|

|

|

#726 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

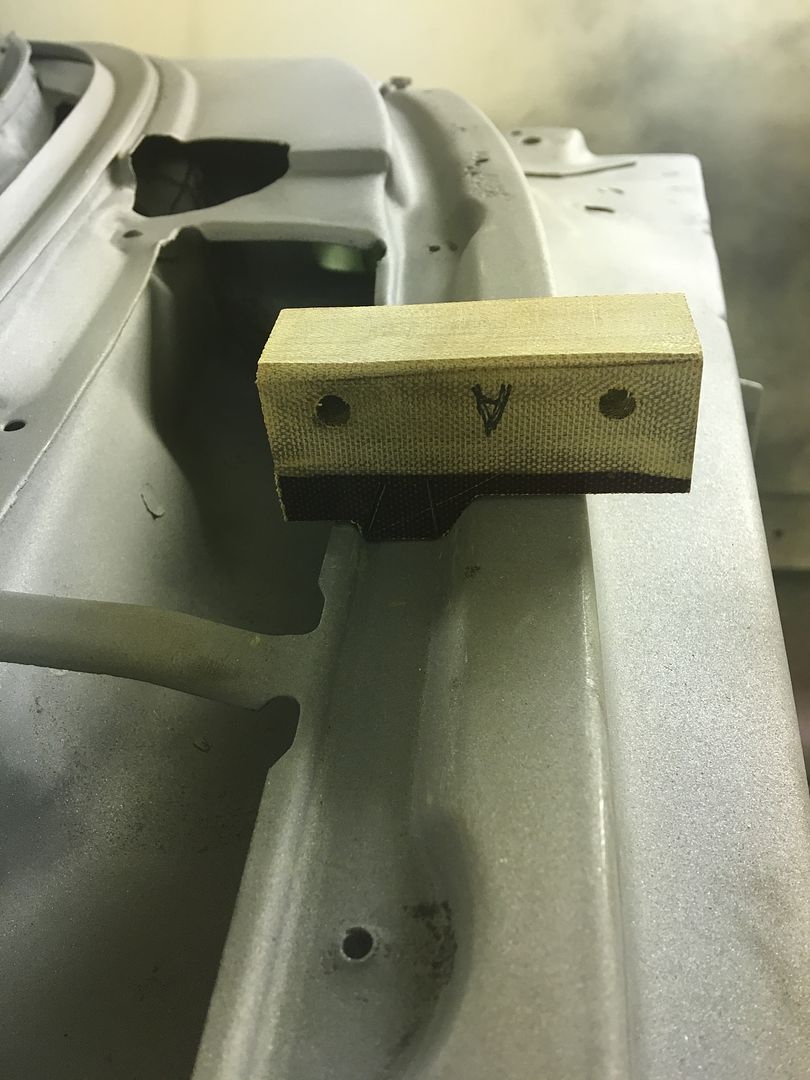

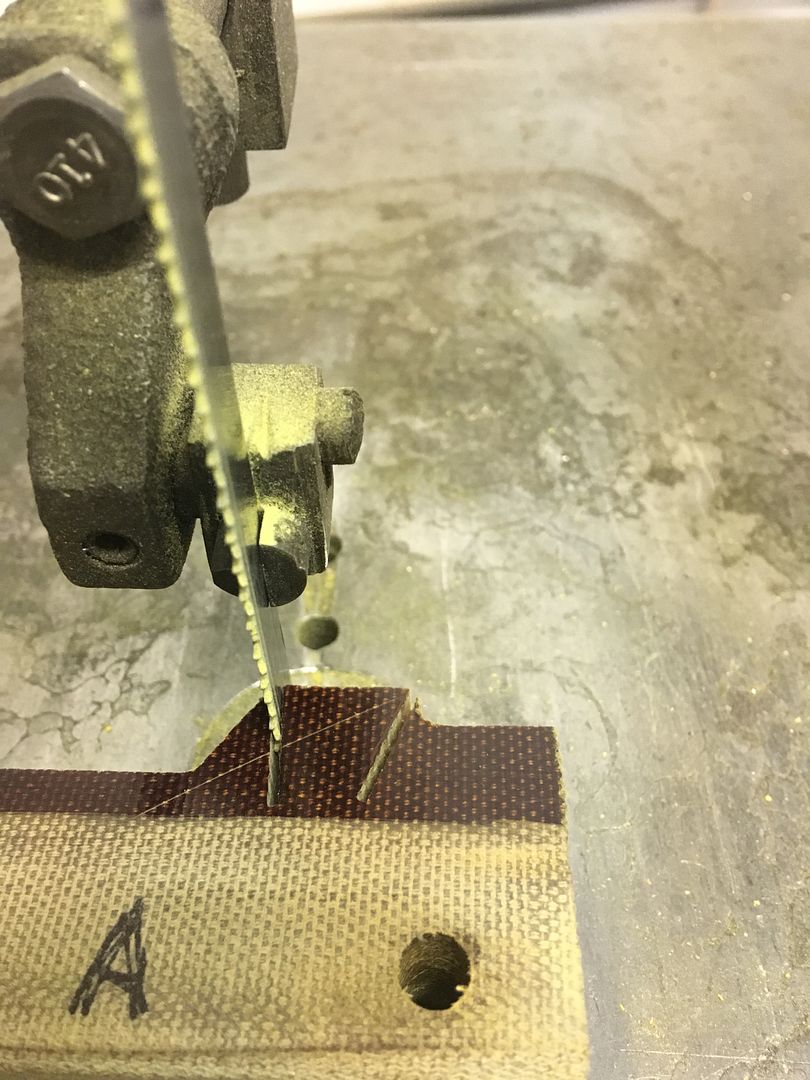

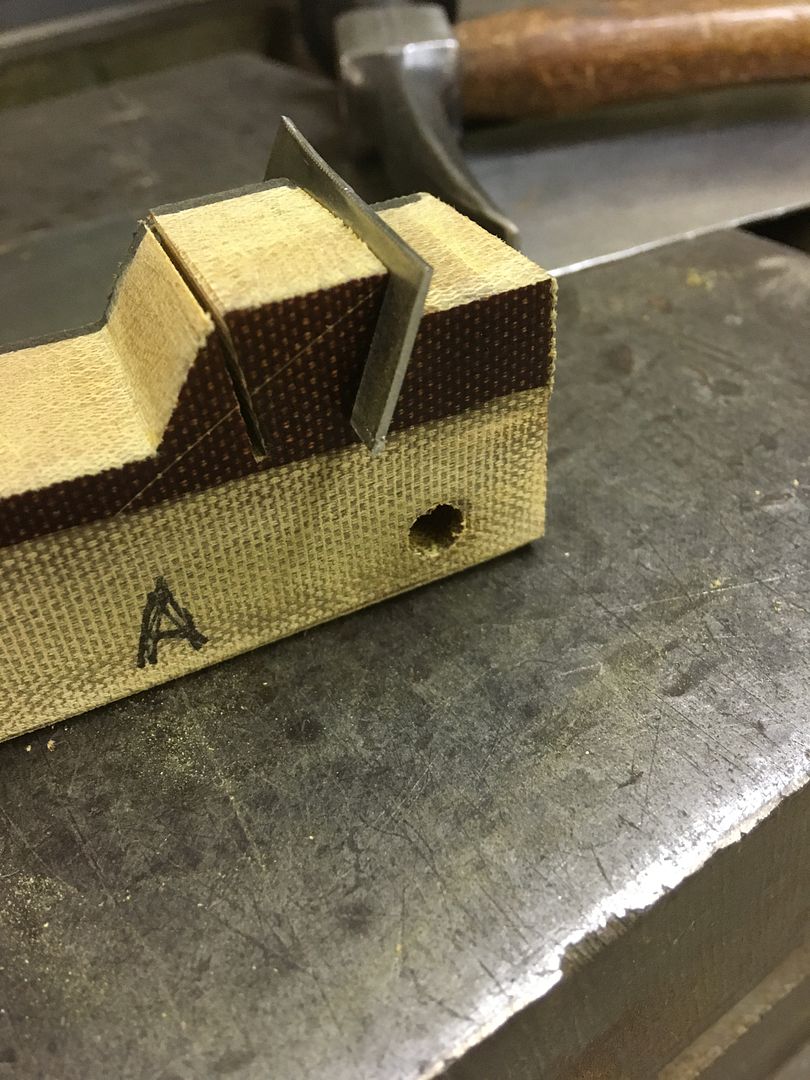

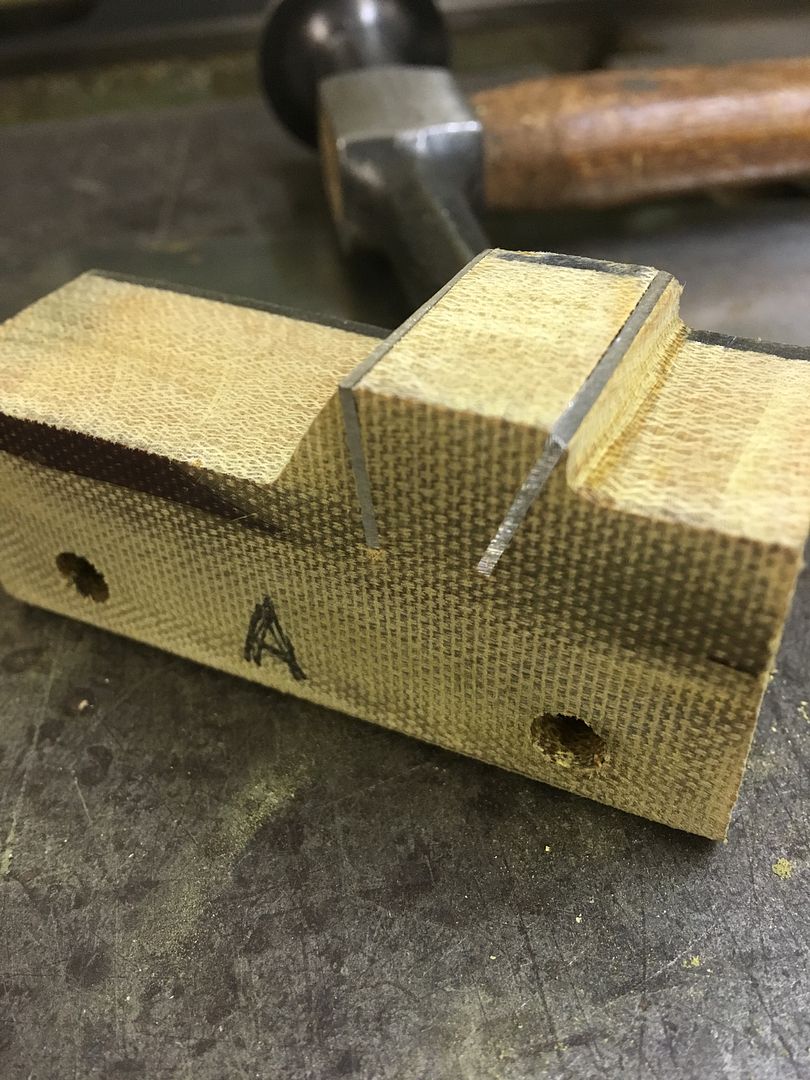

Re: 55 Wagon Progress

Thanks Jim...

