|

|

|

#51 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments guys!

__________________

Robert |

|

|

|

|

|

#52 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

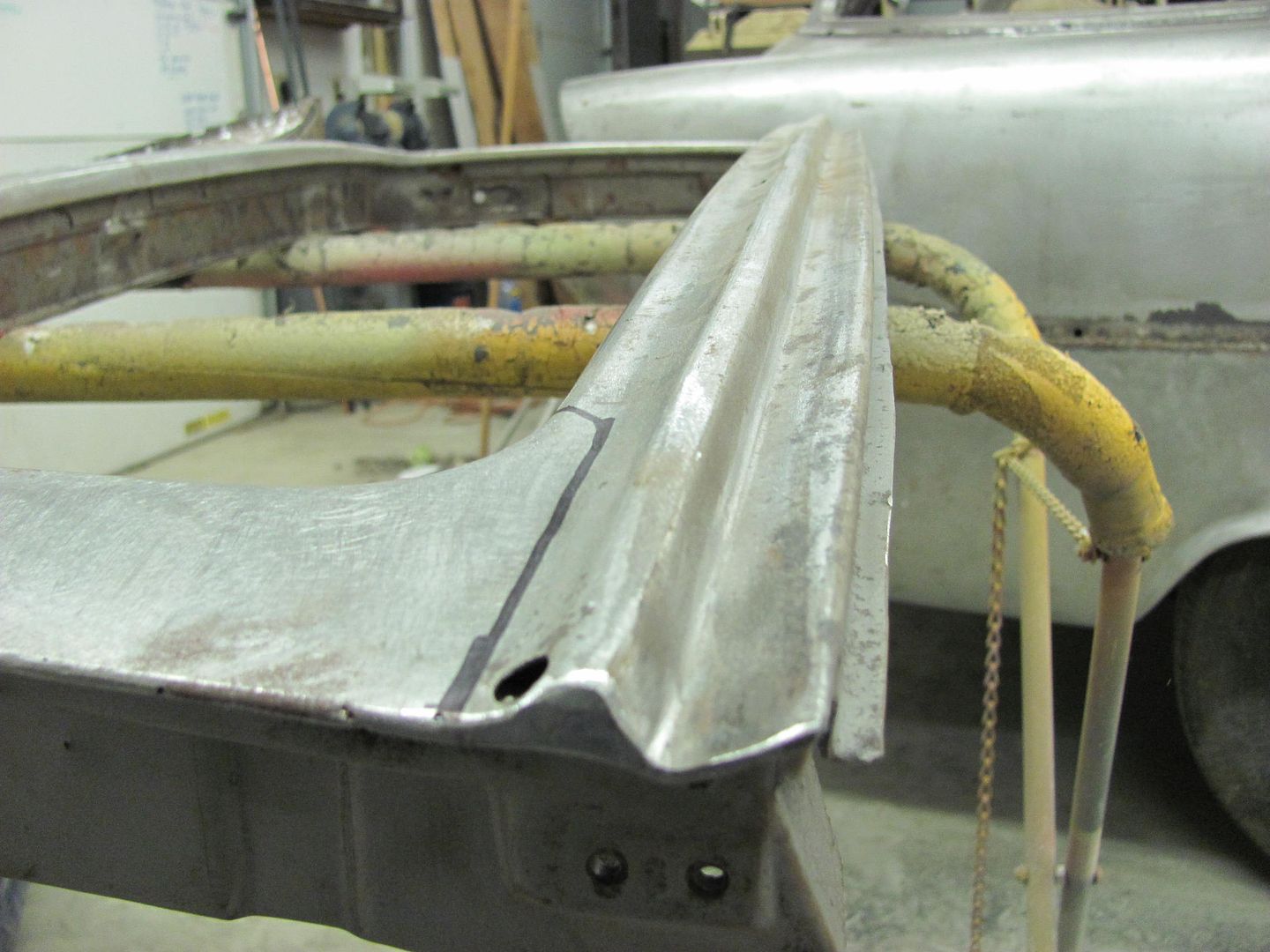

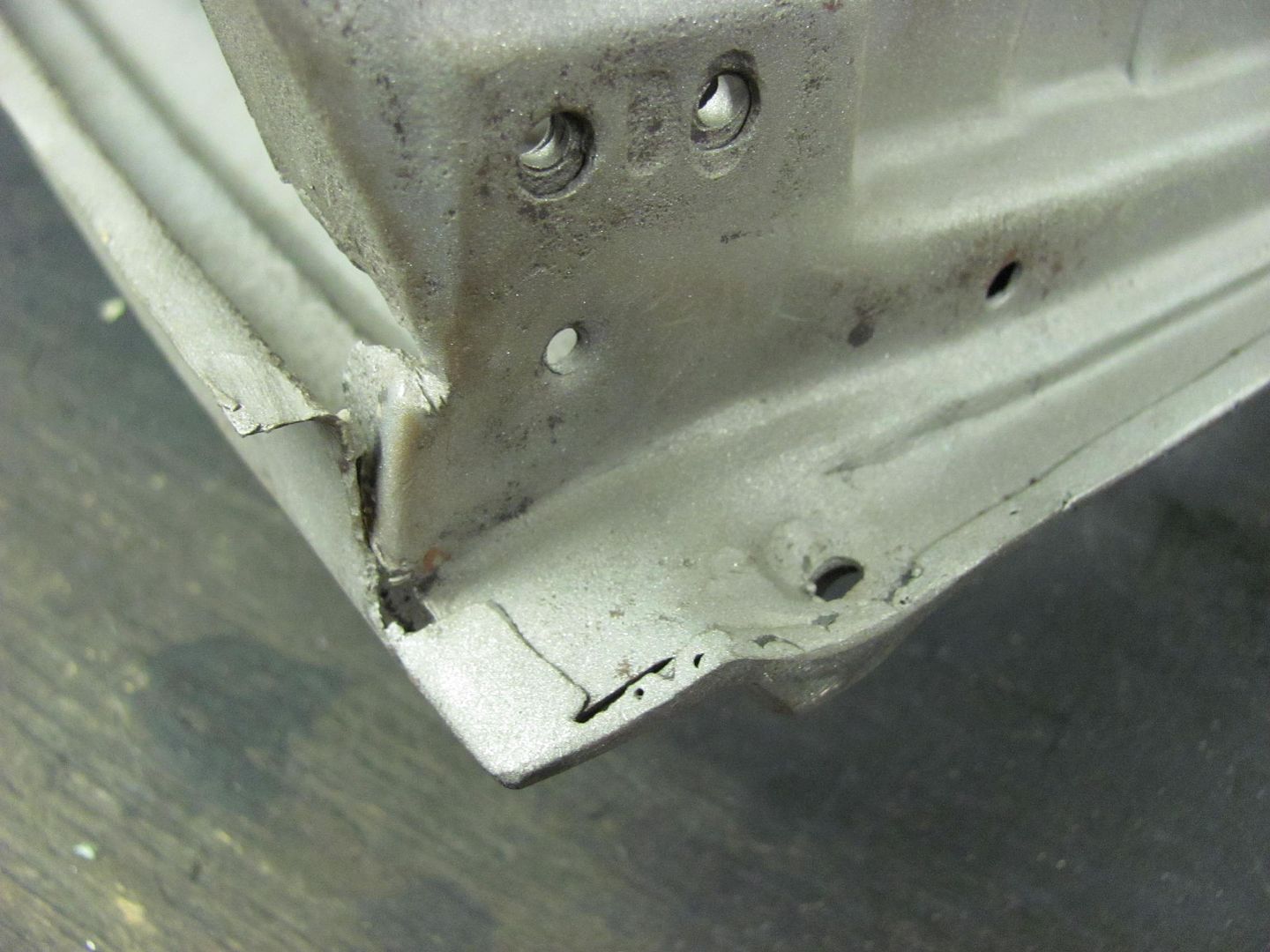

Took the upper gate off tonight...

My tool of choice for removing spot welds is a 3" x 1/16 cutoff wheel. I also use the premium wheels made for stainless steel. It's worth the extra money when you don't have a brown cloud in the shop, like the el cheapo wheels leave, nothing but resin wearing away. The upper layer of metal will start to turn blue when it gets thin and hot, letting you know you're getting close to the next layer. When you have a blue circle with shiny metal in the center, you are now in the second layer, grind around the blue a bit more and pry the layers apart..  With all the spot welds removed, here's what we find inside...    Note the deep pits. The big problem with just welding a hole closed is you don't know where the next pit is lurking, ready to break through your new paint.  Funny, with all the rust and scale inside, then you find this area of bare steel nice and shiney..  The inside will get media blasted to insure there is no more lurking issues and then epoxy primered before re-assembly. Here's a better look at the shape we'll need...

