|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: May 2000

Location: Petrolia,Ontario,Canada but working in Port Huron,Mi.

Posts: 1,772

|

Finally got my A/C working(PIC'S)

Well I had rebuilt my A/C and heating system about 5 months ago but never got around to getting the A/C working.

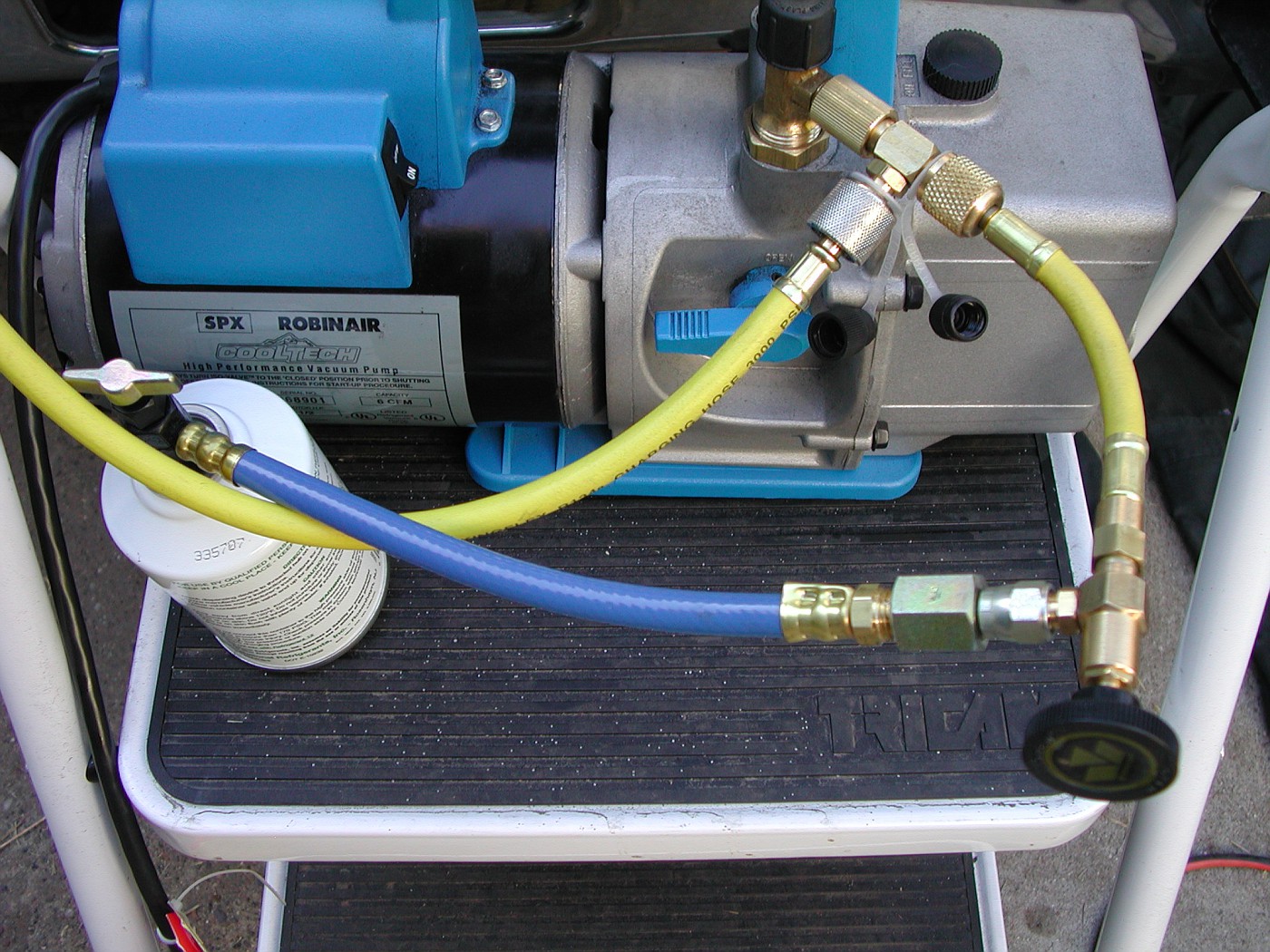

I got er done last week though. I retro'd the system from R12 to R134a and got rid of the POA valve. I used a POA eliminator from Old Air Products.Along with a fixed orafice tube(FOT) and a pressure cutout switch. The system cools O.K.,still some fine tuneing needed but I get about 50F at the vents.Not bad but I'd like it colder. Here's a few pic's of the process. This is the connection to the low pressure side of the system.That's the POA eliminator I had mentioned earlier.An integral pressure cutout switch comes with the POA eliminator. I just spliced into the existing A/C compressor wire.What it does is it shuts down the compressor and prevents the evap. from icing up.(thanks Brian)  Here is the high side connection at the compressor.I used a Sanden SD5H14 compressor.  I used is a RobinAir,1/2hp,6cfm vacume pump to evacuate the system before charging.  The gauge set I used.This allows you to measure the vacume you pull on the system as well as the pressure in the system while chargeing it. In this pic I'm evacuating the system.The gauges are at -29.5inHg,which is as far as you can go on the planet Earth.  The can tap I used.I ended up overcharging the system a bit.I used four(4),12oz cans of R134a to charge it up.  Killin time while evacuateing the system  I connected my can tap to my vacume pump via an adaptor I bought at Car Quest.This way I can eliminate the chance of air getting in the system when I have to change cans during the charging process.  I had to "jump" the cutout switch during the first bit of charging.The compressor would not engage untill some pressure was in the system.  Just an overhead view of things.  This is the top tube of the evaporator core.Condensing like it should,cool to the touch but not iceing up.  And the bottom line.The line on the right is the FOT.It meters the amount of r134a that got through the evap. core.It function like the TVX valve on the old POA system.  Like I said I still nedd to "tune" it a bit.Might need to put in a smaller FOT or take out a bit of R134a.Worst case would be a new parallel flow condensor.I have the orig. type in there now.Through the reading I've done the orig. condensor design may not work that well when retro'd to R134a.

__________________

71 blazer,350SBC,approx.375HP,700R4,factory GM TPI.Dual electric fans,33x12.5x15 ATR on stock suspension. Petrolia,Ontario,Canada but working in Port Huron,MI. See ALL my Blazer pic's HERE Last edited by augie; 04-13-2011 at 01:00 AM. |

|

|

| Bookmarks |

|

|