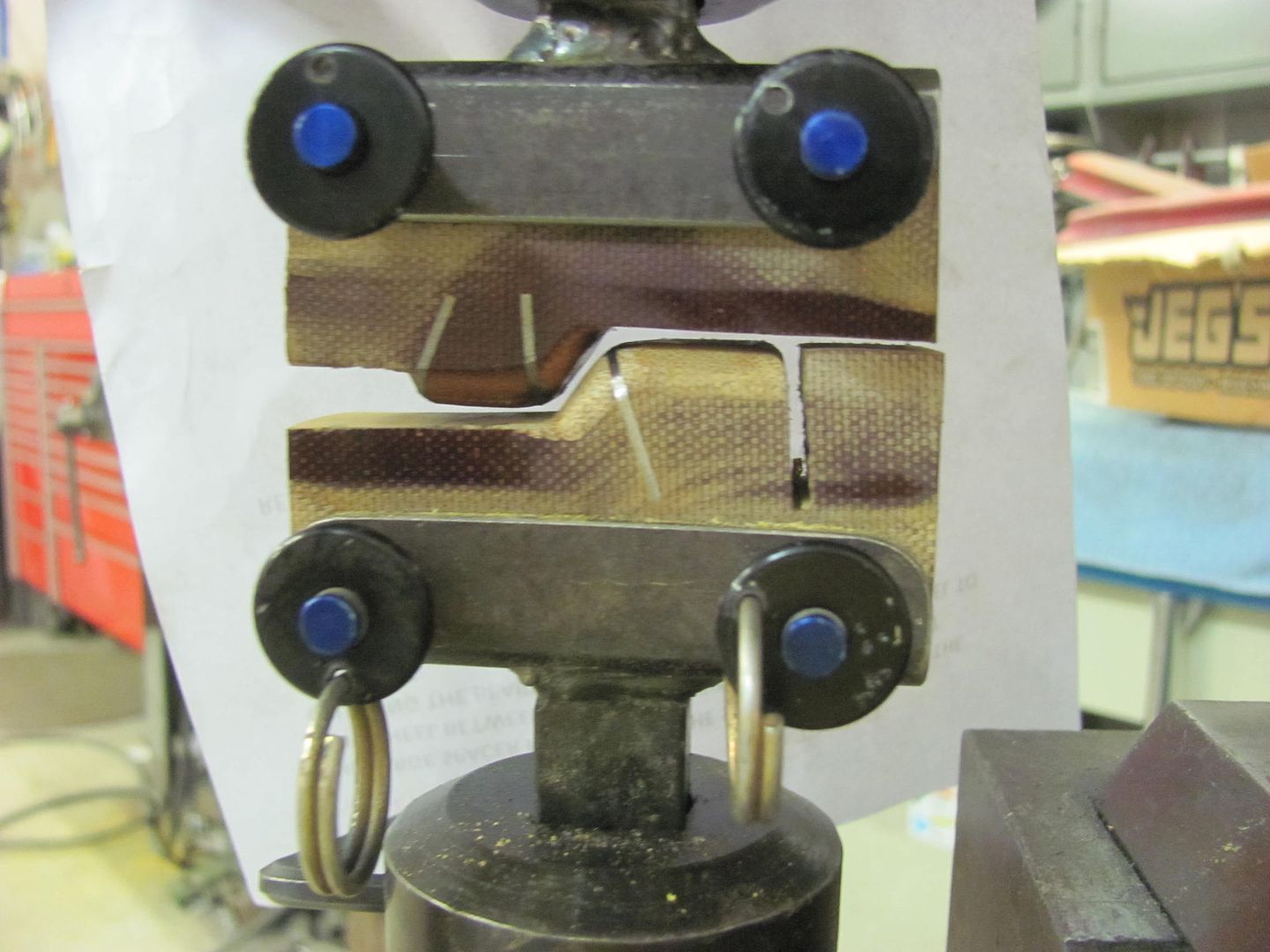

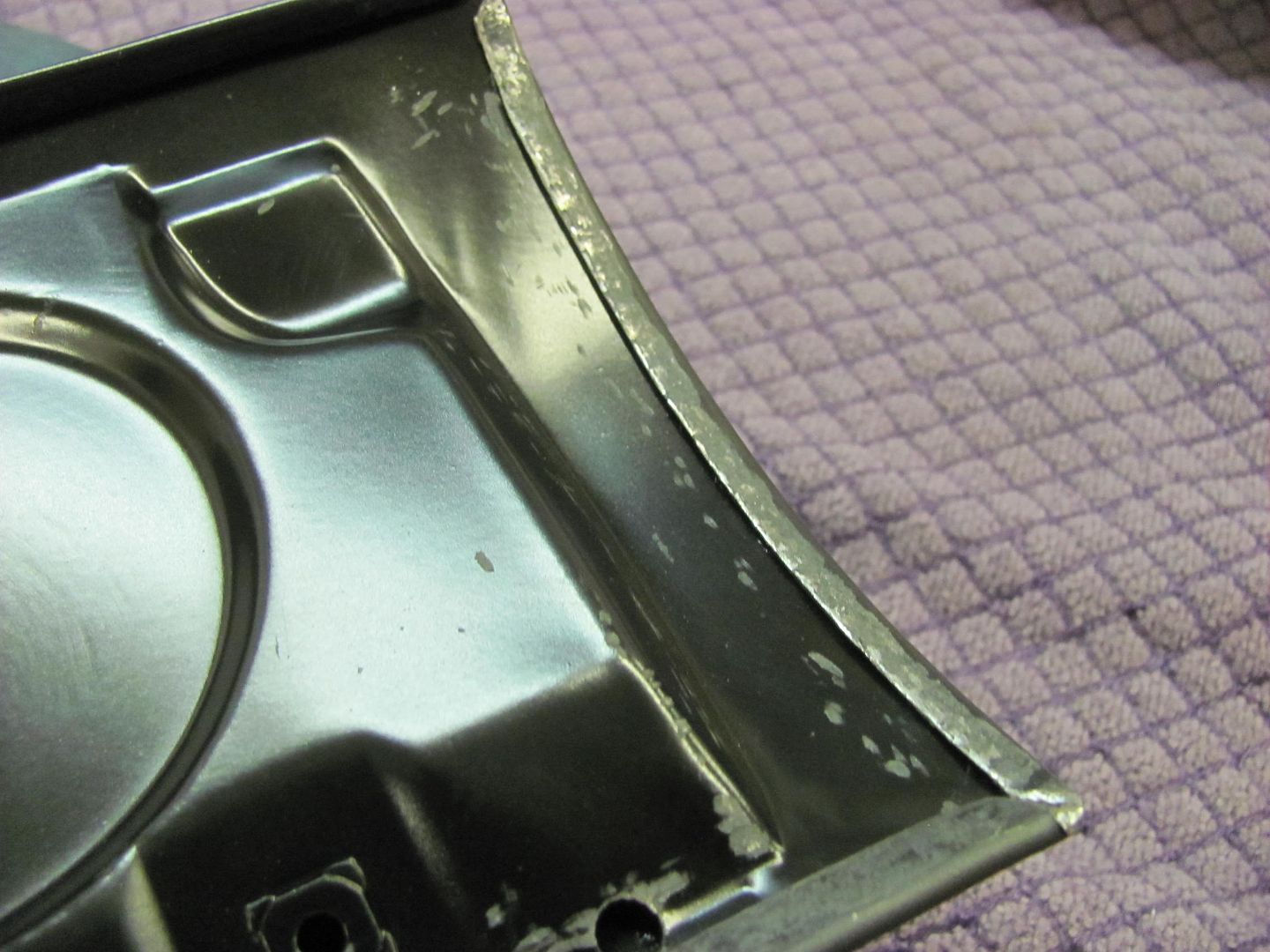

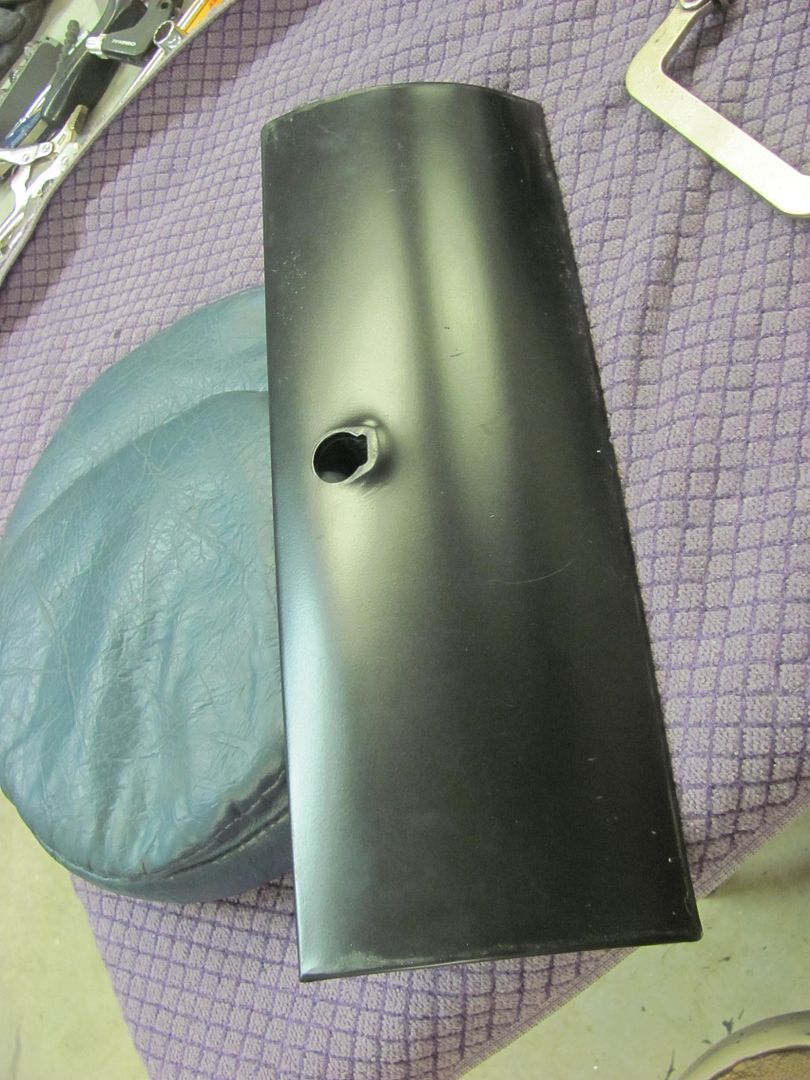

Time to make some dies for the Lennox, here fine tuning the fit..  The outside corners will get some steel added for a sharper detail in the bends..  The 19 ga steel is a good snug fit for the band saw cuts...   The front edge of the panel will be tipped prior to running it through the Lennox, the tipped flange will act as a guide in the slot in the lower die..  Another test run using a straight piece of scrap   Dimensions looking much better.  Enough practice, starting to tip the flange on the good piece.. The tipping wheel on the bead roller bends about 30 degrees and the remaining is done manually with the hand tipping tool..   Flange tipped, some kick shrinking to get the right contour, and we're about ready for the Lennox.. As Kyle was off tonight we'll wait until he returns so we can have two people feeding this long piece through the machine..

