|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

Back to the Basics: Rebuilding a steering coupler rag joint

In an effort to contribute something good around here, I thought I'd do a pictorial of a little job I did this morning. Now, I know this is elementary to a lot of you, but I'm sure there's some folks who haven't ever done this before.

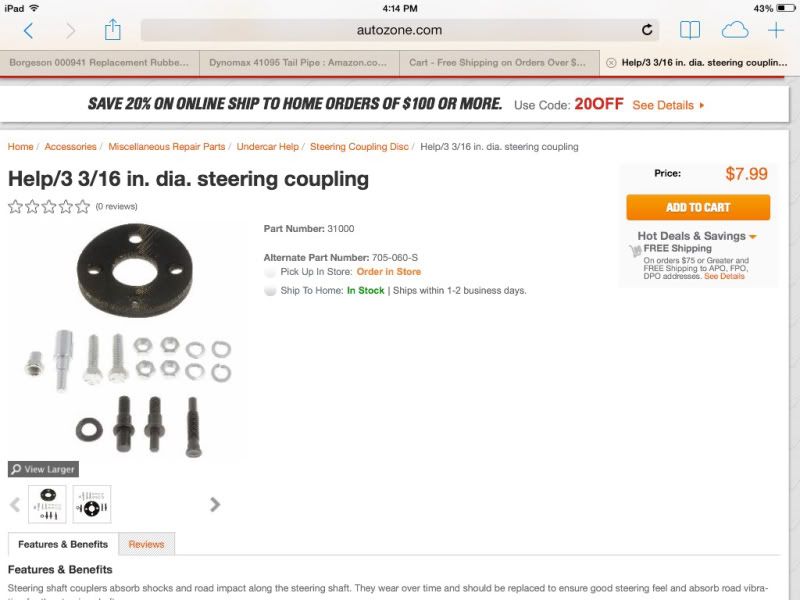

The back story is that the steering on my daily driver stepside was very sloppy with something like 1/4-1/2 turn of play in the steering wheel. All of the hard parts in the steering are sound and tight. The culprit is the rubber "rag joint" in the steering shaft. My truck had a bad power steering leak for many years prior to me getting it. This leak caused the rubber disc to be continuously soaked in fluid which caused it to fail. I had fixed the leak, but the damage was done to the rubber disc. There are three ways you can fix this issue. 1) replace the entire steering coupler for about 50 dollars 2) replace the coupler with an upgrade. I understand there is a Jeep part that works well. I wasn't interested in searching the junkyards and I believe in GM engineering of the original setup. 3) rebuild the existing coupler I chose method three since I'm kind of bucks down right now. The parts to do the job were 9 dollars out the door from Autozone. My time commitment was about 30 minutes total. I find my own part numbers online to avoid frustration at the parts counter   The part number is there on top of the package  Tools needed. A medium pry bar to pry the steering shaft off the coupler. 1/2 and 9/16 wrenches for the bolts and nuts, and a 7/16 12 point socket (a 12 point box end wrench would work but not quite as well if you don't have the socket) with ratchet and extension. Not shown, but you will need an angle grinder or aggressive sander also.  Here is the old coupler still in place. Notice I had shoved a couple of short lengths of fuel hose onto the stubs to remove some slack until I could fix it right. This is very ghetto, but also completely safe. GM engineered this in such a way as if the rubber disc completely failed, the two studs would hit the edges of the slots and allow full steering control. When the rubber disc fails, the slop allows this to happen. The fuel hose just alleviated that until proper repairs could be made.  Fuel hose removed. You can now see the studs and how they fit into slots. In the event of a total failure, that's all the play that would be allowed into the steering before the metal met metal. Hence the moderate but not deadly play in my steering.  Coupler removed. You can begin to see the failure near the bolts.  Take before pictures of top and bottom so you can reference to get it all reassembled properly afterward. Note there is a big bolt and a little bolt. It's important to get them in the proper place when reassembled.   Tap the two captured bolts out. It won't take much. Use a brass hammer if you have one to protect mushrooming the ends of the bolts. At this point you can see the failure very well.  Now, on the back side, grind off the ends of the pressed in studs. They are welded or peened or riveted somehow from the factory. Grinding them smooth removes that and allows us to remove the old studs.  Put it into a vise and using a hammer and punch, tap the remains of the studs out. This will free the rubber disc.     The kit comes with a knurled stud that you install into one of the holes. Just use a small hammer and seat it fully into place.   Reassemble with the included new hardware. I chose to use loctite on all of it for added security. I also reused the two original shouldered fine thread bolts rather than the new stuff included in the kit. The original GM stuff looked much better quality than the generic non shouldered bolts included in the kit.   Now, reinstall it back onto the truck.   The end cost was 9 dollars and about half an hour of work. The results are very much improvement on steering feel. The slop is now gone and the truck is back to driving comfortably with one finger on the wheel like we all know a well cared for GM truck will do. Any questions, just ask and I'll do my best to clarify. This is definitely one of those jobs that's easier to understand when it's on the workbench in front of you than when you're reading about it. It's all very intuitive when you're doing it yourself. Other than grinding off the little welds on the two stubs, it's very basic hand tool work that gives a very rewarding result in the way your truck drives.

__________________

I'm on the Instagram- @Gearhead_Kevin |

|

|

| Bookmarks |

|

|