|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Repairing Sandblast Damage

In many cases warp damage from an overzealous operator will wreak havoc on sheet metal panels. Hopefully this will take away some of the mystery in repairs, if needed.

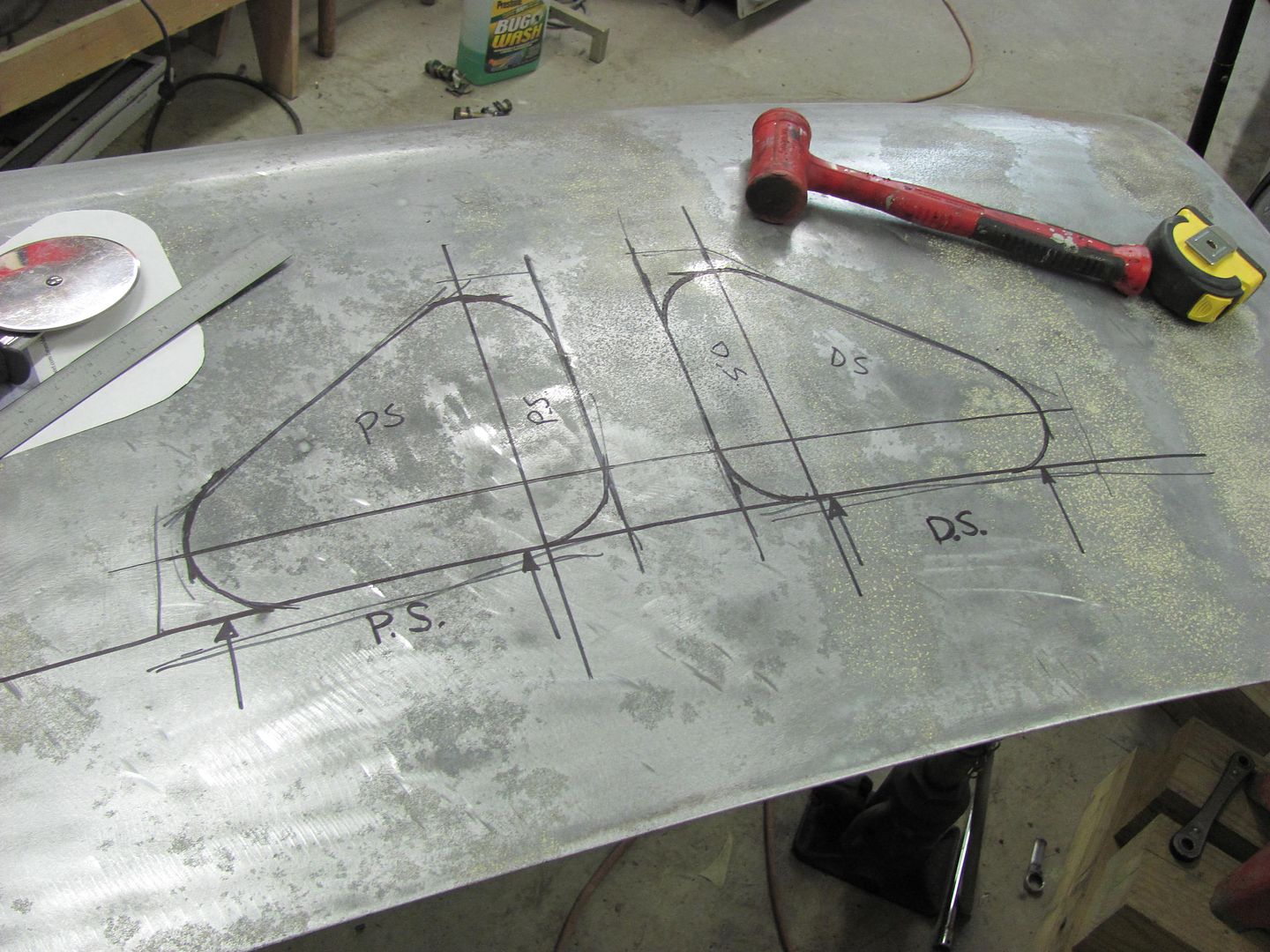

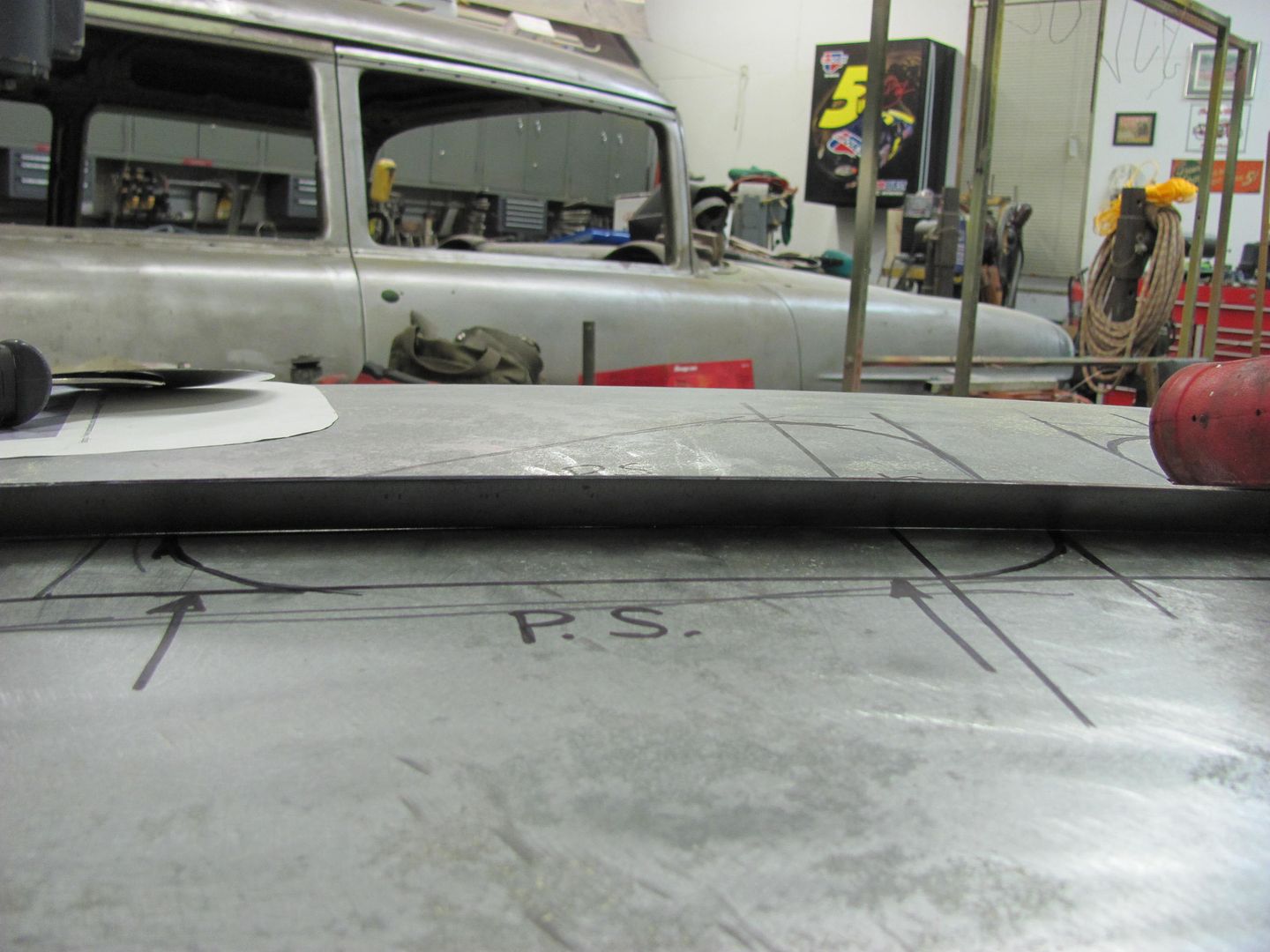

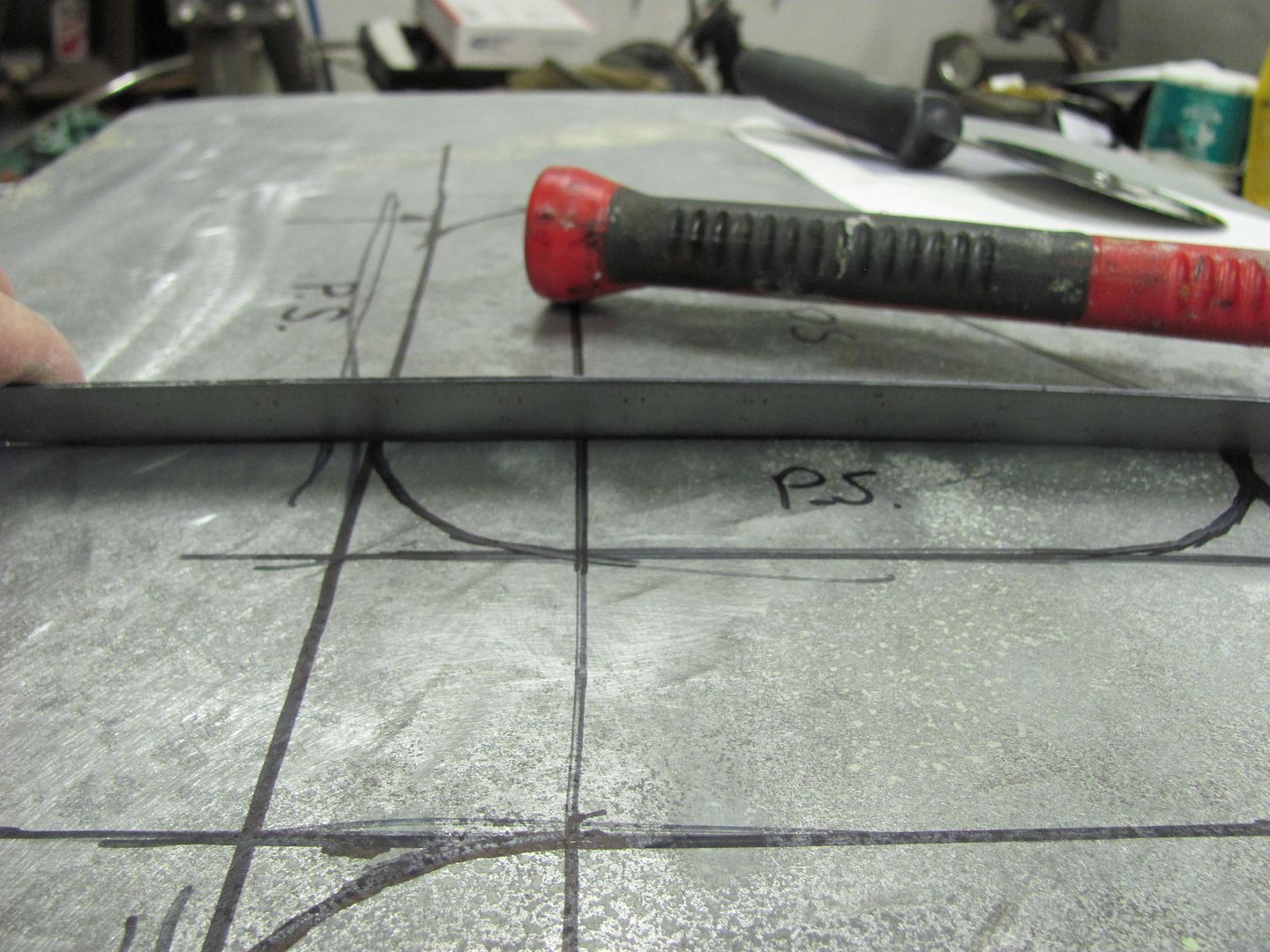

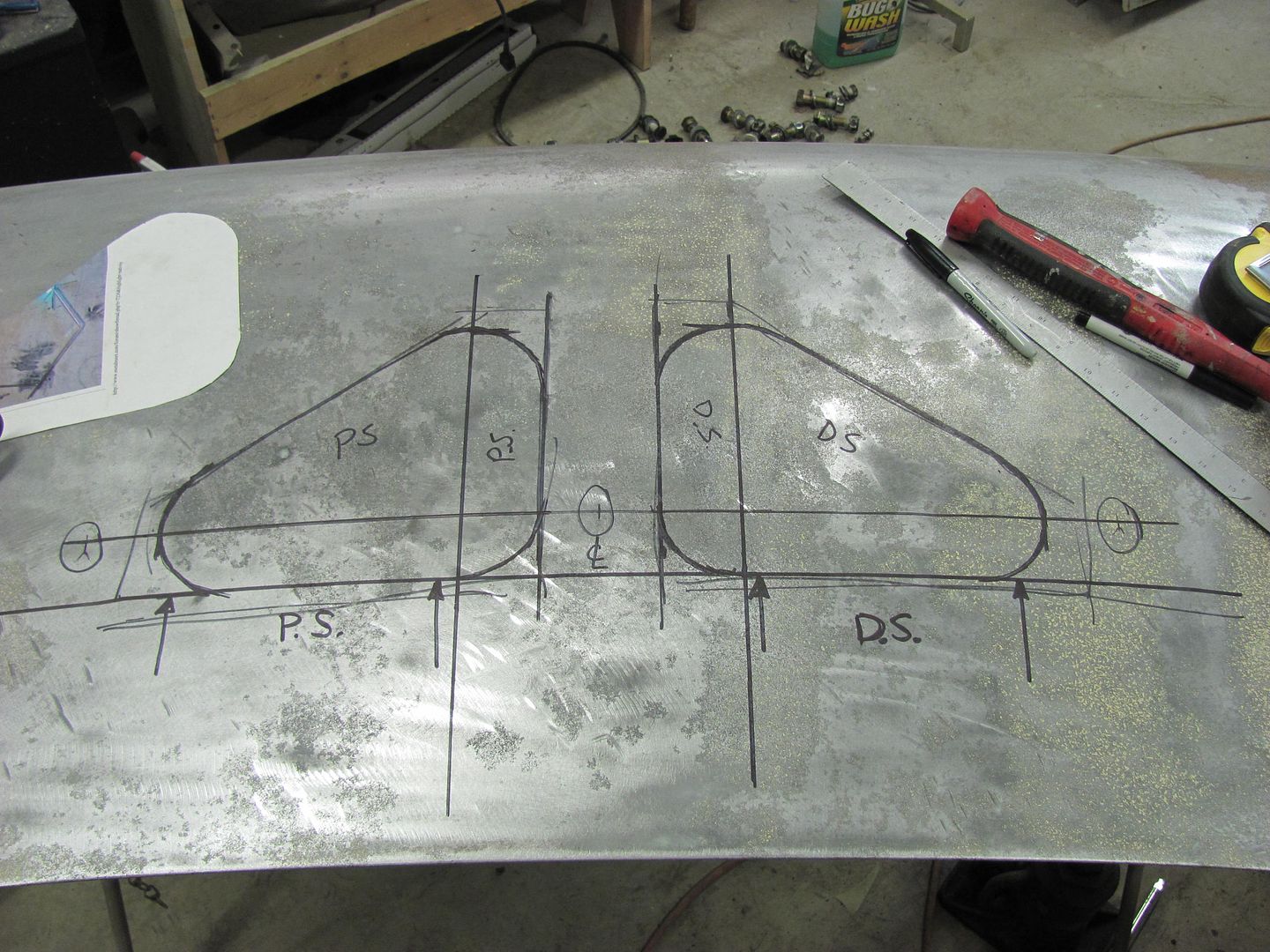

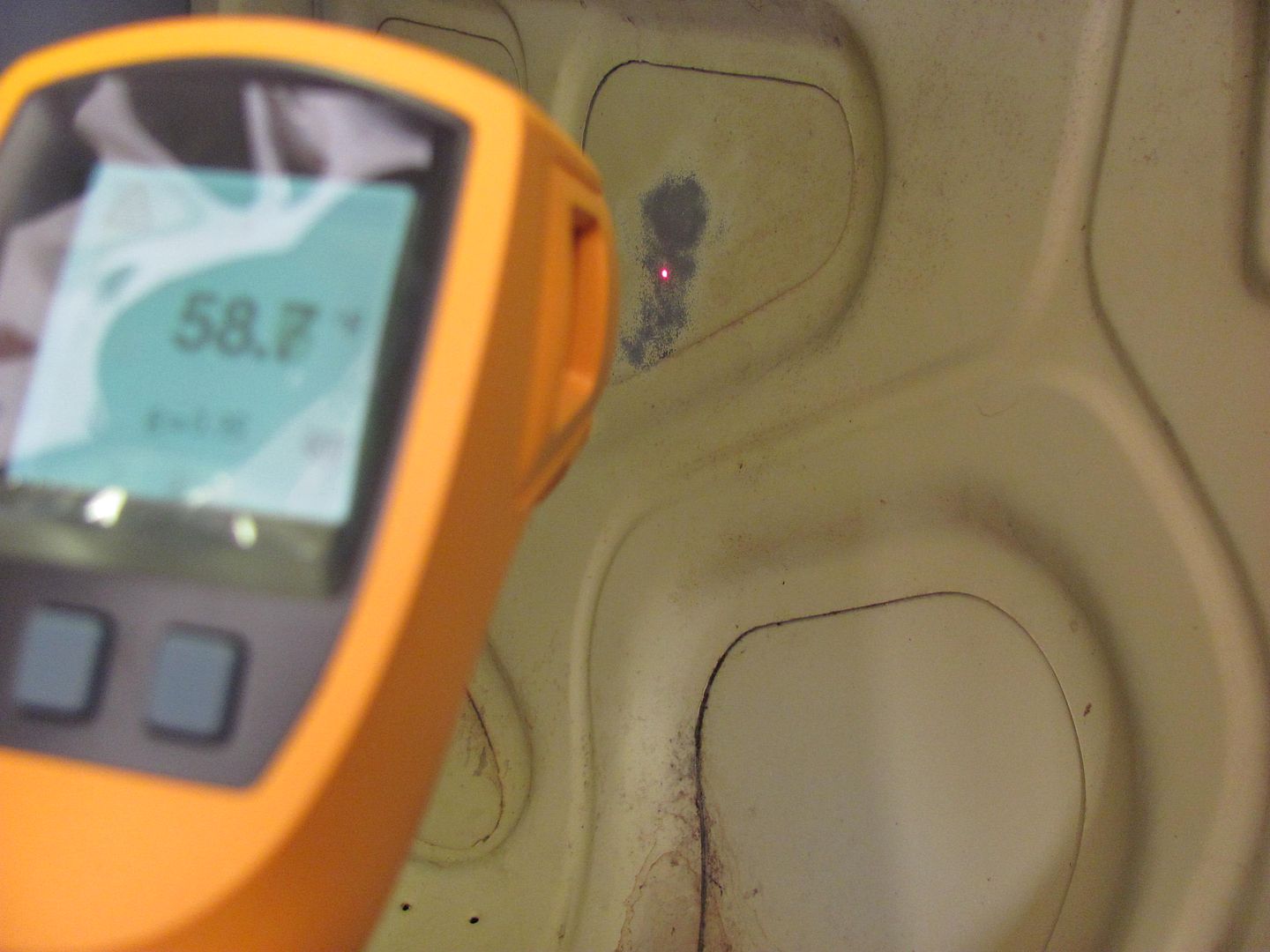

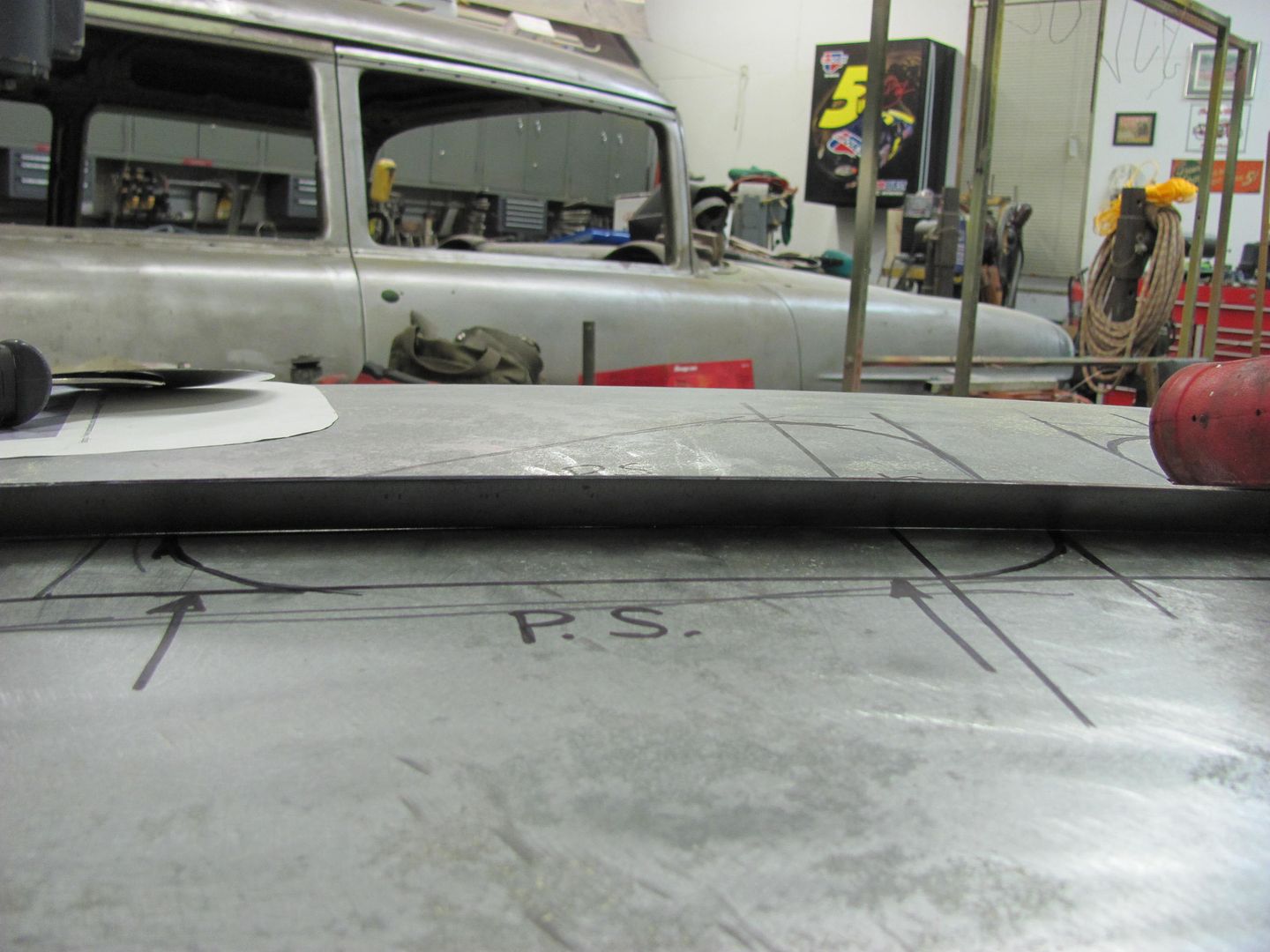

One of the members on another forum had the misfortune of trusting his 55 Chevy to a sandblasting expert ("been doing this stuff for thirty years!") and now is trying to regroup from the damage. His trunk lid was only sandblasted