1,657

|

Re: 1969 Custom/10 clean up

Just 2 mm?

Not much, but if it solved the problem  Don't see what you mean with the Parklever? Park is usually counter clockwise, all the way left... But you know that! So that wouldn't be the right answer??? Doorpanel is nice!

__________________

Cheers!! Kees. 1959 Chevy Fleetside Longbed My build: http://67-72chevytrucks.com/vboard/s...d.php?t=643426 Kool Guyz CC Instagram: _King_Kustom_ |

|

|

|

|

|

#211 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

the metal bracket (shift lever lock plate?) prevents you from pulling the gear selector straight from P into any gear, you have to pull your selector towards you before you can move it down right? so where does it sit on the bracket or lock plate when in park. above the bracket like in pic 1, or on the first position like on pic 2

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#212 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

Here is a picture I took of mine when I was taking it apart. The shifter was in NEUTRAL at the time. I don't know if this will help at all.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#213 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Well yes and no, are You sure it wasn't park?

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#214 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

It was definitely in Neutral. I have the pictures I took of the steering wheel/shift indicator at the same time. sorry

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#215 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Hahaha don't be sorry, it just confuses me a bit more.

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#216 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

You might post the question and your pictures over in the "Engine & Drivetrain" section. I'll bet someone over there could tell you pretty quickly.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#217 | |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Quote:

to me this makes sense. from Park you can't pull straight into Reverse, but from reverse you can go to neutral and drive. But from drive you can't pull straight into the lower gears. going back up you can go from the low gears into drive and neutral, put you can't pull straight into reverse. With the transmission in P and my lever in the P position I adjusted the shift rod until it was the correct length

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

|

#218 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Last Friday and Saturday night I was in the shop tinkering away and actually got some nice work done. I wasn't happy with the rear transmission mount so I was in a local shop who only do USA cars to pick up some door/window handle retainer clips and asked them about the mount for a TH350. Sure enough they had one laying around so I bought it.

with a new mount, the cross member the PO put it, just could stay anymore, so I decided to make a new one. my pal thought out the design and I welded it together.. which was quite a task for me, but good practice. afterwards I sprayed body protector stuff on it (body soot or something it is called?)      the square tubes are 1" by 1" and about 1/16" in thickness. the center plate is close to 1/8". I'll make sure to take a picture of it mounted.

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod Last edited by Steve-W; 12-13-2015 at 07:25 PM. |

|

|

|

|

|

#219 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

That turned out really nice! Can't wait to see the installed pictures. By the way, I did actually find my steering column on a shelf in the barn, and looked at it. It's completely disconnected, but when I put it in park, the little button looks like your picture 1 above. I don't know if that helps any.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#220 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

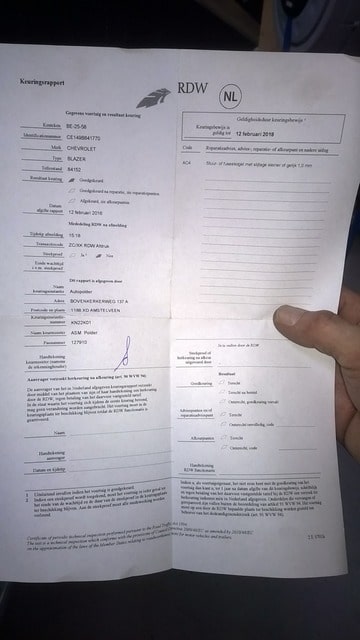

It's been a while since my last update, but I've had a major breakthrough!

