|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,927

|

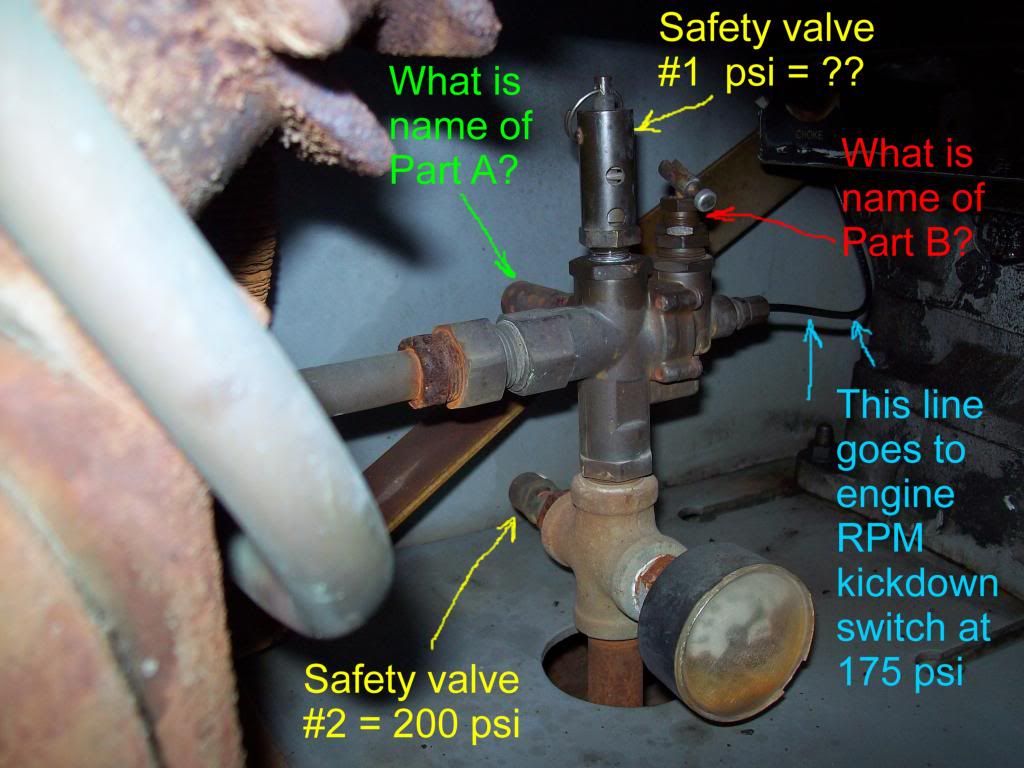

Dangerous compressor! What part needs to be replaced?

Hello!

