|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

New Crew Cab Project Truck....

Hello everyone. I introduced my self on here a few months ago, but i will go ahead and do it again now as well. My name is Taylor, i own a small fabrication and machine shop called Michigan Metal Works. Im no stranger to building trucks, or doing this type of work, going on 10 years now haha.

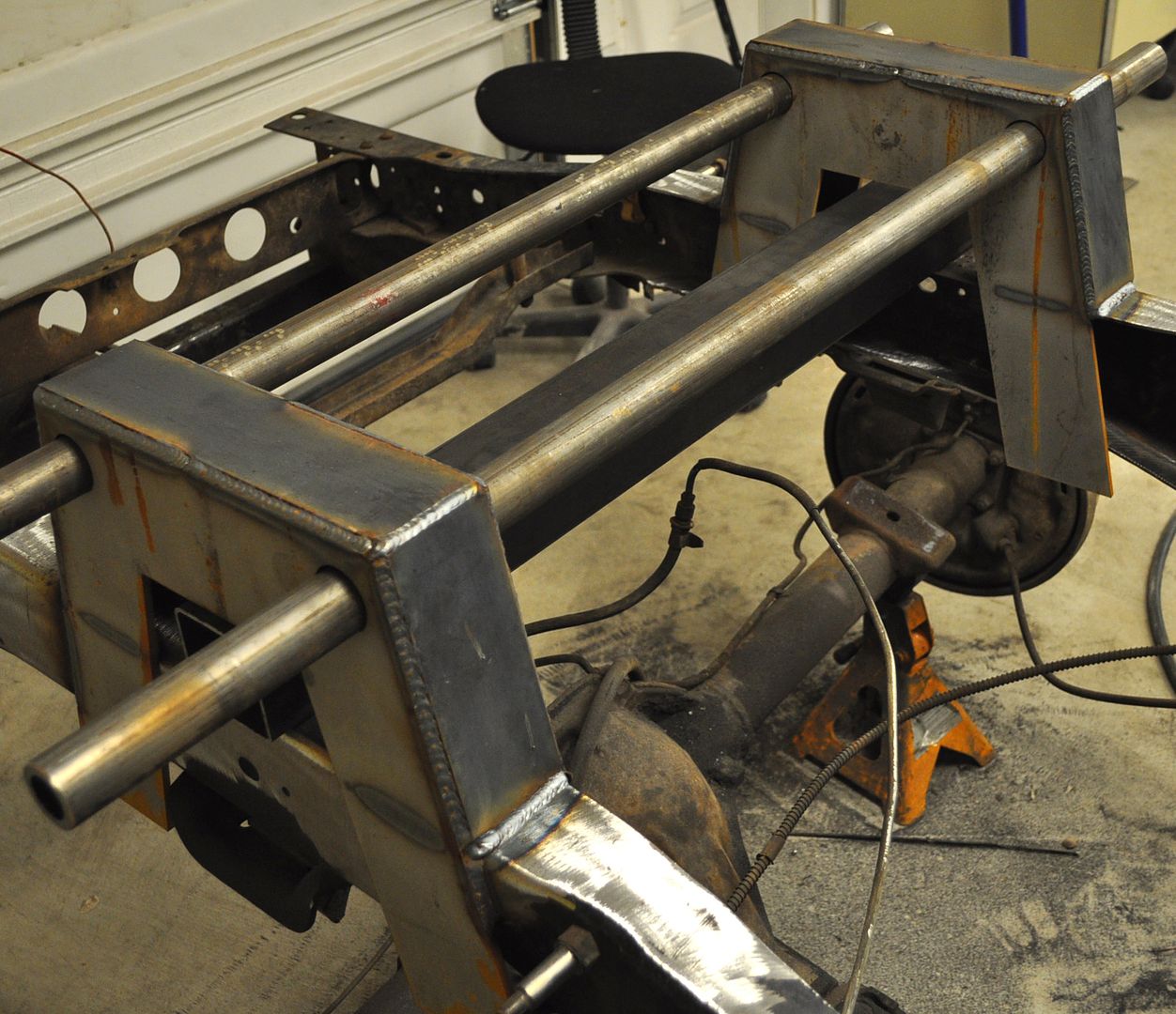

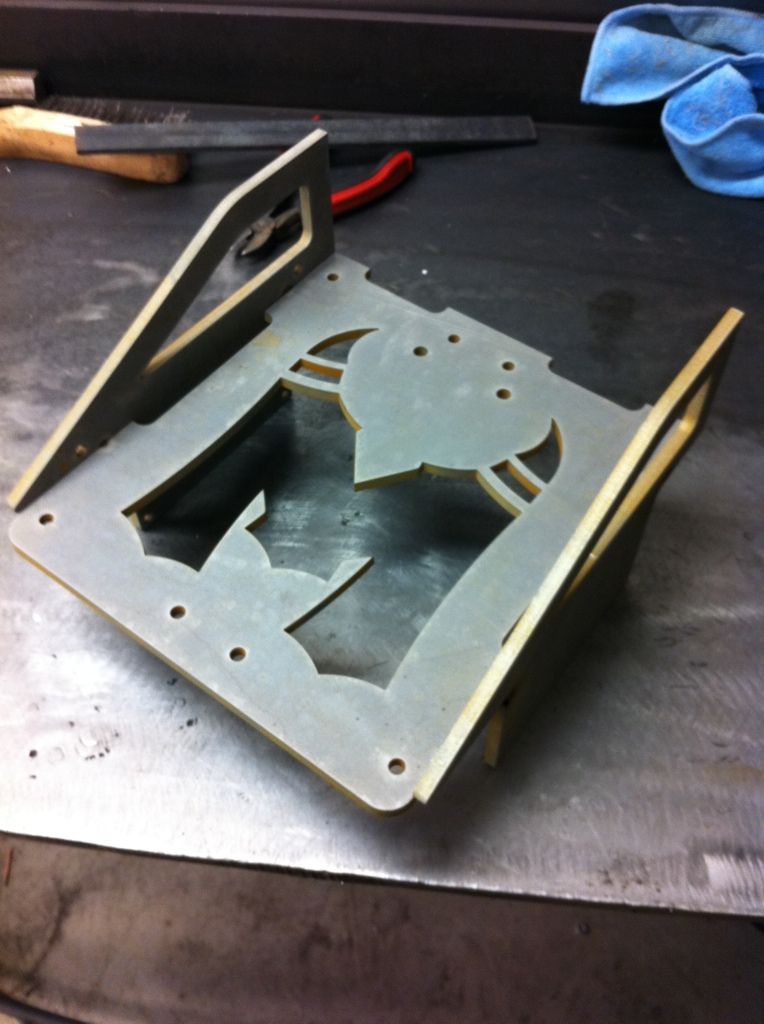

Anyways, I recently sold my previous daily driver truck which was a 2003 Dodge ram quad cab truck, layed complete frame and still hauled around my toys for me. When i sold it i really wanted to get something a bit different than normal for myself, so i happened to find a 85 Crew Cab c10 on this very forum for sale in texas. I contacted the seller, and contacted a shipping company, and a week later, the truck was in my shop. The previous owner had done a fair amount of work to the truck, the main of which was a LS swap to a 5.3 motor. the rest i could have lived without, becuase it made some serious head aches for me, with broken off leaf spring pearches, and off center rear ends.... it was a nightmare, but that motor install appeared to be very solid so i was happy. I pulled the truck into my shop friday of last week and started on it. I am building a very solid daily driver, weekend tow pig that will be layed out on 24" Centerline Rotary wheels, and 305-35-24 tires for some meat. It will have a full kicker audio system, with an ipad in the dash controling it all. Anyways, heres my start after 3 days now, im trying to work on it around customer orders and in my spare time after my work day, so im hoping to have the truck ready for paint at the begining of may. The day i got it: What im building:  The start: Gutted it friday night, stripped of every thing that needed to come off  Rear frame rails prepared for the notch. trimmed to 3" wide on top and bottom, so the notch will the tight and clean fitting. Dont mind the ext cord and rear end lol, i was trying to sweep around everything to clean it all up so i can weld the notch in tonite.   Starting the notch, going to lay frame on a 33" tall tire. Dont want the notch any bigger than it needs to be at all! So, measure 40 or so times, then cut it all once. Got it all cut out on the water jet and lined it up. The bars are there to help keep it straight, as well as keep it in line. Have not decided if im going to use them in the final design or not. Set the notch up with all fillet welds, and all .250 plate:    Then you weld. Its about a 2 hour procedure from start to finish to get the entire top welded up. You have to let the metal cool after some of the longer beads or your frame will turn into bananna, there is a lot of heat and pressure there. The longest bead you should run on something like this is about 8" total. I personally like to alternate sides after each weld that way it distributes the heat a bit better. Im gonna come back out after dinner and cut the frame, then cap in the bottom of the frame. enjoy.         center cut out, inside plated and fully welded.      Some accuair gear showed up, as well as my electric compressors that will back up my EDC, so i started to make a mount for them on the lower part of my frame on the passinger side.        That brings me to today, monday morning. After a long day in the shop working on other peoples orders, i will crank a bit on mine. I will post pics! Taylor |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|