|

|

|

#1 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

4L80E & TH400 Tech.

I thought I would share some Tech for 4L80E & TH400 transmissions.

These units have very few weaknesses. But can be made better with a few mods. Dual Feeding the Direct Clutches is hands down the best mod you can do. From the factory the Direct apply piston is divided into 2 separate sections. In factory form, 3rd gear oil only uses the smaller of the 2 sections to apply the Direct clutches. However, Reverse uses both areas to apply the Direct clutches. The first diagram is D3/D4...Directs clutches applied. Second diagram is Reverse. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

The only thing needed is a parking pawl cup plug, Comes in every 4L80E/TH400/TH350/700R4/4L60E rebuild kit.

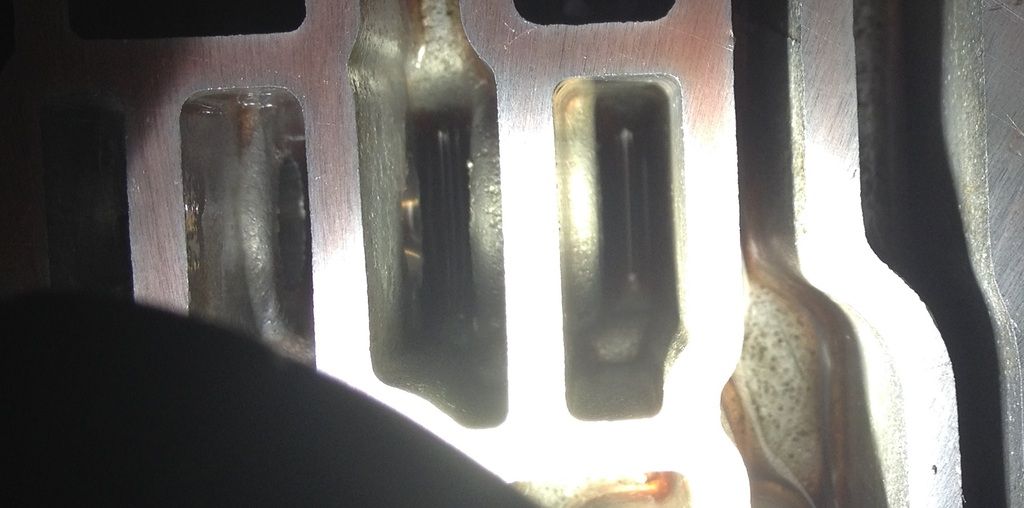

Use the Cup Plug to block the Reverse passage in the case. (the passage to the right of the Center Support Bolt) I recommend using some type of Retainer Compound on the OD of the cup plug & let it set overnight. |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Omit the lip seal in the direct drum & the second sealing ring on the Center support.

|

|

|

|

|

|

#4 |

|

1965 Chevy C10, 2005 4.8L/4l60

Join Date: Aug 2004

Location: DFW Texas

Posts: 8,546

|

Re: 4L80E & TH400 Tech.

Thanks Cline!

__________________

Clyde65 Rebuild of Clyde http://67-72chevytrucks.com/vboard/s...84#post8338184 69 Aristocrat Lo Liner build http://67-72chevytrucks.com/vboard/s...84#post7561684    support our troops! |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Your welcome, Hopefully it helps someone.

The next weakest link is the Intermediate Sprag.... 4L80E's have a 34 Element Sprag from the factory, And are pretty stout. '69 & earlier TH400's use a 16 Element Sprag. '70 & up TH400's have a 8 Element Roller Clutch. Under 450HP applications will be OK, A lot of HP & torque, & Harsh 1-2 shifts will kill this Roller Clutch. If you have a 4L80E, Your good, Though I would replace the sprag with a new Borg Warner. If you have a Early TH400 (Direct Drum), All you need is a 34 Element Sprag for a 4L80E. If you have a Late TH400 (Direct Drum), Buy a Early Drum or a 4L80E Drum. Custom 36 Element Drums are available, Not needed on most anything street driven. **NOTE, Do not mix the Sprag Races on these 3 drums!!!! The 4L80E Race is taller for the 4 Intermediate Clutches vs 3 on a TH400 & will not fit on a TH400 Direct Drum. Early TH400 Drums are getting scarce, Buying a Complete 4L80E Drum is the best option. This is a pic of a 4L80E Direct drum with a 34 Element Sprag. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Apr 2012

Location: Vegas

Posts: 617

|

Re: 4L80E & TH400 Tech.