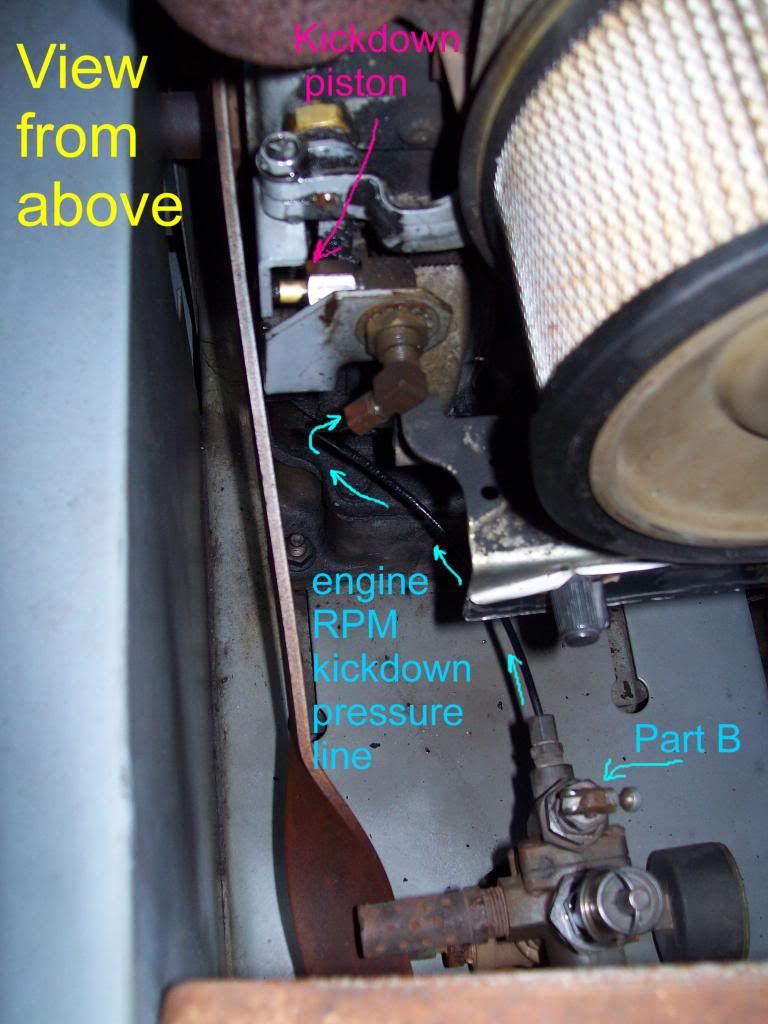

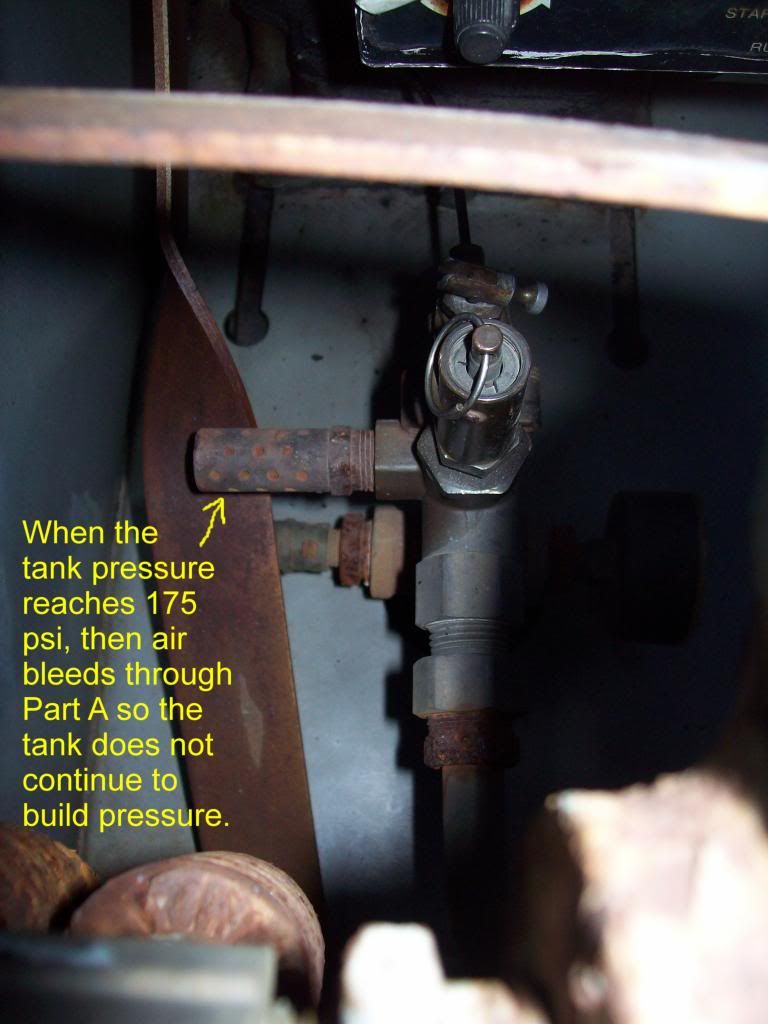

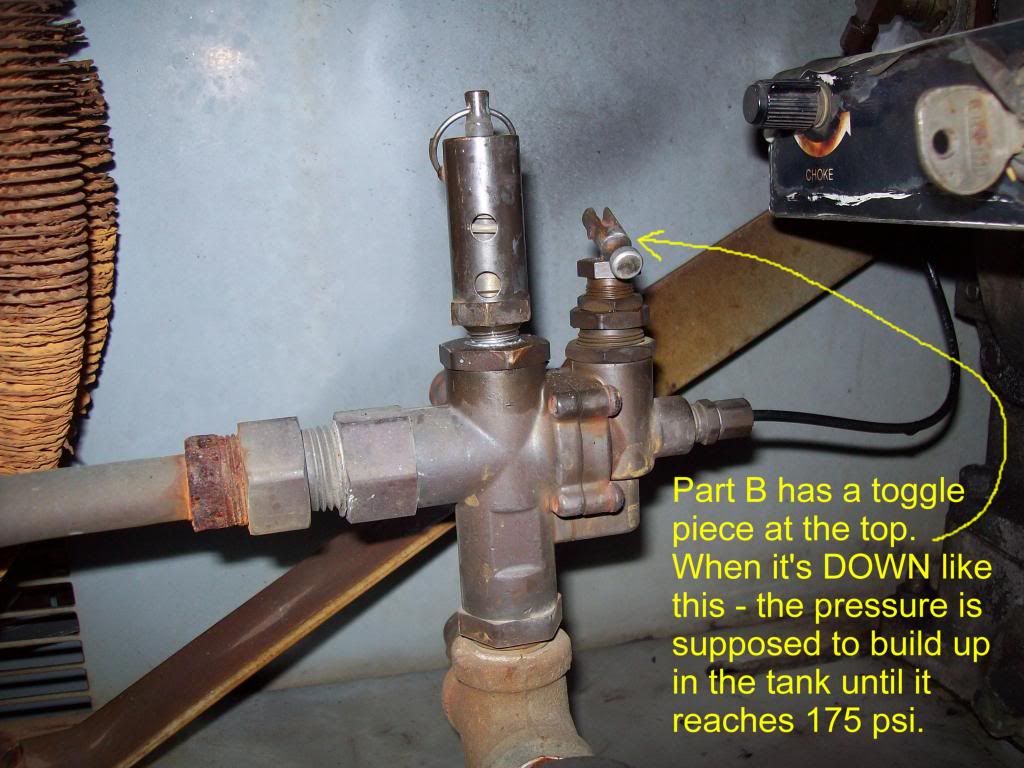

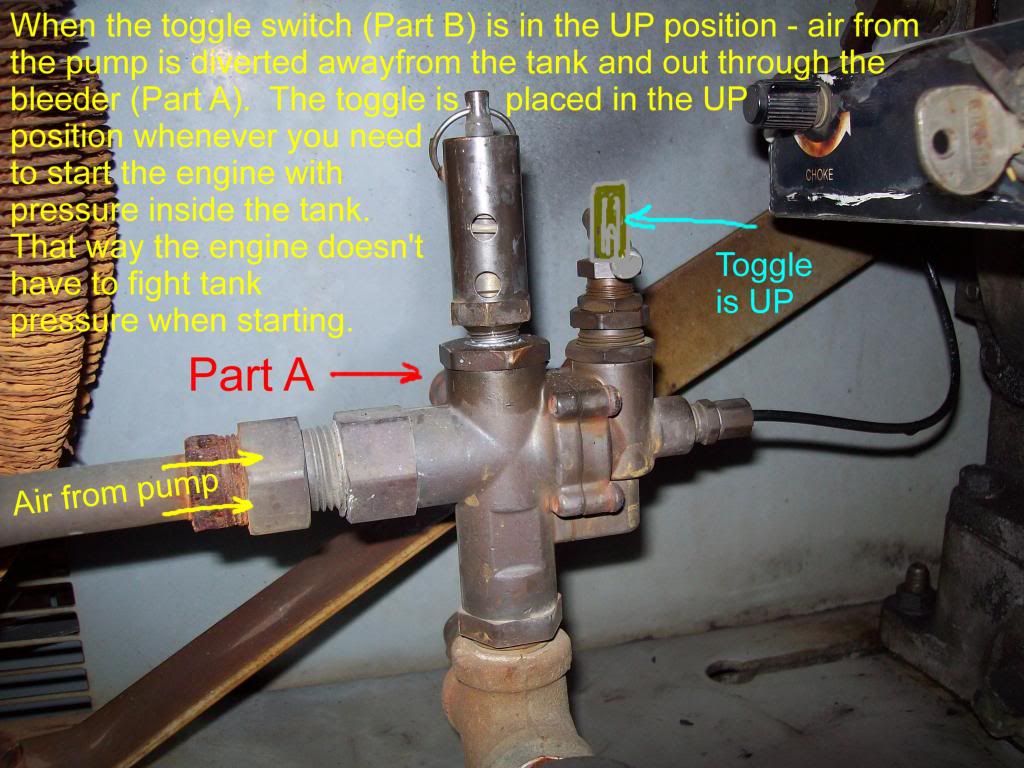

I think my compressor needs a switch or valve replaced. Please help if you can so I don't waste money or make a dangerous repair that is incorrect. I have a new to me (used) Ingersoll Rand T30 compressor. Kohler gas engine and a 2 stage pump on top of a 30 gallon tank. It has some age to it but it makes good air pressure. The pressure builds to 175psi at which point a switch is supposed to divert air away from the tank and out a bleeder valve. That way the tank will not continue to build pressure above 175psi. Well, the switch does not work properly. I think it is the switch I have labeled "PART B" in the photos. It has a toggle piece at the top so that you can manually activate the switch. Under normal operation, the toggle is DOWN and the switch operates automatically. Here's what I think happens, but I really don't know. So I'm asking the experts here. When the switch works properly, at 175psi, it allows air to flow through a thin tube which activates a piston switch to move an engine kickdown lever which slows the engine RPMs. At the same time, air is diverted away from the tank and out through a bleeder. This is all supposed to happen AUTOMATICALLY when the toggle is in the down position. As pressure in the tank drops from use, the switch closes the bleeder and builds air up in the tank again. The engine RPMs kick up so the pump makes air faster. The cycle continues as long as the compressor is "ON". Right now, the tanks pressure builds above 175psi and the switch does not activate. If I tickle the switch when pressure is above 175psi, it usually activates. I got 200psi last night and the safety valve blew off pressure. That's NOT supposed to happen! Yikes! Please see the pictures below for additional info.

