|

|

|

#126 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Well after a week in FL, time to get back in the shop.. I wasn't totally pleased with the .023 EZ grind, but in all fairness I think some of the issue is my welder. It never has been too keen on .023 wire, so looks like my BIL is going to get a new roll of wire for his Hobart.

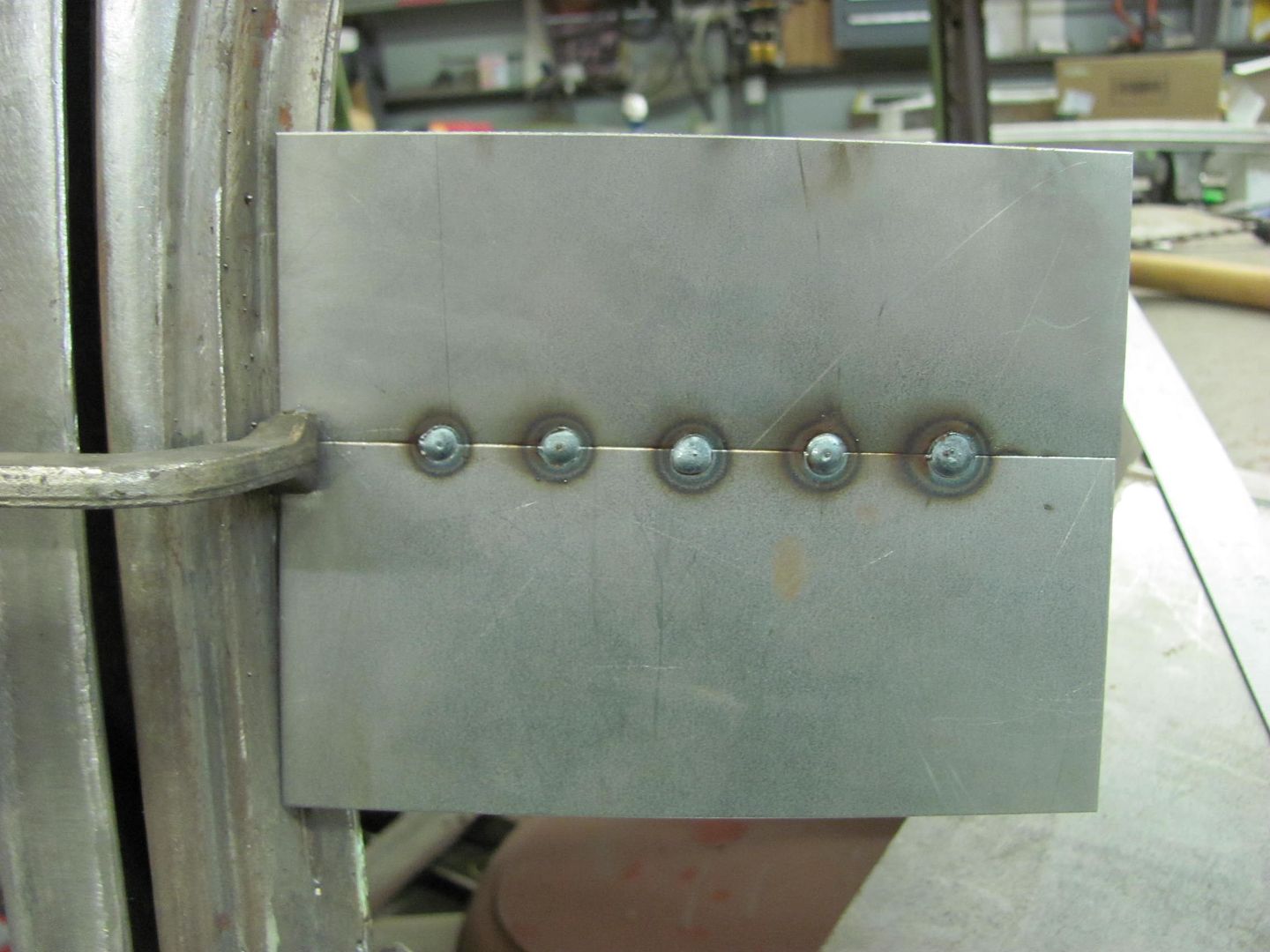

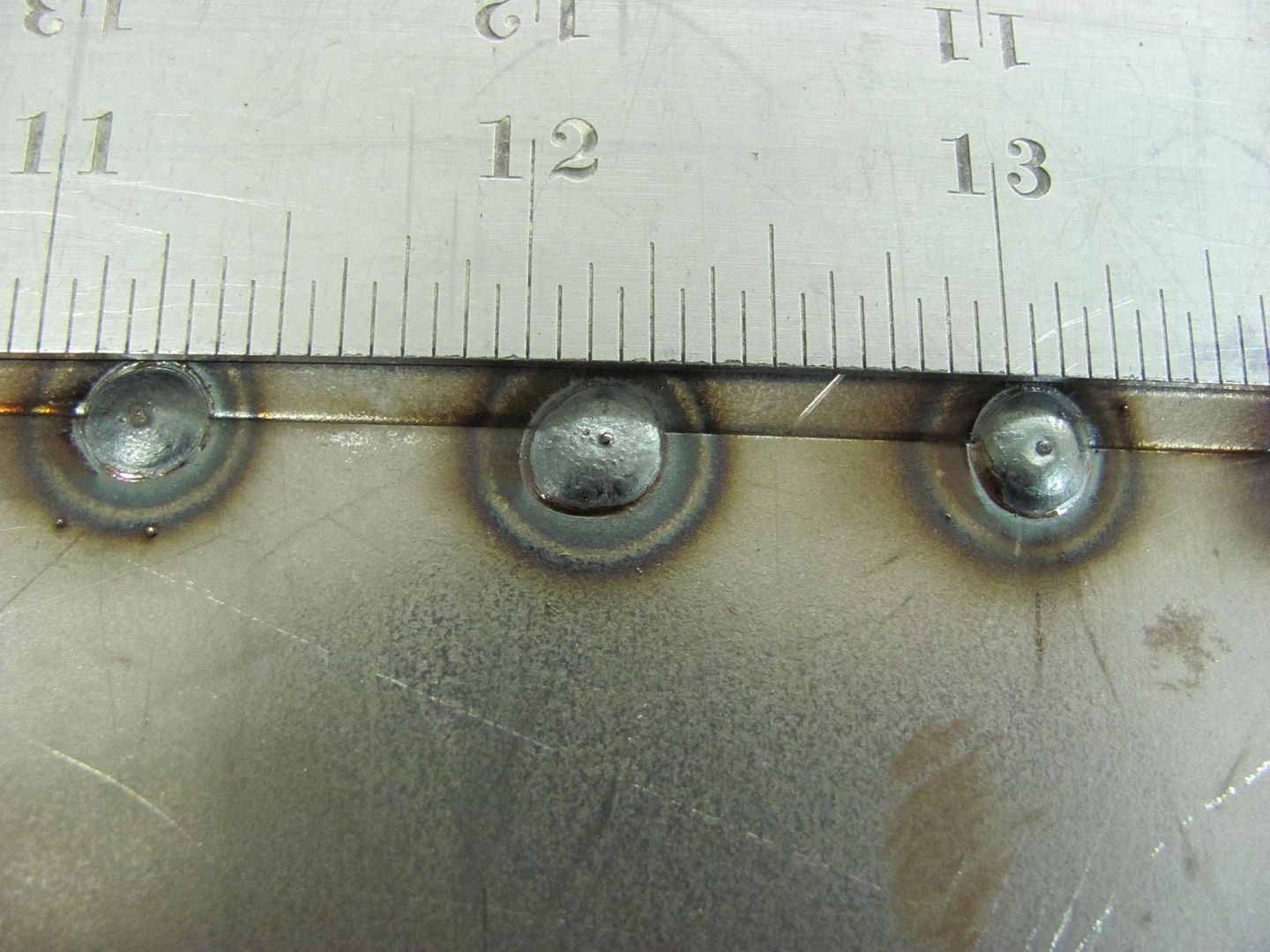

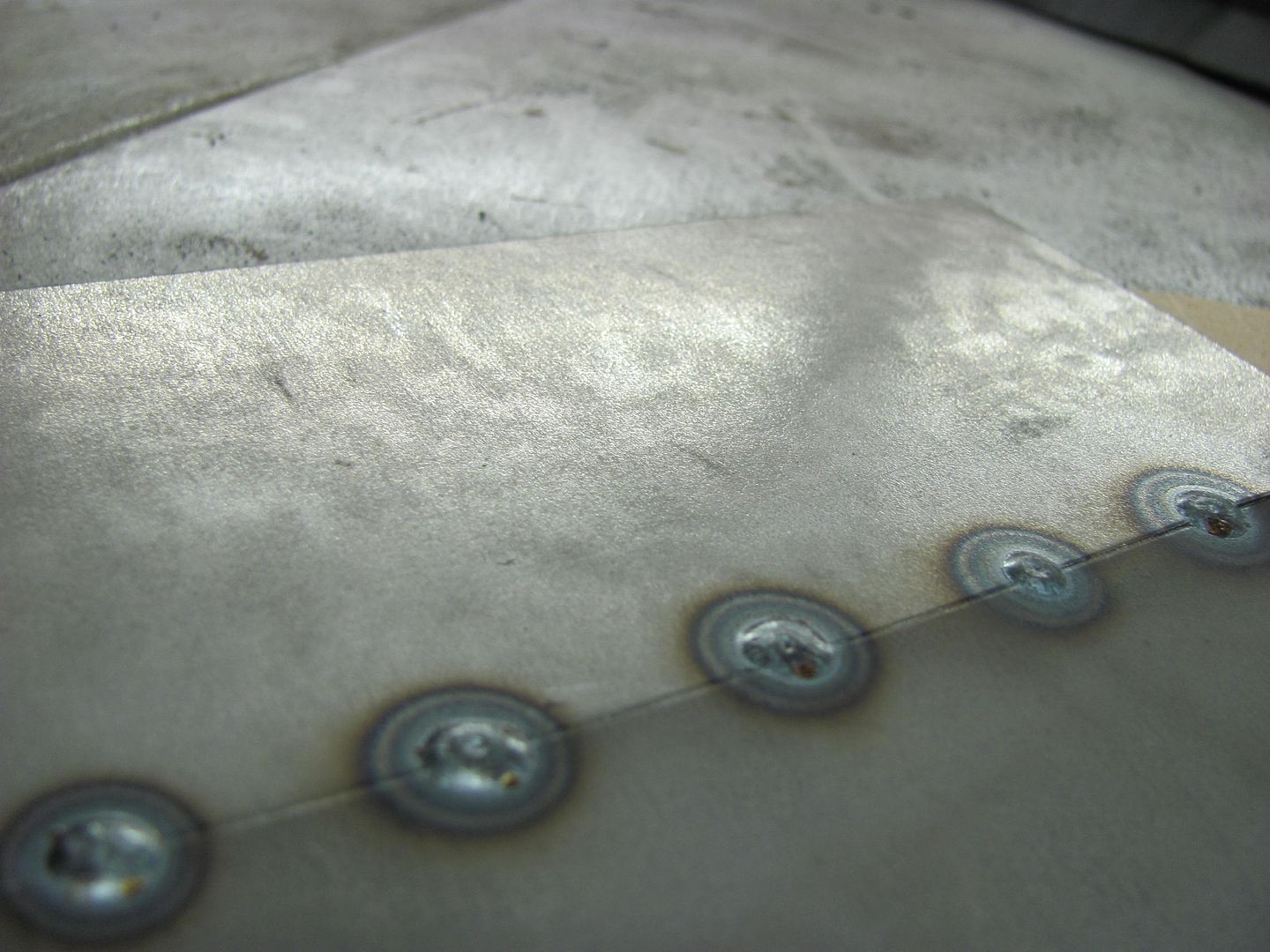

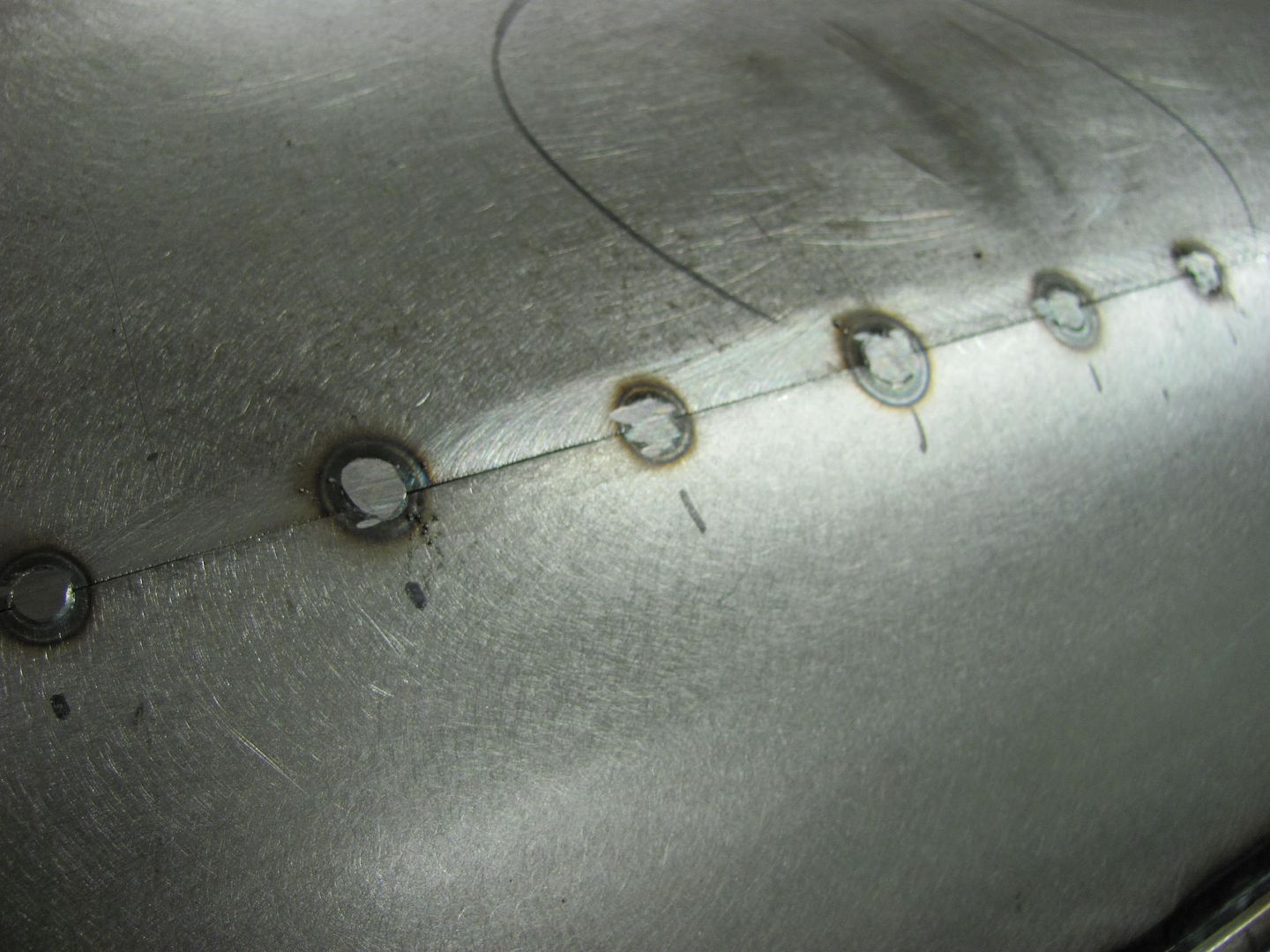

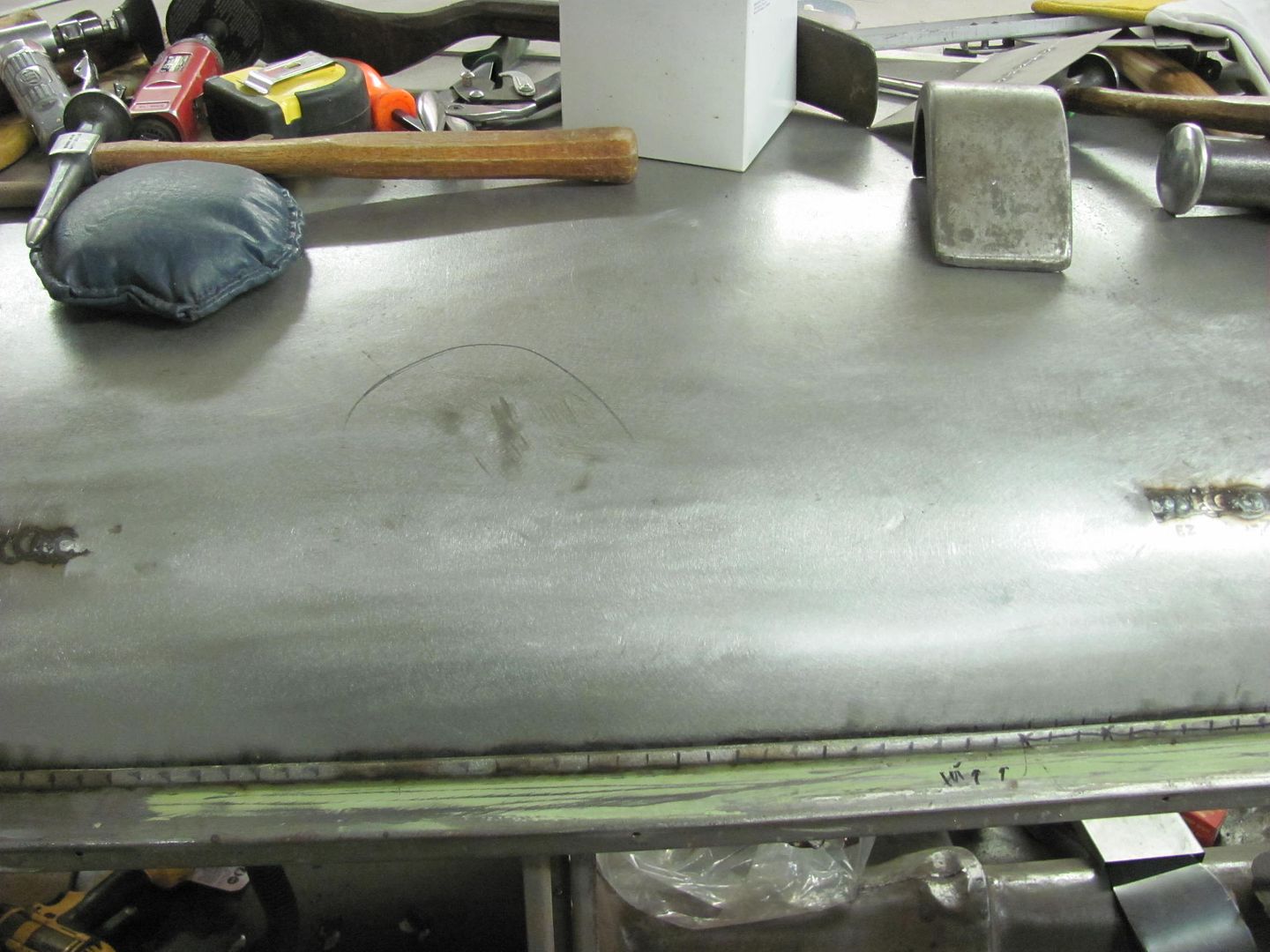

Put the .035 ER70S-7 back in, dialed in the settings for 3/16 thick steel, and ran some test welds...  Front side....   Rear side....  Comparing the EZ grind to the -7 shows less splatter...   The roof cross member made part of the weld seam inaccessible, so it was removed on one end for planishing access...    Welds ground down to just above panel surface...  Our planishing implements this evening.... Low crown hammer and used the Pexto blocking hammer as a dolly...    This shows the weld dots planished....   Full penetration welds.....  Weld, planish, grind, repeat.  We're about halfway done, hope to finish it up tomorrow...

__________________

Robert |

|

|

|

|

|

#127 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Just found this thread and glad i did, haven't been in this section on a long time.

Subscribed. So by planshing, if i got this correct, your actually expanding the weld to keep the patch panel from shrinking where the heat cooling would pull the seam inward creating a void along the weld correct? I did read the first couple pages and posts about the rear quarter.