__________________

Robert |

|

|

|

|

|

#53 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

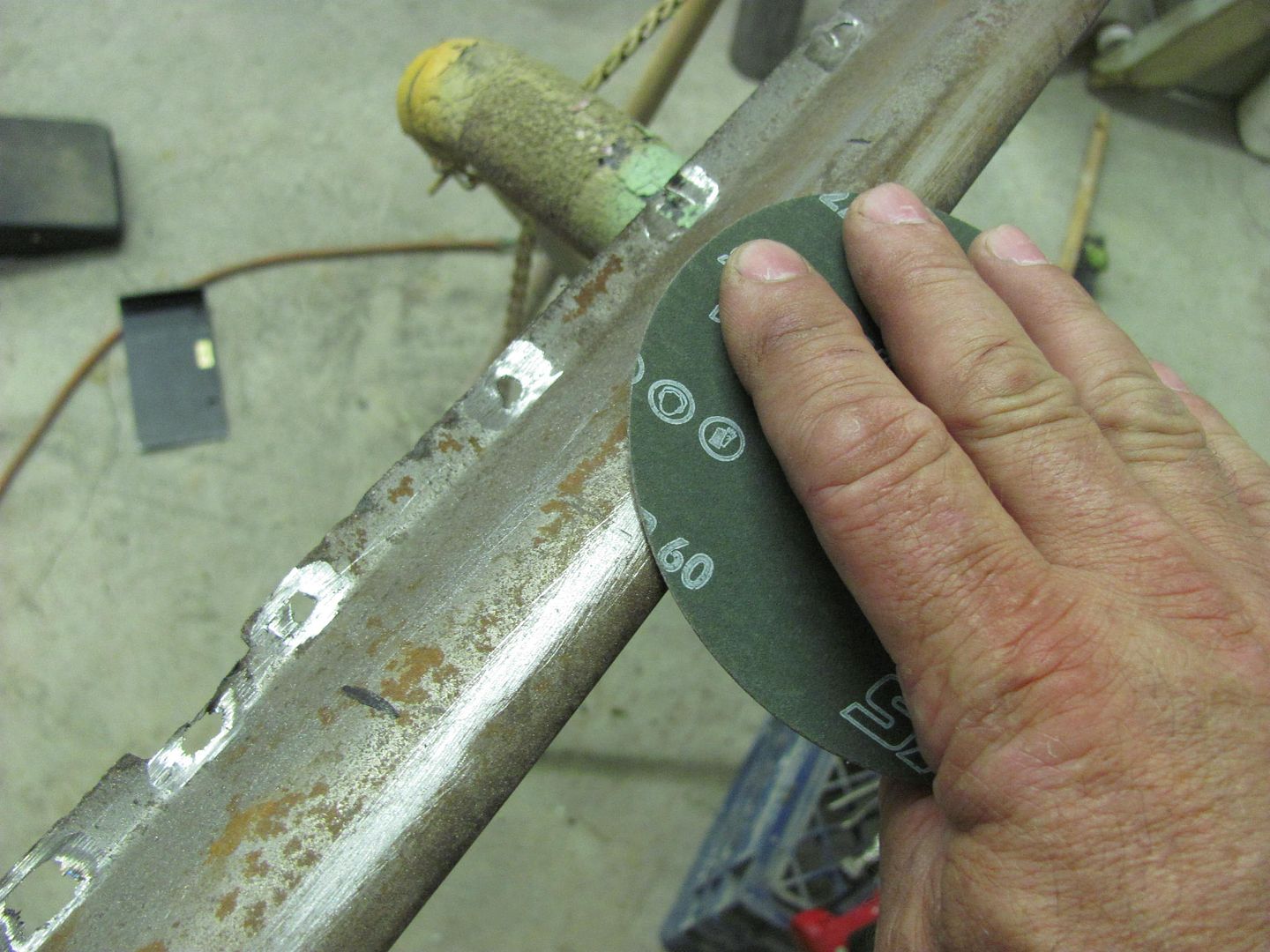

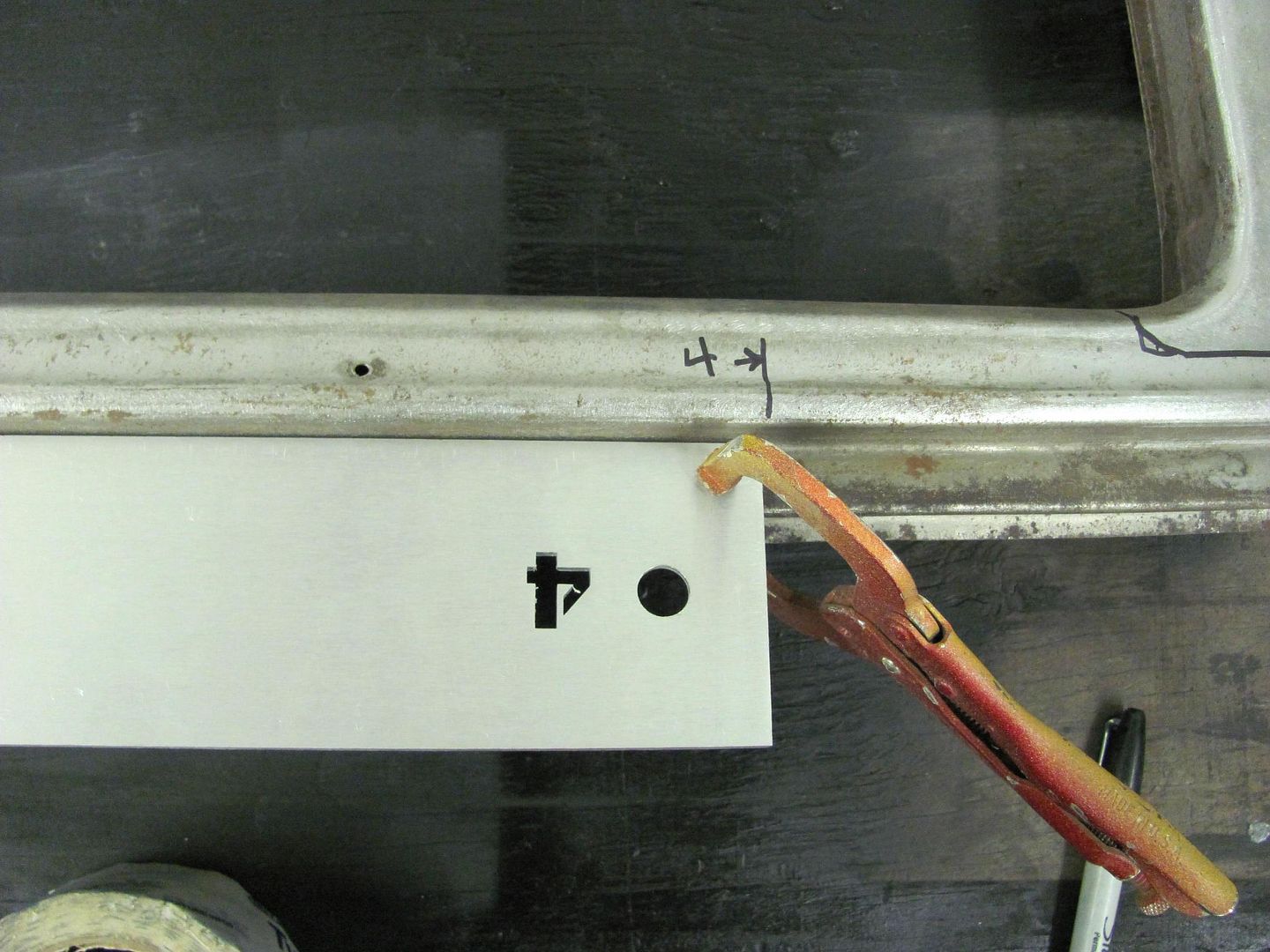

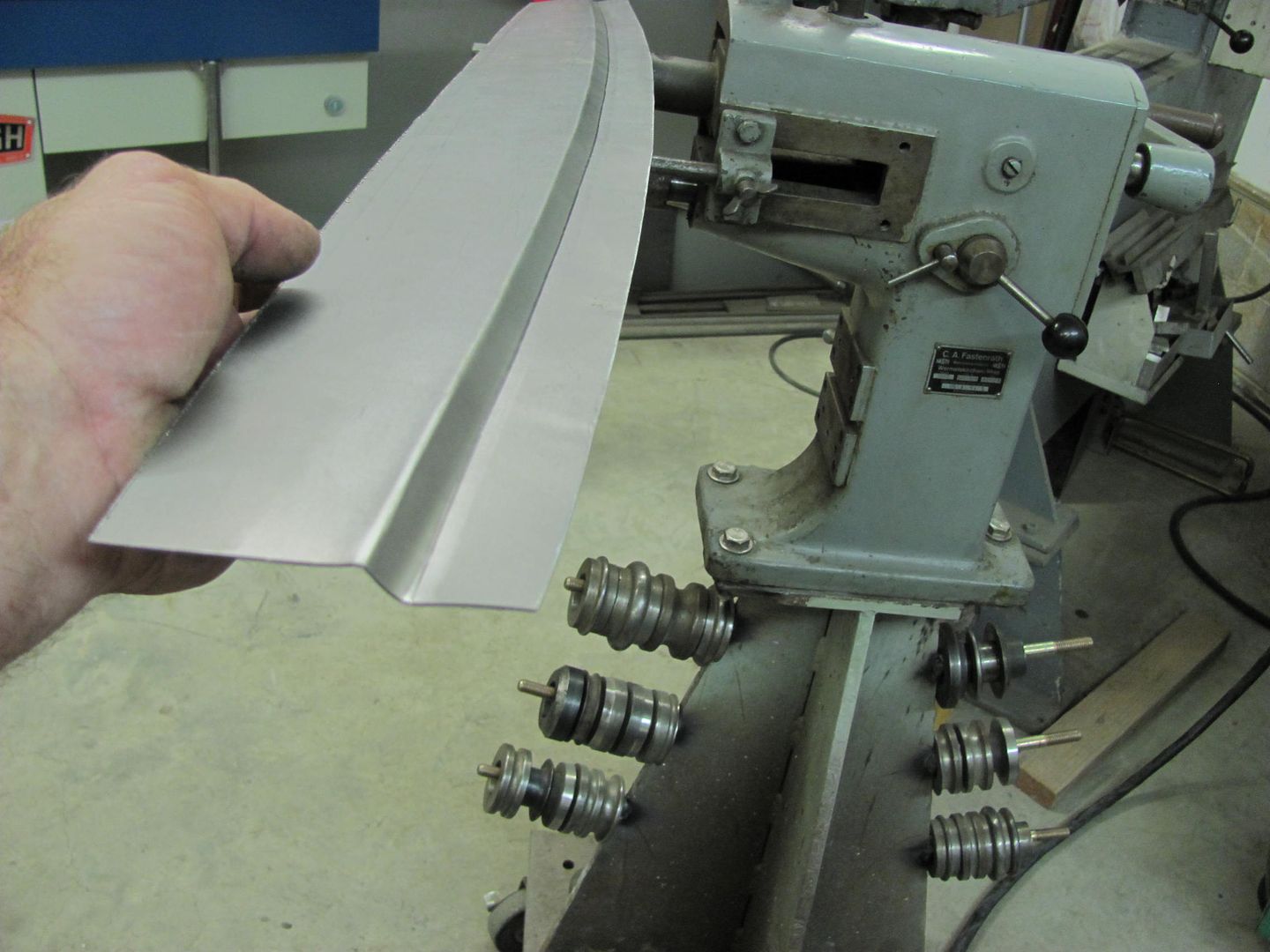

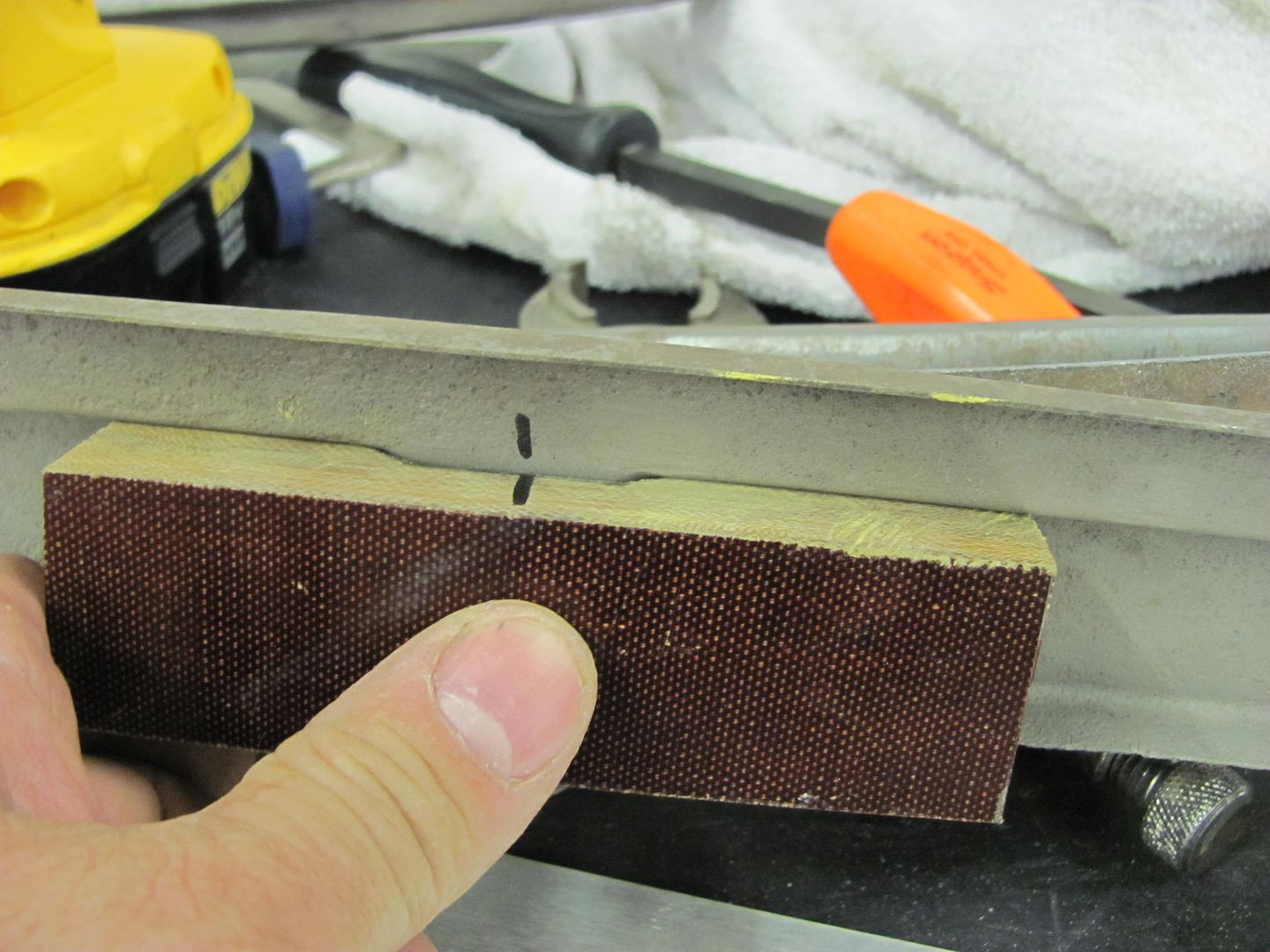

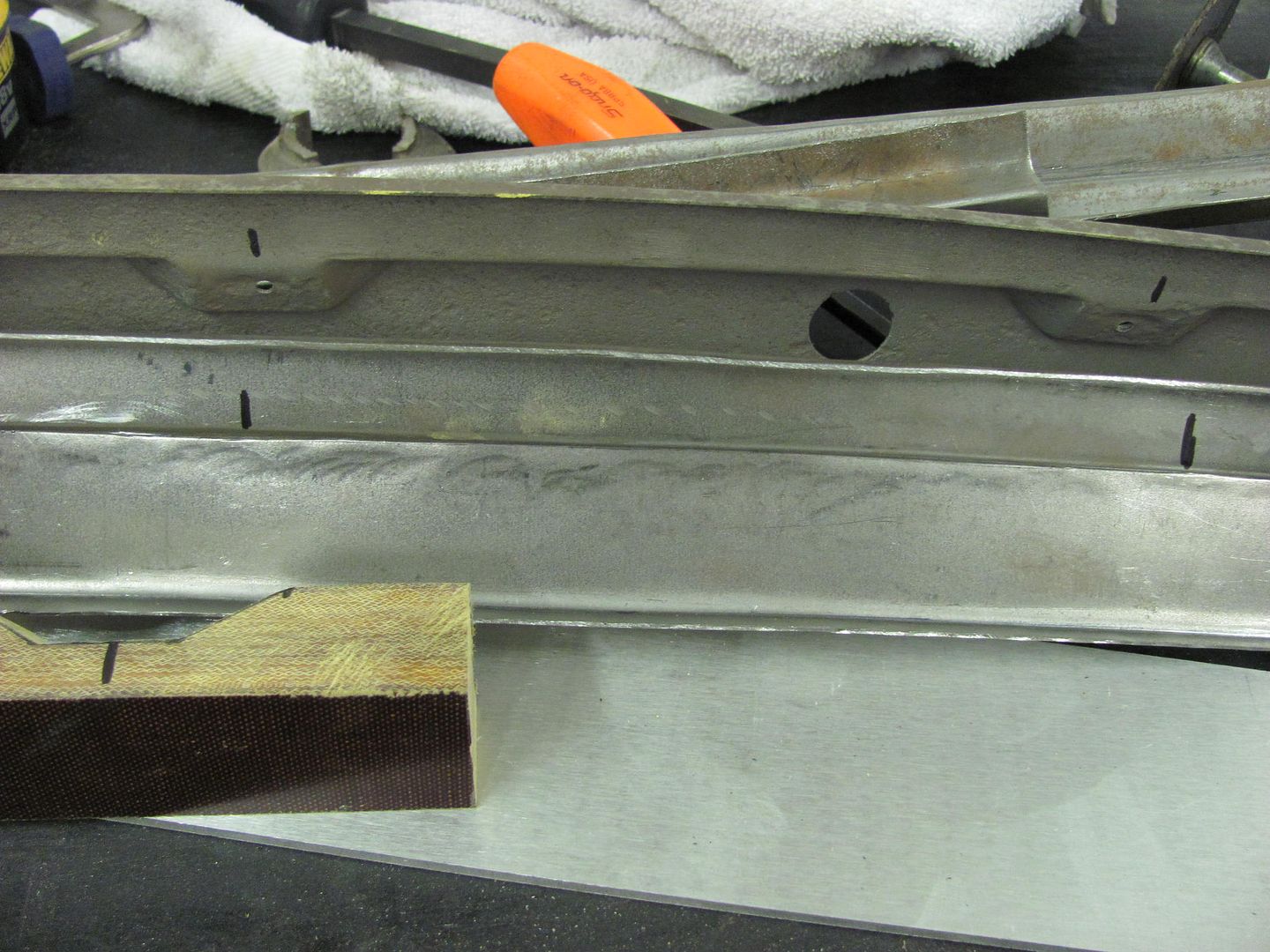

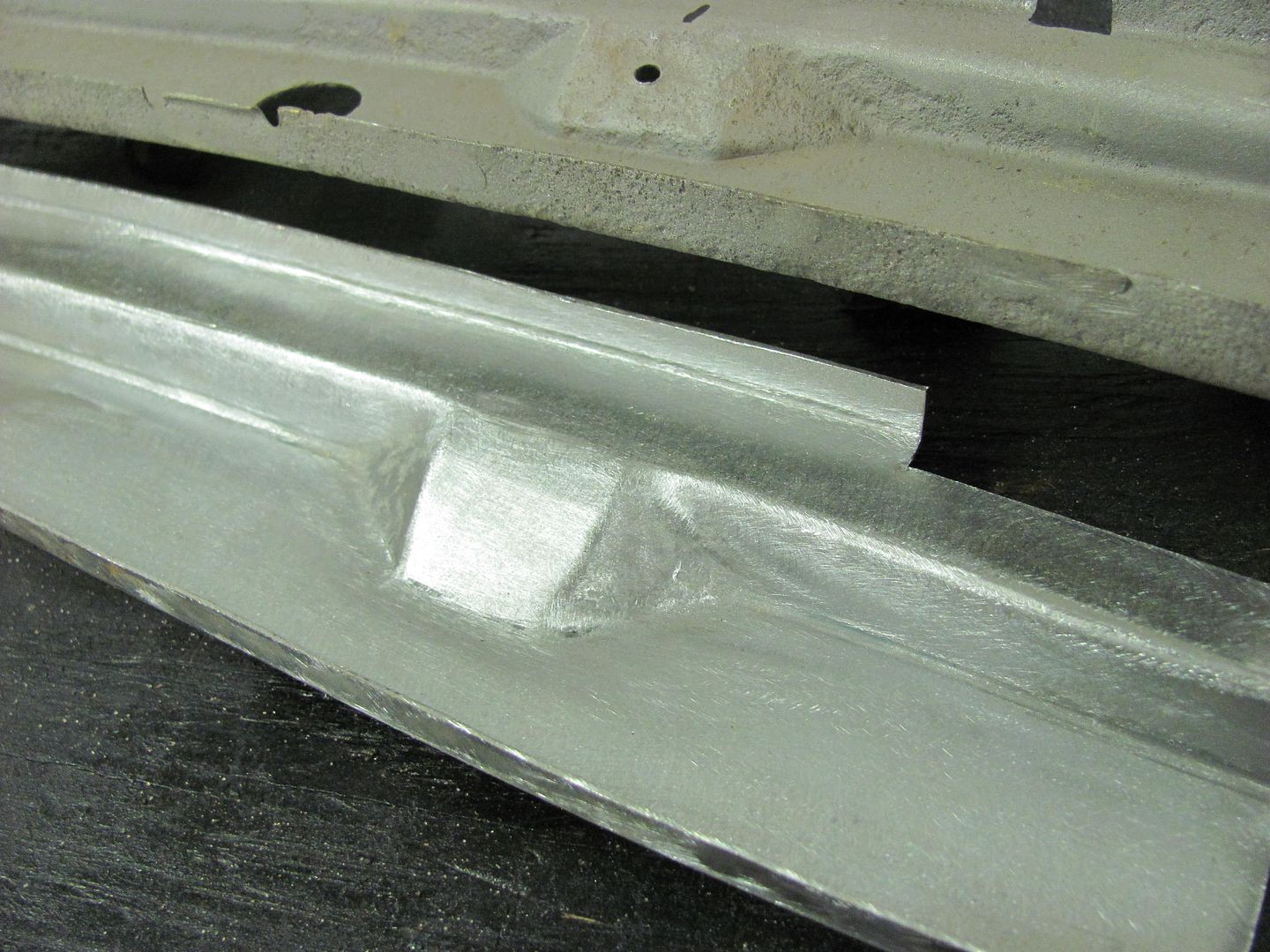

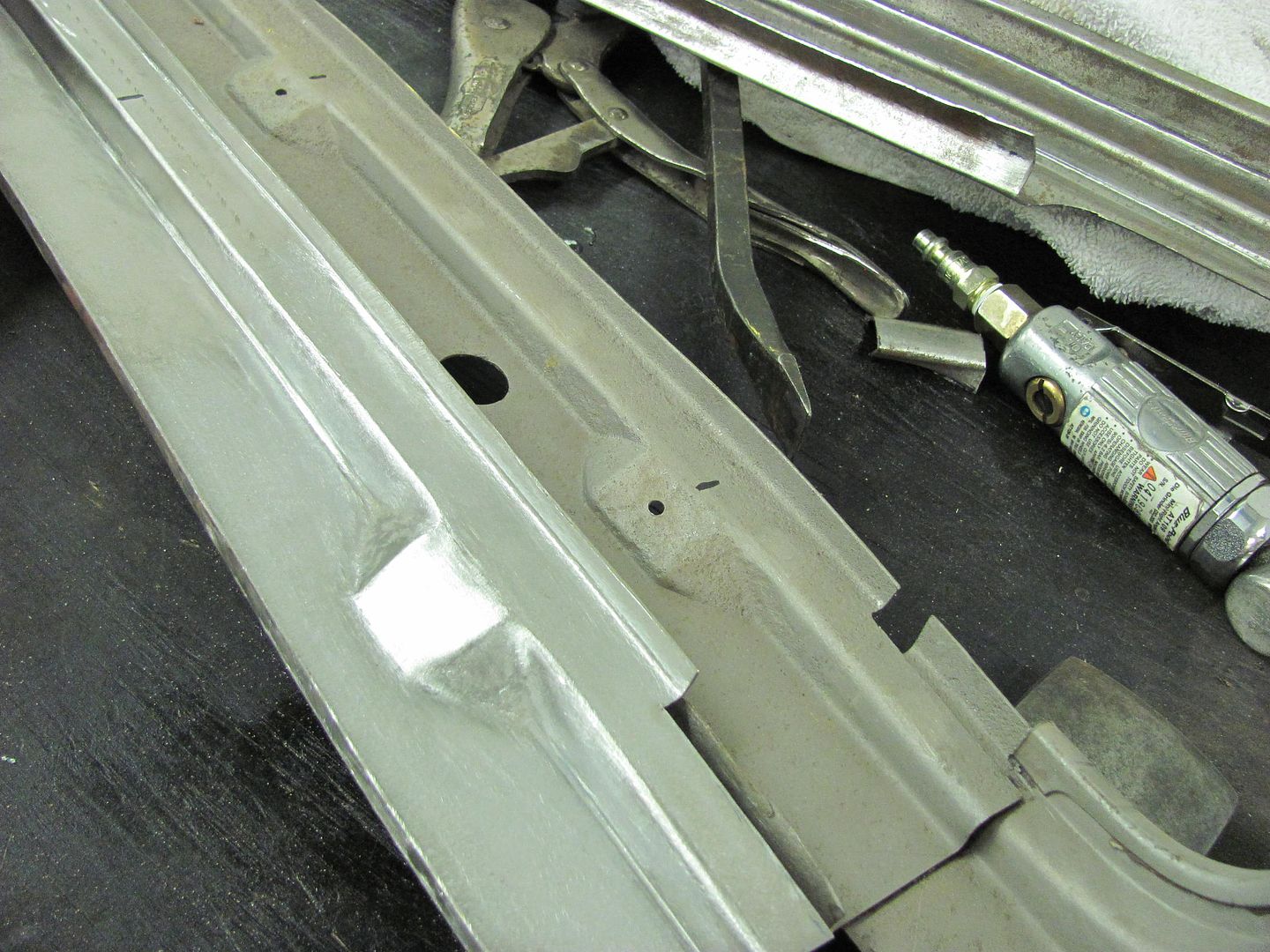

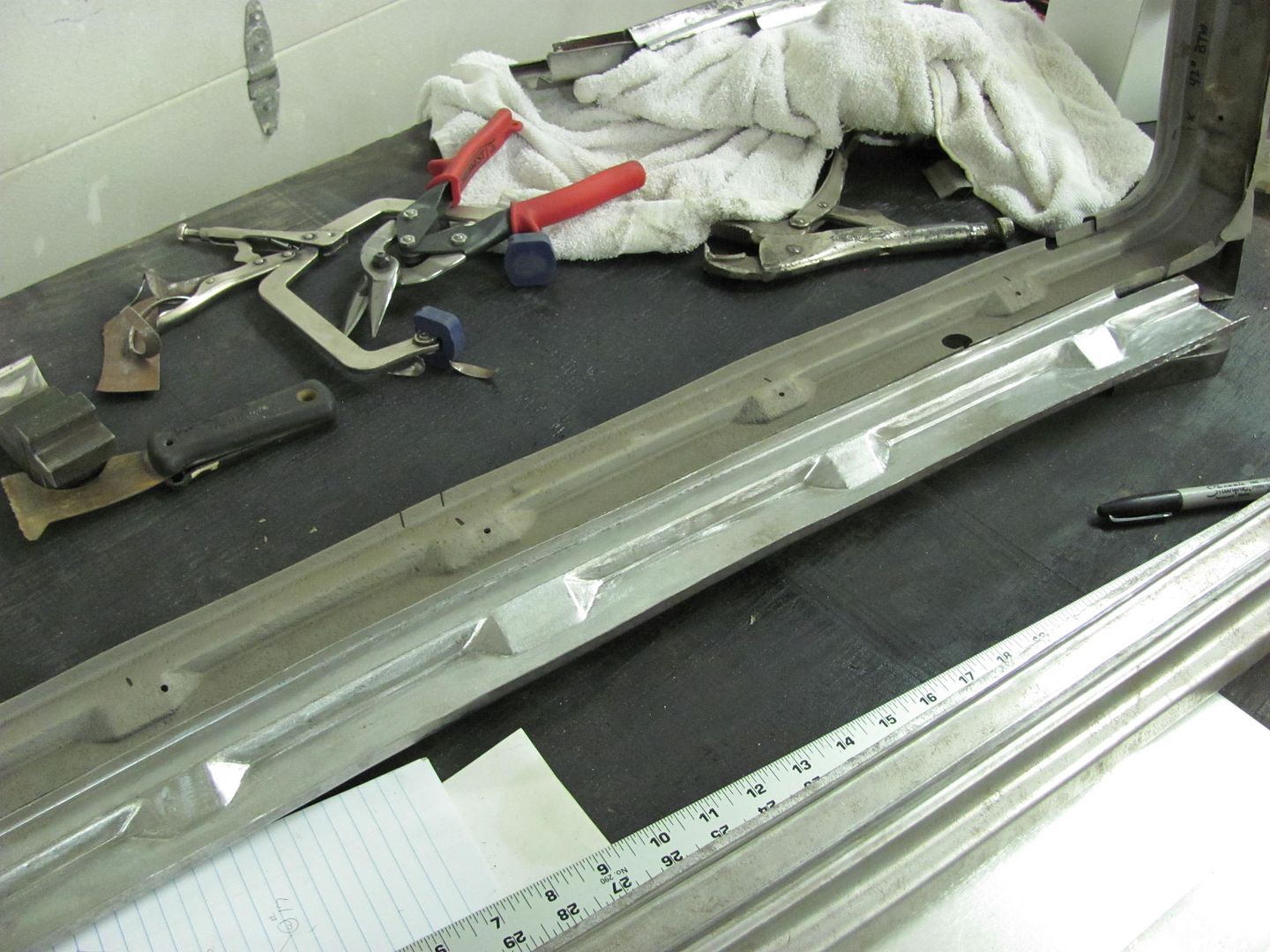

To start the layout on the new metal, I wanted to find the center of the radius along the window opening. By holding a sanding disc on the flats and scuffing, it showed the edges of the radius...

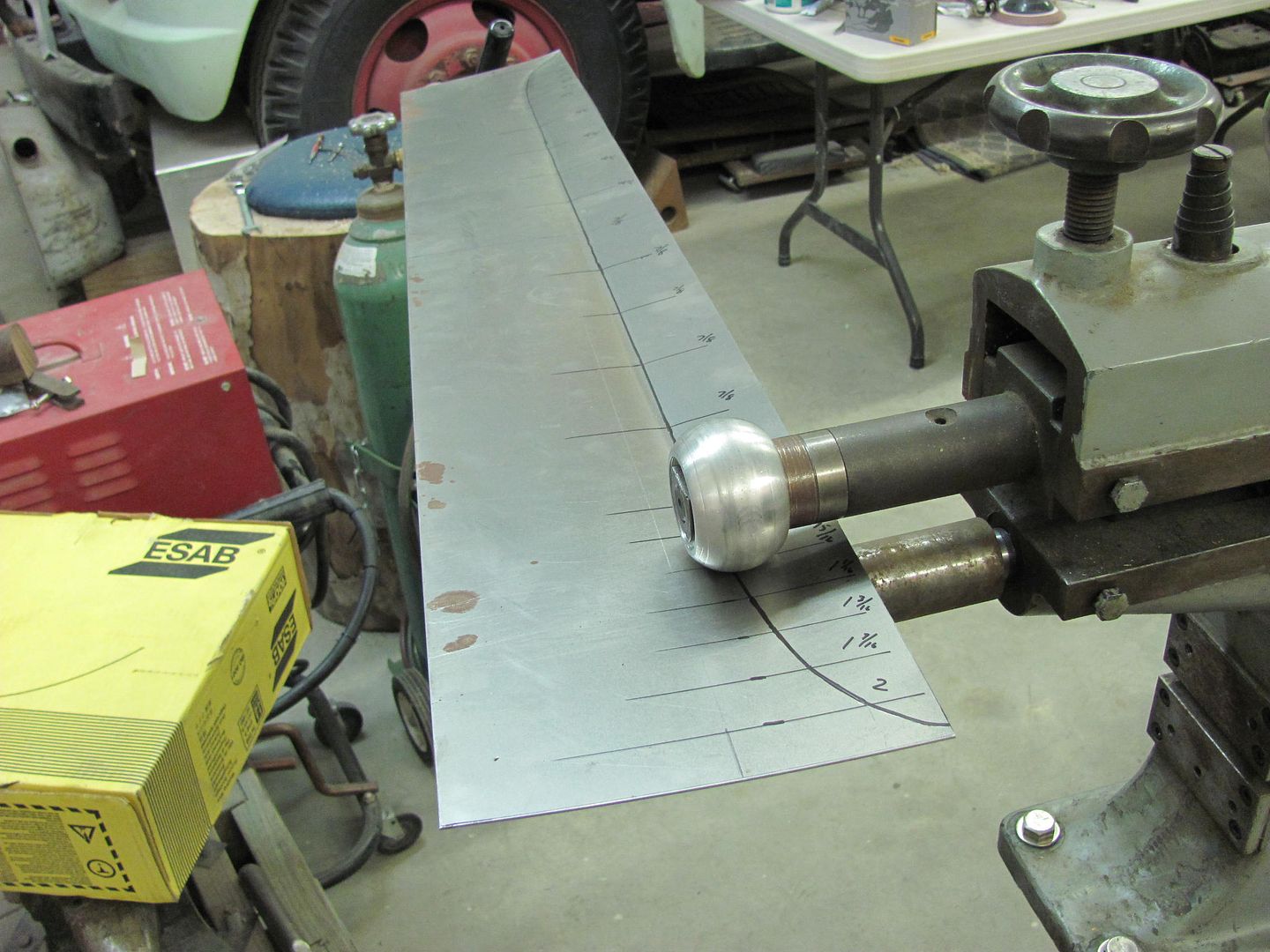

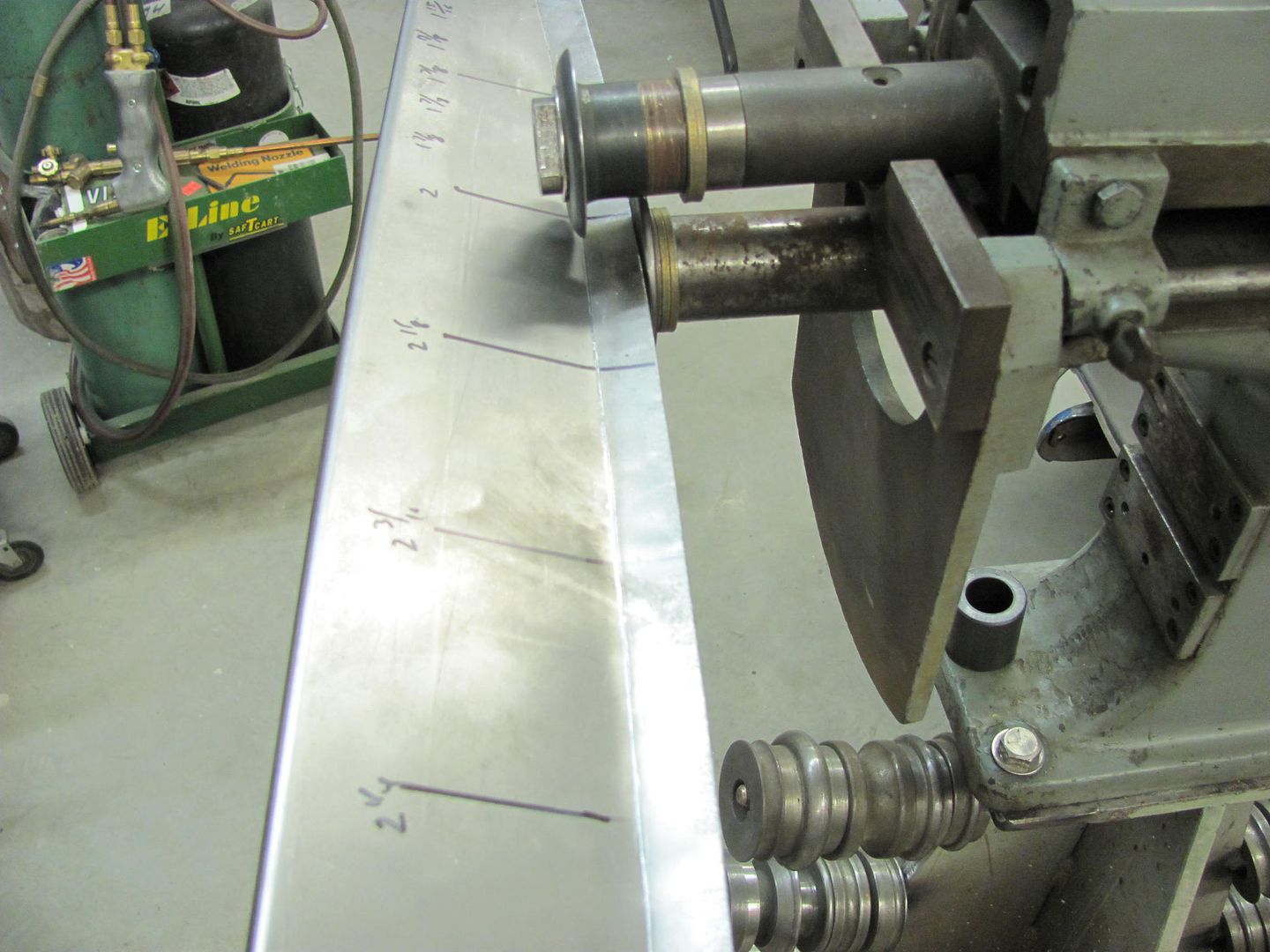

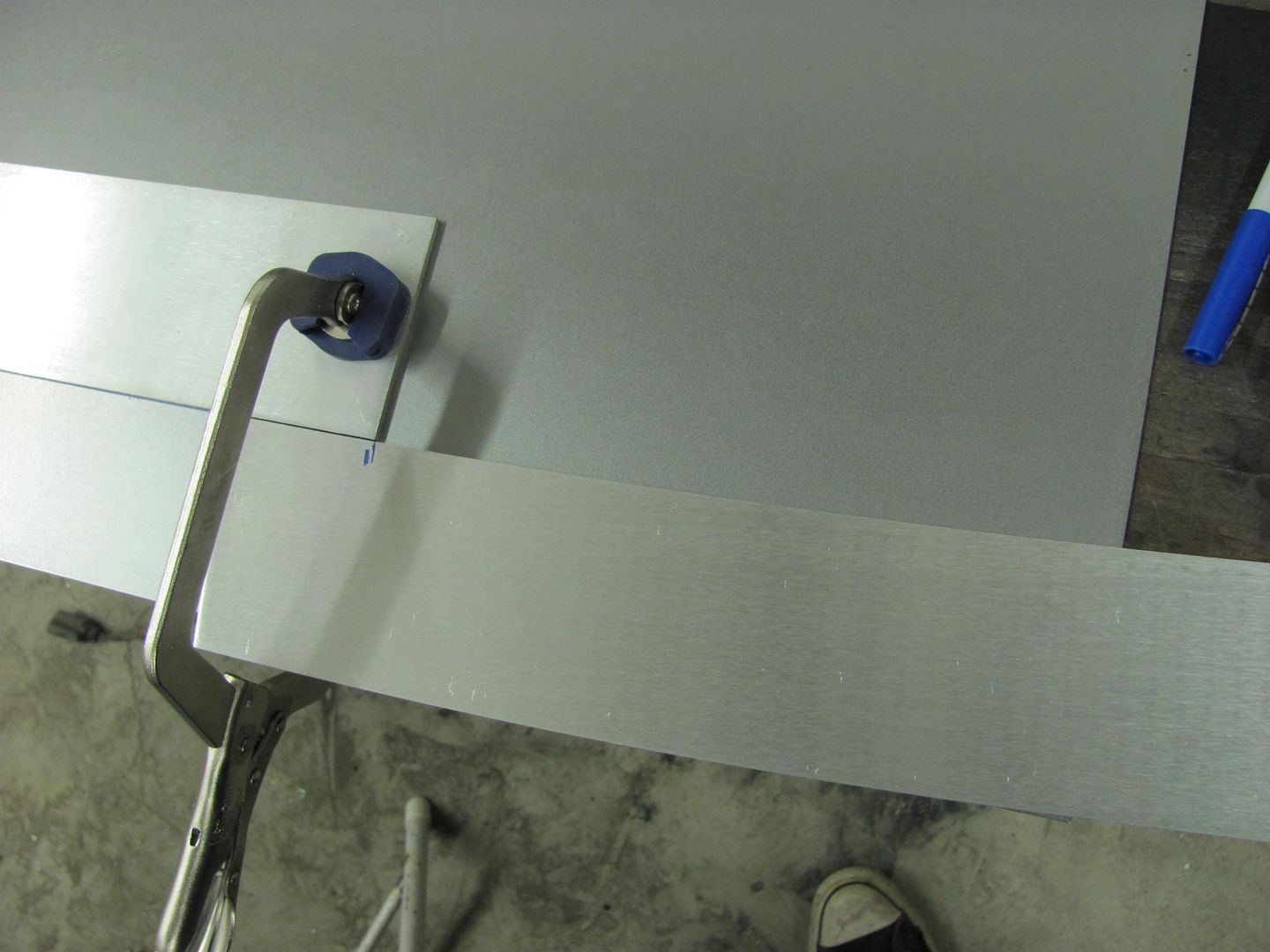

Then laid out a pattern to be able to measure from the bottom crease...  ....and transposed it to the new sheet...    The top edge was trimmed to size and the tipping wheel used to fold over the welding flange...   Comparison....  The bottom was marked with the tipping wheel and folded in the apron brake. Then trimmed to size, again using the tipping wheel to fold over the welding flange...  It's real close right now, just needs a bit of tweaking.       This was made using 18 ga, I think if I had the factory 19 ga metal it would have formed much easier..

__________________

Robert |

|

|

|

|

|

#54 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: 55 Wagon Progress

Very nice work! Love seeing these kinds of threads, you do very detailed work and the end results show it. Those beadrollers are awesome, I haven't done much with ours yet but they're well worth what they cost for the things you can do with them. Even if a patch panel was made for that section of the lift gate, your's probably fits 100 times better!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#55 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks! Actually we've had a couple repop pieces on this project that I've sent back where I didn't care for the fit or precision, and made them myself. Others parts made just plain weren't available. In either case, I've found that just cutting off the bad piece and backing yourself in a corner is a good motivator in getting something made to fit..

__________________

Robert |

|

|

|

|

|

#56 |

|

PROJECT 7DEUCE

Join Date: Dec 2002

Location: GRANTS PASS OR

Posts: 21,606

|

Re: 55 Wagon Progress

Some amazing work right there..

