|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

How To Detail Sand Body Panels, Edges, Corners, Etc.

I'm in the middle of doing the bodywork on a truck at work and thought I'd document the process of detail sanding around the various panel shapes, flanges, and stamped details. You can have the flat panels laser straight but if the other areas aren't detailed then the the bodywork still needs work.

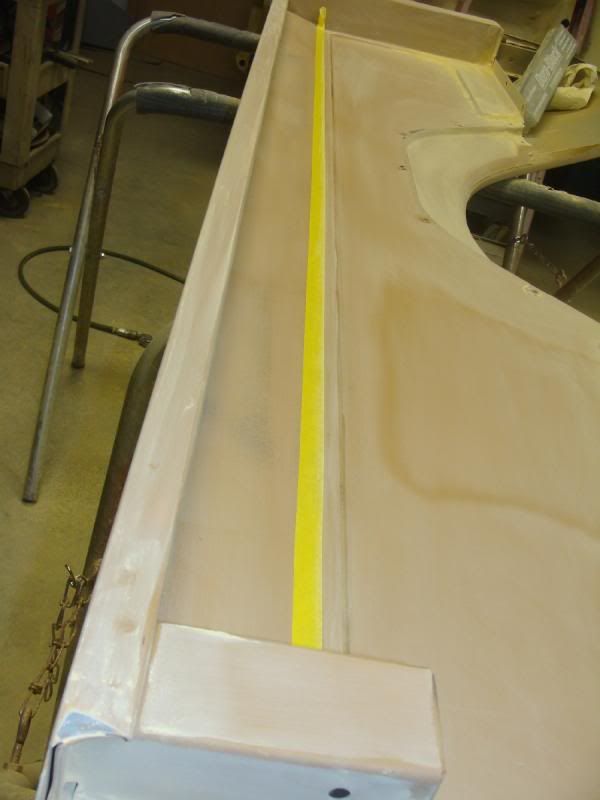

This is the panel I'm working on. Has a raised area around the fender openings that wraps back around the sides and top, corners that have flanges that meet up almost against the raised stampings. The front bed corner wraps around and has a flat area stamped in it so I'll show how to keep the edges of the flat area crisp. It's already been metalworked, and the rough bodywork is done and has three coats of Slick Sand. Slick Sand is perfect for this since it builds thick enough that you have material to work with to get everything straight.  I started by making a sanding block that fits the shape of the panel that needs shaping. Remember that bodywork is about shaping first, not smoothing. Smoothing comes after the panel is shaped properly. This was all done with 80 grit to shape the panels flat, then I use 180 to smooth everything enough for the next step of paint prep. Using a guide coat is a must when doing this to show exactly where and how much you're sanding. This block is just a paint paddle cut in half and glued together, then the edges were trued up and one corner was rounded to match the shape of the spot I was sanding. I wrapped it with a layer of tape for bit of padding. If you use paint paddles, make sure they are square and flat, many are bowed in the middle and aren't fit for getting your panels flat!  This is the area that was sanded with the homemade block, round on one side against the raised stamping, and squared edges on the left side against the flange.   You can see where I sanded against the flange all the way down, even in the area at the bottom where that section of the panel is flat. I'll blend the flat area into the sanded area against the flange later. This way the flat area and the sanded area against the flange are on the exact same level.  Once the area beside the flange was sanded flat, I re-guidecoated it.  Next I sanded the flat area at the bottom using a long/skinny Durablock with rounded edges. I wrapped the sandpaper around the edges and let the edge of the block define the lower edge of the raised stamping. This way the edge of the stamping has an even radius down it's length, and the edge is dead straight as well. Notice the sanding scratches are in a "X" pattern- don't sand parallel with the edge of the stamping or you'll cut a second groove on the outside of the block into the flat area!  You can see that the area I sanded first with the homemade block is still shaded with guidecoat, indicating that the flat area isn't level with the area against the flange yet. Keep sanding until you start cutting into the guidecoat to make both areas level with each other. You can also see how I used a couple layers of masking tape to protect the edge of the flange from being damaged by sanding against it.  Guidecoat against flange is starting to sand off, both area are level.  Underside of raised stamping has been cut evenly across. I like to cut into these type areas enough until you start to hit bare metal. Primer usually builds up thicker in concave areas so this way the primer isn't thick enough to crack later.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#2 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Next I block sanded the flange on the bed corner. I used tape again on the raise stamping to protect it from being marred by the sanding block.

You can see that the edge of the block cut an even radius into the corner of the flange against the bed corner panel.  Once the flange was sanded flat, I re-guidecoated the flange and masked out the flat part and 1/2 of the radius in the corner.  The masking tape protects the already flat flange, and blocking the corner panel into the flange cuts the other half of the corner radius flat and straight.   You end up with a perfectly flat flange, a corner radius that is straight and even top to bottom, and the corner panel blends perfectly into the radius/flange.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#3 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

The corner panel had a slight flat stamped area in the middle of it. It's easy to lose these details if you don't use guidecoat and block these areas specifically. I started by blocking the flat area by itself, watching the guidecoat until I knew it was flat top to bottom. I wasn't worried about the edges being uneven, that's for the next step.

Next I re-guidecoated the center flat spot, and started blocking the right side, taking care to evenly block up against the flat area- again using a "X" blocking patter 45 degrees to the edge of the flat spot. Watch the guidecoat to see when the edge against the flat spot become straight.   And repeated on the left side.  Once both rounded sides were done, I shot more guidecoat on the sides and re-blocked the center flat area with 180 grit to double check for straight edges. Using 180 slows the cut of the block so you can slowly work up to getting the edges dead even. The edges of the flat area are now dead straight.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#4 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

To get the edges of the raised stamping detail sanded, I first had to block the flat panel.