__________________

Robert |

|

|

|

|

|

#727 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,142

|

Re: 55 Wagon Progress

Very nice work Robert!

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#728 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Nice crisp edge.

|

|

|

|

|

|

#729 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks guys!

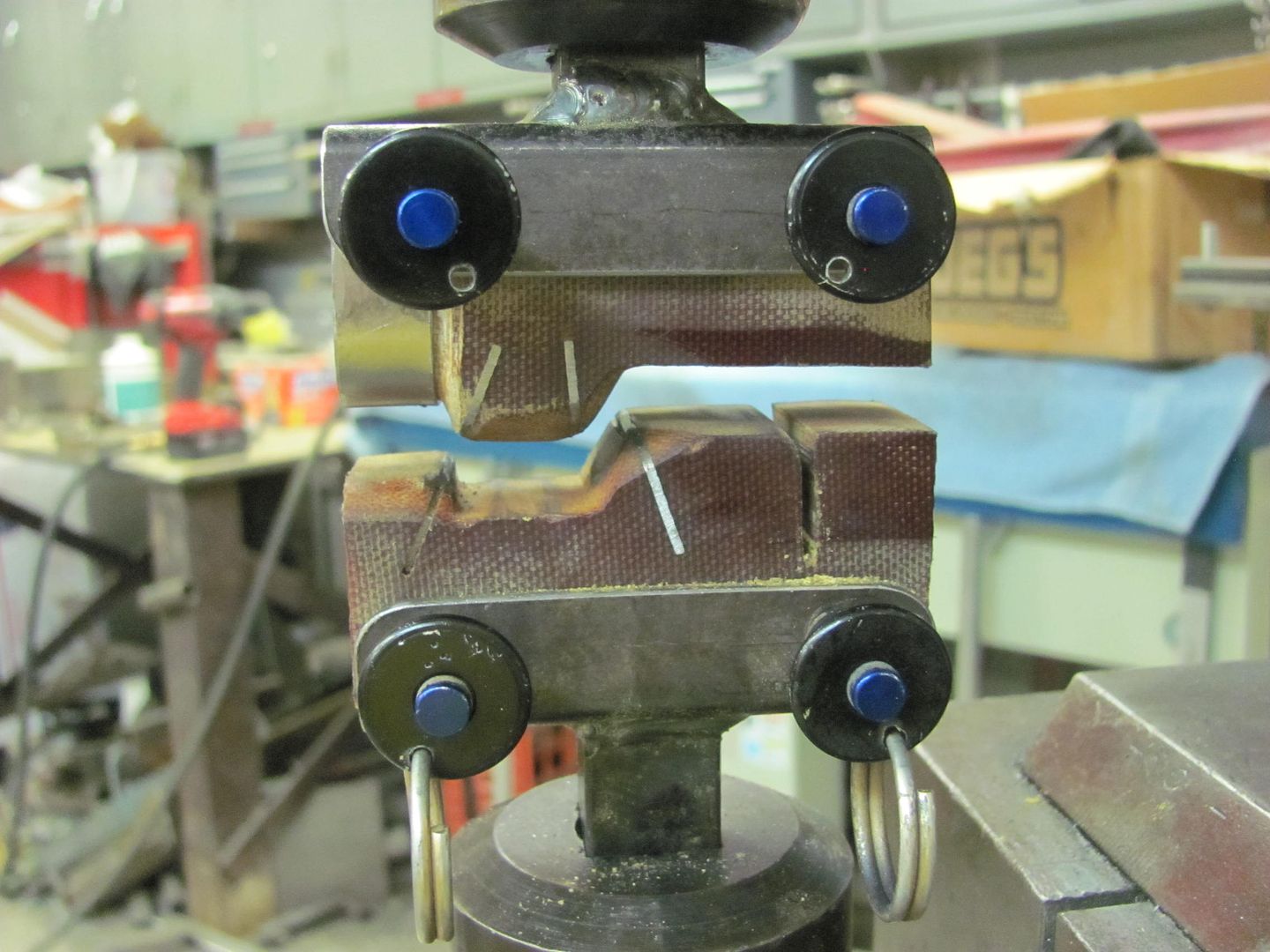

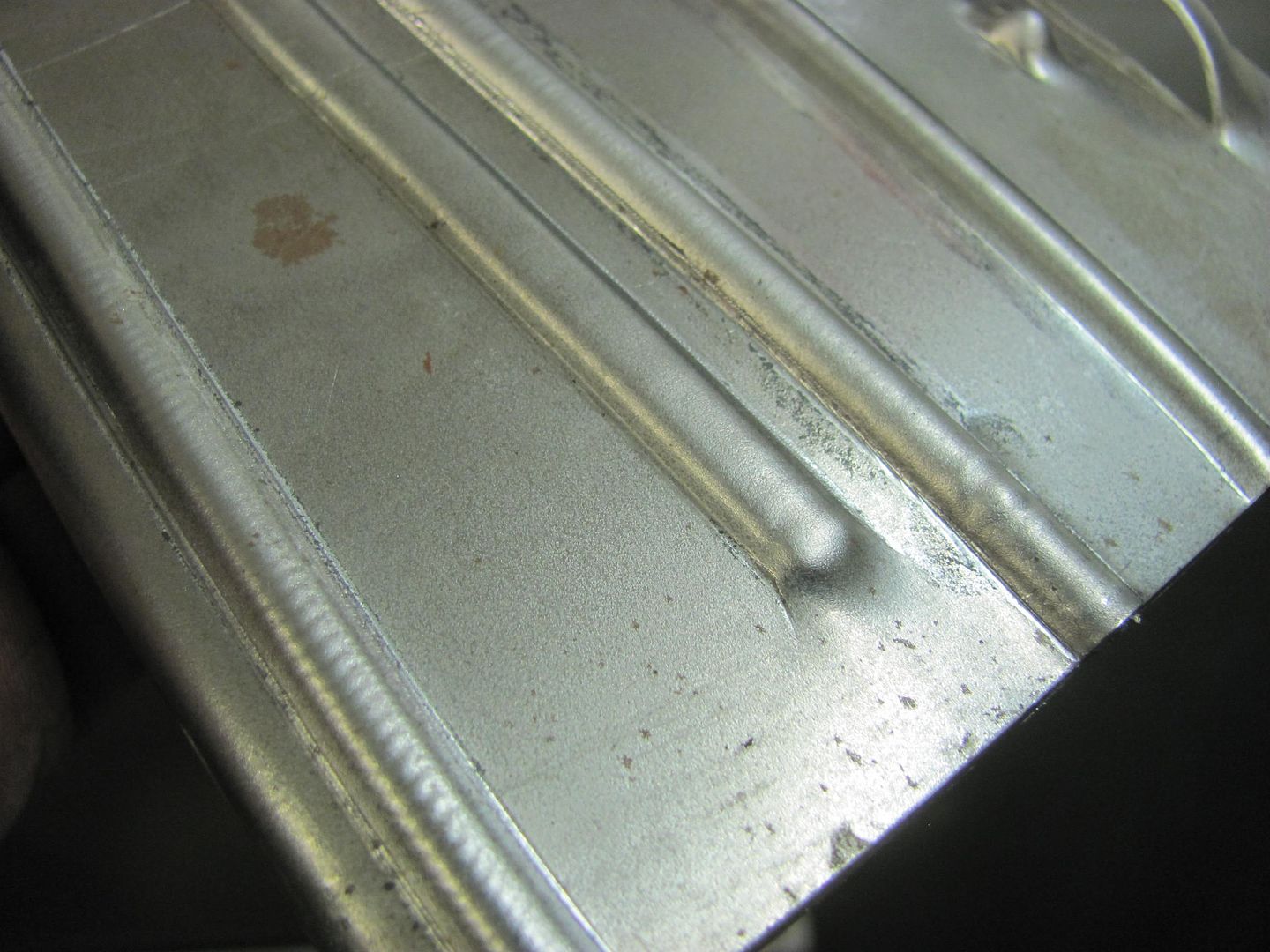

As we found with some of the practice pieces, when you try to shove metal too much into a hole it tends to pull in from the edges.  So to fix that we'll make up a new bottom die to form the ramp fold fully, then change back to the above die to form the step..   The down side to using phenolic is that it gives a bit where it doesn't make sharp creases well or short reverse folds either. The initial practice pieces wouldn't fold the step down flat, so a wrap of steel was added to the top die to better persuade the step flat...   The upper die holder helps keep the wrapped steel in place.  That did the trick, step is laying down nice and flat..   The front flange hangs over just a bit too much, some hammer action will bring it back in place. Real pleased with how well this turned out..  Some of the practice scraps..