from the inside, and needless to say, too much pressure, too coarse media, one or both produced these results......  .......where the peening action caused the inside of the skin to stretch until it bulged inward. Discussion ensued as to the correct action to take to remedy the situation, with the primary differences of opinion being: 1) sandblast the outside to equalize the pressure caused by the peening (that caused a stretch on one side only) and then once equalized, shrink as needed to restore the panel to proper crown. 2) Shrink the panel as it sits, then take corrective action (stretch/shrink as needed) to restore the panel to proper crown. After various inputs, he was rather reluctant to try anything until a concensus is reached. So in the interest of learning something, I decided to help the guy out by conducting a test of both theories, and see what plays out. A local test subject was obtained, and also picked up a bag of medium grit Black Beauty from United Rentals. This was absolutely too coarse for use on sheet metal, but should help us to duplicate the results seen above.   Here is the sample trunk lid after sanding all the bondo off the top. I took some measurements, made a template of the inner brace opening we will be using, and laid out the pattern on the outside so we can monitor the progress of the different methods. A datum was drawn about 2" in from the forward edge and the center edge of each hole. This was chosen as it is approximately the center of the radius on either end.   Next, the panel was checked along the datum lines in both directions to give us a baseline for panel straightness, and we'll check along these lines after sandblasting to see what damage occurs. Where there was a bit of waviness, it was a minimal amount that would have disappeared with some high build primer and block sanding. Given our 57 year old test subject, I guess we're lucky it's that close.     And here's our test subject, awaiting sandblasting.  Well here's phase two of the test. The trunk lid was fitted into the blast cabinet.  You always hear about how the heat from sandblasting is what causes the stretching and warping of the metal. I