|

|

|

#476 |

|

haha, ford guys...

Join Date: Feb 2007

Location: Visalia, CA

Posts: 576

|

Re: Tbi swap build thread

wow! this is truly amazing STICKY!

|

|

|

|

|

|

#477 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

I looked up your cam on Summit Racing (K1101) - it is a mild (improvement over stock TBI cam) and stock ASDU calibration should be able to handle it, but it is always a good idea to dial in VE and SA tables to get best possible performance out of your engine as no two engines are alike. One issue that you'll have to face down the (off) road - is EGR disable when you get VSS installed and functioning. Since your application is for for off-road use EGR will hardly provide any benefits (no steady driving, etc). Getting back at you current problem. Do simple checks first. In TBI system ECM controls timing. As I have mentioned before at idle, 650 RPM, timing should be bouncing between 17 to 22 deg. As you bring RPMs up timing should advance - with no load on engine timing should be climb to about 30 deg around 2200-2800 RPM. The easiest way to do this check is to have timing light with timing retard control. Now - these numbers are just ball park figures as ECM is performing over a dozen timing calculations 80 times per second. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#478 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

Is there anyway to eliminate the EGR from the harness. When you dont need emissions. with out the ses light coming on?

|

|

|

|

|

|

#479 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

The only way to de-activate EGR is to increase EGR enable temperature in EPROM calibration tables from 47.5C to maximum 155C. This way ECM will never be able to enable EGR operation and self test will never run. This modification requires custom EPROM and unless you know how to do this I suggest that you contact Bryan at TBIchips if you have no ability to burn your own EPROM chips. http://www.tbichips.com/ Hacking harness will not get you there. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#480 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

So it will run but the ses light will always be on or it wont run? How to you burn your own chips?

|

|

|

|

|

|

#481 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

I do not burn chips - I have modified my ECM to use flash memory on a special adapter board. It is an advance ECM tuning mod PCBA which allows for rapid operational parameter changes. It is designed to tame highly modified engines or extract the last ounce of performance out of stock. If you want to burn your own chips you'll need to ready and 'study' the following FAQ. And mean read it couple of times for it to sink in. http://www.thirdgen.org/techboard/di...uide-book.html //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#482 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

Thanks for the info. I havent bought the parts needed yet. I went to the junk yard to pull a harness but it all seamed a bit overwellming. I a visual learner and reading all the posts without pics makes my head spin. I need a seqential how to from start to finish on every step and detail but probly no such.

|

|

|

|

|

|

#483 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

What are you trying to a accomplish and how much time do you have (money helps shorten time, but it is always in short supply)? As a group - we can walk you through this. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#484 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

I have a 65 truck and I tired of fighting with carbs and cold starts and I want reliability of efi. I have more time than money. I would like to start with a harness what is the ideal donor vehicle.?