__________________

GO BIG GREEN  GO DUCKS GO DUCKSMEMBER #6377 72 k-5 daily driver 6'' lift 35'' 350-350-205 slowly getting rust free. Project "7DEUCE" check out my build http://67-72chevytrucks.com/vboard/s...d.php?t=267665 Tim Powell..R.I.P EastSideLowlife..... R.I.P.. |

|

|

|

|

|

#57 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

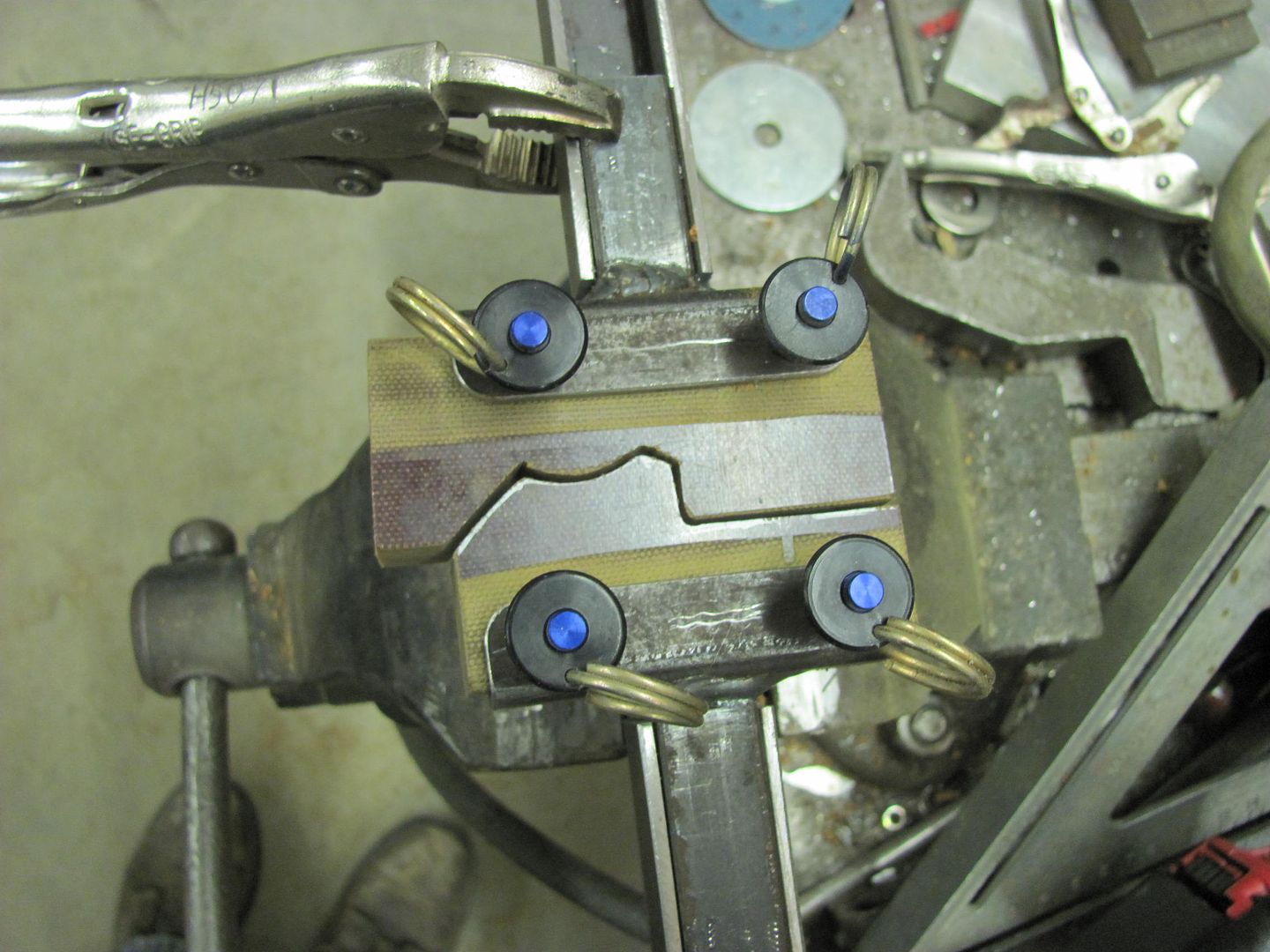

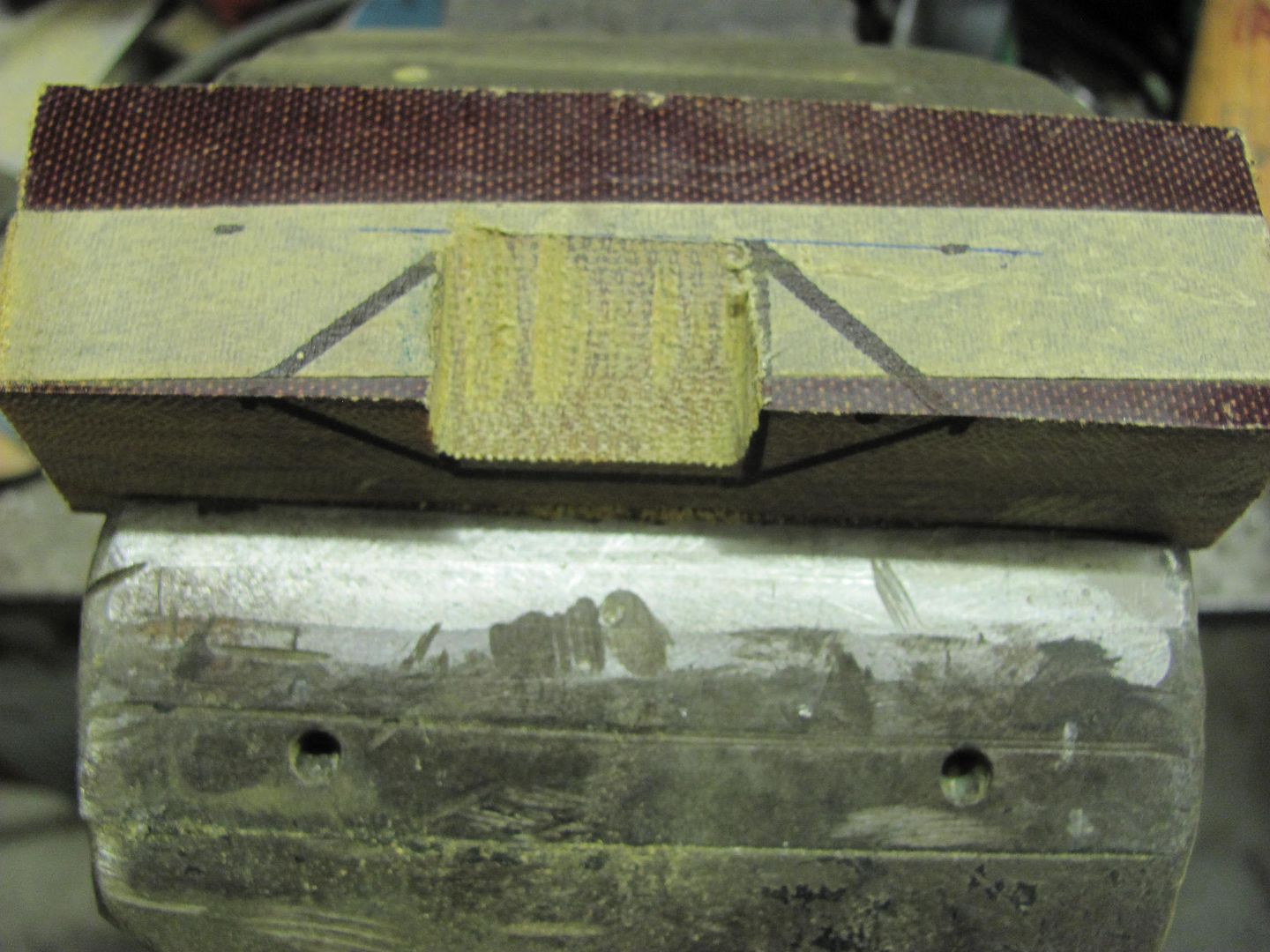

Media blasted the inside of the upper gate to clean it up before welding the new part on. Unfortunately this revealed more in the way of pits, through holes, etc., so it now looks like more fabrication....

