|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

TOTY 2006

Join Date: Dec 1999

Location: Magalia CA USA

Posts: 2,270

|

photo story of custom gas filler.....

Hi All,

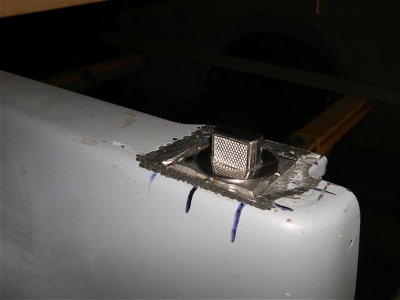

Here are a few shots of what I had to do to create the gas filler for the rear stake pocket of a fleetside bed.... I brought the gas filler assembly from a marine supply store for $50. (there are several kinds, mine has a center section that pops up down pressed, then you can unscrew it) The filler houseing is round, you can see where I cut it down to fit within the opening of the enlarged stake pocket.  What is not pictured is a small hose nipple that I welded onto the filler housing that is about 2 inches below the top of the bedside. This is for the displacement of air when you are filling the tank. Also, depending on how you place this within the pocket, you need to consider the placement of the hose clamp so you can access it from the hole that the tailgate tang goes into. Also consider how much room to clear the tailgate tang or cut the tang down a little bit.... There is the piece of metal that is the stop or the bottom for the stake pocket. When I opened up the hole at the top of the pocket, then I used a chisel and hammer to knock out this stop. It is held on by spot welds, and you make get lucky and have it pop right off if the spot welds are not that deep (as in the case with mine). I also made sure that when the cap is tight, it lines up with the bedside...     Here is a shot of the lower bedside with the 1-1/2" fillerhose and air hose hanging out. I used a 90degree bend of exhaust pipe from a local shop to make the turn at the bottom of the hose.  Here is a shot of the rear bed crossmember and you can see what I had to remove to provide clearance for the gas hose..  Two finished shots...   I also changed the way that my gas tank filler hose and air vent hose came out from the tank. If you look at a factory 67-72 suburban tank (or 69-72 blazer tank), the filler tube exits the tank at a 90 degree, or straight out towards the driver side, I changed my to angle back towards the rear driver side stake pocket. this was done by cutting and rewelding the tube, and allowed me to have no bends in the gas filler hose. I then moved the air vent tube, which is located in front of the gas filler tube on the tank, to the rear of the tank, or behind the filler tube, just to make it easier to access and install the hose onto this vent. One other thing to consider, since these types of filler caps are not vented, you may run into vacumn lock of your fuel. This is where no air can get into tank, and as your driving, the fuel pump is pulling fuel out of the tank, it then creates a vacumn in the tank, and when it builds, pretty soon your pump cannot pull anymore fuel out. Hence the use of vented cap on our trucks!! What I did to resolve this was to buy a $7.00 vacumn ball vent from a local motorcross shop. These go onto the hose of a gas cap for dirtbikes to allow the intake of air, but because they have a spring and ball bearing inside, nothing can come out, kinda like a one way ball valve... I just simply drilled a hole in the top of the tank, and expoxied the vent into place. Now air in be sucked in when needed, but I still have a closed system. Picture of these vent from ebay....  Have any questions, let me know..... I can take more pictures as needed. Last edited by John Fabris; 09-24-2006 at 11:29 AM. |

|

|

|

| Bookmarks |

|

|