Thanks Cline! I'm getting ready to swap in an 86 TH400 and this is just what I needed

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Apr 2012

Location: Vegas

Posts: 617

|

Re: 4L80E & TH400 Tech.

Cost really, I'm getting the TH400/NP205 combo for less than the price it would be for a 4l80E/NP205 Adapter.

|

|

|

|

|

|

#9 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

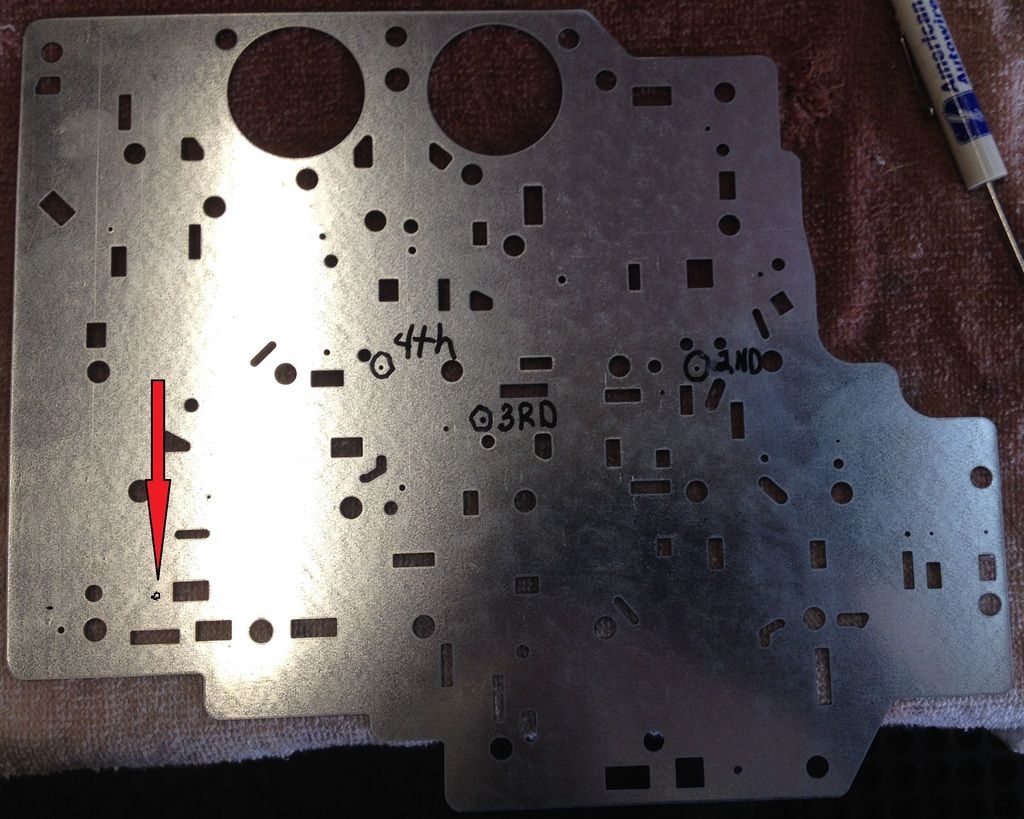

Ok, Back to the business at hand. Separator Plate Hole sizes, We will start with the TH400. These are suggestions. The bigger the feed hole....The quicker & Firmer the shift will be. Clutch clearance affects this as well! A loose clutch stack-up will cause a firmer shift than one that is set-up tight. 2nd Feed Hole, 125" Max. 3rd Feed Hole, 140" is good if your Blocking the 2-3 Accumulator. If leaving the Accumulator functional, .175" is where I like it. Before anyone gets their panties in a wad over such a big 3rd feed hole......The plate in the pic is from a '70 Cadillac TH400 that had a factory 6 friction Direct Drum & has a .175" 3rd feed hole stock. **Note, Removing checkballs will render feed hole sizes useless! |

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Apr 2012

Location: Vegas

Posts: 617

|

Re: 4L80E & TH400 Tech.

Yes, even though it only has 50k miles on it and in good working order, I still feel like it would be beneficial to beef it up now, rather than later. Besides it would make for good video and it's something that I have been wanting to do for a long time.

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Blocking the 2-3 Accumulator. (TH400)

You will need a 5/16-18 tap & a 5/16" set screw. Tap it just deep enough for the set screw to seat good. The red arrow is the accumulator feed hole that needs to be tapped & plugged. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

4L80E Separator Plate hole sizes. This unit is kinda picky about clutch feed hole sizes & don't need to be as big as a TH400.