__________________

Robert |

|

|

|

|

|

#730 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

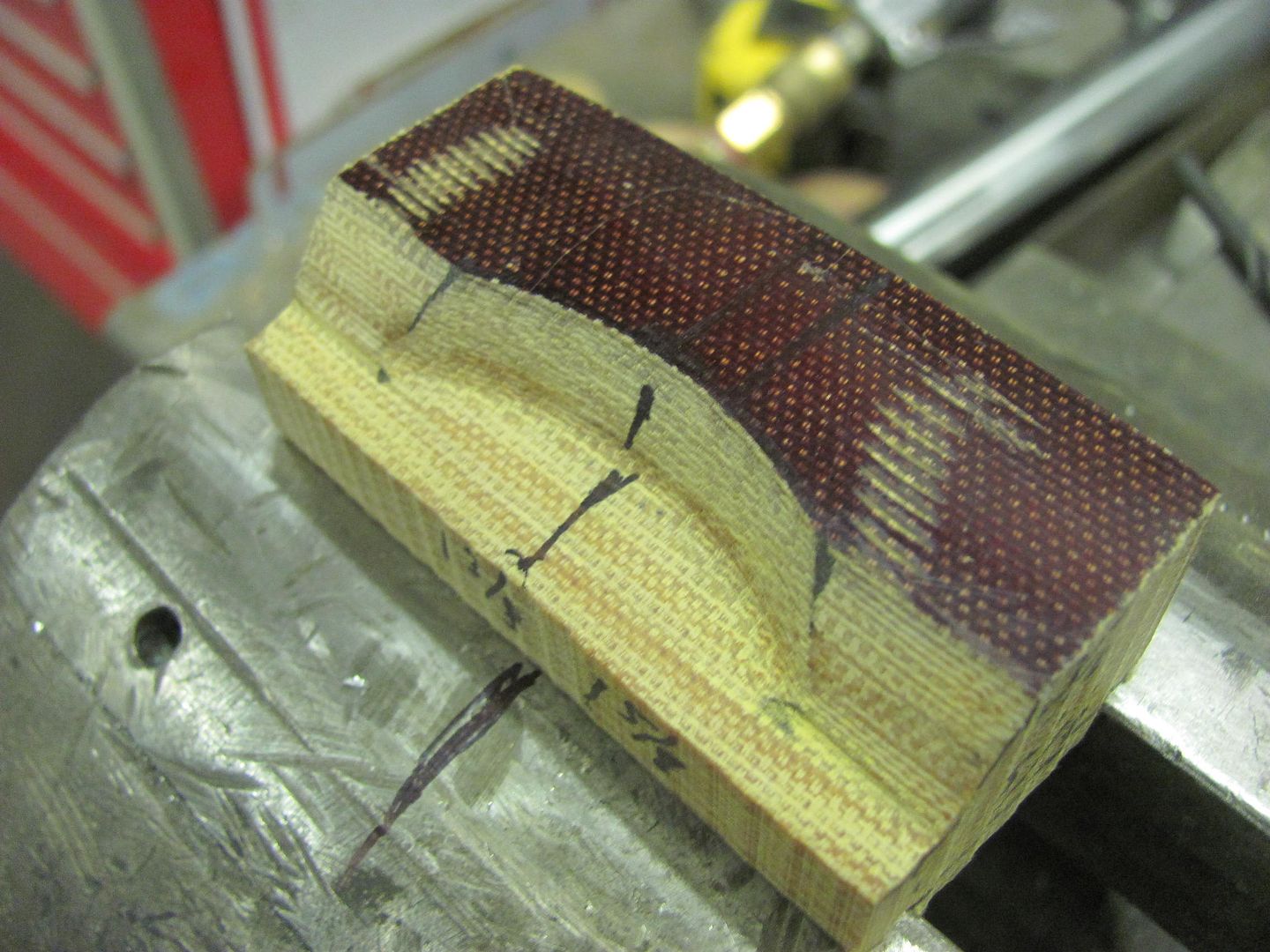

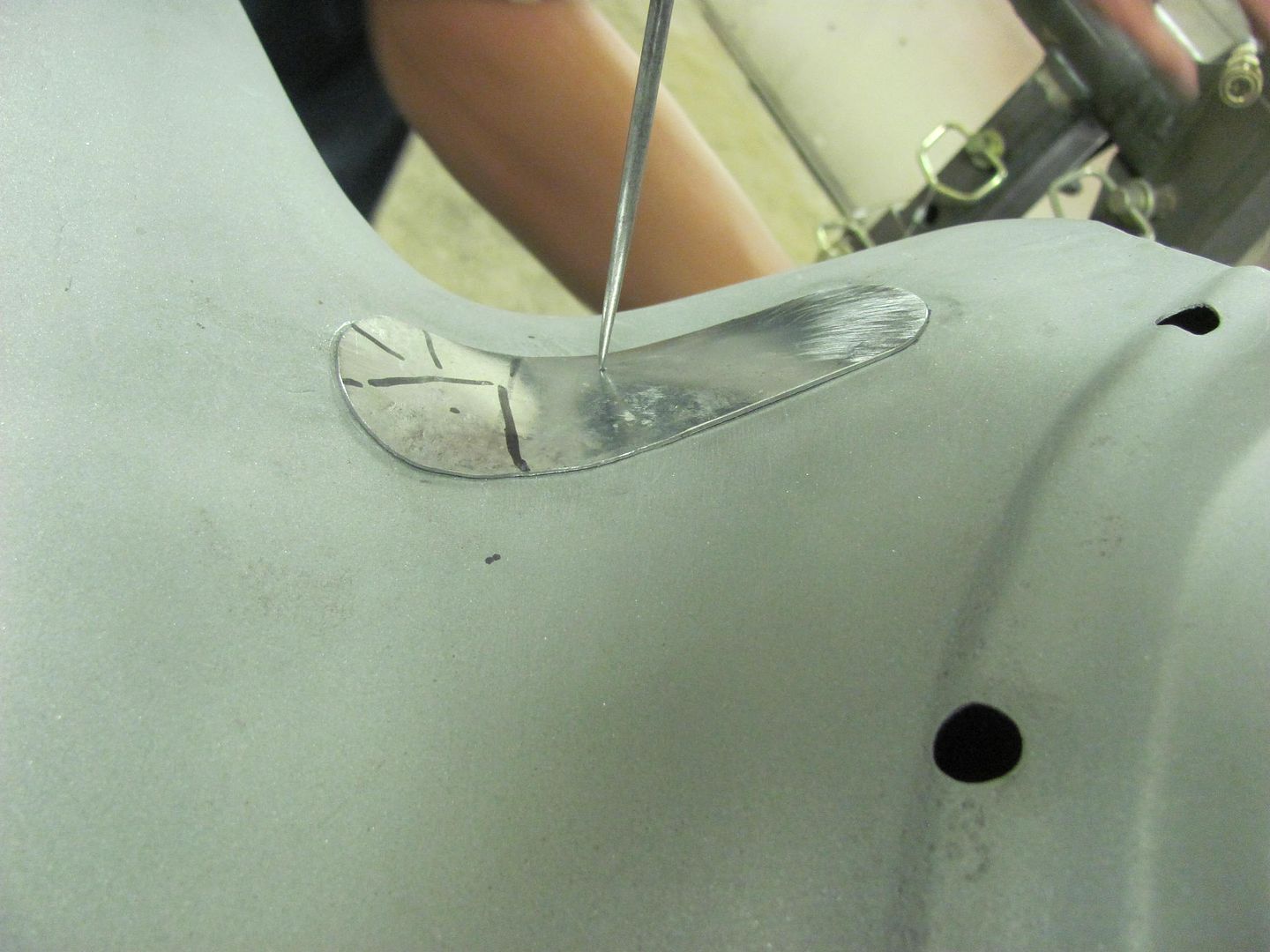

Next task on the list is to add the semi-circular relief areas into the new cowl repair panel..

A suitable piece of Phenolic is cut out, notched at the bottom for "vise support", and used a roloc sander and drum sander to add the relief area in the "hammer form".  Here's the Vise support shown in action... should remain nice and stable through all the hammer action..  Centerline of the hammerform marked, as well as on the vise, to better align our new cowl..  Door skin hammer will be used here to provide the radius, this one was touched up as the factory radius was a bit too large.  Tried it on one of our scrap pieces first..  Back side..  Front side and comparison to the factory version   Action video showing the process: https://www.youtube.com/watch?v=3TawUVtIl5w

__________________

Robert |

|

|

|

|

|

#731 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Thank you for taking the time to show how to do this.

Something learned every day. |

|

|

|

|

|

#732 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Nice work...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#733 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

Wow, good stuff. Great work as always.

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#734 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

I think my jaw needs to be reattached to my face LOL! Nice!!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#735 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments guys..