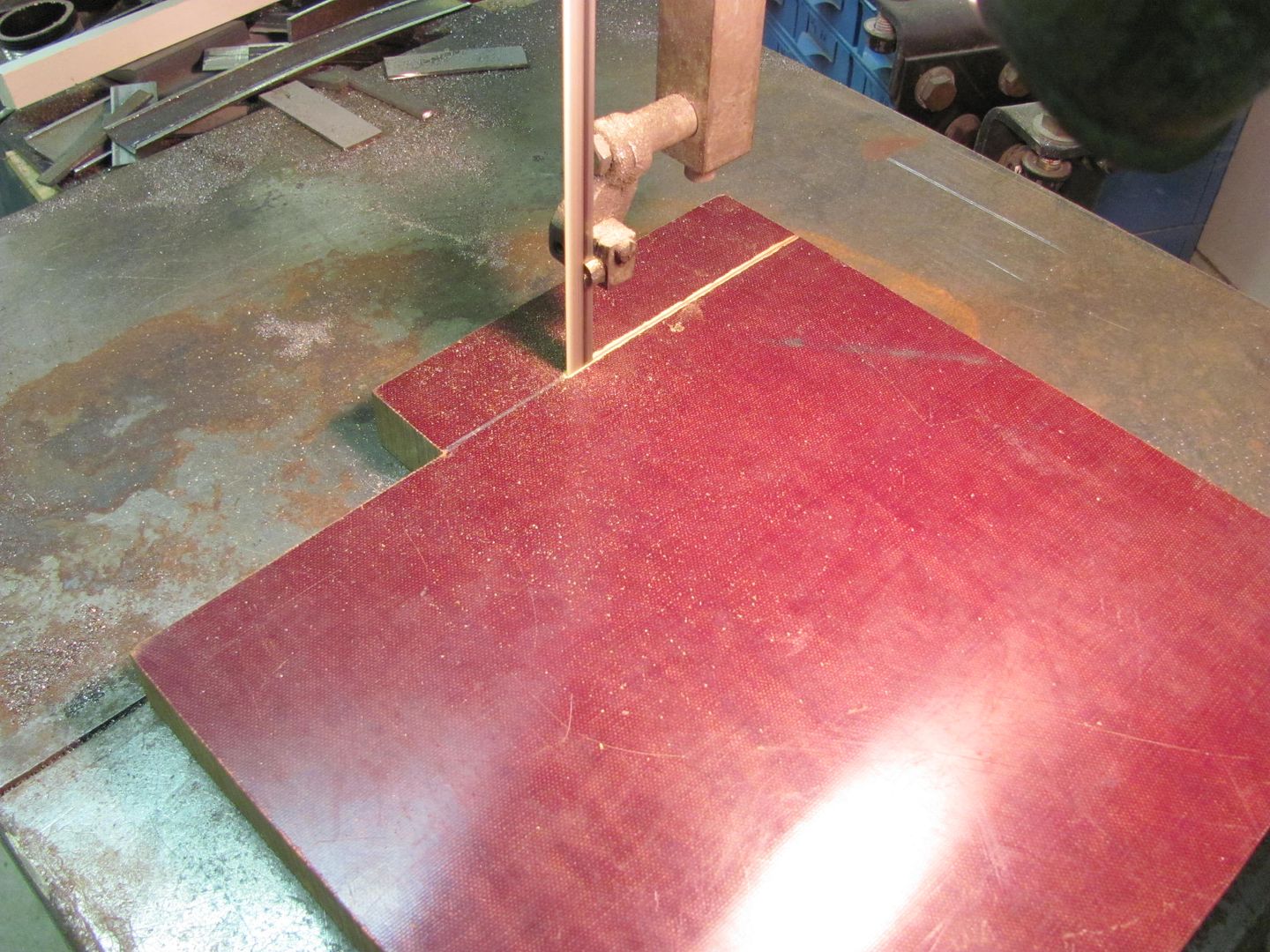

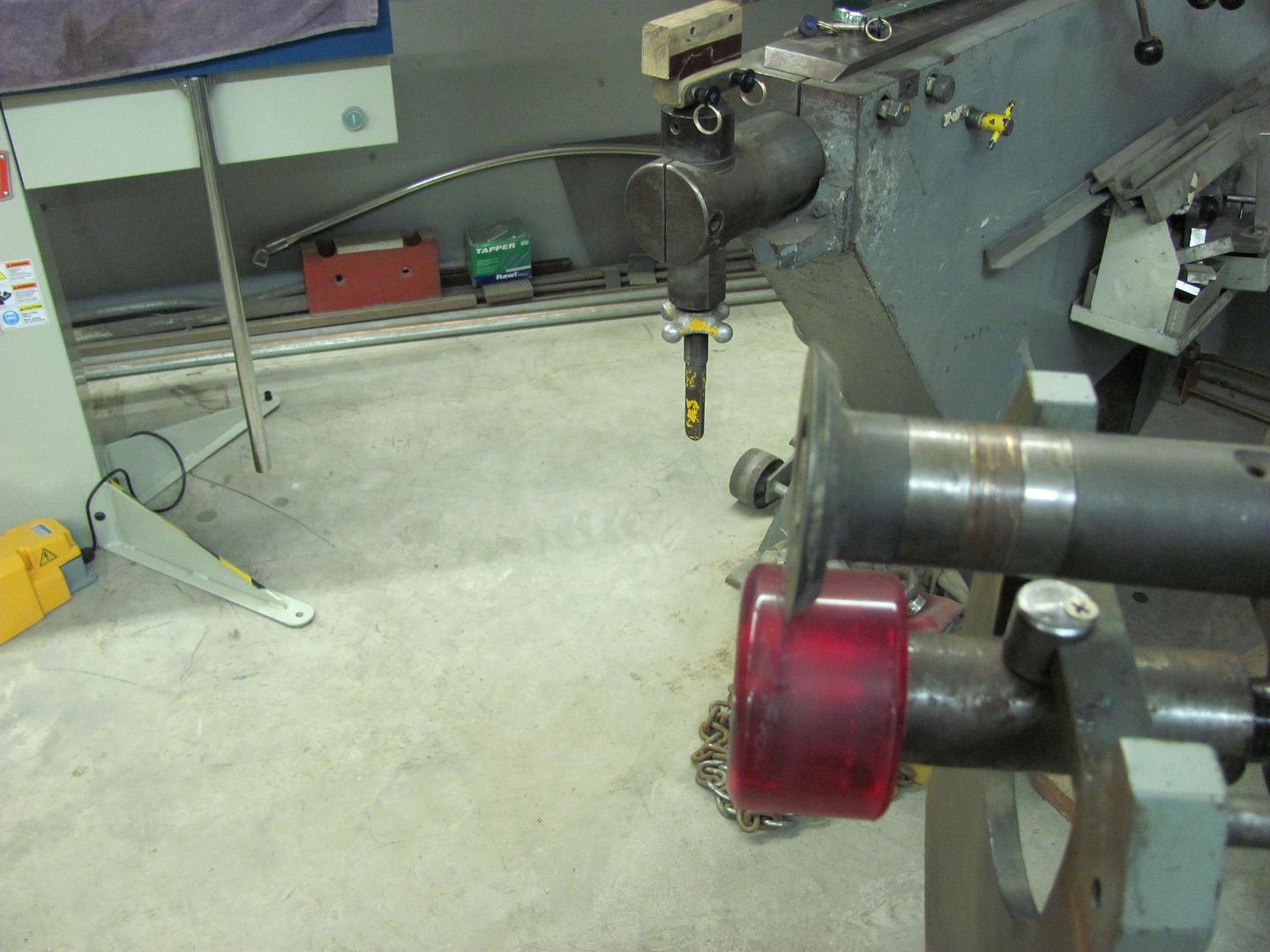

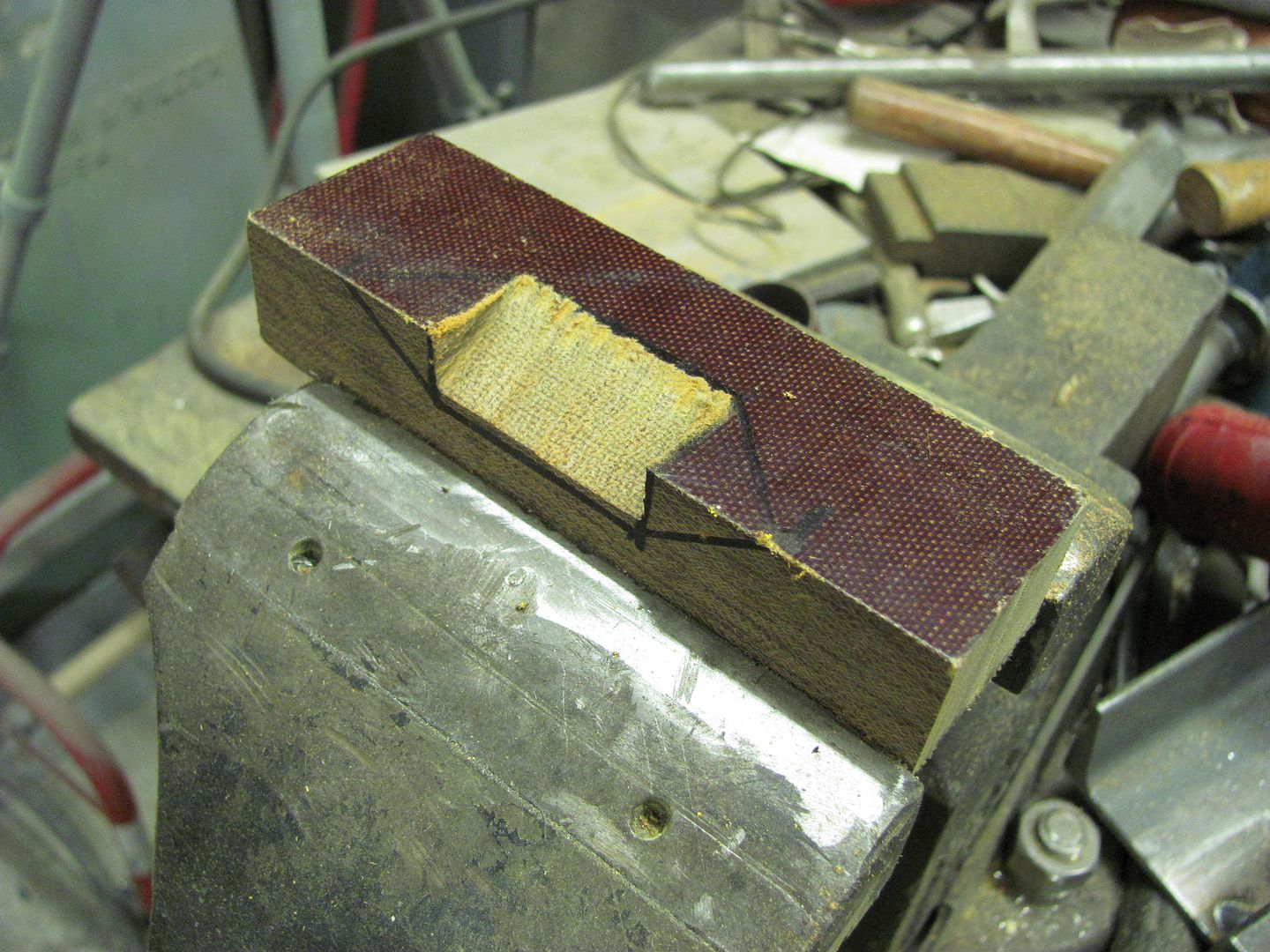

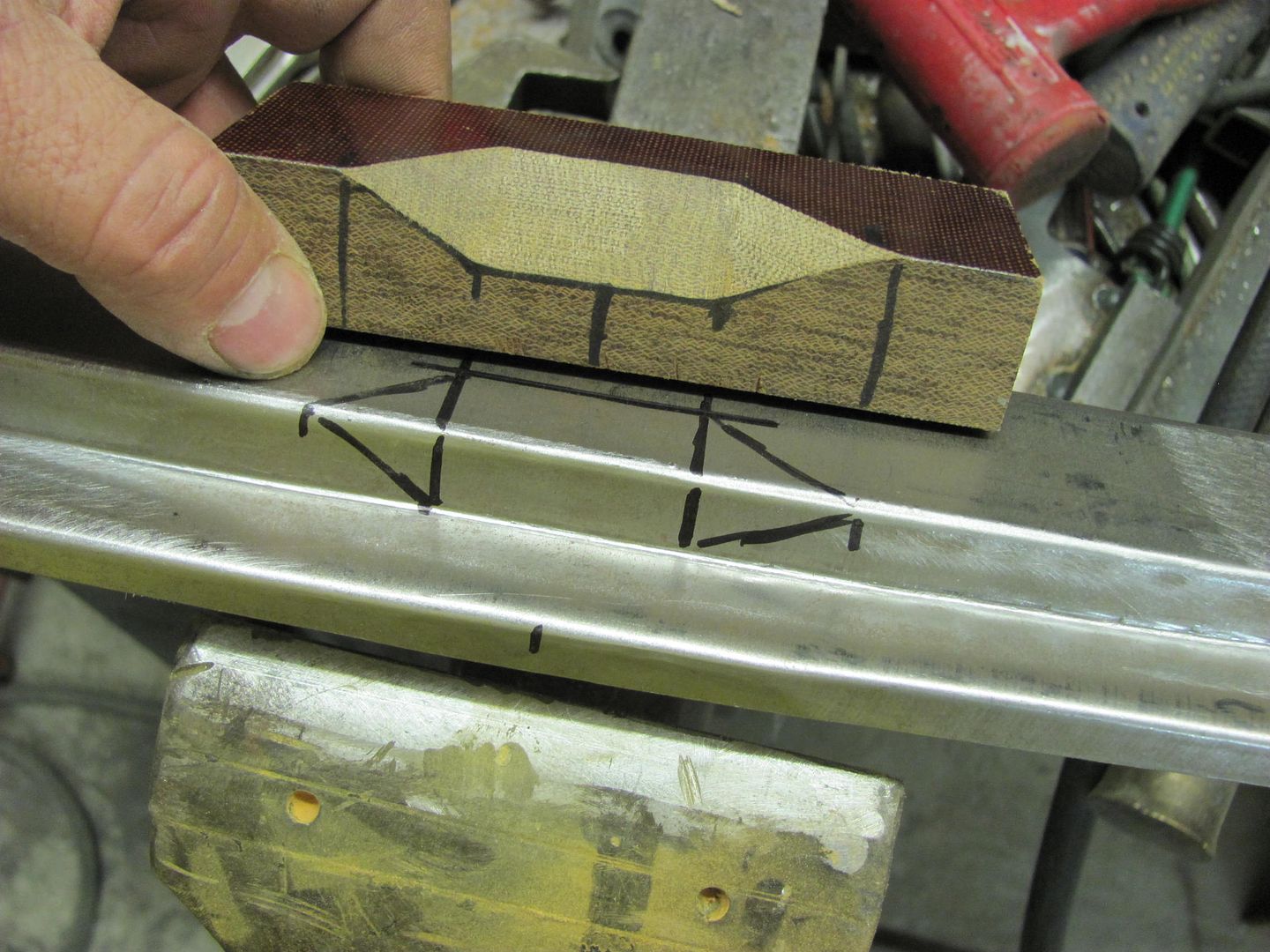

Time to attempt some dies for the Lennox. Tonight's choice is some 1" thick phenolic sheet...  Here's the profile we're looking for...  The dies installed in the holders....   An offset bend was added to the sample 19ga in the brake, then the first of three passes.....  Final pass.....  Dies held up well....   Safety tip of the day, 3" roloc discs do a good job of shaping phenolic, so skin is no match.... (note thumb in above pic) Where my "test sample" was made initially with straight bends in the brake, the actual piece on the lift gate is not straight, so the bends on the "good" piece will need to be bent using the tipping wheel.   The profile needs just a bit of tweaking, and I may try using a piece of metal inserted in a band saw blade cut to sharpen up some of the details.

__________________

Robert |

|

|

|

|

|

#58 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

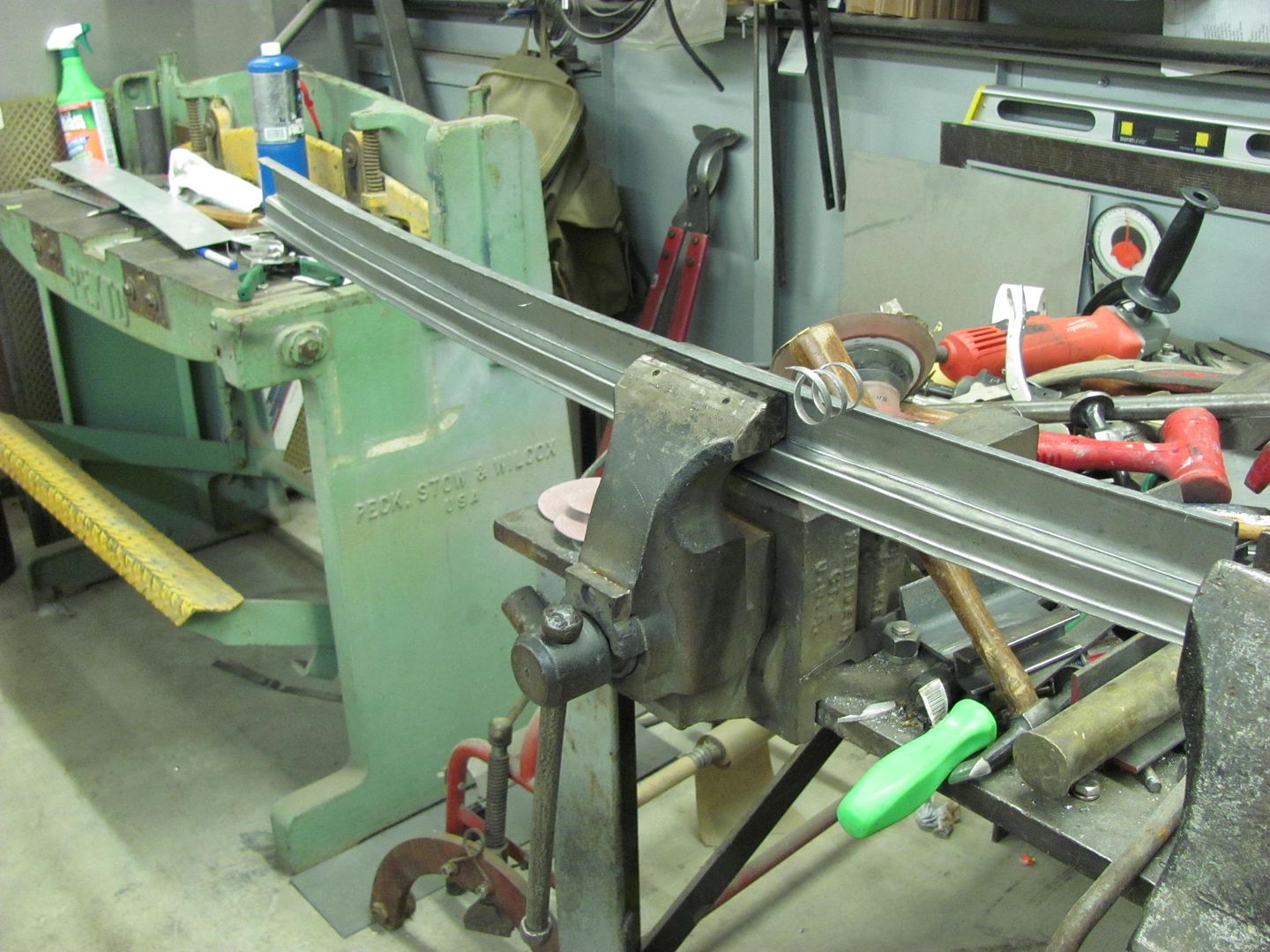

Hopefully this one will be a keeper...