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

|

|

|

|

|

#2 |

|

The One And Only !!!

Join Date: Jan 2007

Location: Hole in the woods Florida

Posts: 4,567

|

Re: Dangerous compressor! What part needs to be replaced?

Part A in your last picture is called a unloader, That's the faulty part causing your issue. There's no rebuild parts for them that I've ever seen (I'm in this business) so a complete unloader assembly will likely solve your issue.

Here is a adjustment procedure you can try to see if that corrects it..... You can also buy parts at Master Tool Repair which is where I get mine, You'll need your compressor model number to get the correct one..... Good Luck

__________________

93 Jeep XJ 88 Buick La Sabra Toys; 88 TA-GTA in the works.... 97 GMC Ext. Cab 502 Crate 5 Spd......Sucks Gas But Haulz Azz !  The primary function of an Engineer is to make it difficult for the Fabricator and impossible for the Mechanic. "Why go out preserved when you can go out beat up, worn out, sliding in sideways screaming, Holy Sh!t What A Ride" !!!

|

|

|

|

|

|

#3 |

|

Hand Crafted C-10

Join Date: Aug 2006

Location: Burien, WA

Posts: 5,180

|

Re: Dangerous compressor! What part needs to be replaced?

Lugnutz65,

I don't know the answer but thought I'd toss in a thank you...this is how we get our FAQ answers on the board so the next guy can learn through the FAQ forum. Also, your's is the kind of picture/explanation our tool forum guys need for diagnosis...perfect; thank you! Good job and welcome to our Tools, Shops and Shop Safety team! BTW---looks like the guys are well on their way to explaining your dilemma. Cool Beans!

__________________

. Forum Guidelines and Rules

