|

|

|

#11 | |

|

Registered User

Join Date: Jan 2012

Location: Motown

Posts: 7,680

|

Re: 58 TRUK intro

Quote:

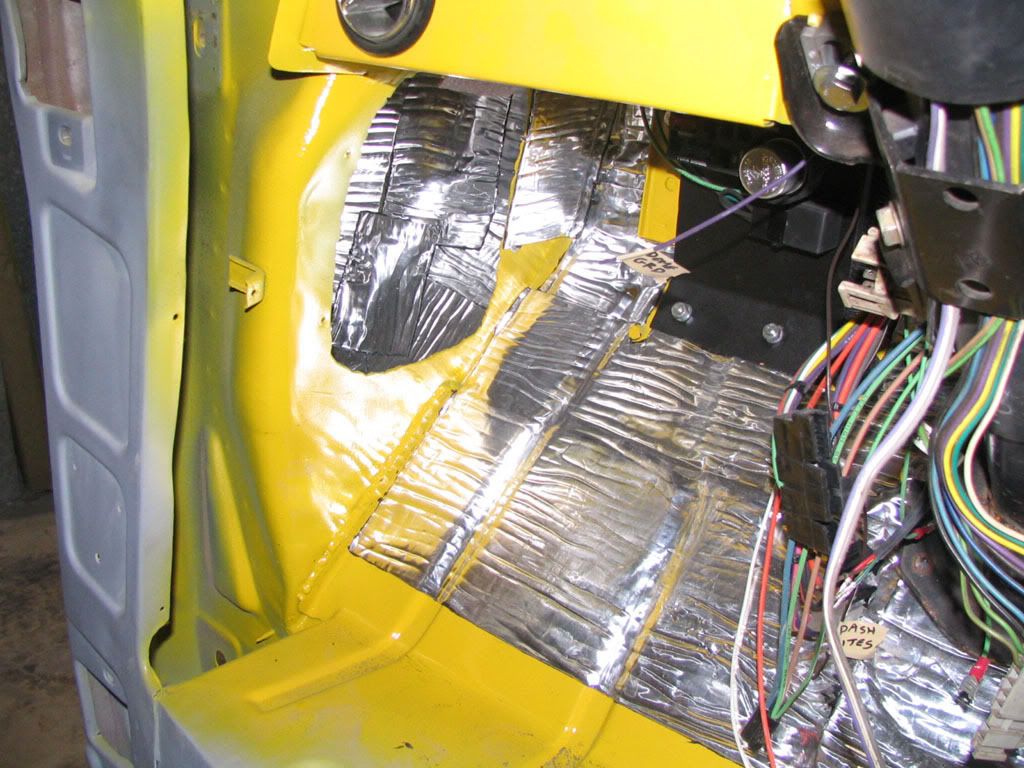

on a custom truck, that seam is just plain old fugly. my cowl and firewall were off by an 1/8'', i'll try to explain my method. i tried to find better pics of the process but obviously i didn't take any. there are 3 pieces of metal in the seam: firewall, cowl and inner cowl. if you pull the cowl vent off you will see the inner cowl piece. i started by spot welding the firewall to the the inner cowl from under the dash. you can see where the welding burned the paint on the top of the flange. then i cut out 8'' pieces of the seam, leaving 6'' pieces in between them. a little push pull to line up the 2 sides and welded the center inch together. then i went back and removed the rest of the seam, lined them up and finished welding it.   it did take a bit of filler to get the finished firewall flat, luckily it was a inny not an outy.  i left a little seam above my inner fenders, it's right next to the hood hinge and doesn't detract from the look. i welded up 100+ holes in the firewall, the easy way would be a flat sheet over the whole thing. but i think the original ribs make for a more pleasing look. also notice that i shaved my cowl vent. the cowl vent is the number one reason our trucks rust. leaves and junk get in the vent, add some rain and you have a recipe for rust. inner cowl rust, front cab corner rust and hinge pocket rust are all caused by junk in the cowl vent. if you do only one mod to your truck, shave the cowl vent...  added bonus of no cowl vent is no kick panel vents. this allows you to put some kick speakers in there...

__________________

cool, an ogre smiley  Ogre's 58 Truk build Ogre's 58 Truk buildhow to put your truck year and build thread into your signature shop air compressor timer |

|

|

|

|

| Bookmarks |

|

|