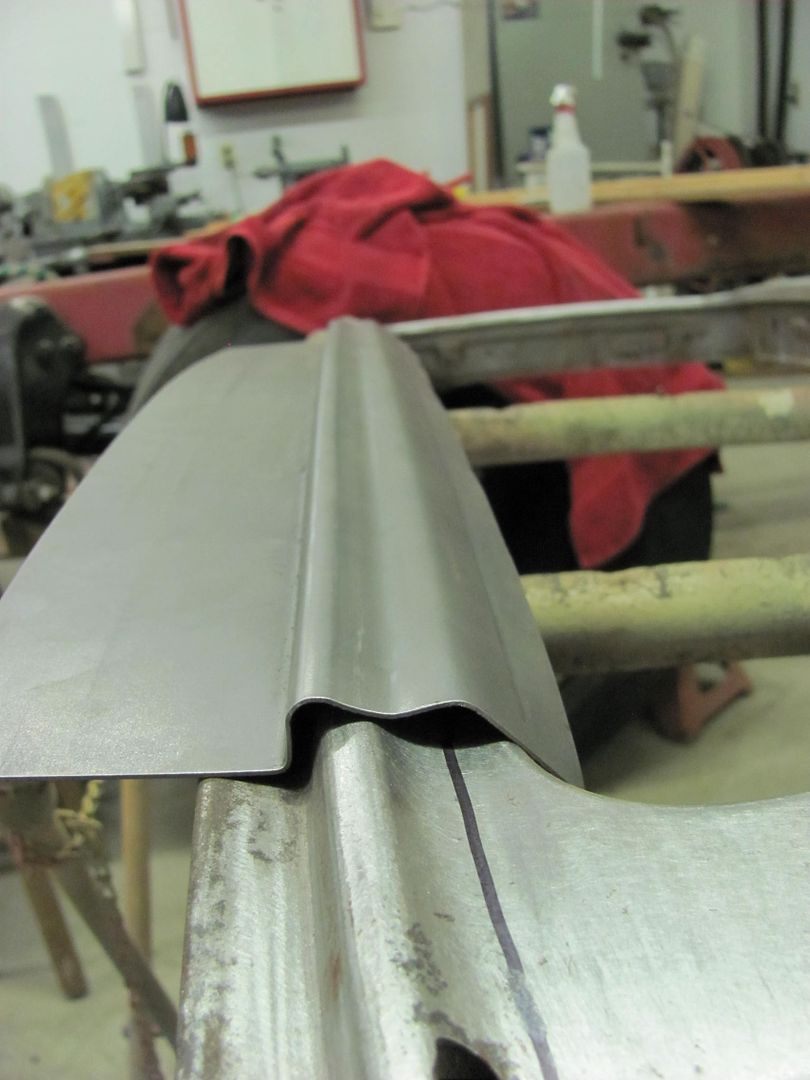

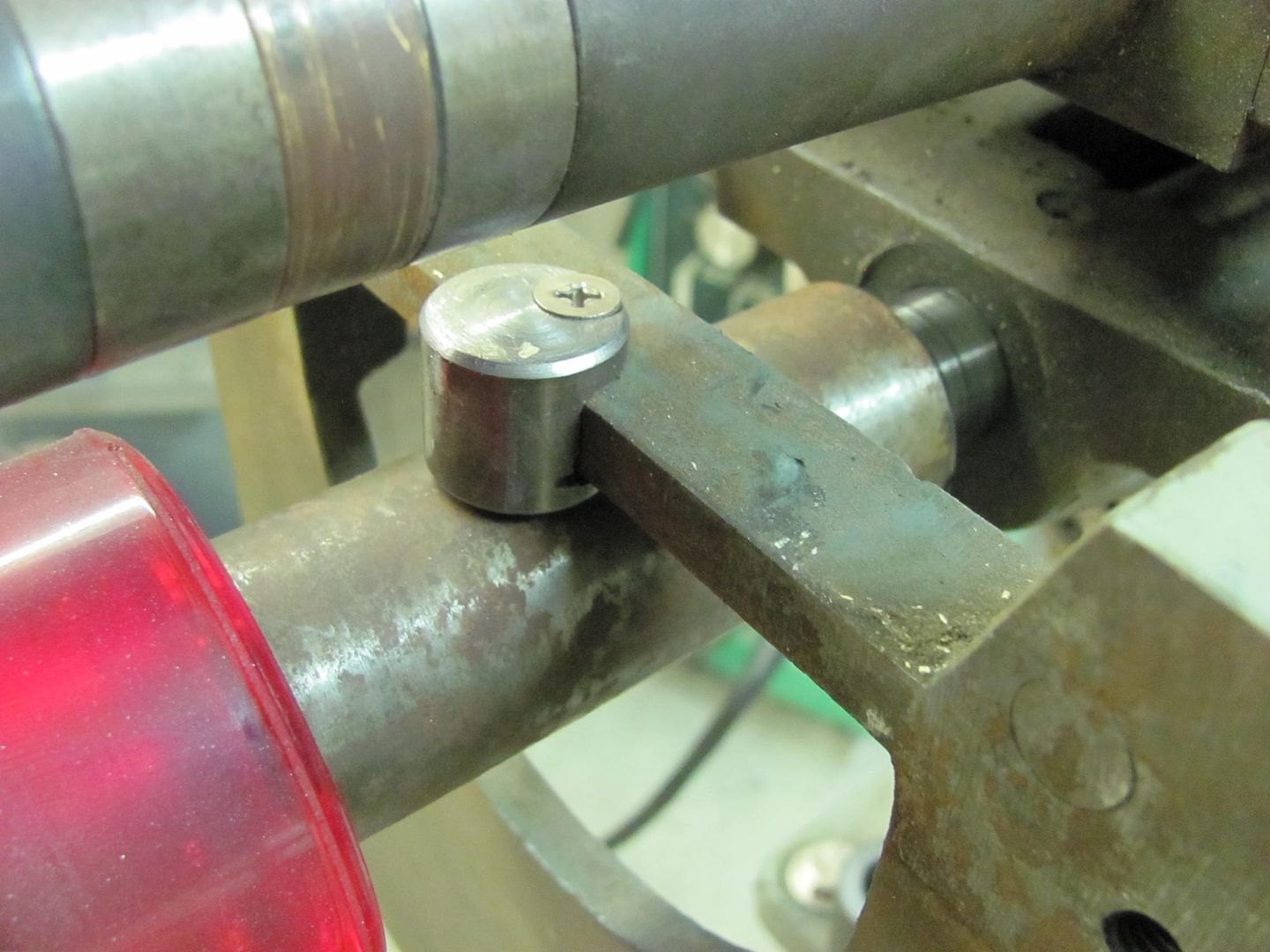

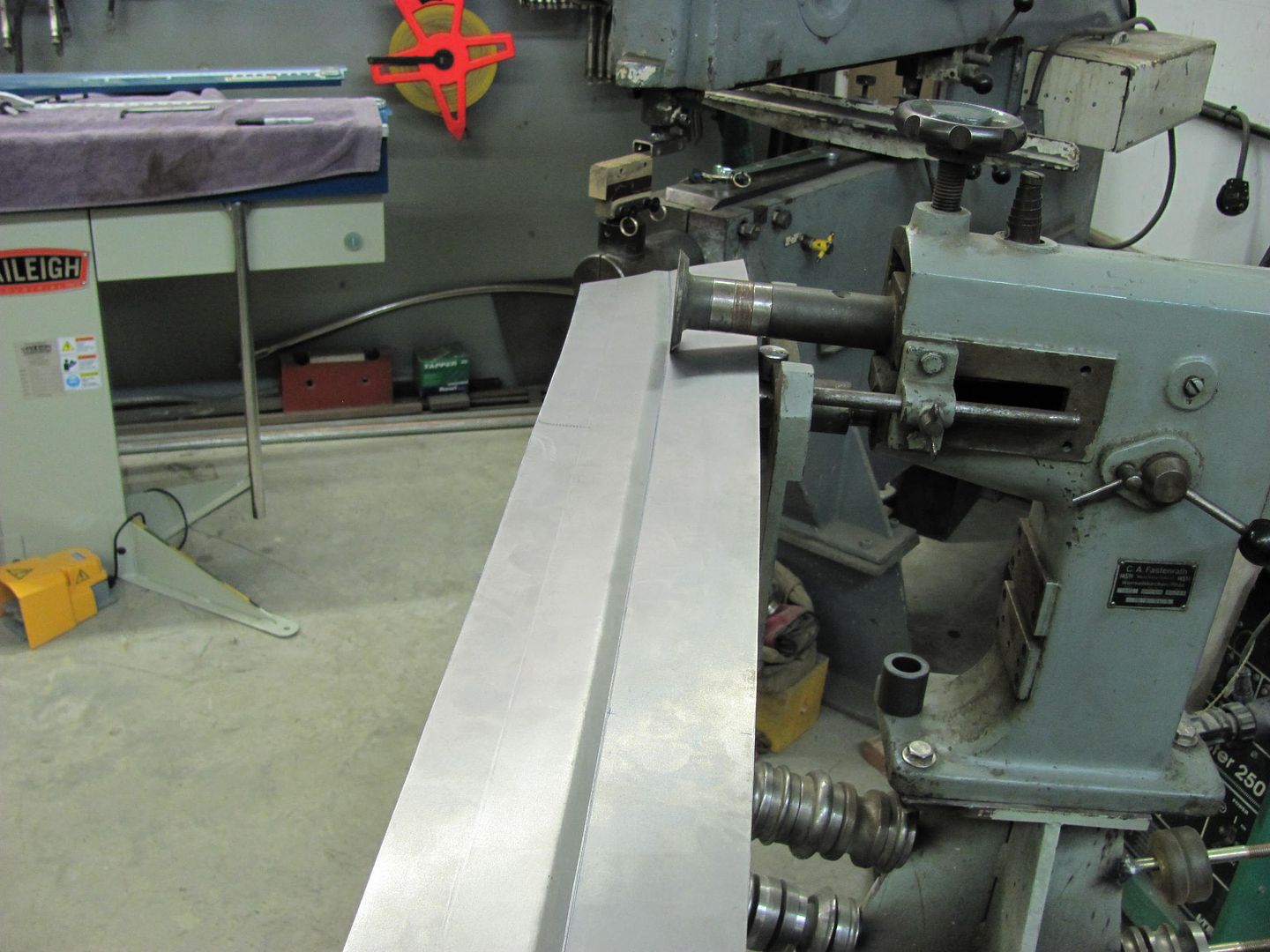

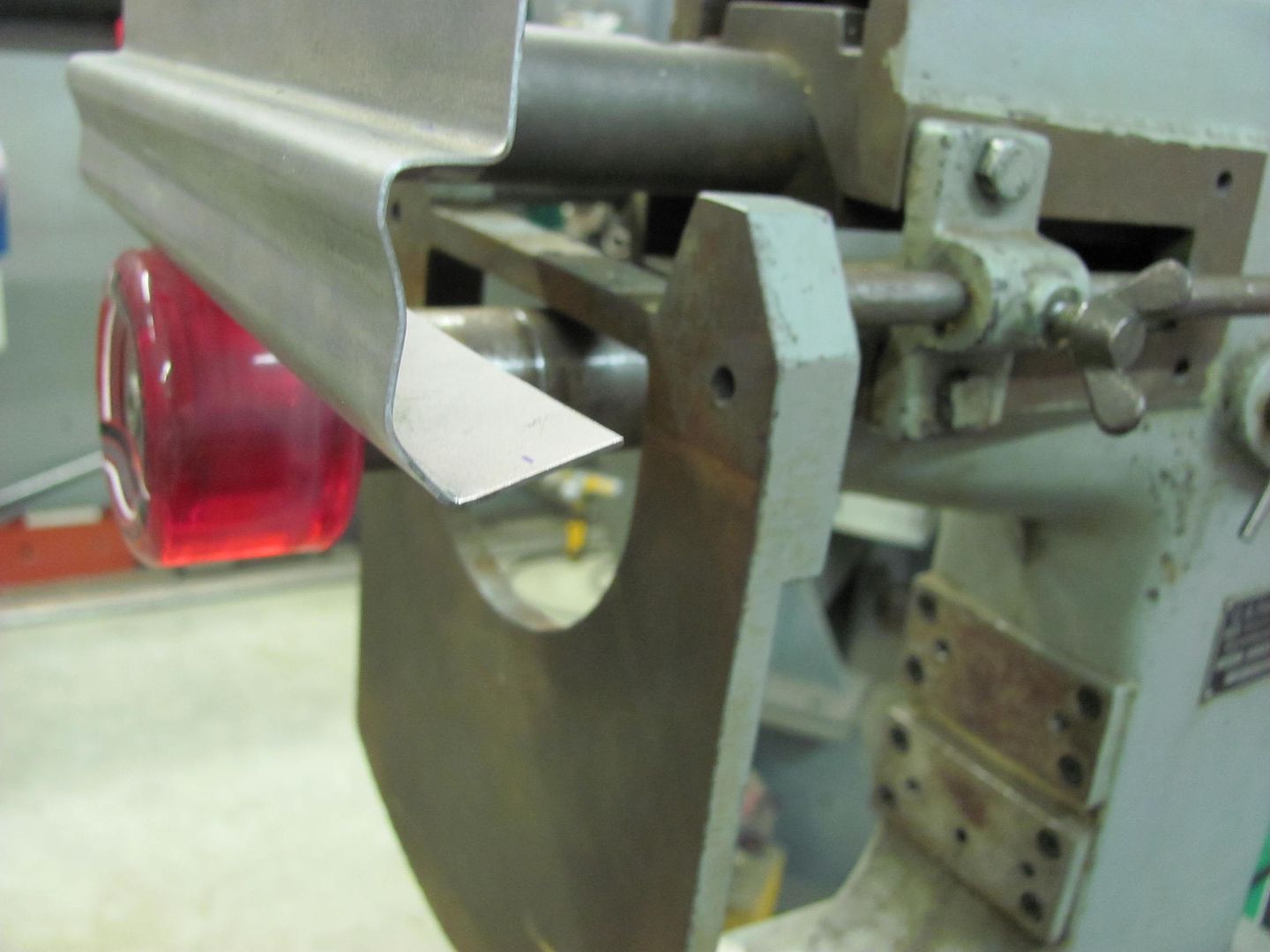

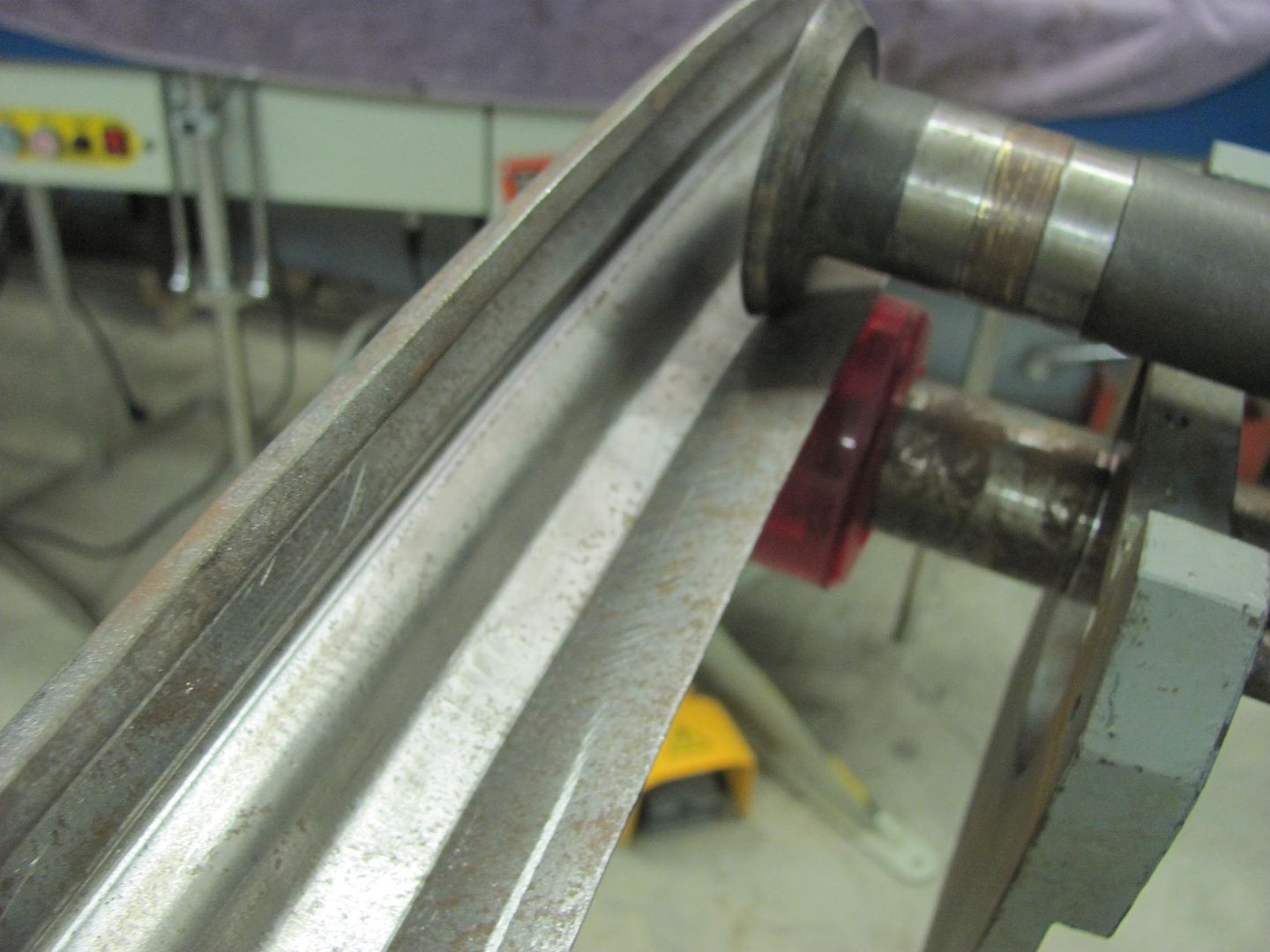

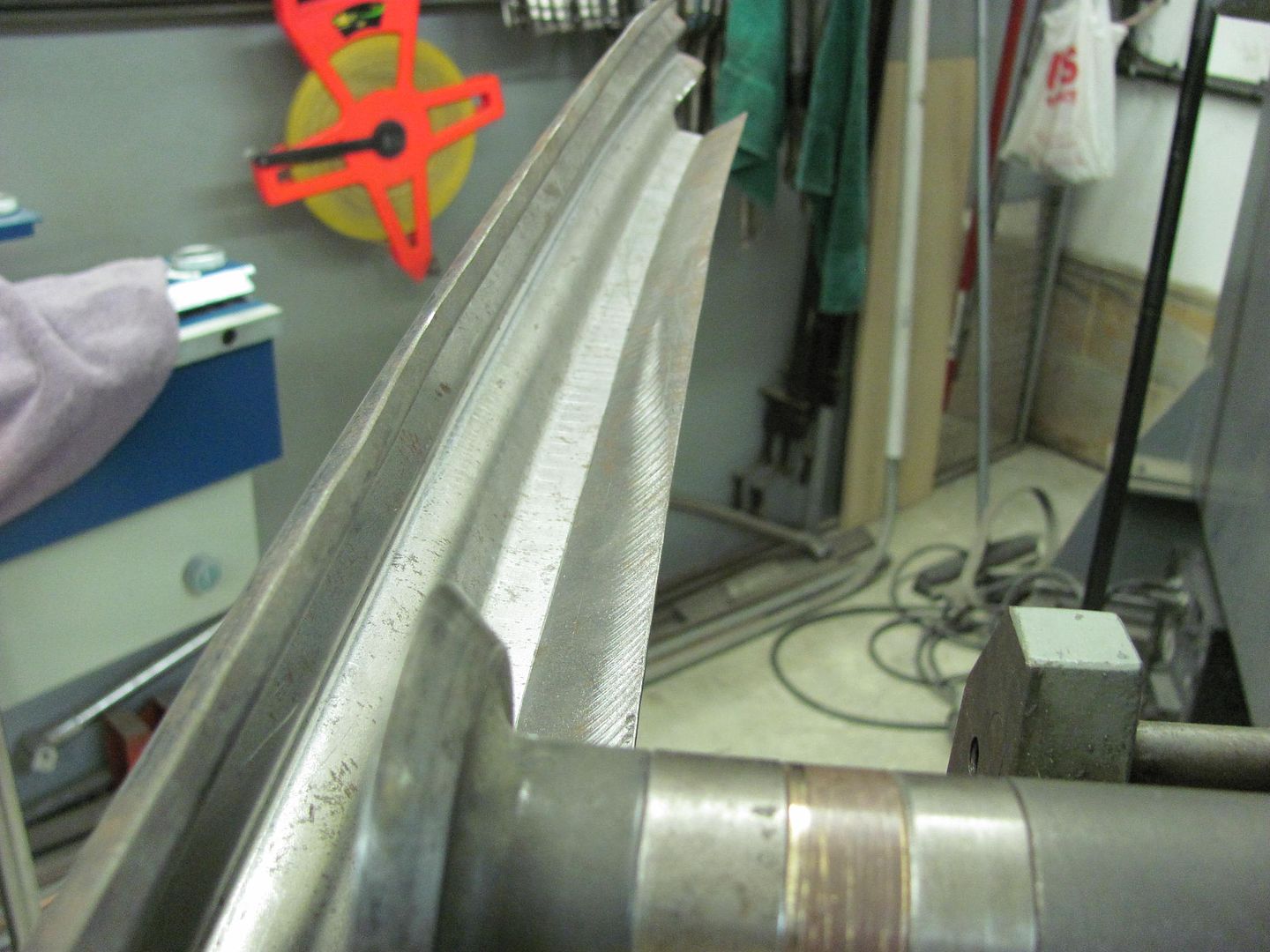

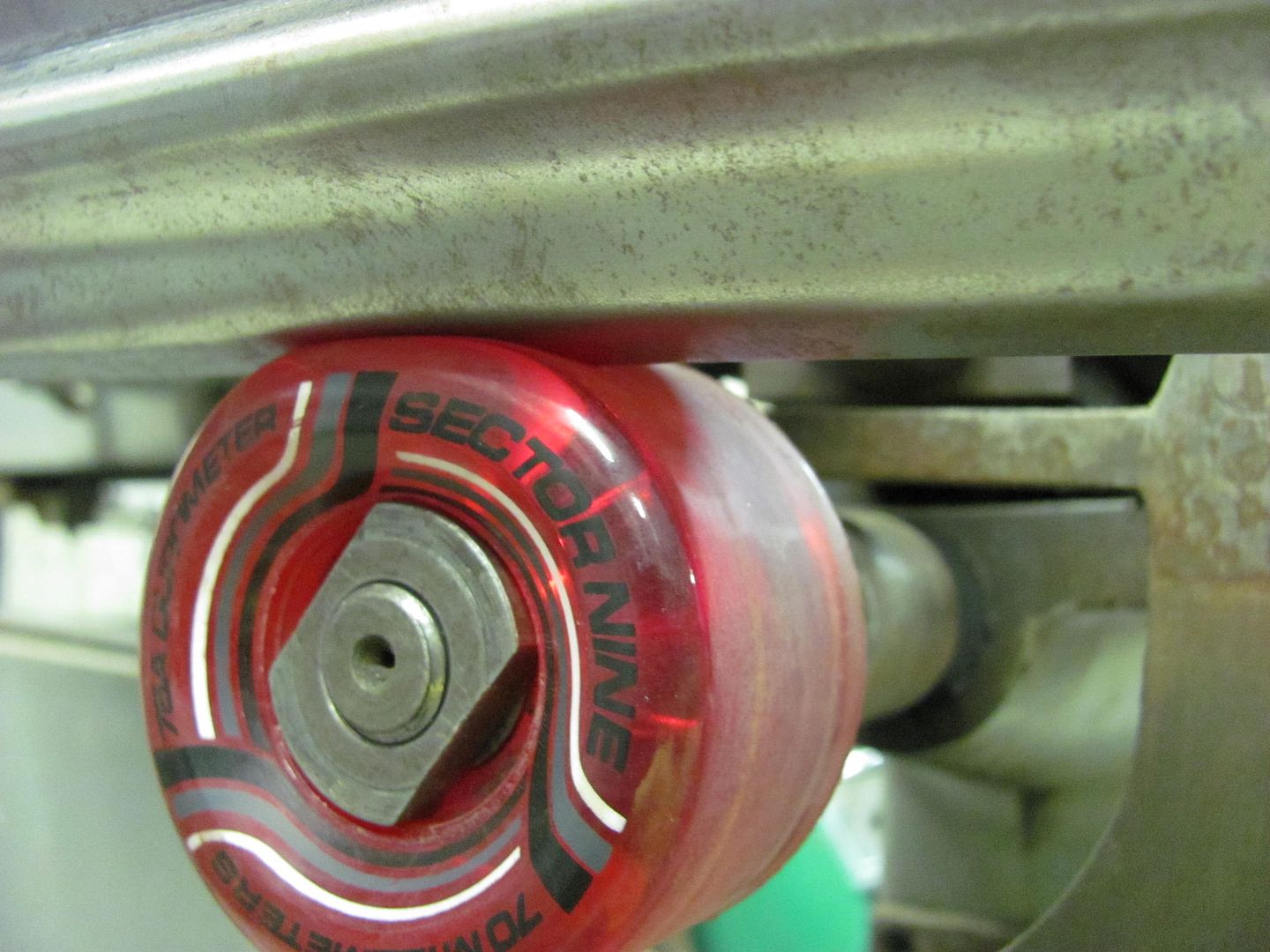

Checked the lower profile of the upper gate with radius sweeps to lay out the new piece...    Laying out the pattern on 19ga steel....   Tipping wheel in the bead roller...  ......and a newly modified back stop, much better than the flat one.....  Offset added with the tipping wheel......  Then run through the Lennox.....   More tipping, then the step die used in place of skateboard wheel with the tipping wheel for the lower 1/4" fold...    Still need to fold the top in the window opening, until next time...