If your running a stronger Pressure Regulator spring or a larger Boost valve (Or both)....Be conservative on feed hole sizes.....Mainly 2nd to keep from shocking the Intermediate sprag. "Stall" Of the converter has a huge effect on shift feel....The Looser the converter...The softer the shifts will feel, Meaning you can run bigger holes. Using a stock converter....Again, Be Conservative! 2nd Feed Hole, .085" to .125" 3rd Feed Hole, .093 to .150" 4th Feed Hole, .085 to .093" |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Pressure Regulator & Boost Valve basics, From a Sonnax Tech article.

Raising line pressure is typically done by using a stronger pressure regulator spring, installing a larger boost valve or doing both. A stronger spring and larger boost valve will both increase pressure, just not in the same way, so it's important to understand the differences before making any changes. Stronger springs have a "linear" effect on pressure. This means you get the same amount of pressure increase at the low and high ends of the pressure range. While a stronger pressure regulator spring will raise line pressure, there is a limit to how much you can get away with before troubles surface. A significant pressure increase that tightens upshifts under heavy load can be too much of an increase when shifting into reverse in the garage. This increase also puts extra load on the pump at idle and can result in the TCC clutch dragging due to reduced cooler flow. Larger boost valves have a "progressive" effect on pressure: they change the rate of pressure increase. Using larger boost valves, it's possible to have a very small pressure increase at the low end of the pressure range and a far greater increase at the high end. This creates an ideal situation: smooth engagements and lower load on the pump at idle, plus a greater increase in pressure as the transmission is worked harder. The significance of changing the rate of pressure increase with larger valves – rather than simply increasing pressure by the same amount with springs – is that higher pressure is created when it is needed most. |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2014

Location: D'Iberville, MS

Posts: 447

|

Re: 4L80E & TH400 Tech.

I'm still having a issue

__________________

Ralph L. Jasper 69 4x4 Suburban PTO winch(NAVY) 13 GMC Ext cab 12 Ford Fusion SE(wife)  MAI Interior shop |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Blocking the 3rd gear Accumulator on a 4L80E, Unbolt the 3rd/4th Accumulator housing from the Valve Body. (The Valve body has to be removed)

Remove both Accumulator Pistons, The one without a guide pin is the 3rd gear Accumulator, The Hole near the bottom of the big bore is what needs to be blocked. (arrow).  Using a 5/16-18 tap, Carefully tap the hole deep enough so the Set screw sits below flush, The Hole is at an angle....Try to keep the tap at that angle.  Test fit the set screw so you know it's seating below flush, You can make fun of the Gold Plated set screw if you want, I bought 2 boxes full of them from an Audio install shop that was going out of business.  You can Block the 4th Accumulator if you like (I generally don't unless a high stall converter is being used), It's the exact same method, Just remove the guide pin to tap the hole.