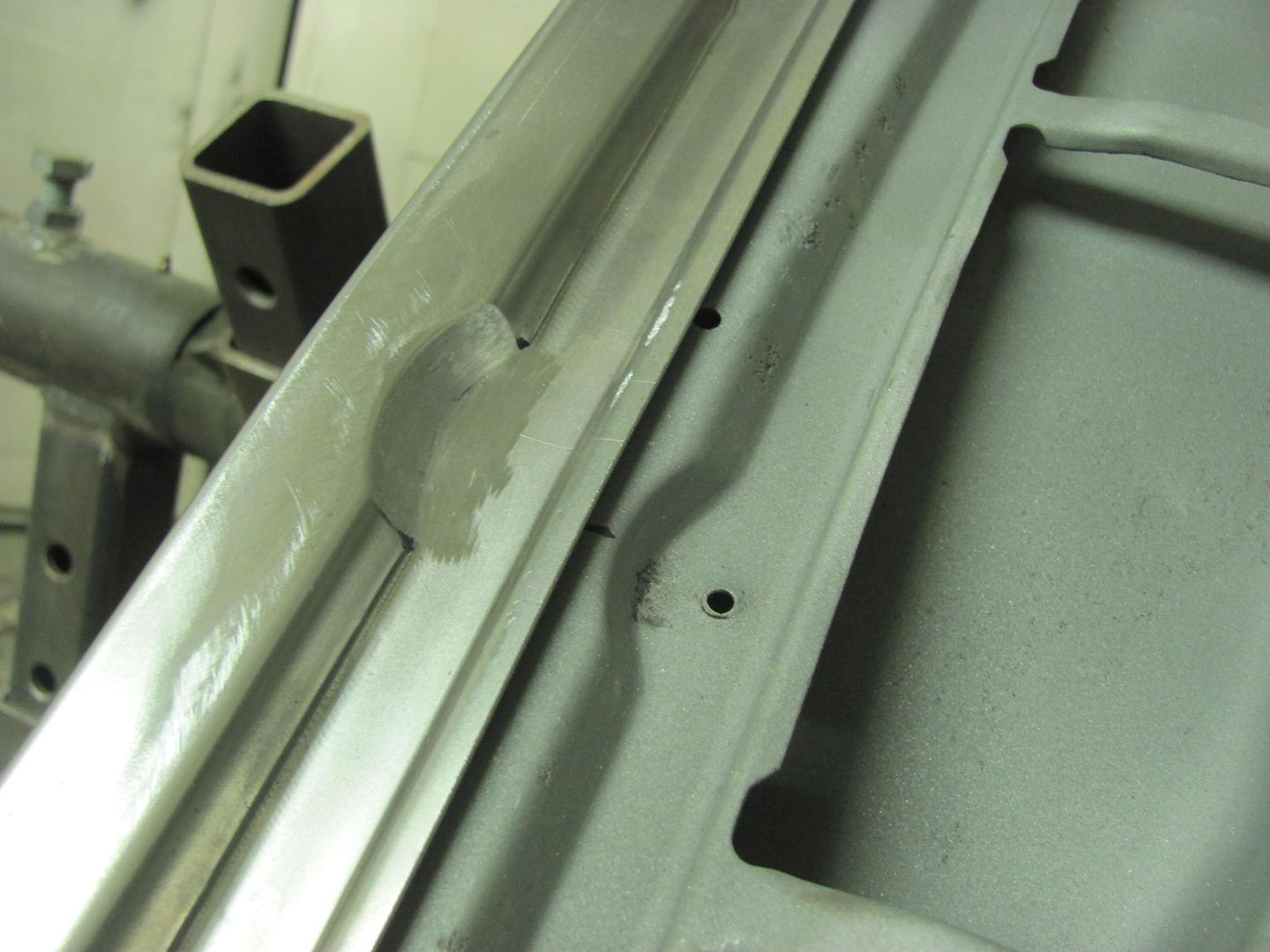

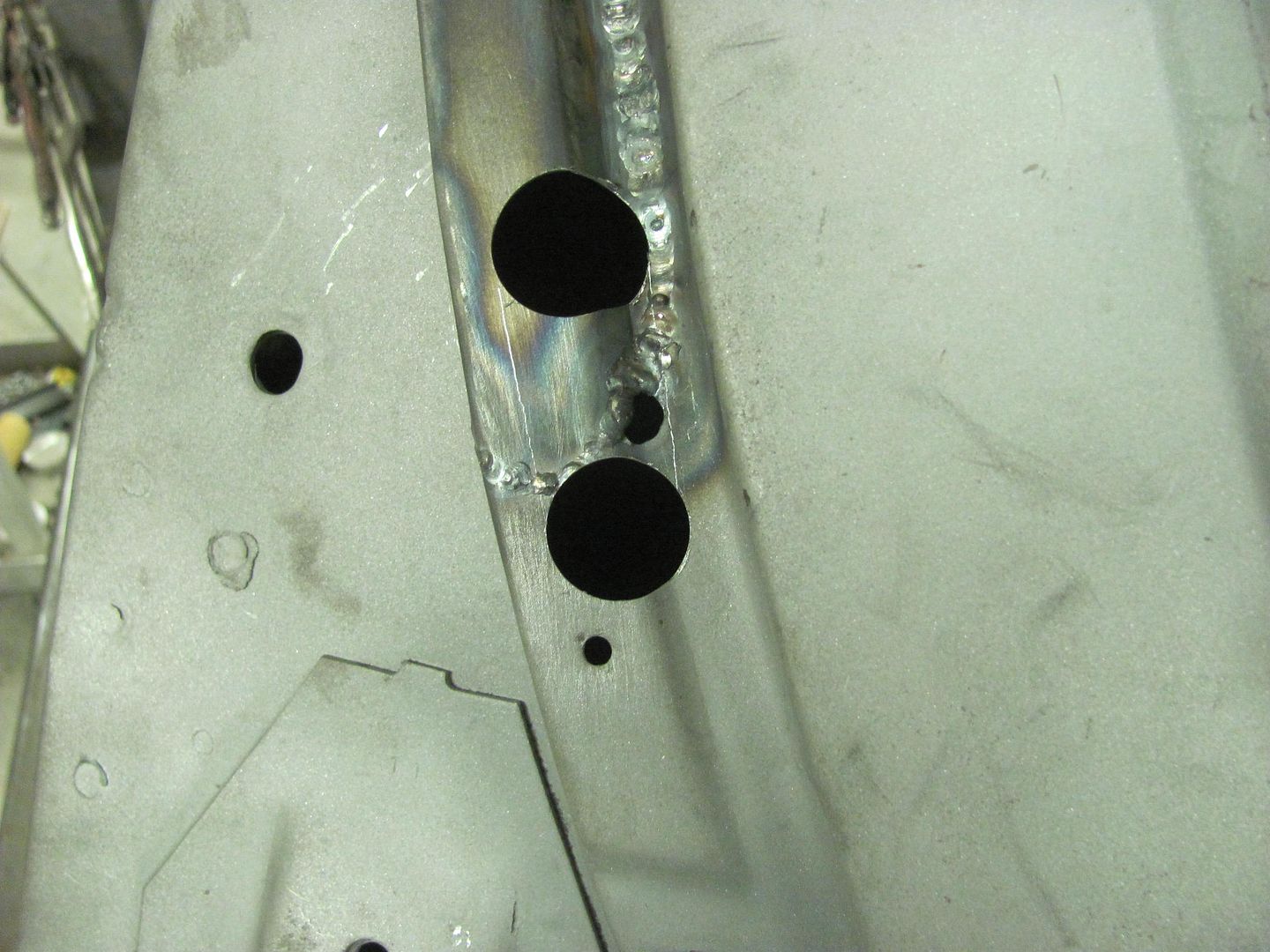

A bit further along on the cowl repair.. Repair patch trimmed to size...  ....and then scribed to the cowl area, which gets rough cut using the 4-1/2" cut off wheel. About 1/4" excess is left for final trimming using the snips..   That should flow some air...  Tacked in place..

__________________

Robert |

|

|

|

|

|

#736 |

|

Registered User

Join Date: Feb 2007

Location: Marana, Arizona

Posts: 3,455

|

Re: 55 Wagon Progress

That is cool, gives me hope for shaping basic patch panels.