never gave that theory much thought before, but while we are testing, this would be a good opportunity to add that in the mix. In an attempt to minimize any outside influence while we measured temperature, the flood bulbs inside the cabinet were unscrewed enough to keep them turned off...  Here is the thermometer we'll be using today....  And here is the baseline temp.....  This is the media we'll be using today, Black Beauty medium grit. A bit coarse for sheet metal, but we're trying to duplicate the damage seen on Joe's trunk lid, so we'll give it a go.....  Then I changed out the media in the cabinet, and started blasting. As I had opened the garage door and it's rather warm out, and I was rather slow in getting the media changed out, I thought I should check the temp again.  After clearing off the one hole, we had noticeable panel distortion from the outside. In checking the temp again, it had not moved since the last check.  So in essence, the temp of the panel did not change from the time we started blasting the one hole until it was finished. If you want to scream conspiracy, well it has gone up a whopping 1.8 degrees since the trunk lid was placed in the cabinet. I doubt seriously this can be attributed to a heat issue. I do have a refrigerant dryer on my air system, so that helps to keep the compressed air from getting warm, and yet the panel stretched still, despite the absence of any significant heat increase. It should be safe to say the damage is caused due to the peening action of the media against the panel surface. Stretching has long since occurred by the time any heat has finally shown up. Lastly, here is the noticeable damage to the panel, measured along the datum lines as before....     Just to show a comparison before and after........     Next phase of the test will be to sandblast one of the damaged areas from the outside to attempt to relieve the compression/stresses of that side of the panel and see how the panel reacts... I'll use our driver's side as that one showed a decrease in length, and well monitor what happens.....

__________________

Robert Last edited by MP&C; 10-22-2014 at 12:27 PM. |

|

|

|

| Bookmarks |

|

|