|

|

|

|

|

|

#485 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

What size engine (an trany) do you have and what shape is it in???? If it is stock 350 and / or it has a mild RV cam the swap is really easy. Even if it is a 283 or 327 the late eighties EFI from C/K, burban can be easily adapted. TBI EFI is a speed density system - it relies on MAP sensor to determine engine load (among other inputs) to calculate amount of fuel and timing to be supplied to the engine. While hunting for a suitable donor on a JY look for the following vehicles: a) 87-92 C/K, burban. ECM should have service part number 1227747 (other service numbers will work as well). For 350 look for BCC ANLW, ANLZ, ASDZ or ASDU and for 305 AFDY or AJUK plus others. Either 305 or 350 will work, but if EFI system is closer to your engine displacement the better. Unless you have V6 or BBC. b) 87-92 F-bodies - these are 305 TBI (LO3). Look for 1228746 ECM (other service numbers are possible. TPI swap is possible, but it is not for beginner! c) 90-93 B-body Caprices/Road master/Rear drive Cadillac. I have seen 305 and 350 TBI engines (LO3/LO5). These are least desirable since distributor is specific to B-body. However the rest of the components are the same. What to grab: Everything! 1) ECM and plastic mounting bracket (located behind glove box in C/K trucks), ALDL connector mounted in cab (you'll have to cut wires, but leave about 12" of wires for splicing.) 2) Harness - spend the time to gently extract it without braking connectors or cutting wires! Expect to spend 1-1/2 to 2 hours for extraction. It is your foundation for a successful EFI transplant. Before starting removal examine the harness - look for anything that may look like repair or a hack. You do not want that. Dirty or oil soaked harness can be cleaned up with brake clean. Due to age some connectors plastic bodies may brake, but it is very easy to replace them. 3) Intake manifold and everything mounted on it - TB, CTS, ESC / MAP / EGR solenoid bracket, etc. See post #7 in this thread. 4) Distributor 5) CCP canister 6) Relays - you may want to grab some spares (look for front wheel drive Buick and cadies and grab both relay and sockets - allow ~12" for wire pig tails). Do not grab knock sensor (KS) - these are not worth re-using and a new unit should be procured from parts store. Did I forget anything???? side note: My preference is to install full size dizzy (HEI). The EFI trucks use small size dizzy with external coil which is known to fail. To get around this I use HEI from early to mid 80's CCC carburetor equipped cars (F-bodies, B-bodies, vans, etc) as these units have four wire ECM connector. It is fully compatible with TBI EFI system, but connector plug needs to be retrofitted. More on this later. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#486 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

A mid 80's G-body Oldsmobile Cutlass mechanical speedo with the optical VSS buffer is probably your best bet and the least expensive route to getting the VSS signal you need from an older transmission. The speedo head can be fit to an older face plate and then it can be recalibrated to match the face plate MPH range and sweep angle of your 65. The Olds speedo is the long rectangular configuration similar to your 65 so it will be closest to what you need. It is possible to change the speedo gears in the transmission to change the range of the speedo from 85 mph to 120 mph by doing a little math. I did this with an 87 Cutlass I had and made an overlay for the speedo face to change the range from 85 mph to 120 mph. If you have a round speedo then the mid 80's C/K speedo with the optical buffer VSS would work better. I am doing this with my 67 C-10.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars Last edited by 68 TT; 03-22-2010 at 01:26 PM. |

|

|

|

|

|

|

#487 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Oh yes forgot about O2 sensor.

If you have headers - run 3 or 4 wire heated sensor. If you have cast iron manifolds - grab exhaust manifolds from a donor (IFRC driver side where stock O2 is mounted). It cost $20 at muffler shop to install O2 bung. A single wire O2 works well in cast iron manifold, but will problematic with headers. I had equal success with BOSCH and Delco O2's, but Delco units are preferred since ECM close loop algorithm is optimized to match their response. BOSCH is a bit different, but still works. Vehicle speed sensor (VSS) - there are numerous approaches (68TT that's a great tidbit!) as ECM needs this input. P/N switch for automatic - this allows for idle compensation when shifting from park into gear and back. Expect to run a new 3/8" fuel line from gas tank to feed TB. Use soft steel line to run fuel line. Yes, it is a bit more expensive and more work, but we are talking safety here. Use existing fuel line for fuel return if it is in good shape (we are talking about 45 year old line here). IFRC in '65 there were no Charcoal Canister Purge (CCP), but its addition keeps gas fumes from escaping your gas tank into atmosphere (and keeps eco Nazis happy). More than likely you'll have to add fuel return and CCP (1/4") to your fuel sending - pickup module. Gas tank pickup module should have 3 outlets - TBI fuel supply (3/8"), TBI fuel return (3/8 or 5/16"), and purge (1/4"). An inline fuel pump is the easiest way to go. I use Carter P5001 and it has worked well for me for the past 3 years. There are numerous alternatives but keep in mind that you do not need supper high pressure pump - 20 to 30 PSI and about 50 GPH is adequate. Now, back to the grind. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#488 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