Buying and Selling Code of Conduct Become a Board Supporter! Truck FAQ Ellen... the boards artsy-fartsy, eclectic, truck-lovin' gal-member... |

|

|

|

|

|

#4 |

|

I am a Referee of life.

Join Date: Jun 2000

Location: Greensboro N.C.

Posts: 13,992

|

Re: Dangerous compressor! What part needs to be replaced?

Even if they have a rebuild kit,don't bother with it.I've never rebuilt one on a compressor but I did "ONE" on a pressure washer.When I replaced it,I was told by the parts guy(not the one there when I bought the kit) that the rebuild kits for unloaders(for either type machine) are only worthwhile if it's nearly new.The brass parts wear in them and usually by the time you buy the kit,the parts that are worn and the labor to rebuild,you have more in it than a new one one.I've replaced a few on compressors and tons of the ones on pressure washers.I've taken quite a few apart just to see the wear and all were pretty well worn.

They are actually considered a wear item on pressure washers and can be in bad enough shape that the machine will not build proper pressure.They can also be adjusted to tight and cause pump failure.I'm pretty sure they do the same on compressors.

__________________

The 47-present Chevrolet and GMC Truck Message Board Network,it's owners,moderators,members,and associates of any type should not be held responsible for my opinion. You can't fix stupid,not even with duct tape. "My appearance is due to the fact that "GOD" does punish you for having too much fun!" Barrett-Jackson has perfected alchemy,they make rust into gold! "You can lead a horse to water but you can't saddle a duck" "Cleverly disguised as a 'Responsible Adult' "Sometimes your Knight in shining armor is just a retard in tinfoil" |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|