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#128 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

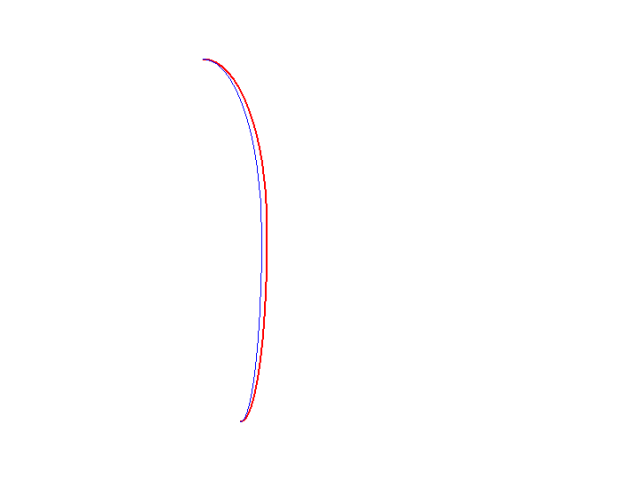

To help explain, let's look at the cross-section of a quarter. Where this is a lower crown panel, and the heat often wreaks more havoc on the center of the panel, in many cases it will shrink, lose some of the crown, (become more flat), and possibly start to oil can as the metal loses its shape. In the picture below, the red arc would represent a vertical weld through the original shape, and the blue shows what occurs as the weld and HAZ shrinks; the arc loses some of its length, becoming a smaller arc or more towards a straight line. This in effect pulls the adjoining metal into a valley. Many people will misread all this "panel movement" as a stretch, but it is indeed shrunk.

To correct this, the hammer and dolly principles as explained above are used to keep the shrinking effects in check.

__________________

Robert |

|

|

|

|

|

#129 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Great explanation Robert. About how many hits or blows do you do on each weld? About how big of a diameter around each weld do you think the shrink is? How much time do you have in welding, planishing and grinding on what you have done so far?

Your explanations are very helpful.

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#130 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

About 3 to 4 strikes is what I use. Just what I did last night was about 3 hours, including welder setup.

