|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#11 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: '66 Sunbeam Minx Project - F20C/6sp/4-link/Discs...

Other stuff I've been up to (while avoiding the paint prep

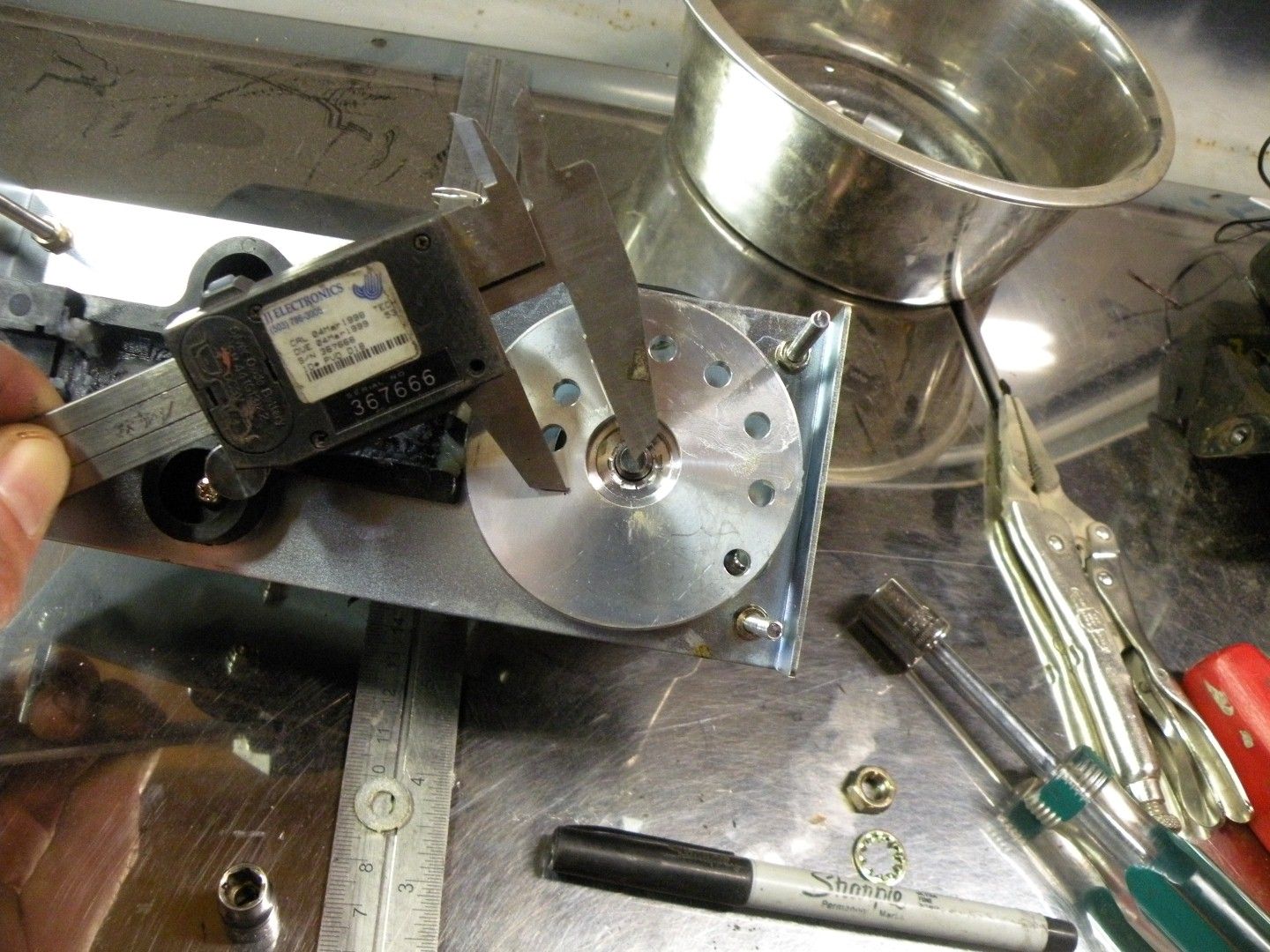

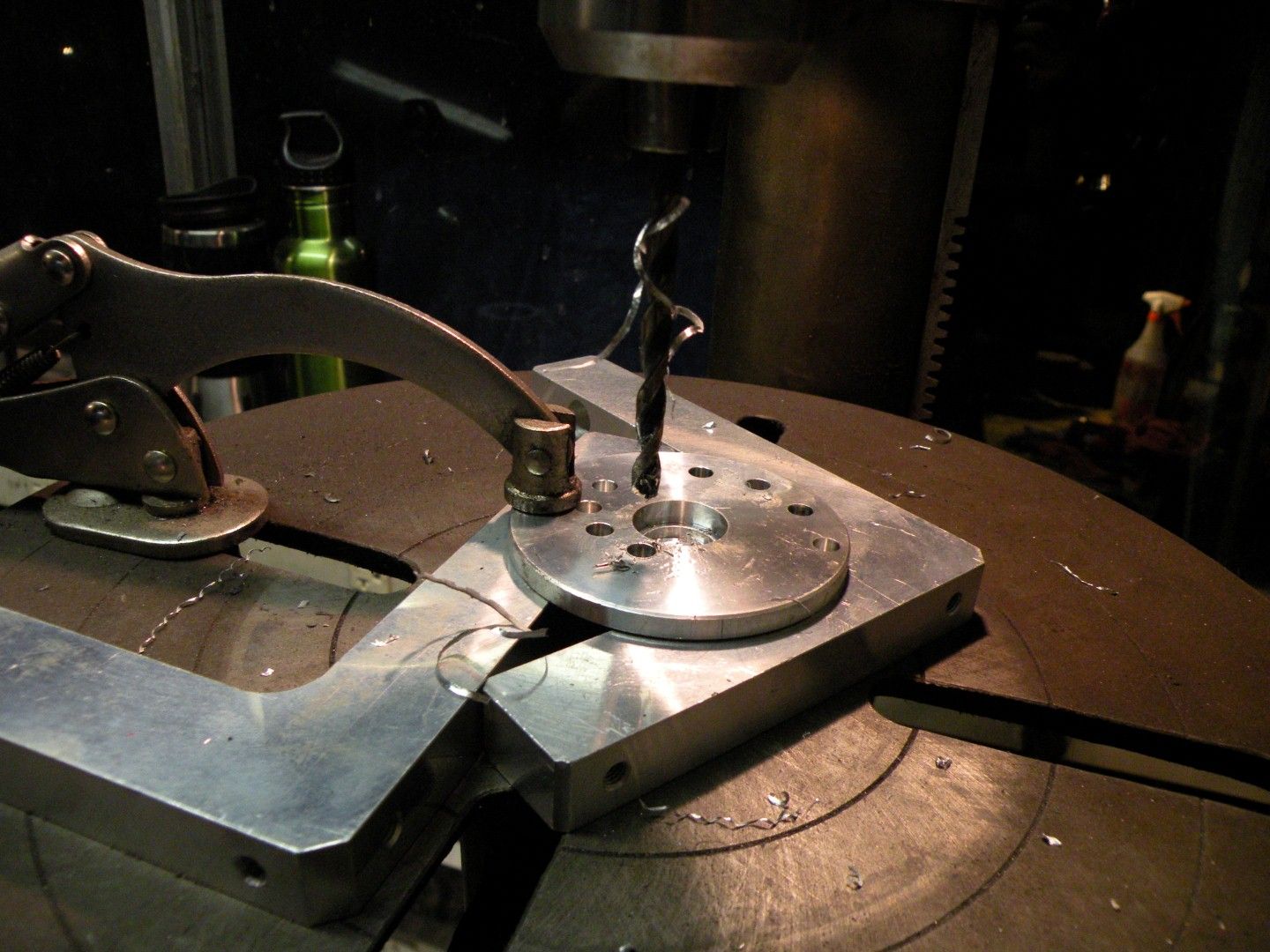

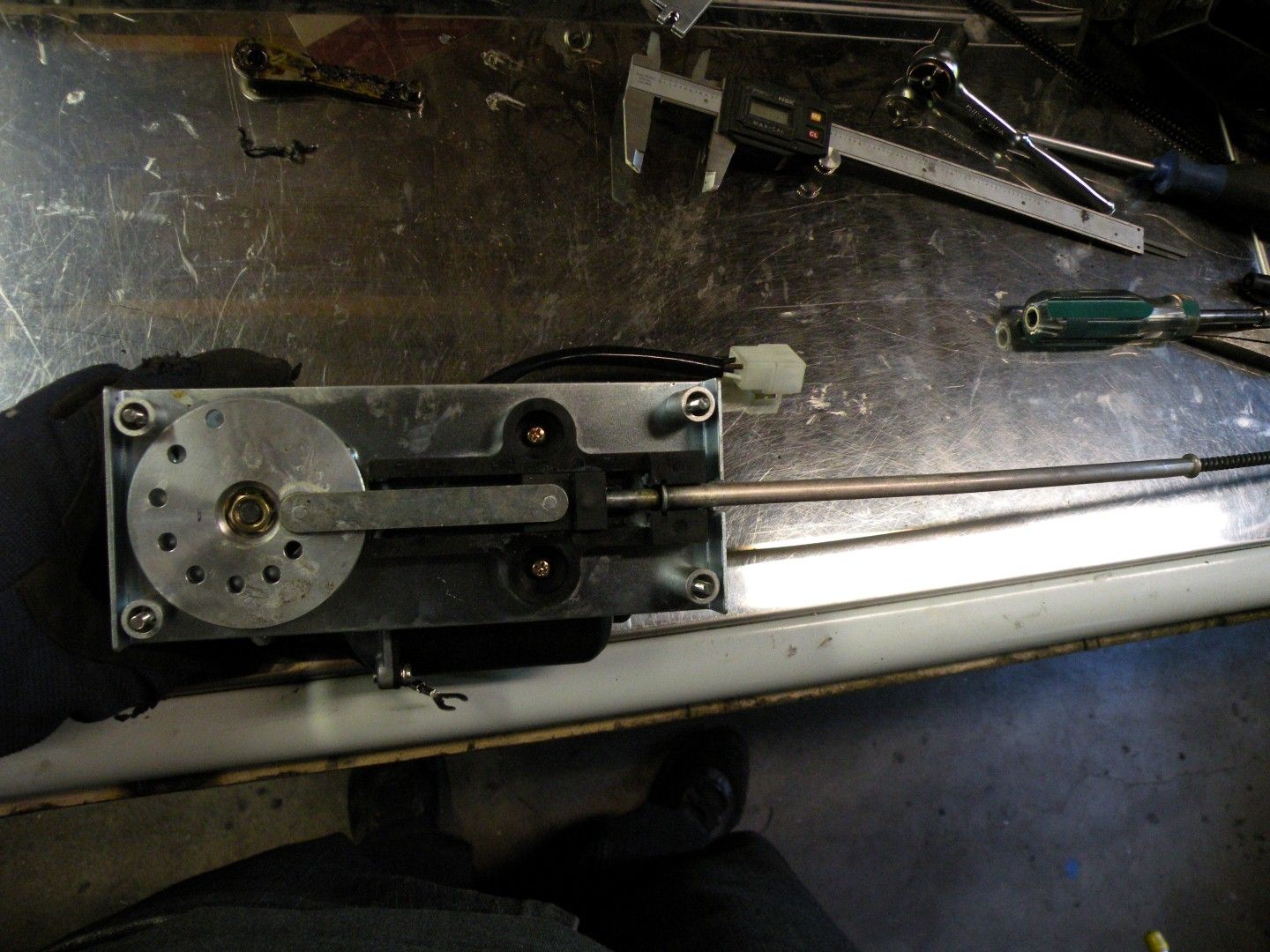

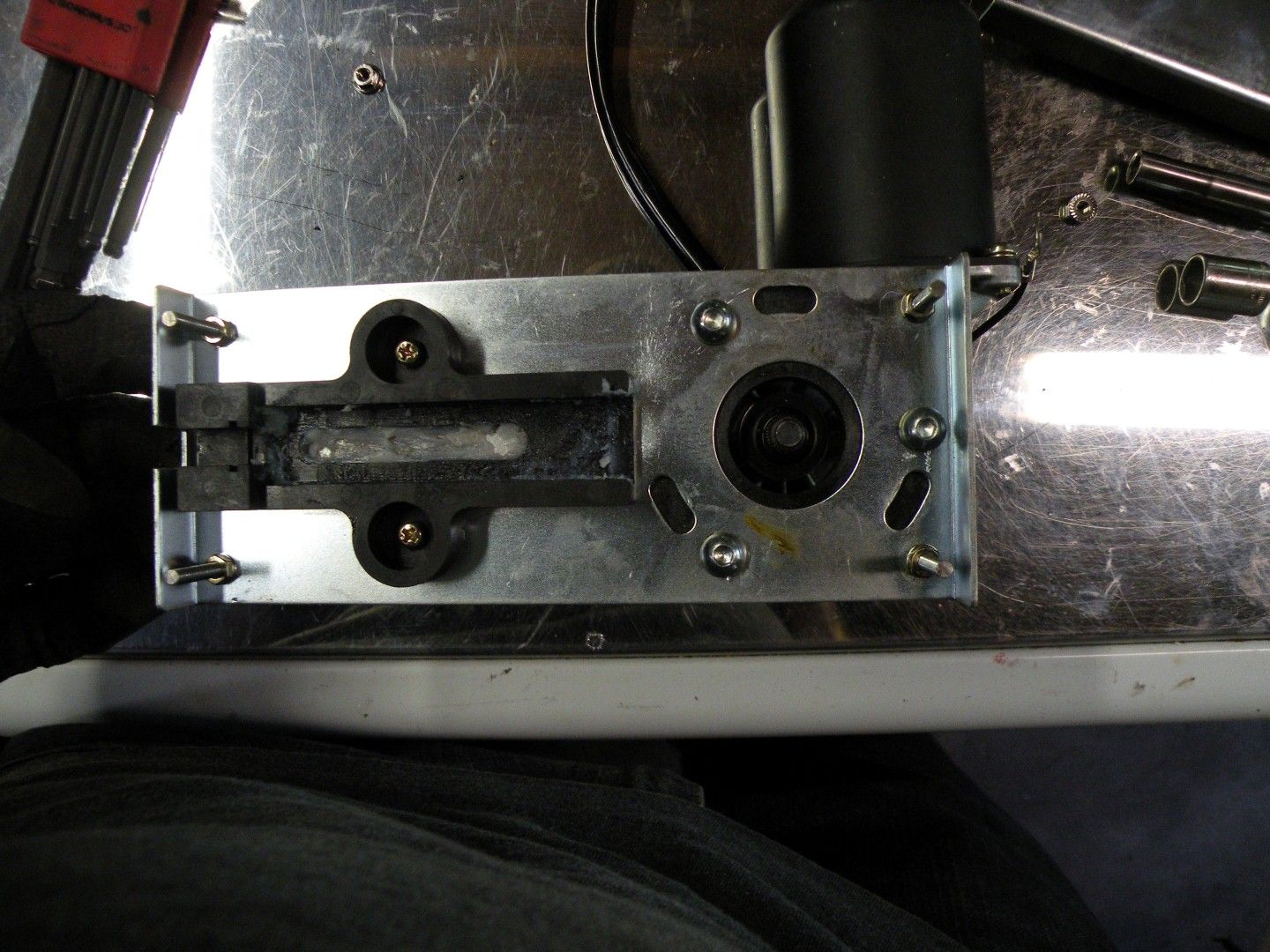

) )-Wiper Motor/Trans Relocation- The wipers' drive unit used to be located quite conspicuously on the driver's side inner fender under the bonnet (hood for 'mericans).  Since I've raised the inner fenders 1.5", and more importantly because it's super fugly, I've relocated it under the dash. I used the EZ-Wiring Wiper Motor Kit which employs the same cable drive function. I actually bought only the drive unit with plans to use the rest of the original parts of the system:  First order of business was to set the new trans to the correct radius based on the original unit:  I found that the radius I needed was smaller than the shortest throw on the EZ unit:  Drill presses are good for these predicaments...  Next I needed the secure the drive cable to the slide mechanism of the new unit. Back to the drill press:  ...and soldered together with the torch:  Reassembled (notice the motor orientation)  Motor clocked 90* (more holes drilled)  Complete assembly  Installed (now you can see why the motor clocking was necessary)   Those two funny-looking eye-bolts are not the primary mounts. The clamp around the motor is. The eye-bolts, which are only tacked in those pics, are my attempt at vibration and sound isolation. They provide lateral support only. The clamp is also semi-isolated via two layers of shrink-wrap and rubber washers sandwiching it at the stud. I went to these lengths because the noise during test runs was significantly louder when the unit touched the car.

|

|

|

|

| Bookmarks |

|

|