__________________

Robert |

|

|

|

|

|

#59 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

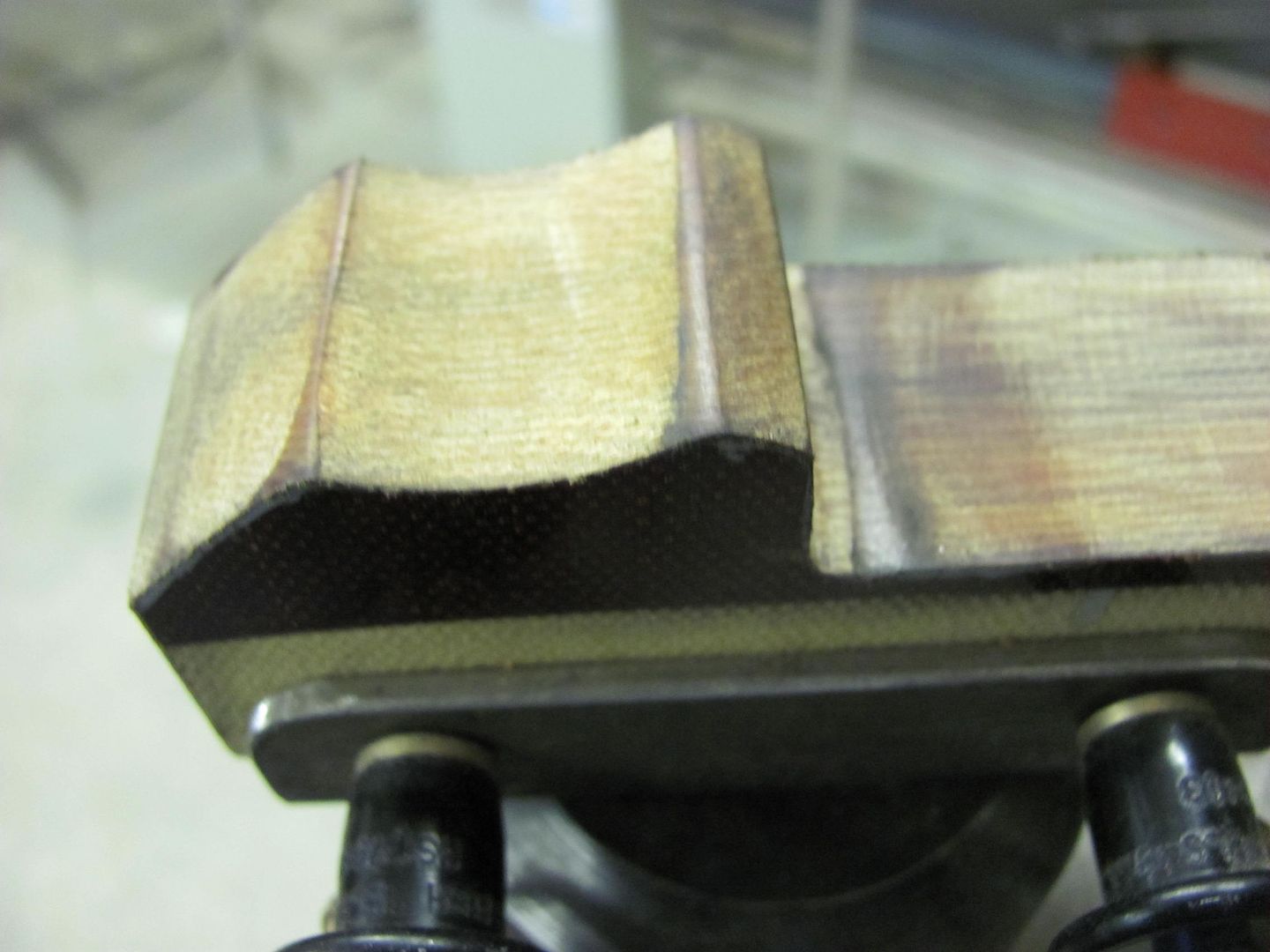

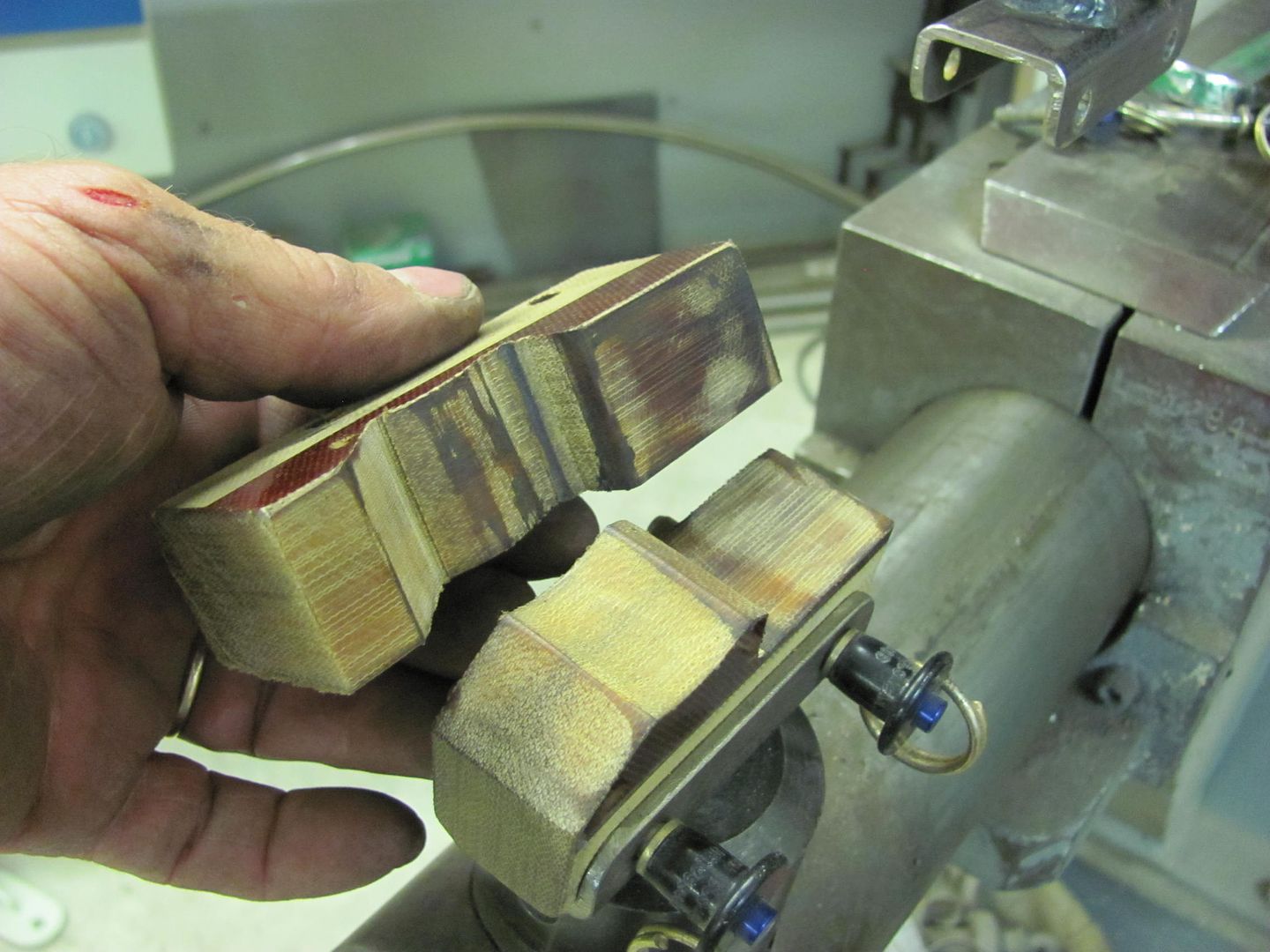

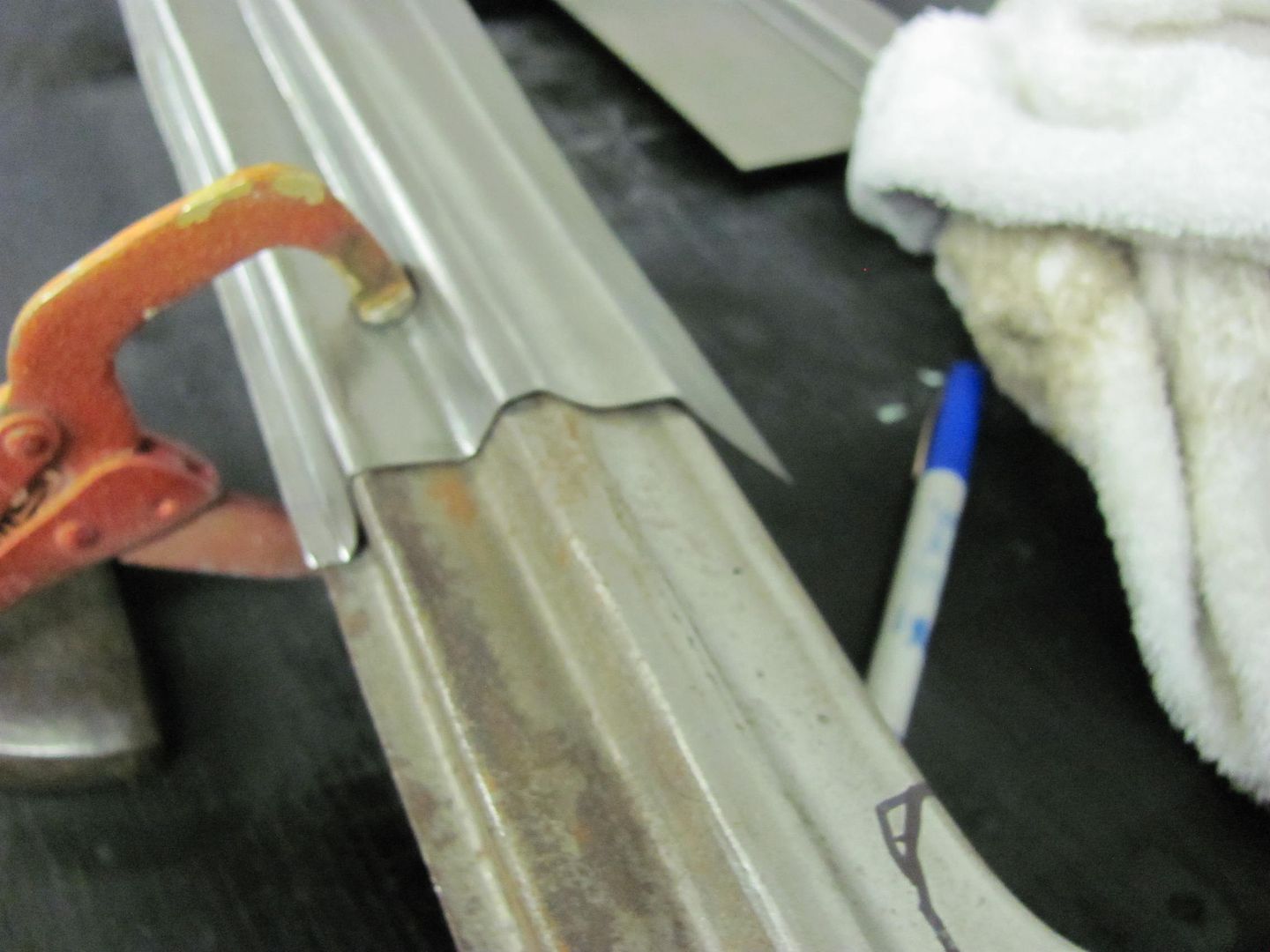

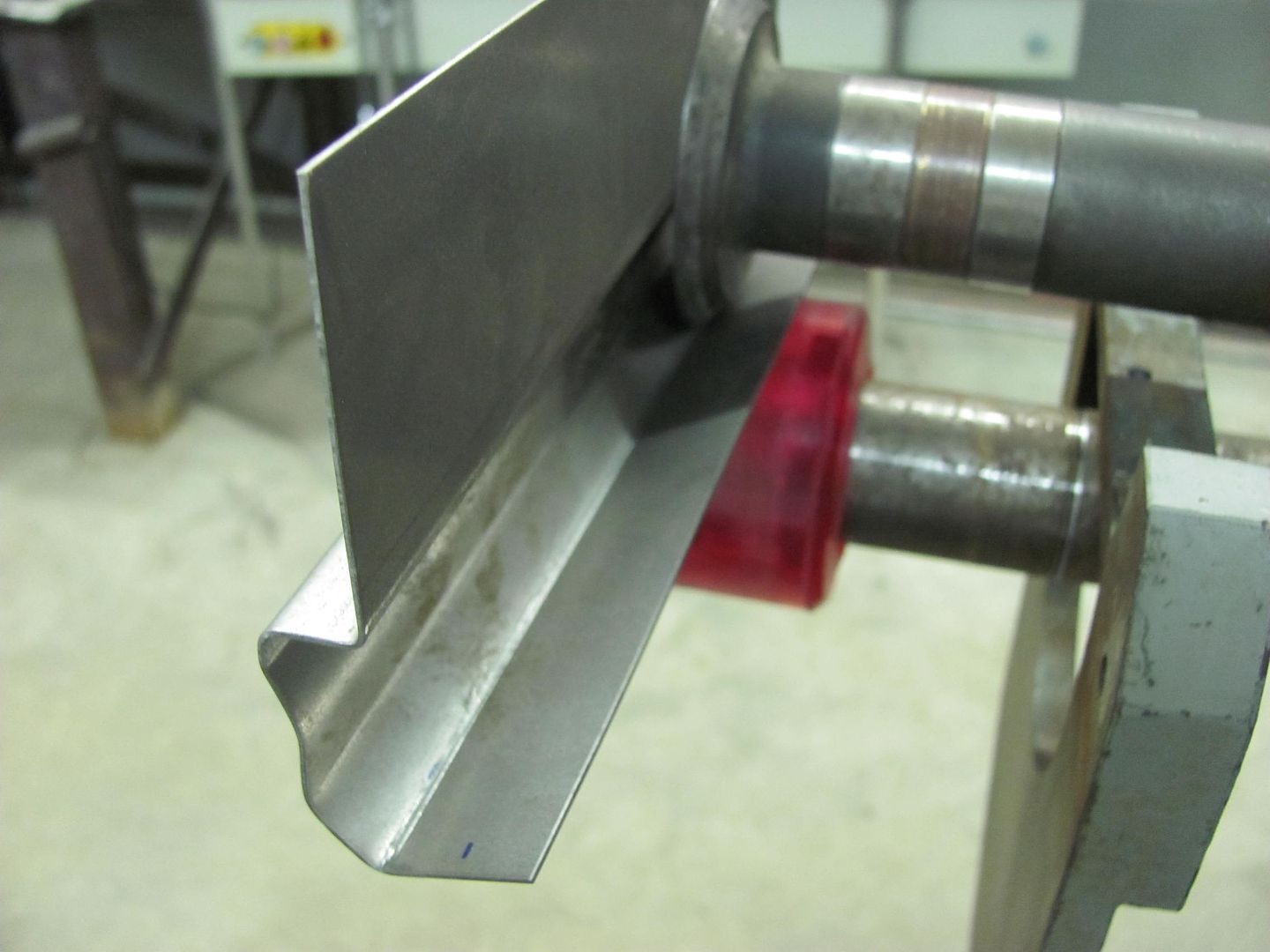

Tonight I made a small sample to test the fold of the window opening. Well actually, a few samples, as I started off by producing a small pile of scraps.....about three tries unsuccessfully, then this one, beginning with using the bead roller tipping wheel....

This is about as far as it would go, and with the good piece already having bends at the bottom, would be a bit less once tried on that piece. This will require a custom made "anvil" for some hammer action... The donor:  As modified:     .....then for some manual tipping...    Comparison to the original....   This looks close, next task will be to cut a sample out of the original and see how close we actually are...

__________________

Robert |

|

|

|

|

|

#60 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: 55 Wagon Progress

Incredible work Robert! It would be quite a privilege to hang out in your shop for a while. I can't get enough of that metal work.

|

|

|

|

|

|

#61 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

If travel plans ever bring you out east, by all means give me a shout!

__________________

Robert |

|

|

|

|

|

#62 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

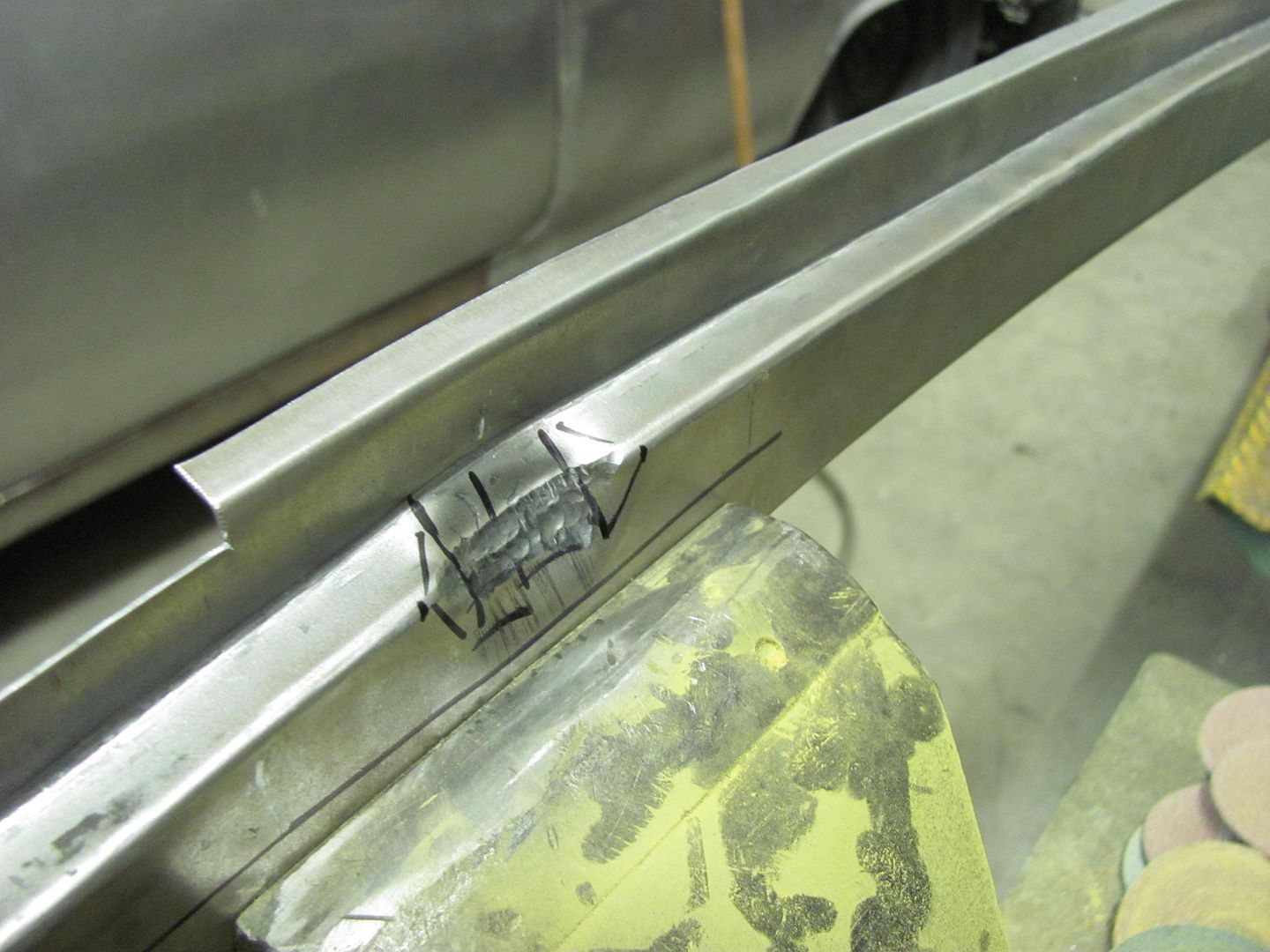

OK, enough of the practice pieces, time to finish the rest of the bends. Just to make sure we don't need any "tweaking", I'll cut a profile sample out of the center. This spot weld one the inner flange is far enough away so I won't need to grind out a spot weld, and still have enough of that flange for a good measurement. In other words, removed with minimal effort where it still holds it's shape accurately.

Our profile template:  Just to compare to our test sample, looks like the inner flange was bent down a bit much in the manual hammering, will have to ease up a bit...  Outside profile looks good enough to leave alone!  Following the measurement used on the test sample, the panel is run through the bead roller's tipping wheel nice and slow to give us an initial mark for the bend, then repeated to tip the flange downward...   This looks about all we'll get without distorting and pulling, so then it's off to the custom anvil...     Then for some manual tipping...   ...and comparing to our profile sample......  Ready to cut off the old next time...