__________________

Robert |

|

|

|

|

|

#131 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Thanks Robert. How hard do you push outward on the mini sledge type dolly when planishing?

Would you be able to explain something to me. I find sometimes if I put a dolly on the outside and hit the weld from the inside, the metal stretches back out much easier and faster. Everything I read suggests the opposite of this. Why is my methods so wrong or not used? Thanks.

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#132 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Hardly at all. Lightly place it against the proud of the weld dot on the bottom side, listen for the metal on metal when you strike from above with the hammer. I should probably back up here and say the primary focus with this "initial" planishing is to add some stretch to where it shrank. Once the full weld pass has been dressed, then you can go back and look at any further needs, bumping, planishing, shrinking, etc. to get the panel nice and true. With those weld dots still there, even while ground down, it's more of a challenge to read the panel accurately. Save the final planishing for the next step... after it's all dressed smooth.

__________________

Robert |

|

|

|

|

|

#133 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Got it, thanks!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#134 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Glad to help!

Well this evening was a short night, back to the day job tomorrow, so we'll have to call it early. Did get the bulk of the welding done. planished, and started to dress the welds. This will still need some final metal bumping, but I like this much better already!     Sorry I didn't have as many in-process pictures, got in a rush this evening....until next time..

__________________

Robert |

|

|

|

|

|

#135 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Some more cleanup work on the roof weld, didn't get much for in process pictures, but then this part gets pretty boring anyhow...

Inside...  I'm pretty pleased with how it turned out this time. Still has some metal bumping needed to address some highs and lows, which we'll work on next time in the shop, as well as welding in the last pieces of the lift gate..

__________________

Robert |

|

|

|

|

|

#136 | |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Quote:

One question though, what did you use to smooth out the inside of the roof? Did you use the same tool to finish out the outside (top) of the roof? May be boring to you but life changing to me. |

|

|

|

|

|

|

#137 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

On both inside and out I start out by knocking down the proud of the weld in between dots using a 3" x .035 (or 1/16 thick if that's what you have) cutoff wheel held perpendicular to the weld. This both gives a minimal contact patch for less heat buildup but also gives the most unobstructed view of any device used to grind down the weld, so you have less chance of inadvertently hitting the panel on either side of the weld, thinning out the panel..