__________________

"I feel the need for speed!"... as soon as I am done with my nap. |

|

|

|

|

|

#737 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

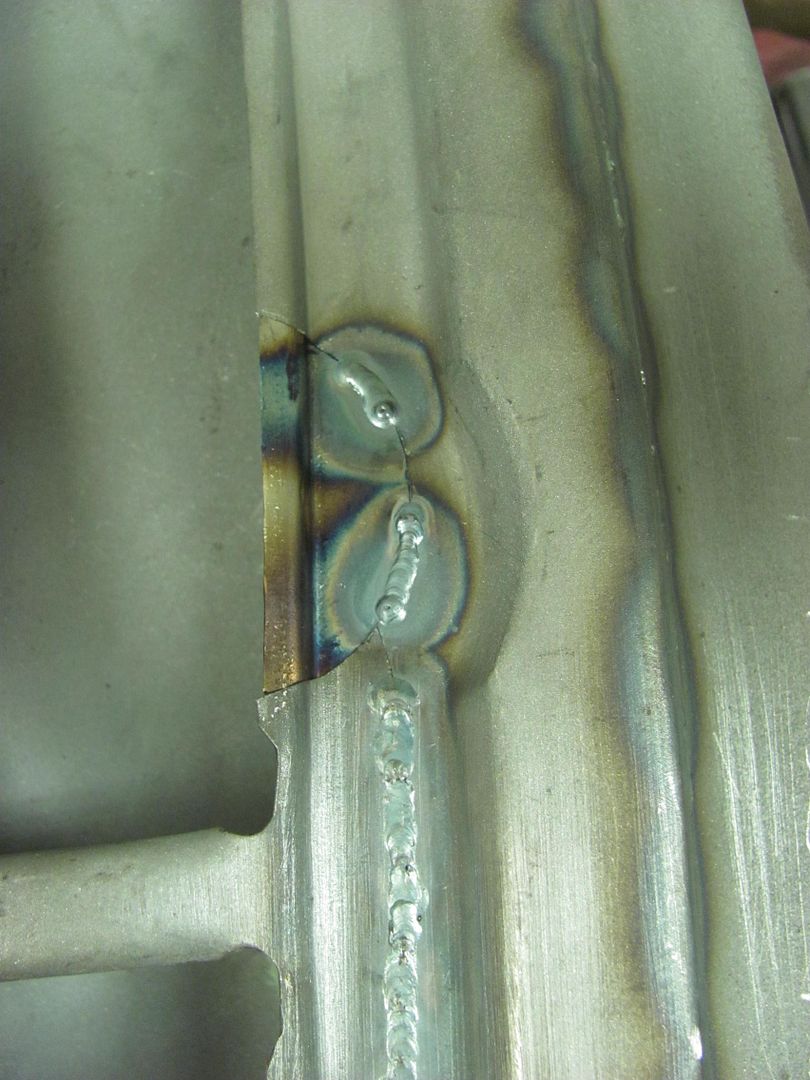

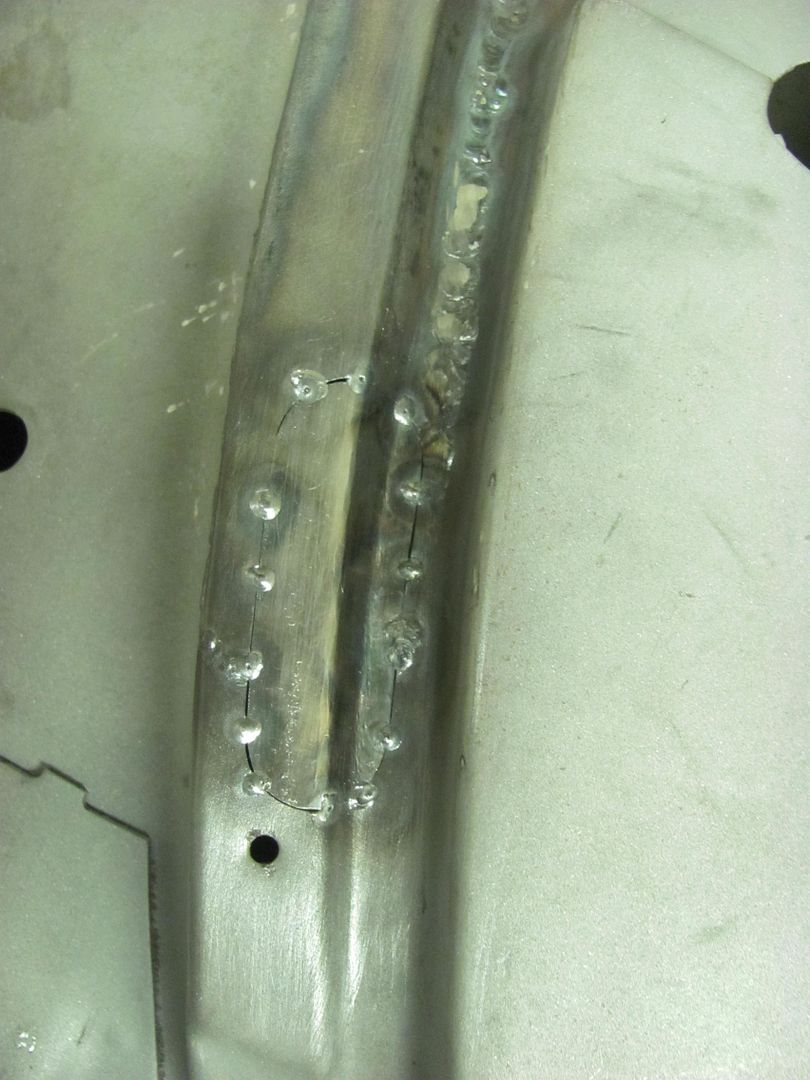

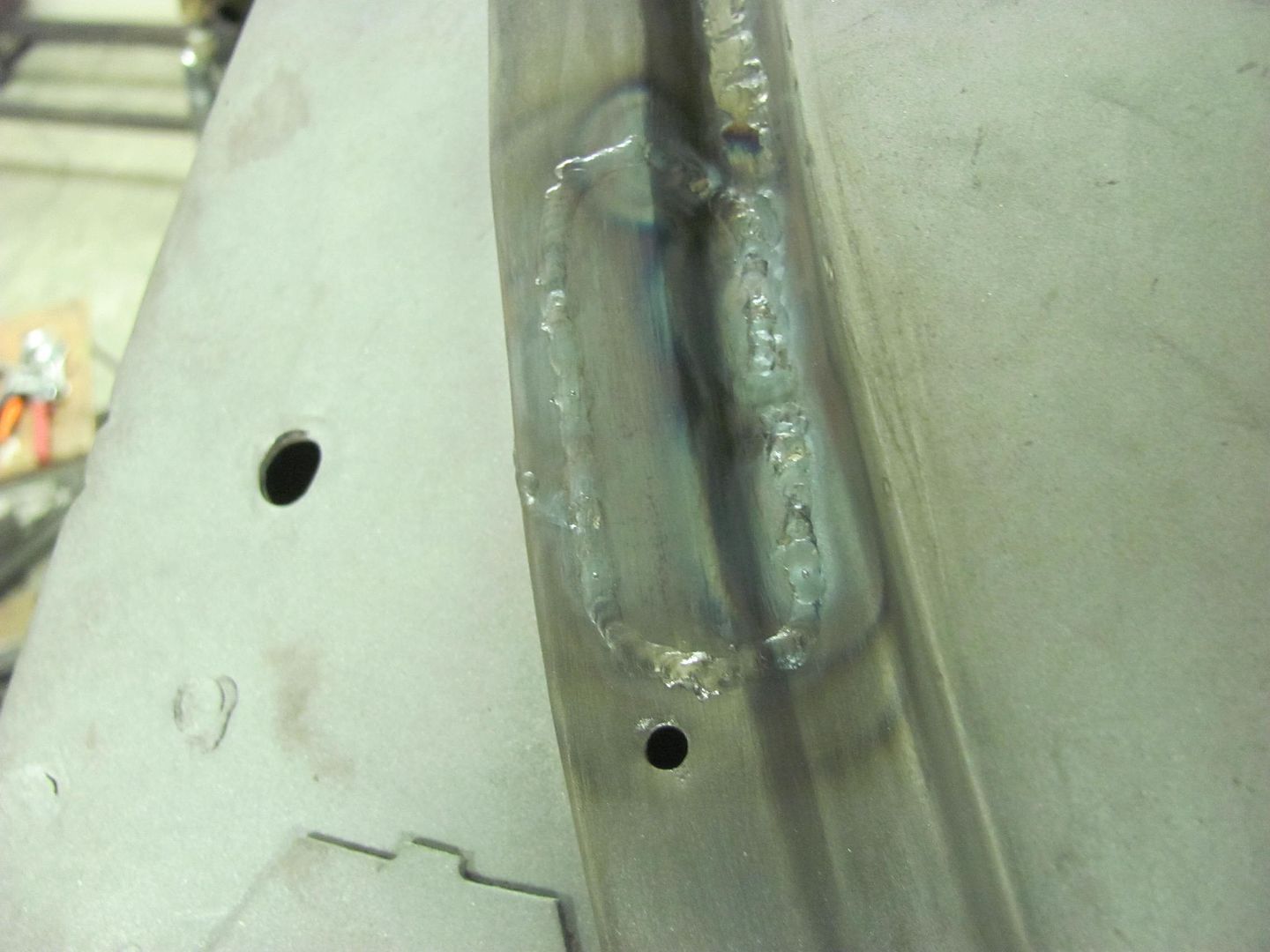

OK, it's been a while since I've TIG welded, and got a little too much heat near the edge. Blew a nice hole, so used one of the practice pieces to cut out a patch..

.....and I got a little heavy footed on the other end as well...  Trimming for the patch's patch.      The final pieces to weld...  Weld dressed and factory relief added...  A few more welds to dress and this will be done...

__________________

Robert |

|

|

|

|

|

#738 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

As usual, very nice work...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#739 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks Jim!