__________________

Robert |

|

|

|

|

|

#63 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

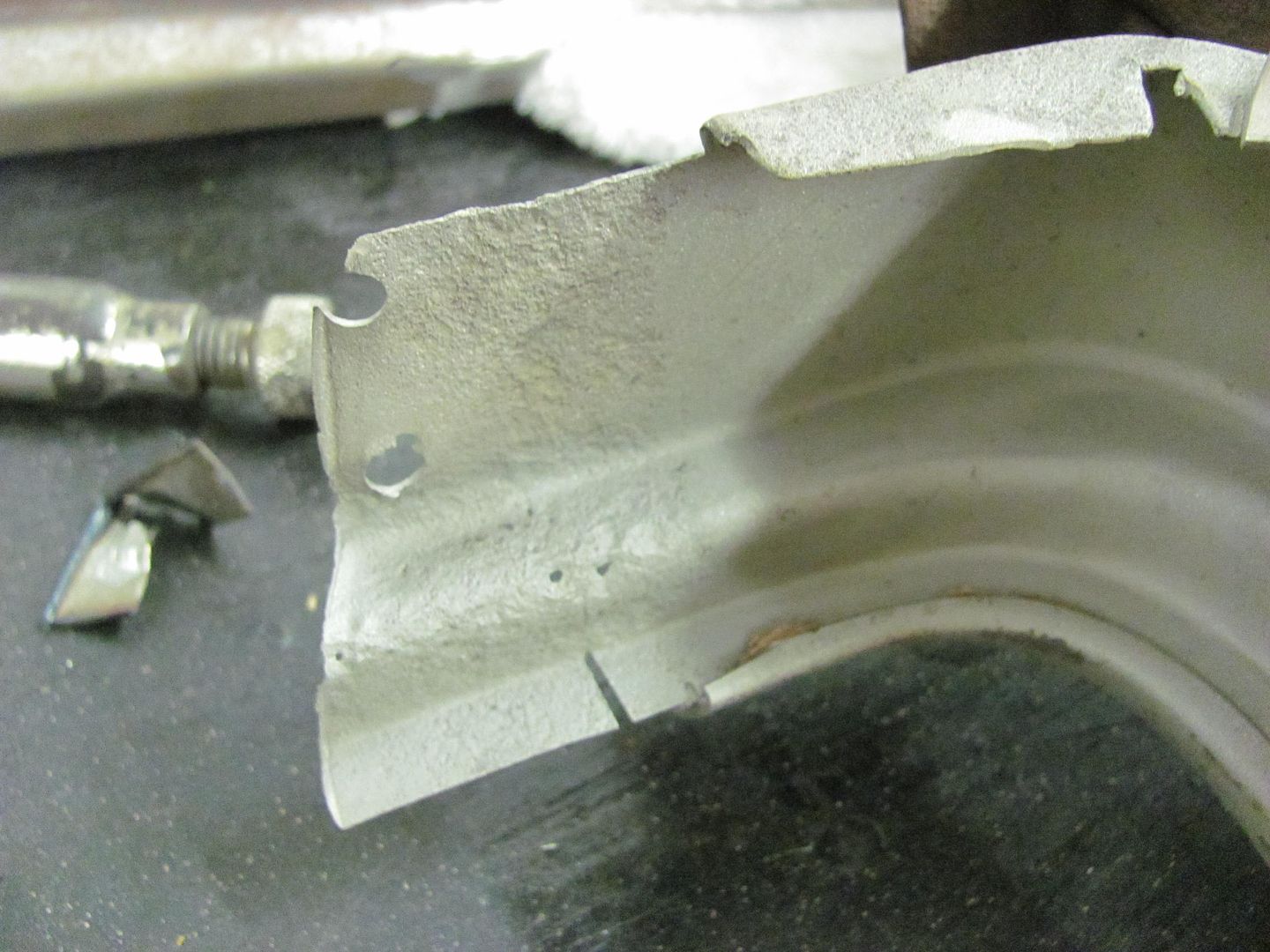

Well tonight's task was to remove the bottom detail of the lift gate and sandblast the remaining structure in prep for epoxy primer. The lower edge did have a flange folded up, so a slit was cut along the edge and the door skin vise grips were put to use...

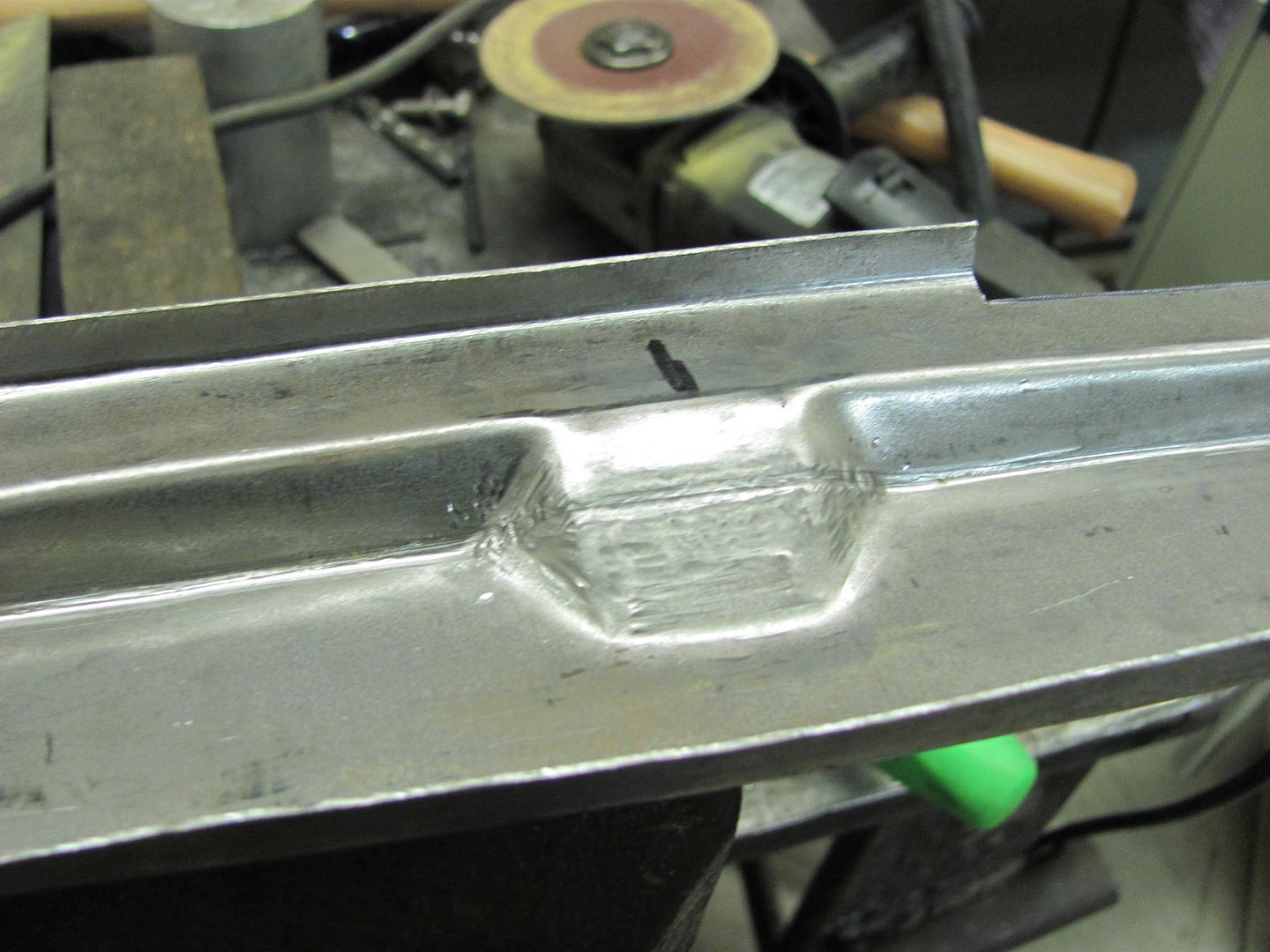

Next, the spot welds inside were ground out.....    Media blasting..... nice to finally see through the glass!  The media blasting revealed a few more holes, and numerous pits, many of them close to breaking through.    With all the other new metal going in the bottom, there's only one thing to do. Using the tipping wheel..........     Comparing to the pitted version.....       Next we'll need to do some corking to add the trim hole pad details.

__________________

Robert |

|

|

|

|

|

#64 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

I'll say it again, Robert. You need to be making videos, or something. You have a knack for turning "oh hell no!" into "no big deal" and showing the rest of us frimps how that's possible. You're the reason I got up the gumption to take on the Mazda (which is almost done, BTW). Kudos to you. I gotta get a bead roller.

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#65 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks, I've said before I do some of my best work after getting backed in a corner..

Now to address the mounting pads for the window molding.... Here's the new "anvil", made from some phenolic sheet.....   Put an alignment mark on the anvil, fitted it to the originals, and added the mark there as well. Then transposed those marks to the new piece...   Anvil was located, and clamped in the vise to hold it's location   Started with the barrel end hammer.....     For the ends, I used a rounded tip chisel....   ....and then another "anvil" to clean up the hammer marks a bit...    Here's all the tools used....  Touched up a bit with a sanding disc, looks close enough.... One down, 4 to go...

__________________

Robert |

|

|

|

|

|

#66 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Last night I worked to finish up the pad details on the inner structure of the lift gate.... The center one was wider, so I used the same phenolic and just added a wider detail to the opposite side. I missed showing this earlier, but a handy-dandy battery saw works well to remove the bulk of the material, sawing parallel cuts and then just working the saw side to side to clear out the remaining....

Once cut out, the sanding disc is used to cut down the angled sides and touch up the bottom..  This compares the two, showing the difference in width...   Alignment marks transposed from the original, and guide marks indicate the area in need of hammering...   I had a request to show the hammering procedure, so here's another video attempt. The first one is using the phenolic anvil clamped against the work piece in the vise, the second uses 1" square stock as an anvil to clean up the hammer marks a bit... http://s5.photobucket.com/user/rmcca...eo232.mp4.html http://s5.photobucket.com/user/rmcca...eo233.mp4.html ...also sounds like I have a loose hammer handle, something for another day....  Then the sanding disc was used for final cleanup. Here's the finished piece, just needs a couple holes drilled....

__________________

Robert |

|

|

|

|

|

#67 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

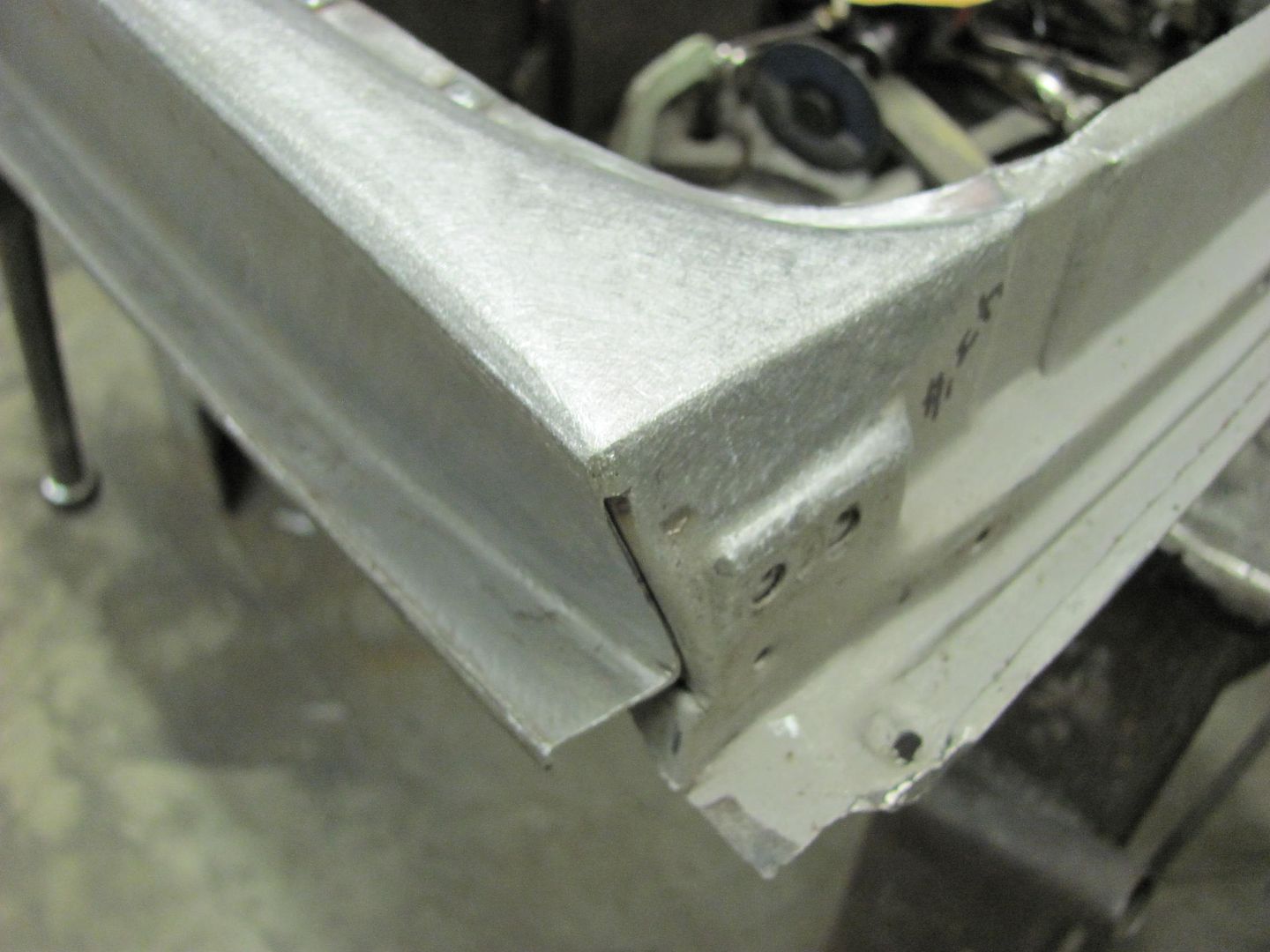

Back to the lift gate, the spot welds in the bottom piece were drilled out. This revealed a couple more pits, which were media blasted and MIG welded.

All cleaned up, the new piece is plug welded on....   Then the inner panel is fitted up and tacked in place....     Top flange clamped to check the fit.....   That's about it until next time...

__________________

Robert |

|

|

|

|

|

#68 |

|

Restoring it $200 at a time...

Join Date: Aug 2008

Location: NE Kansas

Posts: 887

|

Re: 55 Wagon Progress

Artwork. I got nothing else to say.

__________________

Charter member of the 'Put the dimmer switch back on the damn floor where it belongs' Society '68 5.3L-4 speed LWB C20; grandpa bought it for the farm in '71. Now LS 5.3, rather than 327. DD '09 Pilot Weekender '65 Skylark 300-4V-4 speed Wife's '07 Lexus ES350; 117 actuator motors and I can't see the engine. Son's '04 F250 SuperCab 6.0 |

|

|

|

|

|

#69 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

Beautiful work! I'm surprised the "excess" out at the break of the 90 laid down into the relief as nicely as it did. I would have thought you'd have had to slit it at the corner to lay it down and then weld the seam back up. Thanks again for making the seemingly impossible look not only possible, but achievable.

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#70 |

|

Hittin E-Z Street on Mud Tires

Join Date: Nov 2004

Location: Greenville, SC

Posts: 23,090

|

Re: 55 Wagon Progress

It's actually a shame that someone will someday look at that at a car show, and not even notice it. You should make a second one as a cutaway or something

__________________

Jesse James 1967 C10 SWB Stepside: 350/700R4/3.73 1965 Ford Mustang: 289/T5-5spd/3.25 Trac-Loc 1968 Pontiac Firebird: Project Fire Chicken! 2015 Silverado Double Cab 5.3L Z71 2001 Jeep Wrangler Sport 4.0L 5spd 2020 Chevrolet Equinox Premium 2.0L Turbo 2011 Mustang V6 ~ Wife's ride  American Born, Country by the Grace of God  1967 CST Shop Truck Rebuild! My 1967 C-10 Build Thread My Vintage Air A/C Install Project "On a Dime" Trying my hand at Home Renovation! 1965 Mustang Modifications! |

|

|

|

|

|

#71 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

How about we put all the rusty pieces cut out in a 5 gallon bucket and see if they can find where they came from!

Finishing up the welding of the inner bottom panel....used a 3/16 hole for the plug welds this time. I normally use a letter A, but the flange here is a bit narrow, so a smaller hole it is. To make up for it the heat on the welder was cranked up a bit to insure a good weld.   Looking at the back side, these should hold well.  All the plug welds done, then on to the corner seams.....   and after cleaning up the welds.....      Then we'll clean up the plug welds on the flange, media blast the inside for good paint adhesion and some epoxy primer before closing it up..

__________________

Robert |

|

|

|

|

|

#72 |

|

#16876

Join Date: Apr 2005

Location: Auburn WA

Posts: 12,266

|

Re: 55 Wagon Progress

Fascinating

__________________

Posted via Stationary Device '71 Custom Deluxe C-20 402. '67 Buick Special 455. '49 Plymouth Special Deluxe. "I love that old car smell"  Some people are like Slinkies... not really good for anything, but they still bring a smile to your face when you push them down a flight of stairs. |

|

|

|

|

|

#73 |

|

Registered User

Join Date: Nov 2010

Location: SoCal

Posts: 914

|

Re: 55 Wagon Progress

WOW!! Awesome work.

__________________

I'm not tail-gating, I'm drafting.  http://67-72chevytrucks.com/vboard/s...d.php?t=432758 |

|

|

|

|

|

#74 |

|

KEEP ON TRUCKIN'

Join Date: Jun 2005

Location: Sterling, Va.

Posts: 5,730

|

Re: 55 Wagon Progress

Great job. A true master at his craft.

__________________

JIM '97 GMC Sierra K1500 '95 Chevy Silverado C1500 '71 Cheyenne Z71 / LT1 & 4-Speed SWB K/10  Father/Son Project Father/Son Projecthttp://www.youtube.com/watch?v=4l689JKXPnA http://67-72chevytrucks.com/vboard/payments.php "LIVIN' FREE FOREVER"

|

|

|

|

|

|

#75 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments fellas!

Didn't get much accomplished tonight but grinding on some plug welds.   I've had a few inquiries in the past as to my weld grinding process, so I thought I'd use the opportunity for another video..... http://s5.photobucket.com/user/rmcca...welds.mp4.html .

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|