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

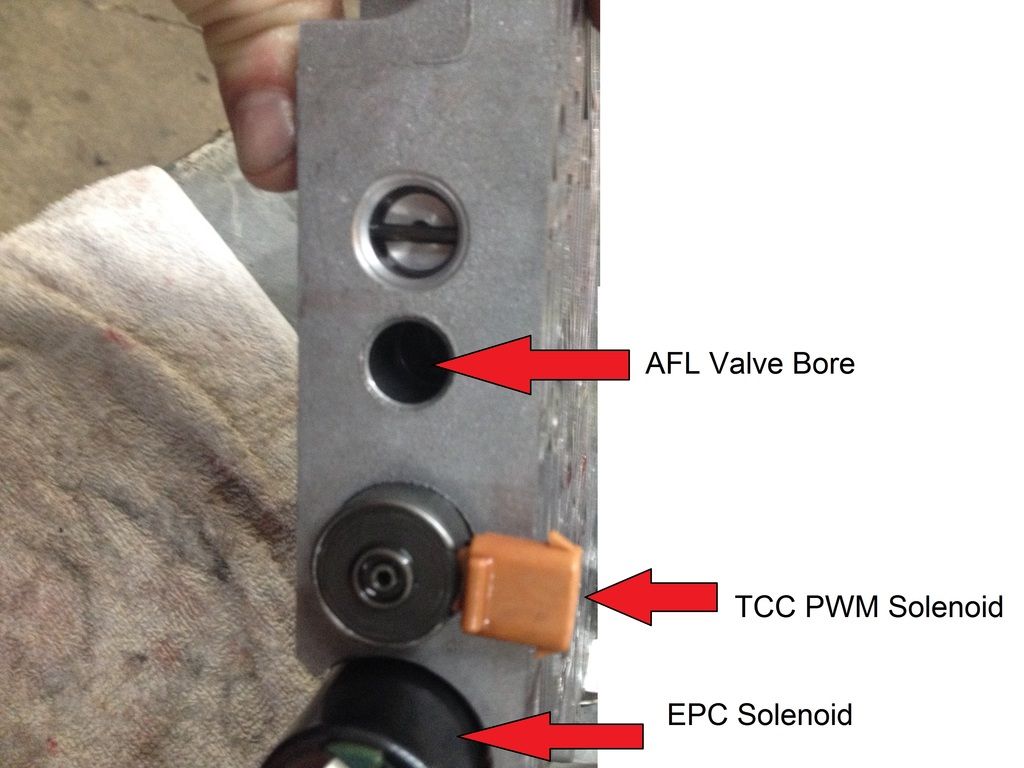

This is Important, Even to you guys that are throwing shift kits in a working 100,000 mile unit!

