|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jun 2012

Location: Portland

Posts: 1,334

|

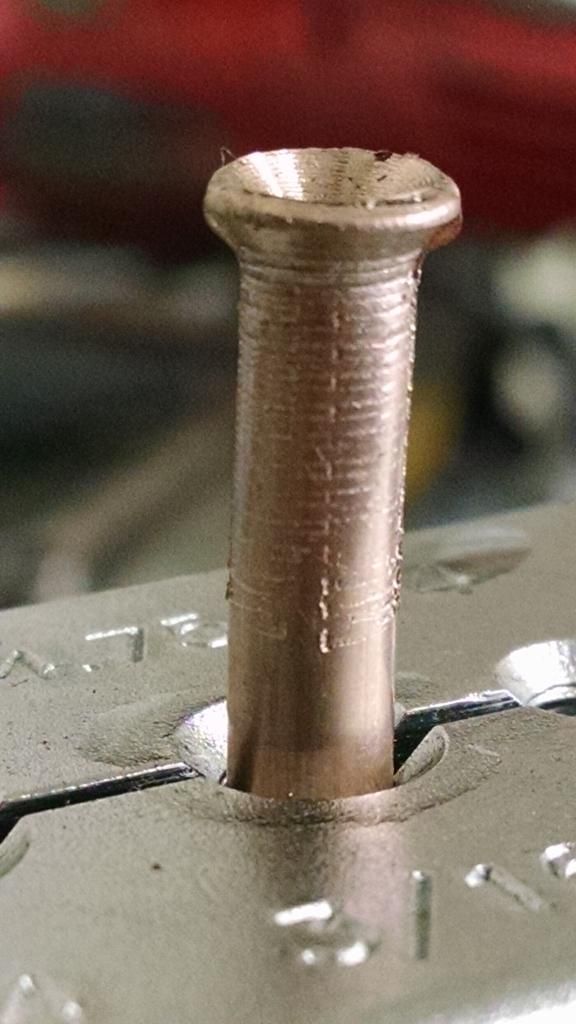

Flaring brake lines . . . need advice (pictures inside)

Hey guys,

Been practicing flaring brake lines. Using Summit's bulk alloy coil line which seems nice to work with. I have never done this before, so just been watching Youtube and reading. Here is the tool I'm using: Hoping it's not too cheap to give good results. Would have preferred a hyrdaulic tool, but got that as a wedding gift so would like to use it if possible. In any case, I have tried about 10 flares, and some seem to come out OK, but others I just can't tell. I'm at the point where I need to make about a 3" line to go between the rear diff split, and the first soft line. Here is how my ends are coming out (btw line is sticking out of the holder so far only for picture purposes):    Not sure if these would seal well or not to be honest, but I don't want to take any chances. Any advice would be welcomed. My process is as follows: 1. Cut the line 2. File it flush using a file and back side of mounting tool 3. De-bur the inside 4. Lightly chamfer the outside on my bench grinder (just to make it smooth and very slightly tapered. 5. Flip the mounting tool, have brake line stick out to bottom ring of die. 6. Insert die with a bit of brake fluid, press it in, trying to get it going straight down. 7. Remove die, press tapered bit in. 8. Done. Most of the time, the resulting hole after using the die isn't 100% centered, or 100% round, but a tad bit oblong, if that makes sense. Any/all help is appreciated. Thanks. |

|

|

|

| Bookmarks |

|

|