|

|

|

#1 |

|

Registered User

Join Date: Jan 2011

Location: Lake Travis,Texas

Posts: 586

|

Old Bent Wrench

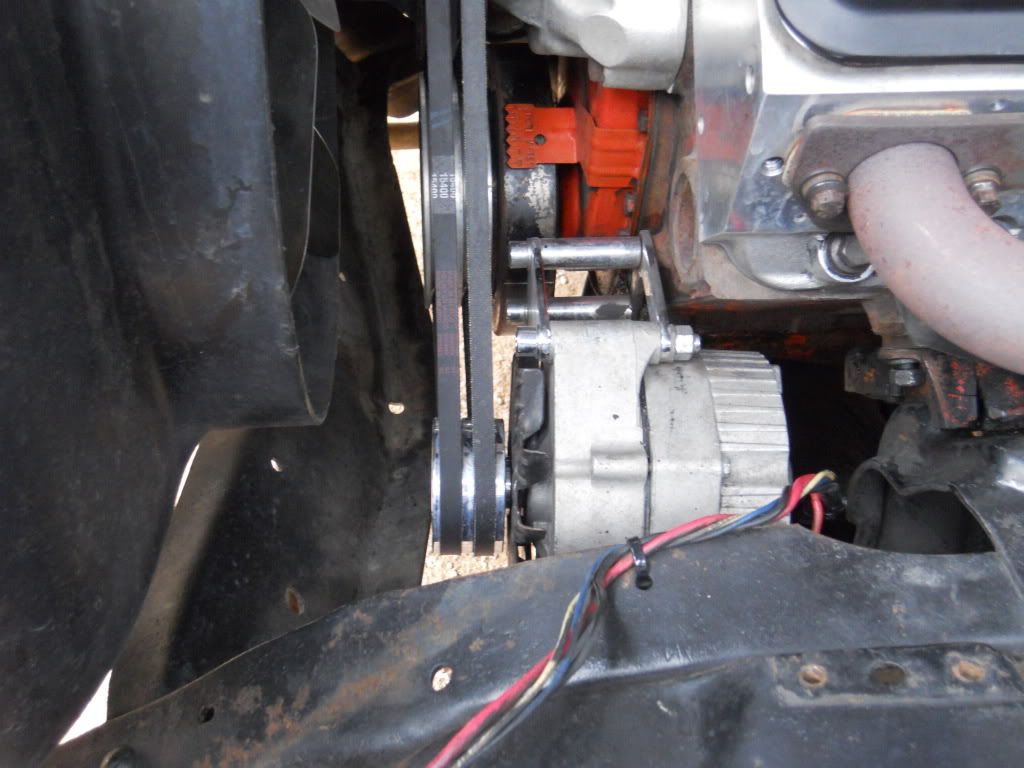

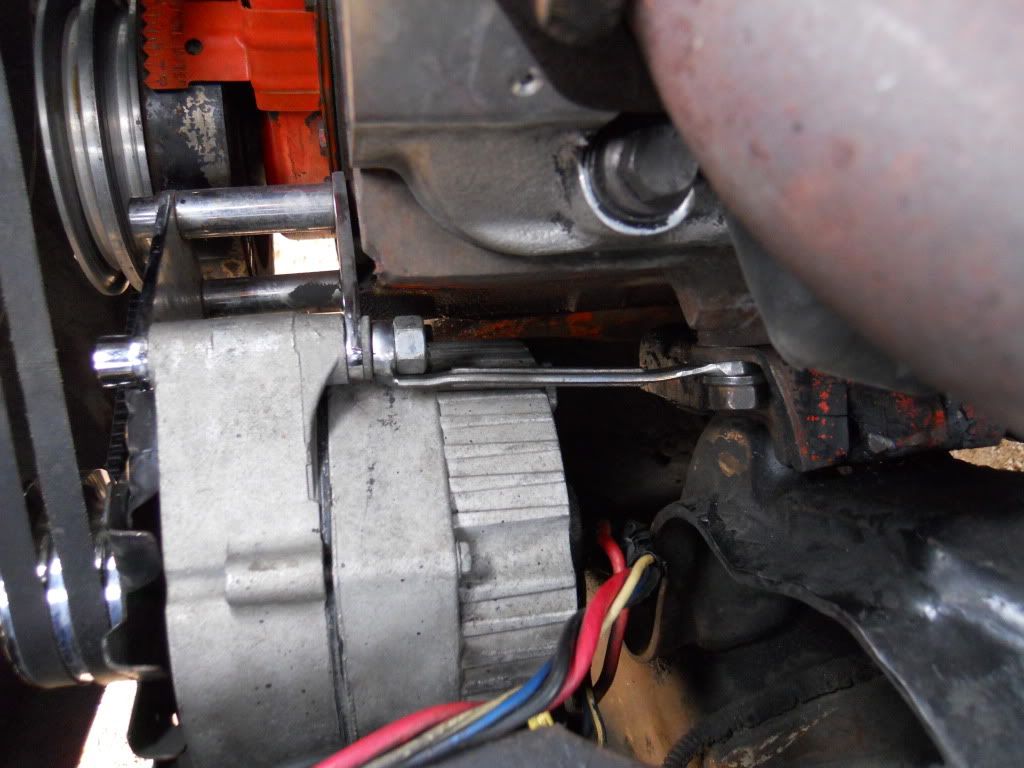

Just thought i would share the brace that I made for my alt. bracket.I got a slick alt. bracket that put the alt. down by the frame rail.This did two good things imo,first it gave me a better belt angle than the stock set up.Second, it hid the alt down low for a cleaner looking engine bay.The problem is the brackets themselves are a bit thin and the tension of the belt bent them slightly so the alt. pulley was crooked.

Also, when the engine was running,the bracket moved back and forth a bit.I was looking at the bracket and thought to myself ''Hey there should be a brace at the pivot point to stop the bracket from bending or moving'' or somthin like that.After a few minutes of looking for stuff to bend into shape, I found a couple old wrenches that looked to be about the right length.After clamping it in a vice, putting a torch to it, and hammering the crap outta it, I bent a 3/8-7/16 box wrench to 90 degrees on the 3/8 side.The back side of the bend fractured a little so I welded a bead across the gap to make sure it would stay in place   I ground down the 7/16 side to thin it down a bit and found a longer bolt for the motor mount and bolted the 7/16 side to it.Then all it took to bring the alt,bracket back into proper shape was lock washer as a spacer.  Now both my belts are tensioned the same and the bracket assembly is nice and still while the motor is running, and...NO MORE BELT SQUEALL!!!! This is my fist thread,Plz let me know what yall think of my work.Yall be good Flint70step

Last edited by Flint70step; 03-15-2011 at 06:57 PM. |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|