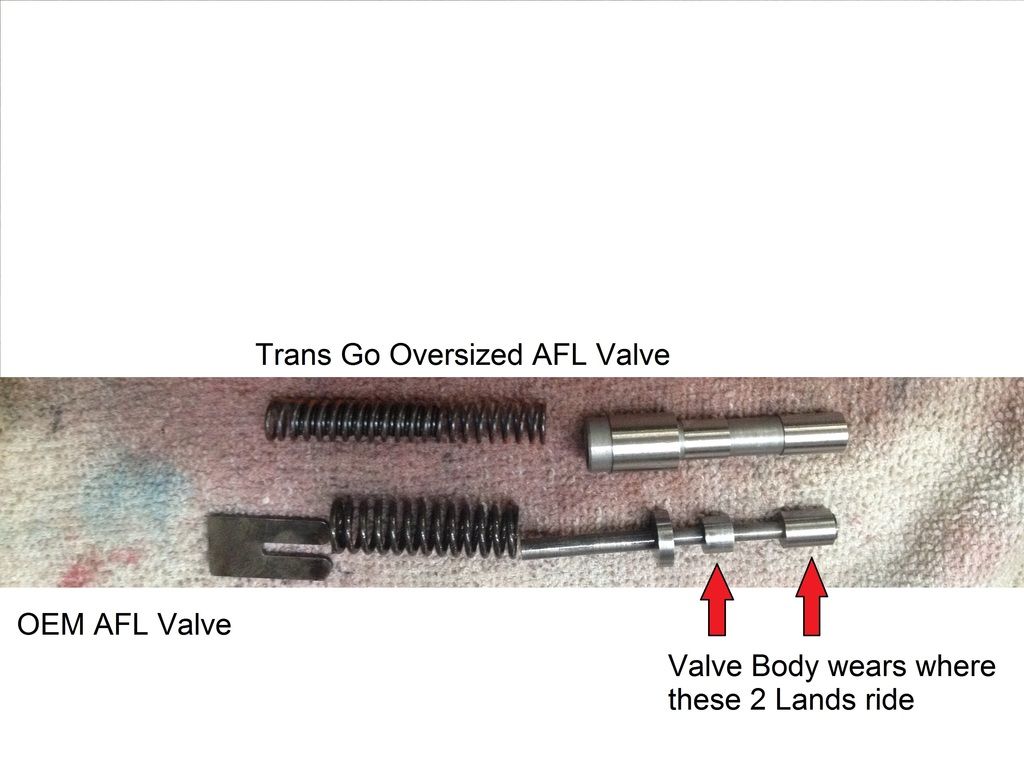

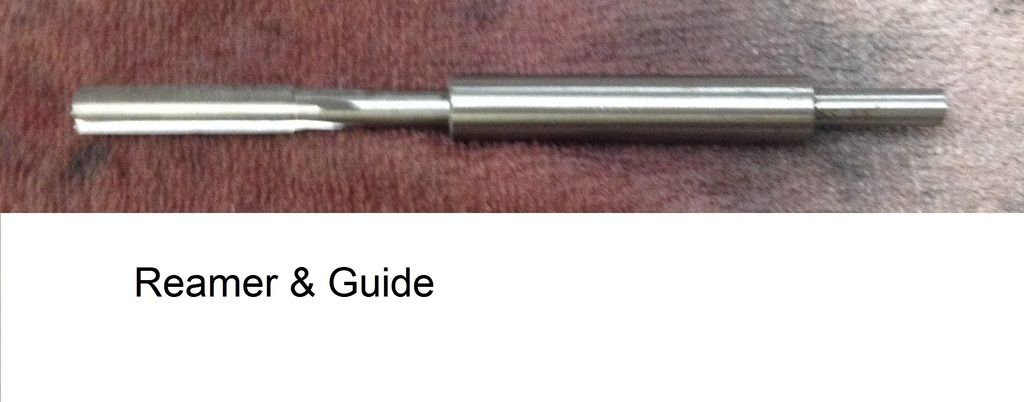

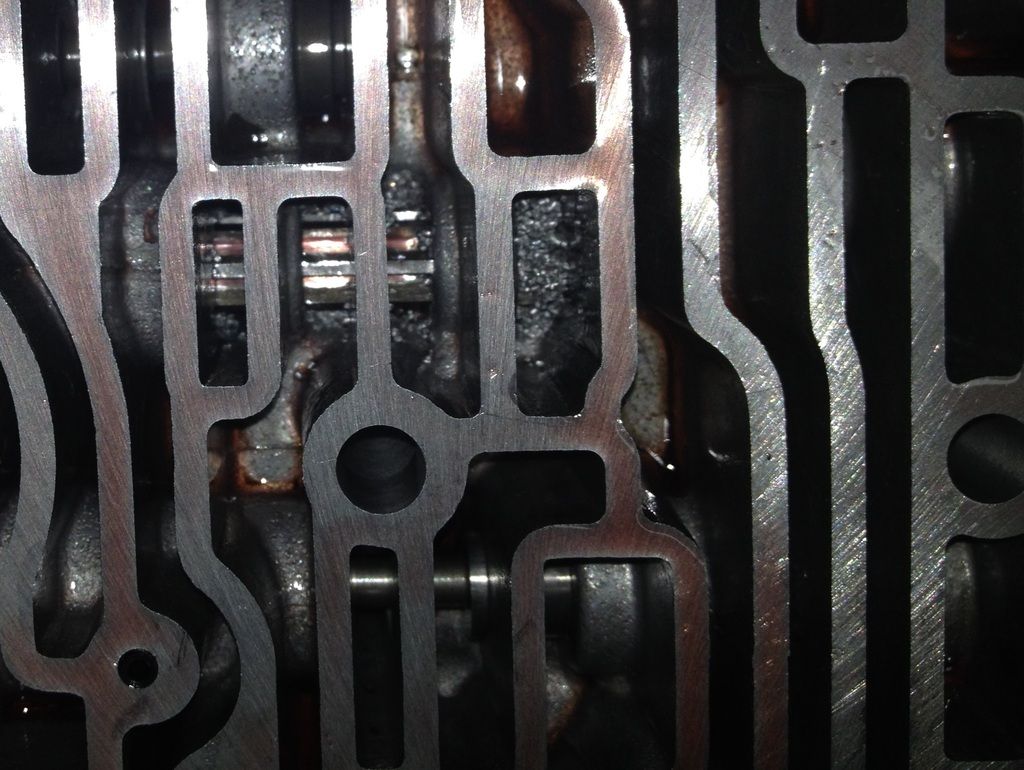

4L80E's have issues with the Actuator Feed Limit (AFL) Valve wearing the Valve Body. The AFL valve regulates actuator feed pressure to all three shift valves, to the pressure control solenoid and to the 1-2 and 2-3 shift solenoids. The pressure is not fed to any clutches but is used to position the shift valves, which then will direct line pressure to the appropriate clutch. When AFL Pressure starts to drop from wear....The Pressure drop over time is small at first, Then the wear/pressure loss starts accelerating to the point the valve is starting to take chunks out the Valve Body. (Not Linear) This problem will first appear after you take a long hot 100+ mile trip & it Falls out of 4th, Then it starts falling out anytime the unit hot, Wrong Ratio codes, TCC codes, Shift Solenoid codes, Limp mode, & Random 2nd Gear starts........That all the new Solenoids, Harnesses, Tuning, & Half a$$ Rebuilds in the world will NOT fix. There are 2 fixes for this. The preferred method is to Ream the Bore larger, Install a Steel Sleeve & install a new AFL Valve. The Sonnax "Sure Cure" kit is a great product & does more than just the AFL Valve, The Tool Kit alone is over $300 (Reamers & Guides), That is not including the Sure Cure kit itself. The 2nd choice is to Oversize the Bore & Install a Oversized AFL Valve, Transgo has a kit with the Reamer/Guide/Valve/Spring. Part# 48-ACT-TL (It actually fixes 6 Valve Bodies) http://www.transgo.com/products.php?...dcountview=Yes It is under $100 & worth every penny, The down side is.....The valve body will eventually wear again, But good for another 100K. I'm going to cover the Second Choice, Because the cost & Ease of install. Locate The AFL Vale Bore (Next to the TCC PWM Solenoid), Depending on year model, Remove the Roll pin & Plug(Early), Or The Clip(Late, Shown), Remove Spring & Valve.  Comparing the 2 Valves, You will only be enlarging the Smaller Spool, The Larger Land is just longer to ride on an "Unworn" part of the Valve Body.  Reamer & Guide  Guide & Reamer in place...  Follow the Directions, DO NOT ream past or into the "Wall" the Valve bottoms out on, The "Wall" is where all the cuttings are.  This was performed on a 150,000+ mile '01 Core, The Middle Land was worn the most, This is a before shot.