See here for the grinding method, this is on a plug weld but the grinding process is the same: https://www.youtube.com/watch?v=V2WHT_zMOE8 After getting the bulk of it down on the entire weld, a 3" 80 grit roloc sander is used on the outside to dress the panel, and on the inside an 1-1/2" diameter drum sander is used to clean up the high spots and finish with the same 80 grit roloc. Not saying this is the right way or the only way, but it's what has worked best for me.

__________________

Robert |

|

|

|

|

|

#138 | |

|

Registered User

Join Date: Apr 2009

Location: Amarillo, Texas

Posts: 636

|

Re: 55 Wagon Progress

Quote:

__________________

Father and son built. Driven daily since 2012. 283, 3 speed. Mostly original. '81 PS and disk front. Fuel tank relocate. Maintenance, repairs and upgrades on his dime now. http://zacks64longfleet.shutterfly.com/ Higher res. photos in my gallery. |

|

|

|

|

|

|

#139 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Yes, exactly. I have the 3/4 and 1-1/2 diameters.

Got tired of buying the drums by the 3 pc blister pack at the local True Value, so my welder supply ordered me SAIT in boxes of 100 qty of 60, 80, and 120 grit... Cheaper per drum and better quality

__________________

Robert Last edited by MP&C; 02-25-2014 at 08:53 AM. |

|

|

|

|

|

#140 |

|

Registered User

Join Date: Apr 2009

Location: Amarillo, Texas

Posts: 636

|

Re: 55 Wagon Progress

Thanks for reply and the supplier tip.

__________________

Father and son built. Driven daily since 2012. 283, 3 speed. Mostly original. '81 PS and disk front. Fuel tank relocate. Maintenance, repairs and upgrades on his dime now. http://zacks64longfleet.shutterfly.com/ Higher res. photos in my gallery. |

|

|

|

|

|

#141 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

More questions~

Somehow I've gathered sanding drums from garage sale finds but have never broke'em out. Do you prefer the sanding drums over sanding flapper wheels? And Cleaning up the inside of the sheet metal that will be covered up is that for bumping purposes or any other reason? I clean up unseen areas just cause I'm too anal at times. |

|

|

|

|

|

#142 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

For dressing welds I use the 3" cutoff wheel for the bulk of the weld, to get it to just above flush. This has a minimal contact patch for about the least amount of heat buildup possible. It also gives you about the maximum visibility possible to insure you get the weld down as far as possible without inadvertently hitting to either side of the weld and thinning out the parent metal. The flap wheel fails on both these points as it causes too much heat buildup, and you can't see what you're doing. Flap wheels are not suitable for sheet metal IMO. After getting that far with the cutoff wheel, then use the 3" roloc sander to blend the remaining weld to the parent metal.

On the sanding drums, they are used in the same fashion when dressing inside radiuses. Save your cutoff wheels when they get smaller in diameter for tight spots, good for dressing welds in tighter spots. Then when weld is down to just above panel surface, revert to drum sander. As far as cleaning up the rear of the welds, multiple reasons. First, the weld dots should have gone through the "initial" planish while the dots were still isolated by themselves. Then grind down to get rid of the bulk so it's out of the way for planishing the next. When you get done and have finished the weld with you roloc sander, now you have nice flat panels that are more receptive to metal bumping, and more predictable when it comes to metal bumping. Leave weld dots proud on the back side and you are risking panel distortion as the welds deflect off the dolly, possibly causing more distortion than left by the welding operation. Lastly, just like the lapped seam gives the possibility of a ghost line in a finished panel, leaving a weld proud, whether on the back side of the panel or a cold joint left on top and "hidden" by mud, thicker metal expands slower than thinner. Leaving weld proud on either side risks ghost lines just like the lapped seam does.

__________________

Robert |

|

|

|

|

|

#143 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Thank you for explaining it to me. Wealth of information on metal finishing.

|

|

|

|

|

|

#144 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Glad to help!