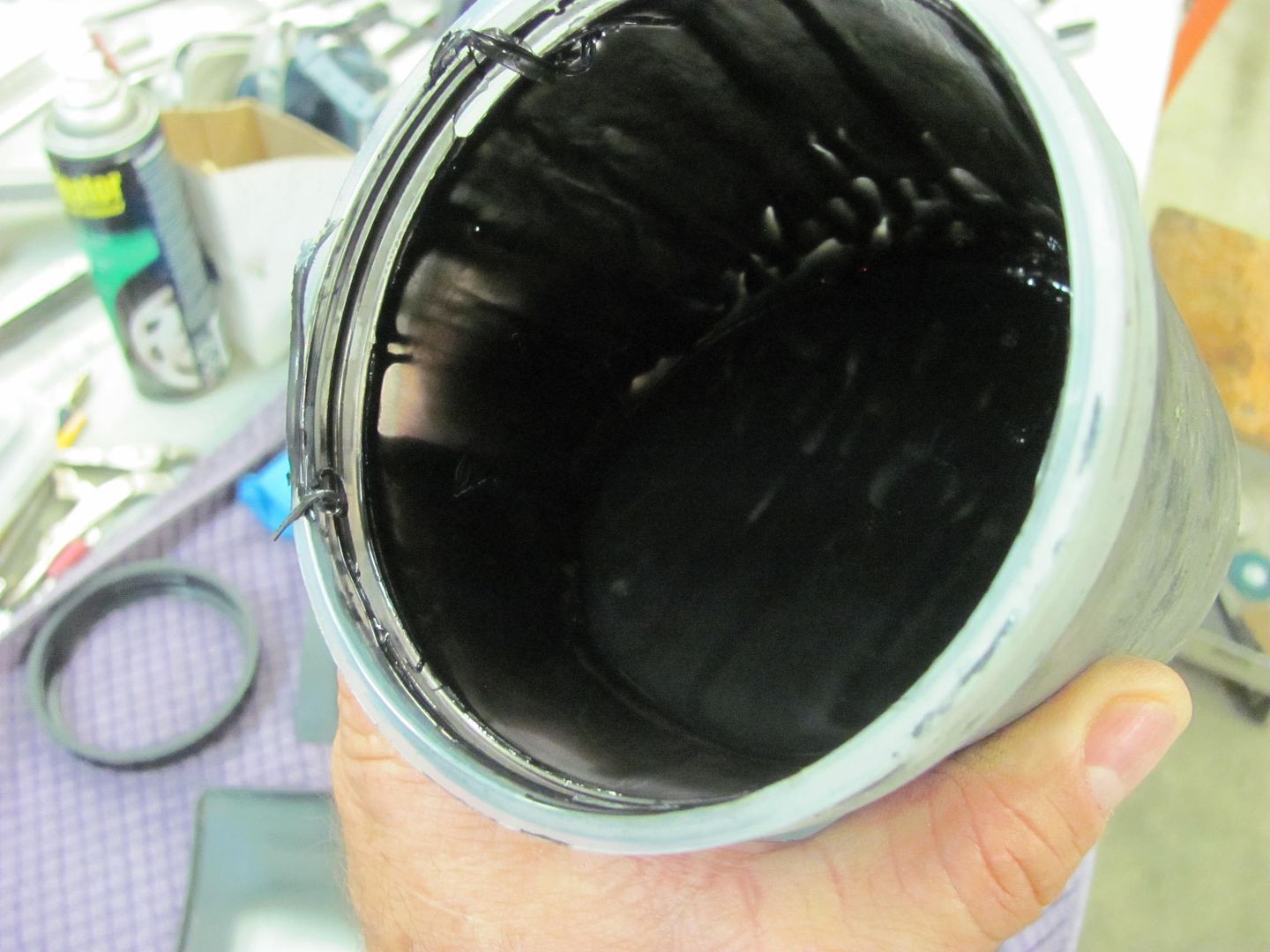

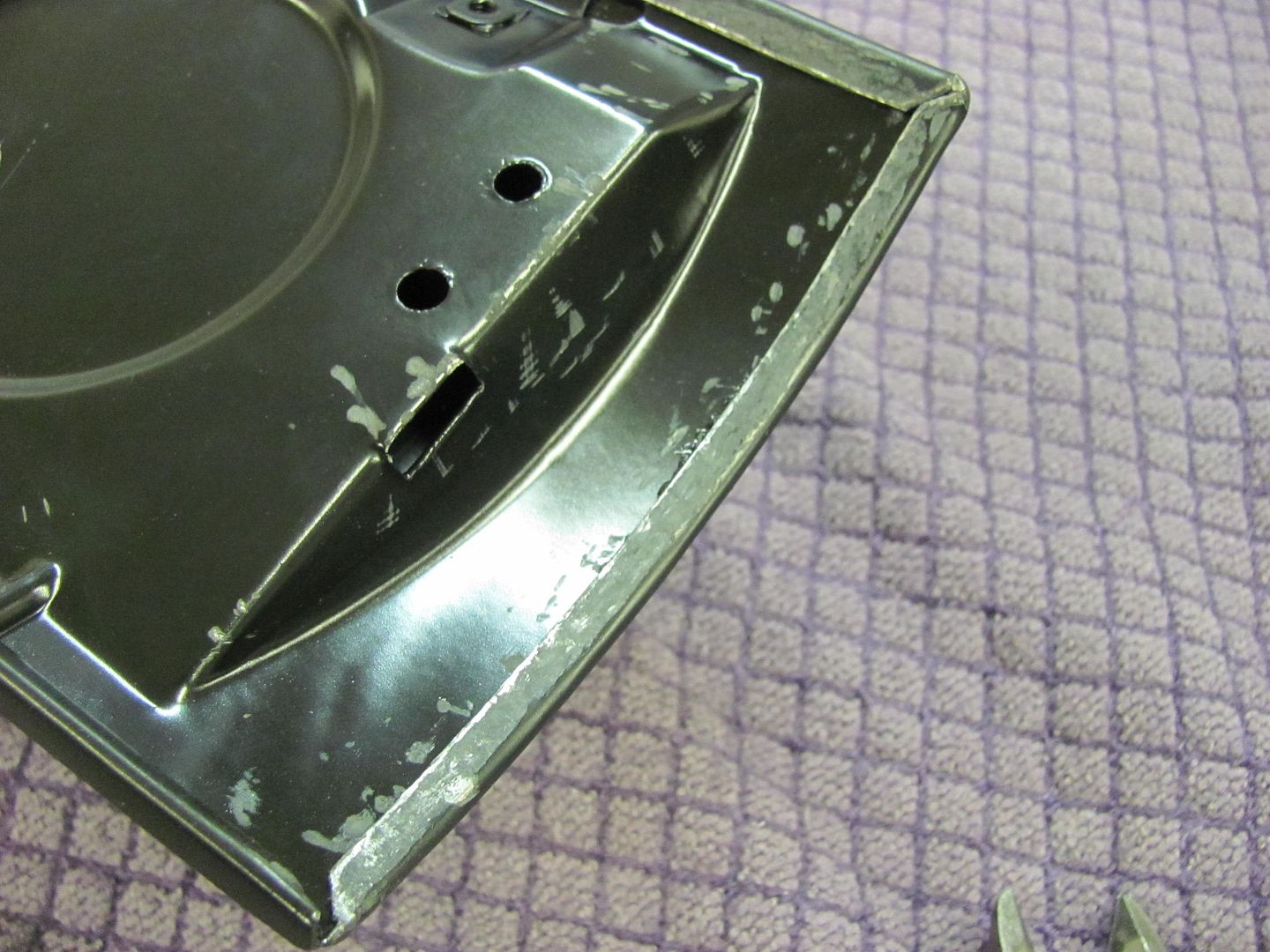

Cowl repair all complete...  One more thin spot from the media blasting where we had removed the leaded seam...   Test fitting the patch for proper contour..  TIG welded in place...   Started off with some SPI epoxy on the underside...  ....and then the firewall  .....as well as the new glove box door skin...  The entire interior was primed by standing through the window openings...   Then the outside was tackled...

__________________

Robert |

|

|

|

|

|

#740 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

Uh-oh...going to primer...I'm sure going to miss the metal working lessons! dug

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#741 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

There may be a bit more metal work before all is said and done..

Well the epoxy has cured for about three days, time to put the glove box back together... The adjacent areas are scuffed for some official door skin adhesive..  ....in the form of some leftover primer from this weekend..  Good thing this gets covered up...  Using the door skin hammer on the leather shot bag, the ends are folded first...    and then the bottom flange...  All together...

__________________

Robert |

|

|

|

|

|

#742 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

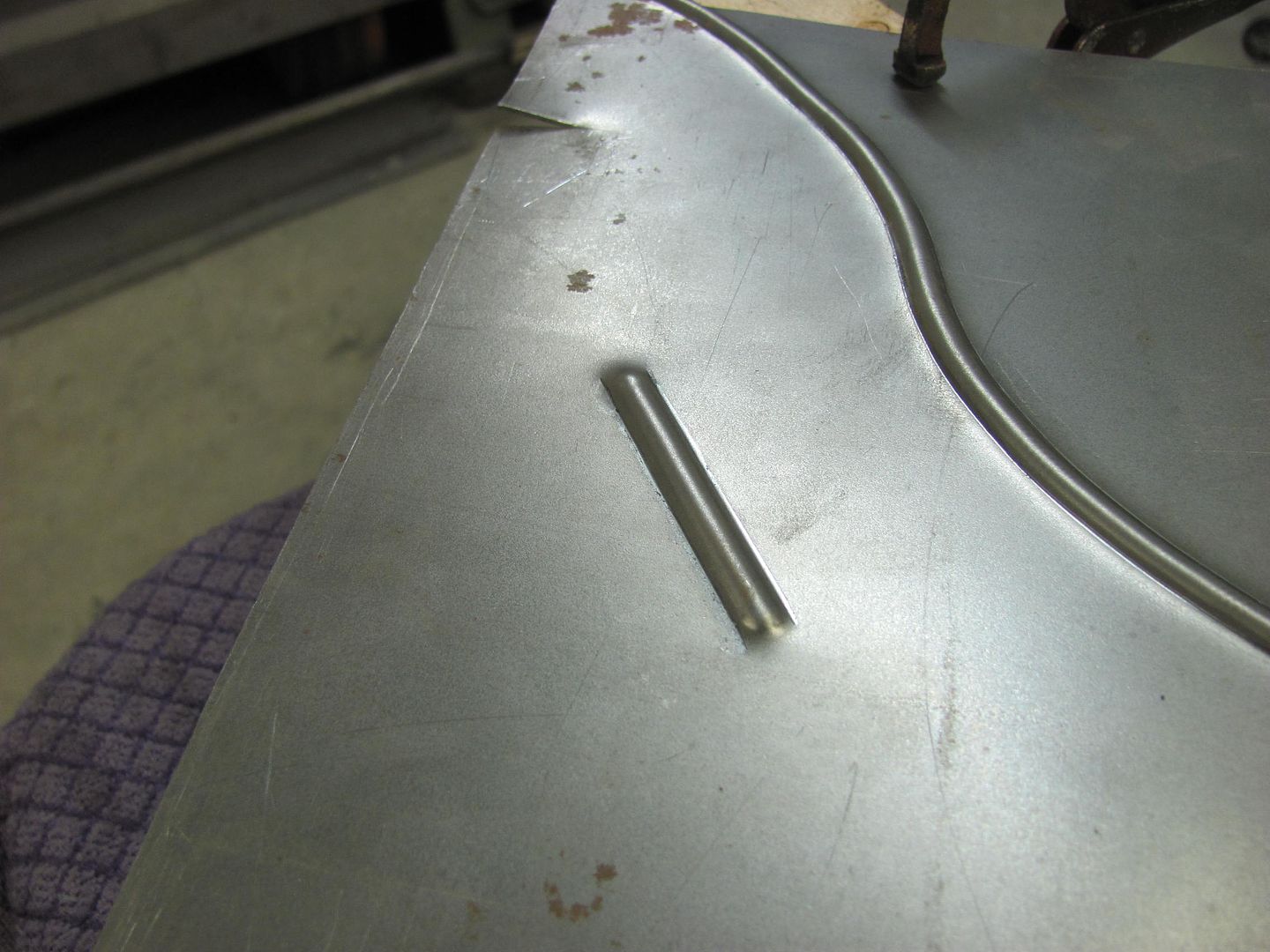

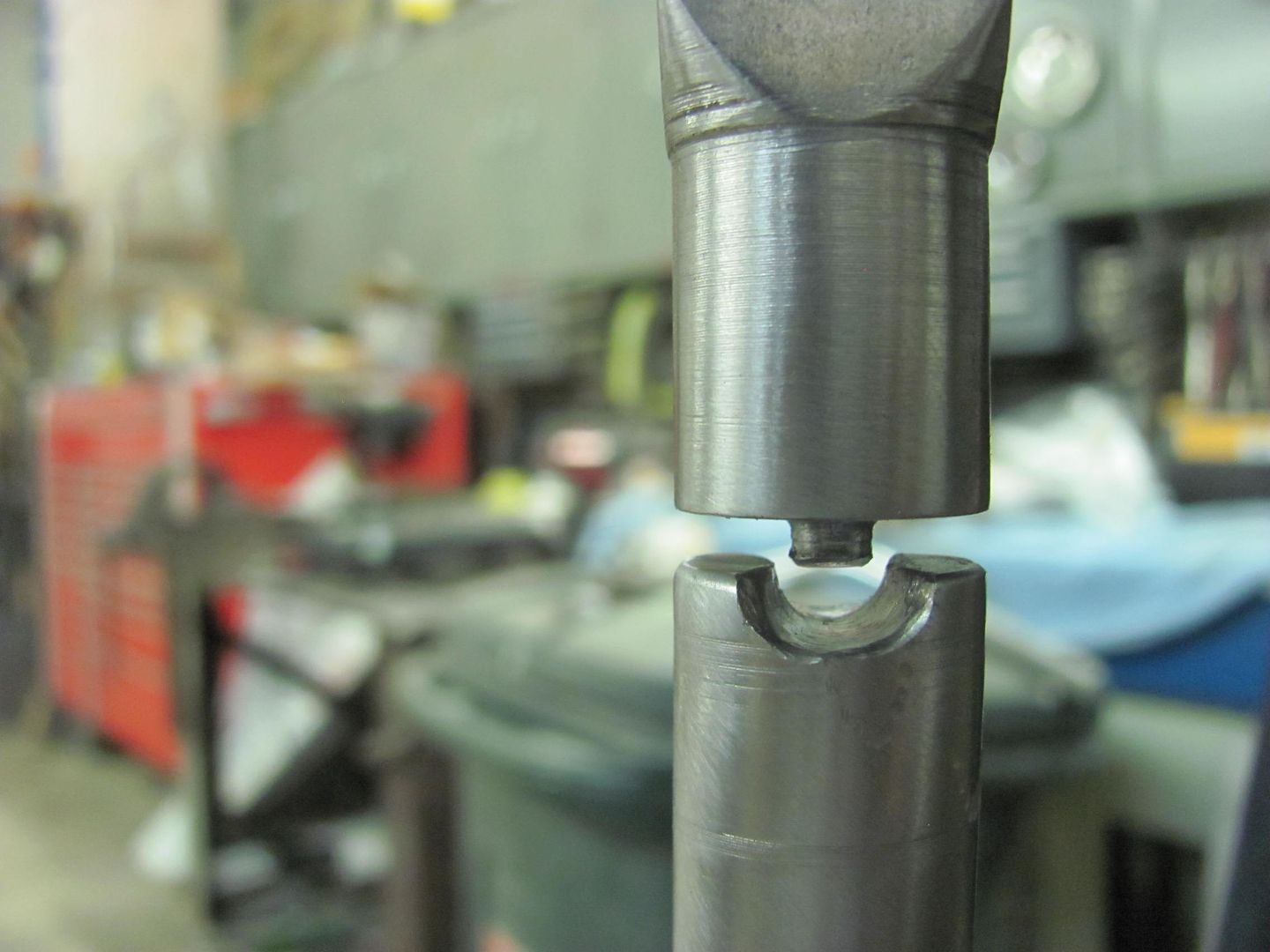

Got a "requirement" for some bead detail work and don't need the panels losing any of their shape. The bead roller does a nice job, but the forming process is more of a relocation of the metal from elsewhere, which would cause a panel to possibly lose some crown.