Wow ok thanks for the info I have a motor going in. It is 87-92 350. I have a th350 trans but i plan to by a 4l60E for the fuel millage. As for the fuel lines i get a little lost on the lines and pickup moduel and such i need a pic. Thanks again for the help!

|

|

|

|

|

|

#489 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

You will need the 94-95 vintage 16197427 PCM or one of its clones to run the transmission and the TBI system. You can use the older 16147060 PCM and a few others too but they are much less popular and not as well hacked as the 7427. You will need either an electronic speedometer or an expensive conversion box or tail shaft housing retrofit. None of which are budget friendly in a 65. I like the e-trans but in your case trying to keep on budget you are much better off using an earlier 4L60 / 700R4 transmission that already has the mechanical speedometer output and can be run on the much simpler and much easier to find 1227747 ECM. You could do a stand alone PCM to run just the trans (like the diesel trans controller) and use the 7747 ECM for the TBI system but you would still have the electronic speedometer issue to deal with.

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#490 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

To keep things simple I suggest that you stick with upgraded 700R4 which only has TCC, and top gear indicator (three wires that go the trany in 87-92 TBI motors). 2) Fuel tank plumbing parts can be found in post # 135, ? 3) Parts needed for a TBI swap can be seen in post # 172 //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) Last edited by rfmaster; 03-22-2010 at 05:43 PM. Reason: Double with 68TT |

|

|

|

|

|

|

#491 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

Yet again thanks for the info.

|

|

|

|

|

|

#492 |

|

Registered User

Join Date: Feb 2010

Location: Loganville, Ga

Posts: 170

|

Re: Tbi swap build thread

rfmaster what vss and fuel pump do you have, where can I buy them and the cost? thanks

|

|

|

|

|

|

#493 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Part Number 2PRS. $75 includes shipping. There are other VSS vendors, but I have not tried them - thus I can not comment. 2) There are numerous fuel pumps that will work just fine for TBI conversion. For my conversions I used in-line, externally mounted fuel pump. I use Carter P5001 which can provide up to 20 PSI at TB inlet while flowing 50 GPH. Stock or near stock TBI systems do not need high pressure or excess volume fuel pumps as it leads to increased fuel temperature rise and excessive delivery pressure may cause FP regulation variances due to return fuel path restrictions. It is available from numerous online vendors for about $152 (summit, jegs, etc). The reason why I like this pump is that is self priming and does not have fuel pulsing found in lower priced pumps (Airtex, master, etc). //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#494 |

|

Registered User

Join Date: Mar 2010

Location: SLC Utah

Posts: 1

|

Re: Tbi swap build thread

The info in here is amazing and tons of it. I joined because of this sticky.

My question is I have dual tanks from a 79 chevy and wonder what I can do to keep both tanks or if I need to straight plumb one and reserve fill from the other? Also on the harness there are factory splices on some of the wires. When I cut down the harness do I need to remover or retain the factory splices? Thanks for all the info. |