__________________

Robert |

|

|

|

|

|

#145 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

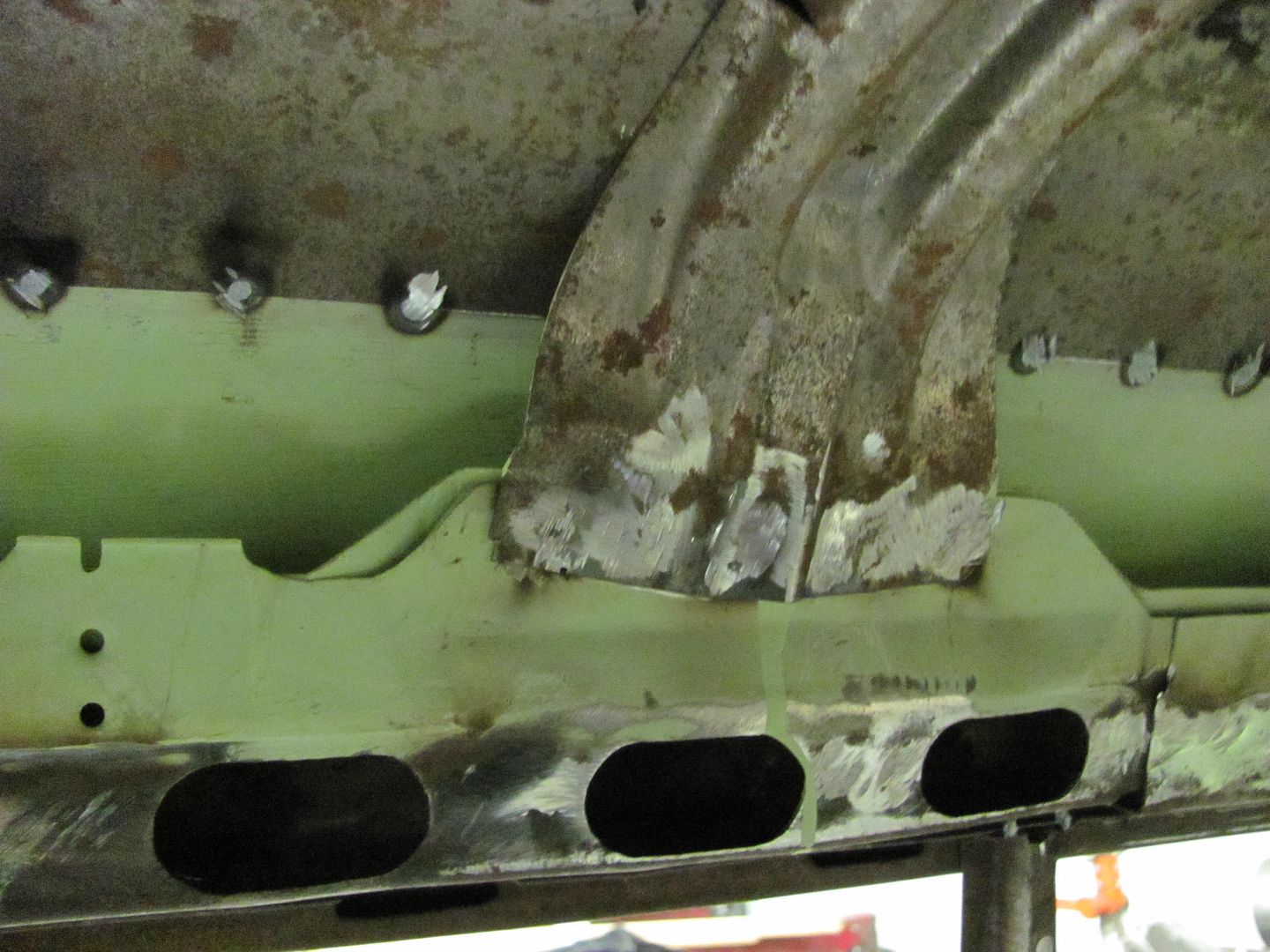

My nephew Chris worked inside the wagon to clean up some of the welds...