|

|

|

|

|

|

#17 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,142

|

Re: 4L80E & TH400 Tech.

Clinebarger, I was wondering if you would share what I need to get to build a 4L80E to hold 600hp reliably. The trans is from a 96 truck. Will that be an issue? The trans is going behind a 2000 5.3 in a 40 Ford with a mid frame S400 turbo and I'm sure it'll see some abuse. I'm going to use the GM PCM to run it so do I need to change any connectors to a later one or is it cheaper to get the adapter harness? Thanks for your time, Ryan.

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

On the wiring, Your going to use a 2000 chevy truck 5.3L/4L60E harness? If so, You can just swap some wires around at the Trans Plug & PCM & run 2 Input Speed Sensor wires, The Trans plug will reach.....Simple stuff. Now if your running a 4th gen F-body harness, The Plug will not reach & buying a adaptor harness is best. Ok, On to the parts list... Of course you will want to "Dual Feed" the Directs. Billet Input Shaft, http://www.ckperformance.com/View/CO...ON-INPUT-SHAFT If your planning on running drag Radial/Slicks this is absolutely necessary! Billet Forward Hub, http://www.ckperformance.com/View/FO...ZED-CLUTCH-HUB Recommended for any Boosted application. Spiralock Intermediate Clutch Snap Ring, http://www.ckperformance.com/View/TH...UTCH-SNAP-RING Late 4L80E Direct Drum/Intermediate Sprag, http://www.ckperformance.com/View/6-...L-RETAING-RING Actuator Feed Limit repair kit, http://www.transgo.com/products.php?...dcountview=Yes AFL Filter End Plug, http://www.sonnax.com/parts/2031-afl...lug-o-ring-kit Large Ratio Boost valve, http://www.sonnax.com/parts/2170-lin...re-booster-kit Line to Lube Pressure Regulator Valve, http://www.sonnax.com/parts/1989-lub...egulator-valve TCC Regulator Valve, http://www.sonnax.com/parts/2025-tcc...ator-valve-kit Torlon Check Balls (you need 8), http://www.sonnax.com/parts/1689-checkball No Walk Case Busing, http://www.sonnax.com/parts/1981-case-bushing Requires careful installation, Cannot use a typical bushing driver...The bushing will break! Rebuild kit with Frictions, Bands, Steels, Bushings, Seals etc. http://www.ebay.com/itm/4L80E-Transm...-/360815789616 "HEG" High Energy Graphite Carbon frictions are superior to "Red"/"Blue"/"Tan" materials. Alto rates their proprietary "Red Eagle" friction material as the "Best". Raybestos rates their proprietary "Blue Plate Special" friction material as the "Best". These 2 companies both make HEG frictions as well, But have to pay royalties too Borg Warner because Borg Warner holds the patent on High Energy Graphite Carbon friction material. Alto & Raybestos wants to sell their proprietary frictions because they make the most money that way, Not what is best for the end user! |

|

|

|

|

|

|

#19 |

|

Always a work in progress

Join Date: Jun 2007

Location: Harker Heights, TX

Posts: 1,599

|

Re: 4L80E & TH400 Tech.

Clinebarger-

I am currently looking for a decent 4l80e to build up and I can only find the 91-96 cores in the price range I am comfortable with. It will be behind a 5.3 and will eventually have a turbo or 2. My current th350 wont hold fluid and is slipping real bad so I need to replace it. Can I control the 91-96s with the 03 computer? Can I add an aftermarket floor shifter later on down the road? I plan to do everything you have listed, can you explain why? Just for my knowledge, not questioning you at all.