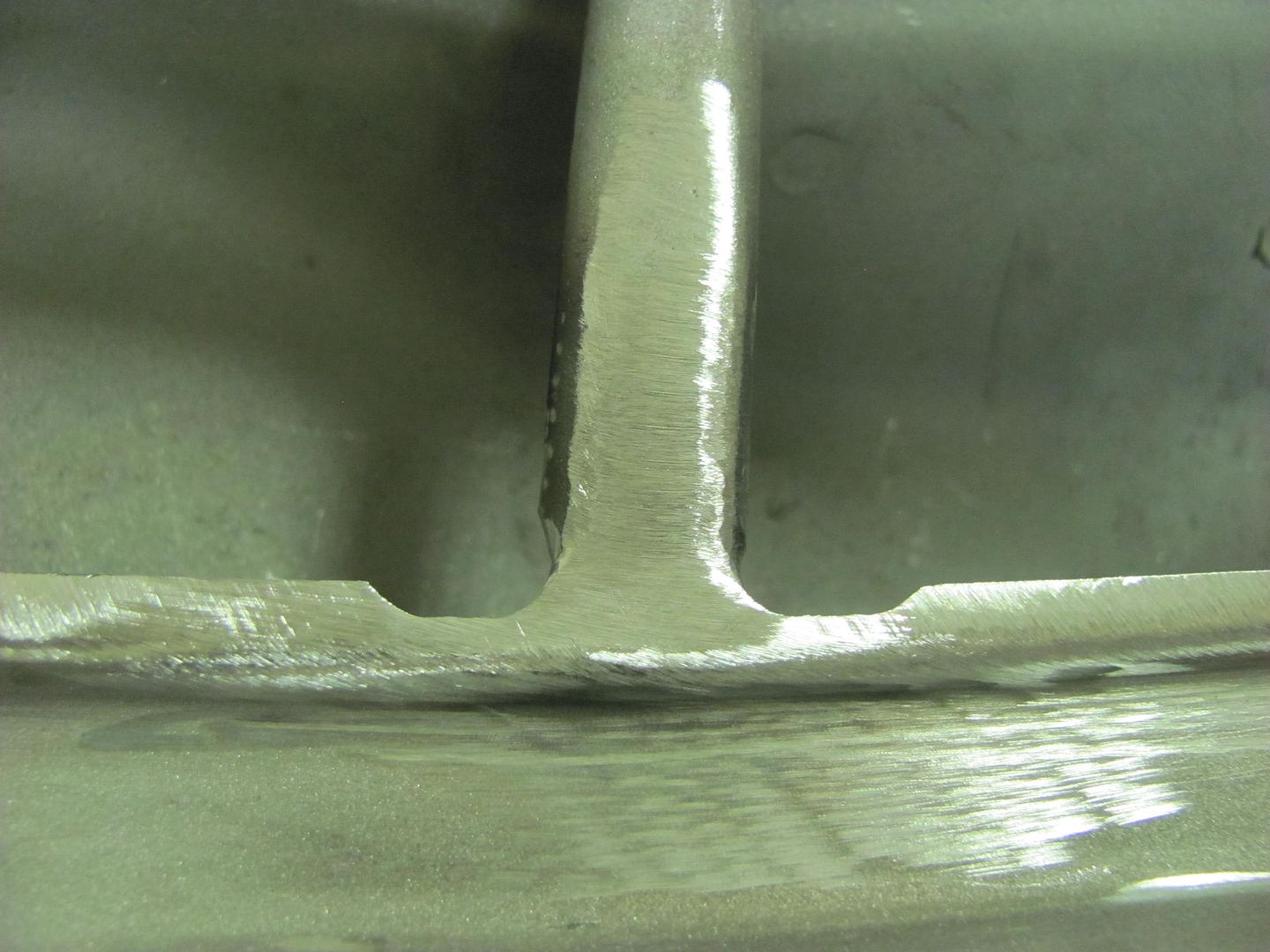

The Lennox (Pullmax) as a reciprocating machine does a better job of stretching the metal as the bead is formed, so there is less issue of losing panel crown. Here we're making the female die in the South Bend milling machine.  Ball end milling bit clamped in the chuck, square stock clamped in the Aloris tool holder..  The ends of the tooling was also turned in the lathe to give a nice round feature that will work better for use with a guide.    Test run...  Nice crisp lines, the "chatter" should be cleaned up if I can get the feed speed more consistent. The small diameter of the upper die's "punch" provides the needed stretch, with the downside being the marking from too fast of a feed speed. Making the upper die in more of an oval shape will eliminate most of the marking, but it won't stretch as well.. To keep from losing panel crown, stretch is our preference here..  This shows how well the die provides stretch, when you can add a bead in the middle of a panel....  ......and there's no distortion on the ends of the bead on an otherwise flat panel..

__________________

Robert |

|

|

|

|

|

#743 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

Love the Clarke Co. apron verbiage!! dug

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#744 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Here I thought I was the only one to blow off stuff while tig welding. lol

Thanks for showing the little hiccups along the way. Excellent bead work. |

|

|

|

|

|

#745 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Thanks for the comments guys! Not much to show on the 55, we've been block sanding, metal bumping, adding filler, lather, rinse, repeat. On the beading dies from the other night I wasn't too pleased with the shape, IMO they were too rounded. Especially for where this will be used, it needs to better match the rest of the car. So another upper die was made using a more blunt end tip with a slight ramp.

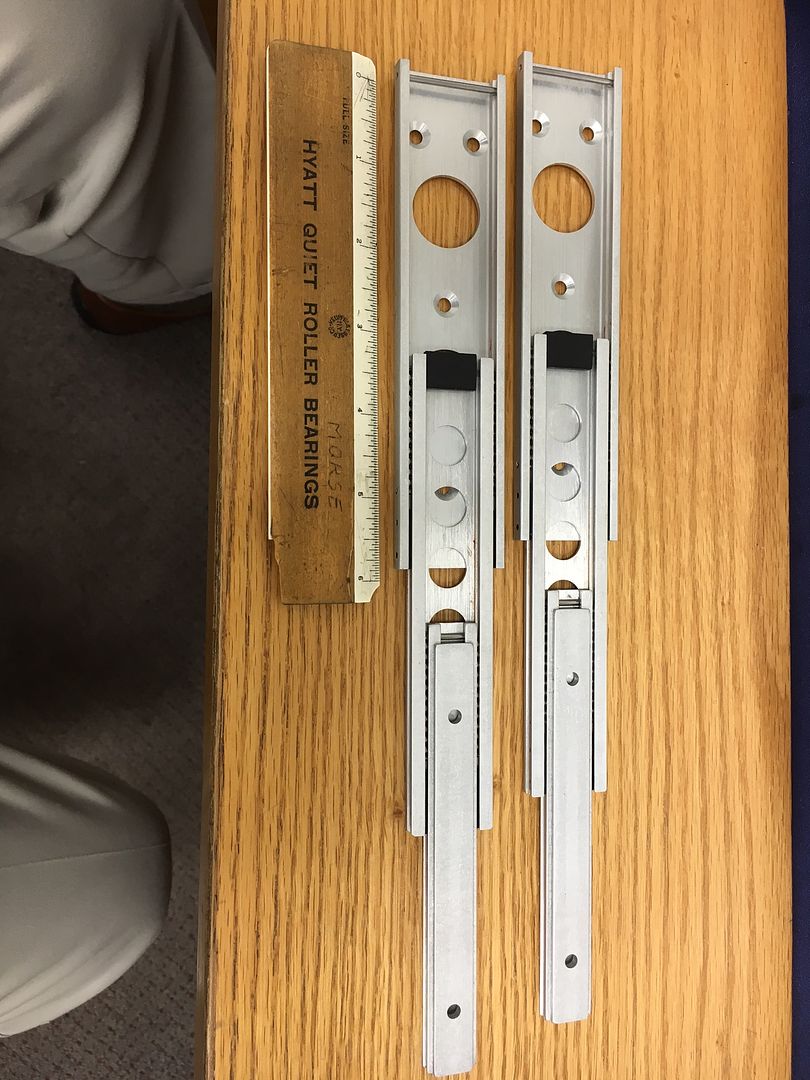

The lower die was relieved to better accommodate tighter corners...  Comparing the two dies....  Looking at the center two sample beads, the one toward the left shows a flatter bead using the new die..  And on the Wheeling Machine front, I've been contemplating a storage drawer for under the base, but have struggled to find a good slide track to hold it.. Until yesterday, the guys at Dyna Rep Company came through for me, a 6" long full extension slide, in stock! Thanks Brad!  These will be mounted between the mounting legs coming in from the side, drawer deep enough to hold all the extra lower anvils and hopefully the goKart slick...

__________________

Robert |

|

|

|

|

|

#746 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Sorry I've been lax on wagon pics. When you get to the bodywork stage it doesn't show progress well. We did get another dose of SPI epoxy sprayed on the quarters today so we can better see how we're coming along..

__________________

Robert |

|

|

|

|

|

#747 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Yes, body work is one of those things that takes forever, with little results, until the paint goes on. Then it really shows....Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#748 |

|

Registered User

Join Date: Jul 2012

Location: Rosenberg, Texas

Posts: 3,506

|

Re: 55 Wagon Progress

Wow, that looks pretty good!

__________________

-Duane C/10 Club Texas member 1971 Chevy C10 "Brutus" SWB Fleetside 2016 6.0L (L96) 6L90E (driver/project) 1965 Pontiac GTO "Royal Goat" 400/TH400 w/AC (my baby) |

|

|

|

|

|

#749 |

|

Man of Mini-Talents

Join Date: Sep 2009

Location: Oklahoma City, OK

Posts: 4,295

|

Re: 55 Wagon Progress

Outstanding work

__________________

Steve Project - Ruth 66 Skylark Project - Lola 60 Biscayne Project - Iron Ox 54 GMC 100 Project - Darth 69 Camaro |

|

|

|

|

|

#750 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Coming along straight as a pin.

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|