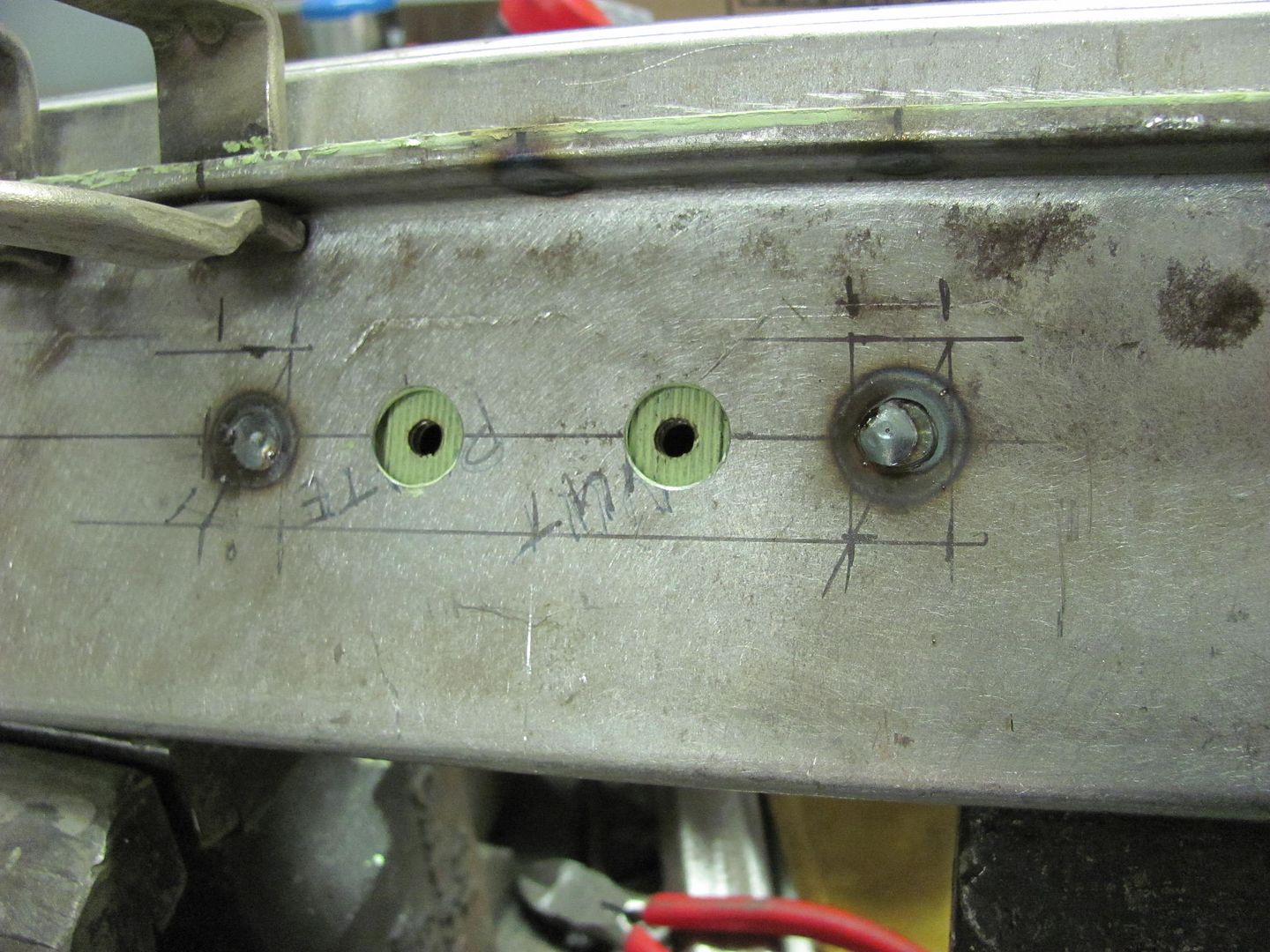

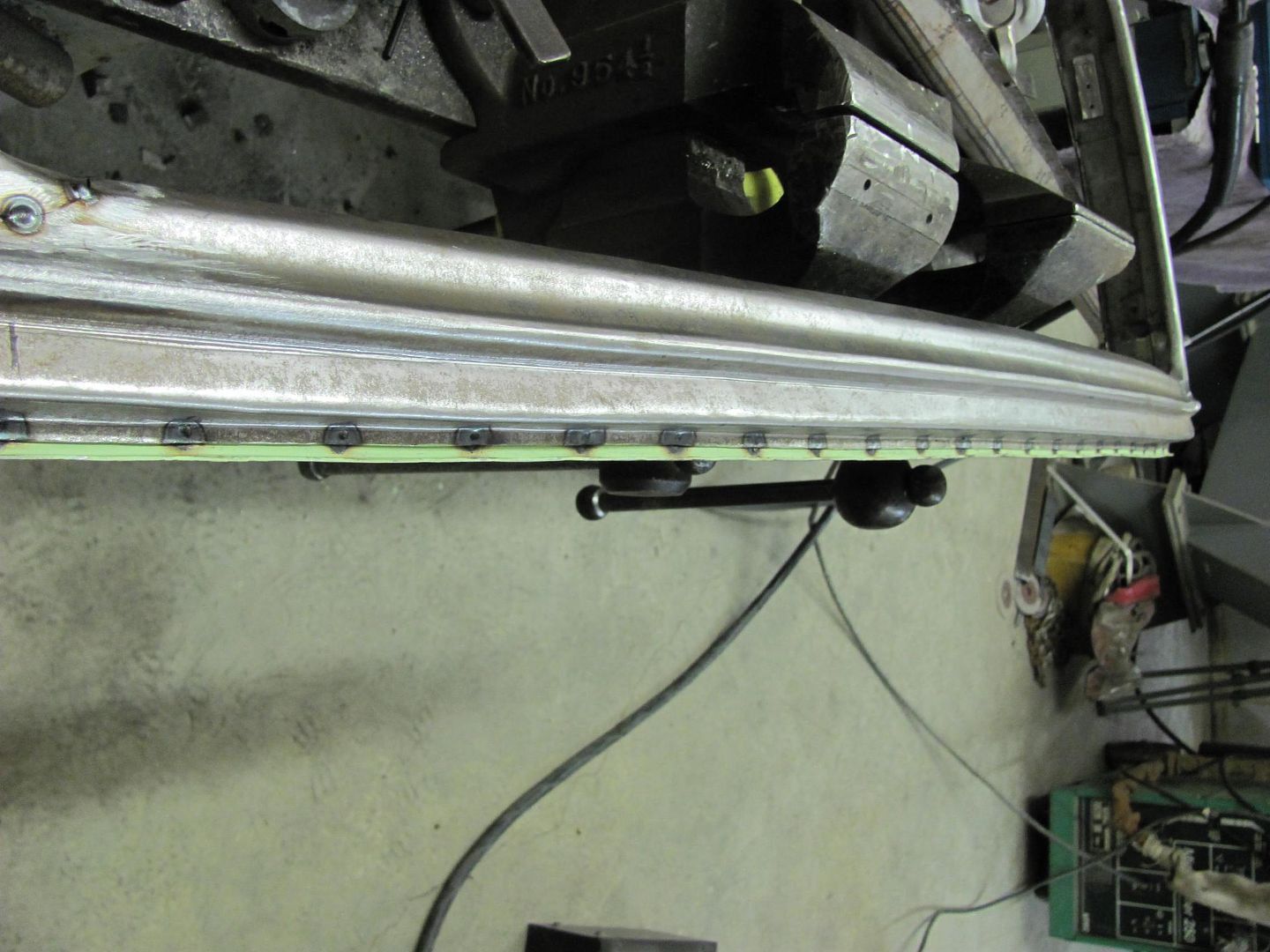

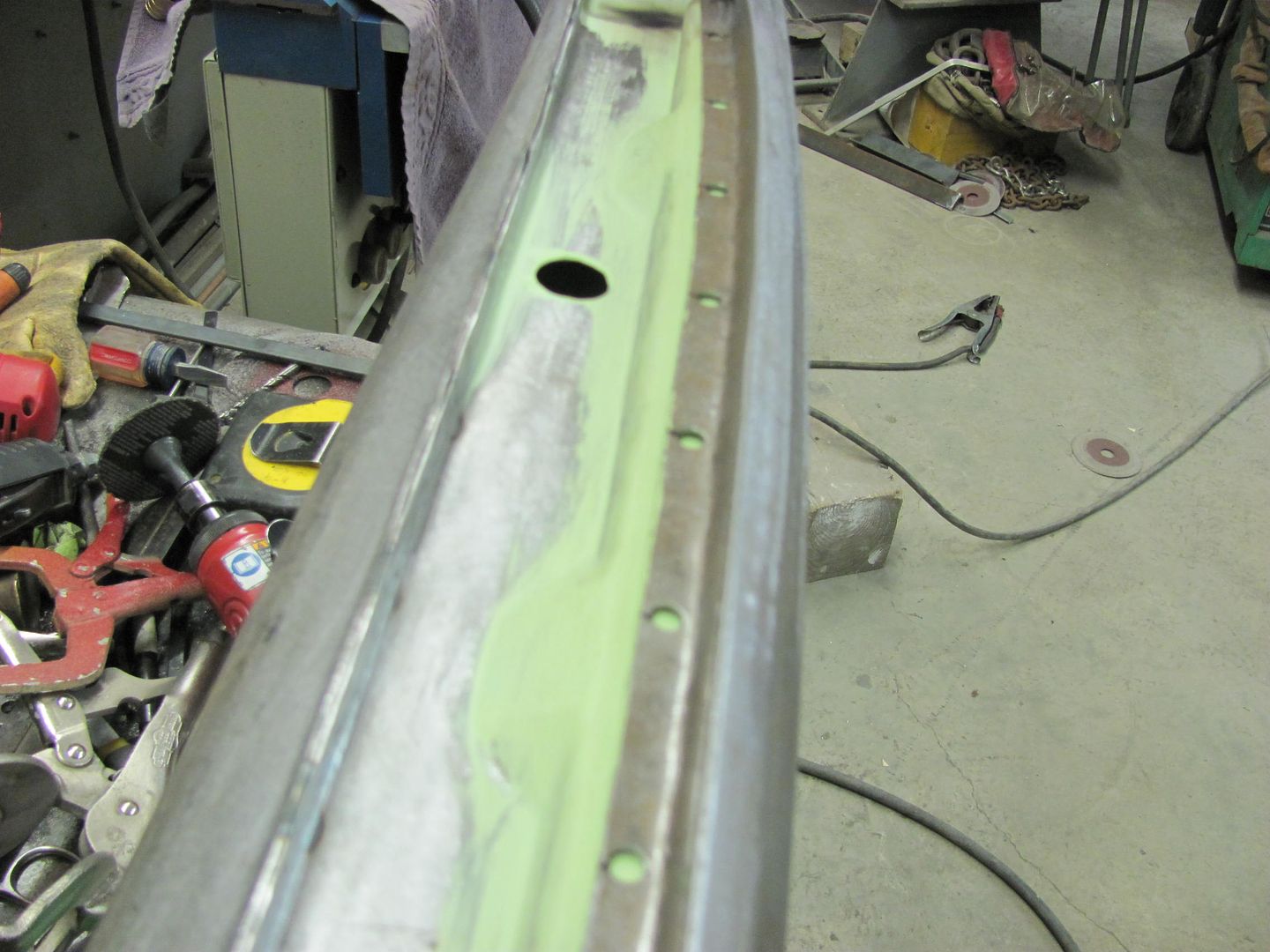

Before closing up the lift gate, we have a couple more items to cross off the list. A rubber bumper gets installed at the bottom in case the gates are closed in the wrong order, you won't scar up the paint on the top of the tailgate... The old sample only had one good hole location for us to use...     Next, the floating nut plate was plug welded to the bottom....  With that done, we could prep for closing up the bottom. In order to use the spot welder along the bottom seam, we needed to clean off some epoxy primer where the spot welds would be located. Used and even spacing of 2" and marked both flanges...   In order to remove as little epoxy primer as possible, we decided to use the modified plug weld drill bit (the flattened one) over all the errant marks a roloc sander would make. In order that the flat drill bit didn't walk all over the place, another specialized tool was made....     Here's another close up of the modified bit...  .....and the "prepped" flanges...   Ends tacked in place, and spot welded the bottom flanges together...

__________________

Robert |

|

|

|

|

|

#146 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

A bit more welding.......