__________________

USMC Retired Never trust a man who can't laugh at his own fart! 2010 Silverado Crew Cab 73 SWB 5.3/4l80e Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=695168 |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

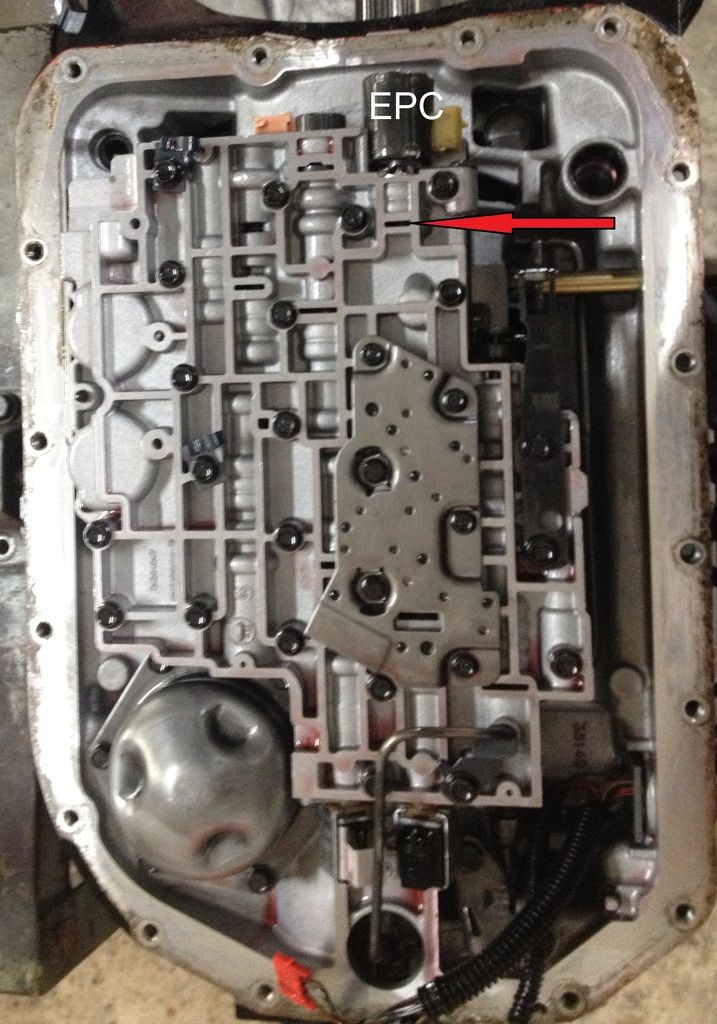

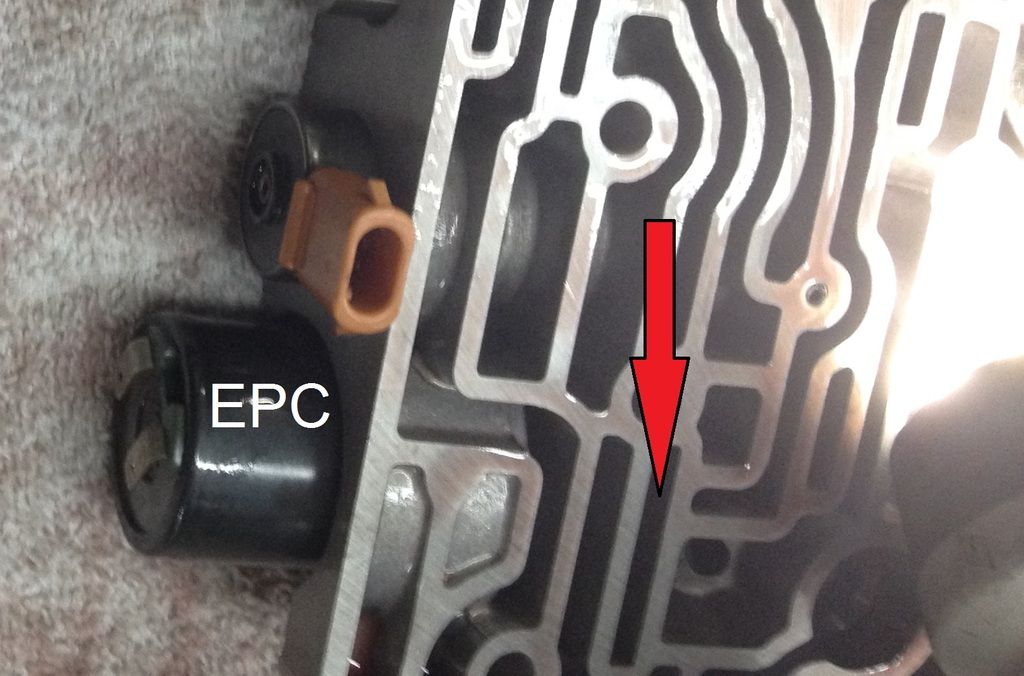

A 91-93 can be modified to work with a '03 PCM. '94-'96 will work with no modifications. I will cover the '91-'93 modification in detail because others might need this also.... '91-'93 models use a "Silver" Bosch EPC Solenoid that is not compatible with '94 & up PCM's, It was replaced with a "Black" EPC. It is an accepted method to just replace the EPC with a '94-'03 version, And most of the time it works fine, But in some cases it will cause line pressure issues, Besides if your rebuilding....Do it right from the Start!!! Parts needed.... '94-'03 EPC solenoid .093" drill bit Trans-Go Separator Plate part# 48-PLT-01 IF your core has the original internal harness, You will need a '94-'03 Harness First INDENTIFY your Valve Body! Parts get swapped all the time.... Notice the EPC is Black, This is a '01 Core. Notice the Arrow pointing to a slot in the Valve Body, This is the EPC Vent. A '91-'93 will not be vented.  Once the Valve Body is removed, Flip it over, Remove the EPC, At the Arrow, Drill a .093" hole through too the other side, This will Vent the EPC with a hole instead of a machined slot.  I am including this for Information, '91-'93 will have a EPC hole in the Separator plate, This is no longer needed now that you Vented the Valve Body, The Trans Go plate does not have this hole, You have now completed your conversion to the Later/Better/Compatible EPC solenoid. Picture of where the EPC hole is in the plate...

|

|

|

|

|

|

|

#21 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

I listed a lot of things that NOT EVERYONE will need, Do you have a max horsepower/torque goal? Slicks/drag radials? |

|

|

|

|

|

|

#22 |

|

Always a work in progress

Join Date: Jun 2007

Location: Harker Heights, TX

Posts: 1,599

|

Re: 4L80E & TH400 Tech.

Probably drag radials and enough horsepower to run low 10s to high 9s. I'm not sure on the power level needed to reach those numbers. It will be a while before I add the turbo(s) so I am trying to get the overdrive for now and slowly accumulate all the needed upgrades like the billet shaft. A basic rebuild is all I am looking to do for now due to the $$$ and time schedule.