my truck made it through it’s bi-yearly roadworthy test. (MOT in the UK, no idea what it’s called in the US. ! I had it registered as “off the road” back in 2011, so I didn’t have to go for the obligatory MOT checks. 3 weeks ago I just wanted to know where I stood so I drove over to a certified garage who did the test. it failed the test as I expected, but on far less critical points then I thought might cause a problem. - Brakes had sufficient power, but the pedal went all the way to the floor. - left headlight gave of a weird image - Oil leakage on the right exhaust, which wasn't there before, but apparently started on my drive over. - missing high beam indicator in the dash Well the brakes where my main concern, seeing how I have been messing about with them. So we did another round of bleeding them, I then re-adjusted the rear shoes and getting them even tighter into the drums. The problem is that my new aftermarket drums do NOT have a hole on the face side so the drums have to come off to adjust the shoes. But perhaps I can drill a hole in the backing plate? Anyway this did improve the travel of the brake pedal somewhat, but it was still too deep in my opinion. As a last resort..which perhaps should have been my first..I adjusted the brake pedal. The pedal couldn’t go any higher, so by making the pushrod longer I put some “pre-tension” on the Master brake cylinder? I had no idea if this was going to do the trick or would just get my brakes to drag. Well seeing I made the MOT, you can guess the answer…my bakes are finally, working properly! I had about 2,5KN (Kilo Newton) of stopping power at every wheel..so I’m a happy camper. I haven’t tried to get it in a 4 wheel lock, but I’m sure I’ll manage. Then I turned my attention to the oil leakage which I hadn’t encountered before, mind you, this 2,5 Mile was the longest drive I had since I started this project… It turned out to be the return oil line for the trans. It had been rubbing against a sharp edge and I didn’t spot it before, so I guess the drive over to the garage was its waterloo. I put in new lines, re-routed them and now it’s all hunky-dory. For the High beam indicator we really went ‘out of the box’..or perhaps it had to do with having consumed large amounts of beer at that particular hour. We fit a lamp in some 1” tubing and tie-ripped it to the top of the dash…MOT approved! I then went for a 50mi testdrive and nothing came off, nothing caught fire, but if was @#$$@!# cold!! Oh yes, my heater still need to be fixed among a 1000 other things, but at least I am now legal to drive it for the coming 2 years!   A while ago my old wiper motor just stopped without reason, so after checking the fead and ground I chose to change the motor. I picked up a refurbished one and to my surprise it didn’t work. So I pulled it apart and found this:  I then made a hybrid out of the old and ‘new’ one and got it working. All I need now is a washer tank and pump, but I’ll order the universal kit from LMC Another thing that was missing was a battery holding bracket and I got creative an build my own from some old shift rods.   One question I have is about this ridiculous big antenna hole? Its on my cowl on the right side and measures 34mm (1.3 Inch) Is that a normal spot for the antenna?  And last but not least, after being declared road legal again we had to celebrate!  This thread will stay alive, because my list of to-do’s is a mile long and I will keep you updated on the progress. Stuff i need to do: Restore the bed, finish the inside of the cab (trim, heater, carpet, seat belts etc), probable a suspension renewal incl swaybar…and god knows what else So stay tuned people!

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#221 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

Good news! Congratulations on passing the inspection!

The antenna hole looks like the correct factory location and size. The hole should be 1.12 inches in diameter.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#222 |

|

Registered User

Join Date: Dec 2013

Location: Purmerend, Netherlands

Posts: 1,657

|

Re: 1969 Custom/10 clean up

Congratz Steve!!!

Another one on the road!! Wishing you many save miles, and I'm sure we'll meet!!

__________________

Cheers!! Kees. 1959 Chevy Fleetside Longbed My build: http://67-72chevytrucks.com/vboard/s...d.php?t=643426 Kool Guyz CC Instagram: _King_Kustom_ |

|

|

|

|

|

#223 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

Now moving along, I could use some guidance: the top of the bedsides are very rotten.

for me this is great practice for my welding skills, but it's double sheeted metal (I hope I described it the right way) so actually, I have no clue where to start. here are some pictures:      the pockets are all in reasonable shape  I can buy complete replacement side panels, (I haven't seen any repair sections?) but that's the easy way out, and over budget  so I hope you guys can give me some pointers so I hope you guys can give me some pointers

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

|

#224 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: 1969 Custom/10 clean up

Steve, I don't have any pointers for you. I think if it were me, I'd work on the budget for replacing, lol! I would recommend that you post the question over on the "body and paint" section, where more folks who know this stuff will see it.

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

|

#225 |

|

Registered User

Join Date: Aug 2010

Location: Hoofddorp, the Netherlands

Posts: 582

|

Re: 1969 Custom/10 clean up

truck has been put on hold for a few weeks because we have a new crew member I need to attend to:

Emily Marie Westerkamp 7 pounds, 20" and a healthy set of lungs!

__________________

Feedback is always welcome! projects: 1969 Chevy C10 1950 GMC 100 1958 Chevy C60 Viking ratrod |

|

|

|

|

| Bookmarks |

| Tags |

| c10, europe, netherlands, rebuild, swapped |

| Thread Tools | |

| Display Modes | |

|

|