Cleaned up....   Other side.....     Only thing left on this piece is the plug welds in the window opening. Need to put the rubber on the window glass and fit it to the opening to see if this part needs shifting prior to welding...  This might even work....

__________________

Robert |

|

|

|

|

|

#147 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Nice!

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#148 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

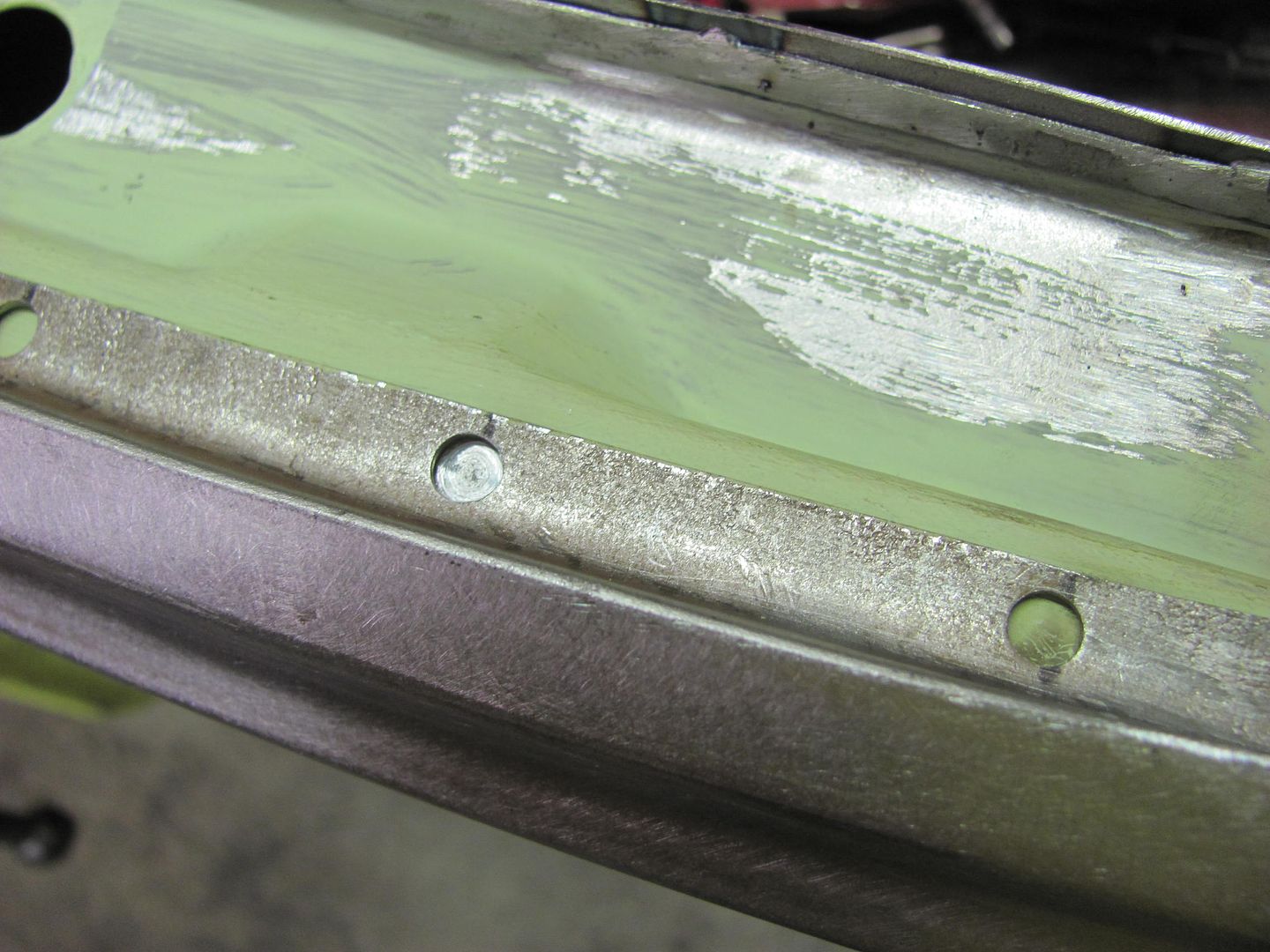

Thanks! Not much progress to show, but I did test fit the rear window, and finished the plug welds.

Cleaning the epoxy out of the holes...    Welds cleaned up.....

__________________

Robert |

|

|

|

|

|

#149 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Looks good Robert. Picking up some epoxy primer that is green like the stuff you use. I'm following your advice!

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#150 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,648

|

Re: 55 Wagon Progress

Keep in mind if you're getting the House of Kolor stuff it does not play nice with rust converters like Ospho, etc. Didn't know if you were using any of those converters, but always good to check with the Epoxy manufacturer is there are any compatibility issues..

__________________

Robert |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|