Will I need to do a segment swap to be able to control the 4l80e?

__________________

USMC Retired Never trust a man who can't laugh at his own fart! 2010 Silverado Crew Cab 73 SWB 5.3/4l80e Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=695168 |

|

|

|

|

|

#23 |

|

Always a work in progress

Join Date: Jun 2007

Location: Harker Heights, TX

Posts: 1,599

|

Re: 4L80E & TH400 Tech.

Cline-

I got a 98 model with 80k on the odometer now that is in good working order. I want to just put it in for now, should I go ahead and do the AFL fix now? I want to get it up and running, and start collecting the parts for a proper rebuild. I want to overbuild the transmission to handle 800-900hp but I will probably live in the 6-700 hp area.

__________________

USMC Retired Never trust a man who can't laugh at his own fart! 2010 Silverado Crew Cab 73 SWB 5.3/4l80e Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=695168 |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Dec 2010

Location: Dallas, TX

Posts: 160

|

Re: 4L80E & TH400 Tech.

Cline, thanks for this thread, found it google searching for a few things on my 80E valve body rebuild-mod and it's absolute gold.

I have a question re: the AFL bore wear. How can you tell if it's bad? I don't think my 91 has ever been apart other than the fluid and filter I did at 78k. it has 93 on it now. Do you work at a local DFW transmission shop or are you "retired"?

__________________

2010 Basalt Black Porsche Cayenne GTS - Daily driver 1991 2500 Suburban, Black - 454/80E tow monster, soon to go under the knife... Again.  1979 16' Action Marine/"Johnny Cash" Merc Bridgeport Champ Motor - Metalflake Maniac |

|

|

|

|

|

#25 | ||

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Quote:

Symptoms of AFL wear are....Wrong gear starts, Converter clutch slip/Fall out Hot, Codes P0757, P0894, P0730.....If it gets bad enough....Clutch Burn-Up. Quote:

If ya'll want to check the Bore physically, Remove the AFL spring, Move the AFL valve 3/16" from the bottom of the bore & wiggle the valve, Compare that to how much wiggle it has when at the bottom. It is hard to explain "Feel" & "technique".... I stopped working at Transmission shops long ago, I work at a specialty Performance shop here in Fort Worth, We specialize in TH400/TH350/700R4/4L60E/4L80E performance builds, Ring & Pinion installs, And LSX swaps. PM me for contact info. |

||

|

|

|

|

| Bookmarks |

|

|