|

|

|

|

|

#495 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

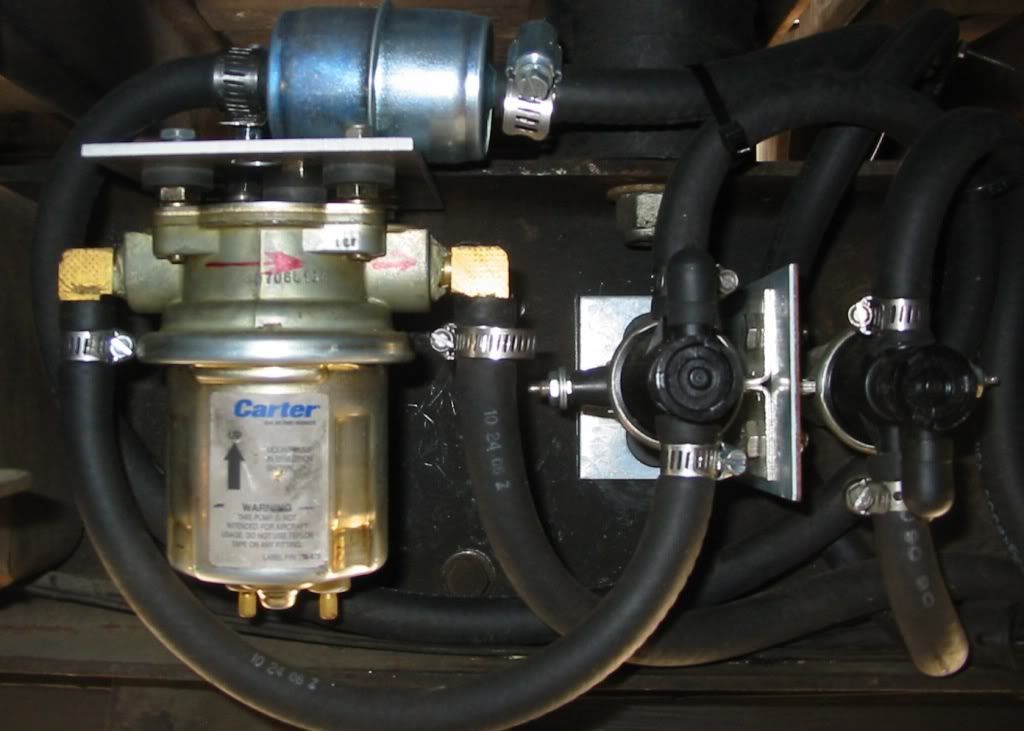

This is my as build dual tank system, but it can be simplified if you have 6-port valve.  Surge tank  Fuel selector and low pressure lift pump  On the splices - those are probably are ground - post photos of the splices to be sure. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#496 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

__________________

miSSed opportunity - ground up creation of an AWD 1994 454 SS that never was http://67-72chevytrucks.com/vboard/s...d.php?t=795577 69 C10 shortbed stepside 400 small block - built like what a super sport truck could have been 69 K20 lwb TBI 350 4L60E NP208 14-bolt Dana-44 w/disc 68 Camaro SS / RS 500hp 439 inch roller cam big block 4L80E 79 Malibu TPI 350 4L60 w/ Z28 steering & sway bars |

|

|

|

|

|

|

#497 |

|

Registered User

Join Date: Nov 2009

Location: Parachute, CO

Posts: 183

|

Re: Tbi swap build thread

I swapped in a 88 FI454 into my Jeep/buggy.It runs fine.But it won't start on it's own.I need to dump a touch of gas in the tbi then it fires and runs.What could be the problem?I kept the stock engine harness mixed with a universal harness for the rest.

__________________

1984 1ton 4x4 crew cab dually 6.2 diesel,465,205,D60,D70,1987 3/4ton 4x4 suburban 5.7 FI350,TH400,208,1985 CJ-7 FI406,465,205,D60,FF14, 1970 Jeepster 350,465,205,D44,FF14, |

|

|

|

|

|

#498 | |

|

Registered User

Join Date: Jul 2009

Location: West Jefferson, OH

Posts: 999

|

Re: Tbi swap build thread

Quote:

__________________

-Andy '77 K5 Blazer '78 K10 Shortbed '78 C20 Suburban '79 K30 Crew Cab Dually '84 C10 Short Stepside '88 K20 Suburban

|

|

|

|

|

|

|

#499 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

When you pour a little bit of gas into TB engine fires and oil pressure switch NO contacts close once oil pressure is in excess of 6 PSI thus providing power to the fuel pump. Check and see if there +12 volts supplied by ECM to FP relay coil circuit when engine is running (the aforementioned A1 dark green-wht wire) . //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#500 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

| Bookmarks |

|

|