Once the flat panel was blocked out and shot with more guidecoat, I masked the edges of the surrounding panels (also masking 1/2 of the radius that's already been cut earlier) and used a long/skinny durablock to evenly round the edges of the stamped panel. Using guidecoat shows how far the radius is extending into the flat panel- this way you can get radius even along it's length.   That leaves the corners of the raise panel to sand. I trimmed down a section of a paint paddle to fit the shape of the corner, and also sanded the edge of the sanding block to match the radius of the corner. I used masking tape to protect the areas that were already cut flat around the corner.   The top edge of the corner can be sanded by hand, using the fat part of your thumb tip and 180 grit. Using 180 grit cuts slower so you can more precisely cut the shape you want.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#5 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

The curved areas around the fender mounts can't be blocked like the flat edges. You'll have to do this with the fat part of your thumb, going slow and using guidecoat to show exactly where you're sanding and how far into the flat area you're shaping the radius of the edge.

Once all of the edge have been sanded smooth, shoot guidecoat over the entire flat area and block off the guidecoat with 180 grit. This will show how evenly the radius of the edges extend into the flat area.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#6 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

At this point I had everything sanded with 80 grit. I started the process over using 180 grit to prep the primer for a round of PPG K93 tinted surfacer. With the K93 shot, you can really see the effect of detail sanding the panels. All of the edges are crisp, straight, and the edges all have the same radius. The corner panel's flat center is well defined and is very noticable. Paint will make the details stand out even better.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#7 |

|

Registered User

Join Date: Jan 2009

Location: San Antonio, Texas

Posts: 1,374

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Marking for future reference. This is an excellent tutorial, and the pictures and detail are fantastic! Thanks for taking the time to put this together!

__________________

1972 C10 LWB, 350/350 Deconstruction began 5/2009, mostly completed restoration, 5/2017 |

|

|

|

|

#8 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Your metal working/paint skillz are top notch!

Thanks for sharing. When Im working on my stuff I always strive to meet your standards. I fall short but am always trying. Thanks. |

|

|

|

|

#9 |

|

Registered User

Join Date: Aug 2011

Location: Montrose, CO

Posts: 972

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

You, sir, are a true artist, as well as a great guy for sharing all your knowledge. Thank you. Currently using your tutorial on refurbing a gauge cluster.

|

|

|

|

|

#10 |

|

Registered User

Join Date: Aug 2012

Location: Fort Campbell, KY

Posts: 494

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Absolutely outstanding, and thank you VERY much for taking the time to post this, awesome reading.

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jun 2013

Location: Somewhere

Posts: 3,122

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

This and your other thread are great!

I love the more metalwork and less filler. Many just slather on the filler... Still, I'd like more pics and info on the process, and steps of welding in new metal. I think grinding the welds is the toughest part. Not destroying the underlying part, and not warping things is/are difficult. |

|

|

|

|

#12 |

|

Registered User

Join Date: May 2009

Location: Monroe, LA

Posts: 2,104

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Excellent tutorial! Your attention to detail is outstanding!

This shows how much time goes into the fine finish work for a high quality paint job, which is why it's not cheap to have done. Posted via Mobile Device

__________________

Keith SOLD - 1963 C10 Short Fleet 350/700R4 4/6 drop 1967 GMC Super Custom - Short Fleet COPO concept w/427 BBC T-400 w/Doug Nash overdrive 4/6 Drop, Buddy Buckets, etc... Frame Off (In Progress) I call it "Vulgar Display of Power" 1980 Silverado Original paint 49k Original miles 4/6 drop Check out my build thread here: http://67-72chevytrucks.com/vboard/s...=1#post6209941 |

|

|

|

|

#13 |

|

Registered User

Join Date: Jul 2011

Location: El Campo, Tx

Posts: 1,246

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

You are correct, I DO like it!

Posted via Mobile Device

__________________

72 Chevy blue LWB, 99% original Oklahoma truck, 28,000 miles 72 Chevy SWB: http://67-72chevytrucks.com/vboard/s...d.php?t=486626 (Attempt/Mistake #2) 2003 Harley Davidson Dyna Superglide with 2007 Street Bob front end 2000 Ford F350 Powerstroke 4WD CCLB, 310,000 miles running great (STOLEN St. Patricks Day 2014 AND NEVER RECOVERED) 2002 Ford F250 Powerstroke 4WD CCLB (To replace stolen one) Hook em Horns!!! |

|

|

|

|

#14 |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Excellent write up. I hope that you do a part two and show the next steps and grits you use to finish the panel for paint. Thanks for taking the time to document this for us.

|

|

|

|

|

#15 |

|

I'm just glad to be here!

Join Date: Jan 2008

Location: Longview, TX

Posts: 4,788

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Very good write up. I am always impressed with your work at your age. I tried to get my son interested in this, but he is impatient and does not like body work. I try to use your techniques when I can and it always helps me out in the end.

Thanks for sharing!

__________________

Karl  1965 Chevy Stepside(Grandpa's Old Blue) and (July 2015 Shop Build!)(2020, the Saga Continues) http://67-72chevytrucks.com/vboard/s...d.php?t=372424 The LST Challenge: http://67-72chevytrucks.com/vboard/s...=1#post7812257 Korbin's 1st Square: "Sunburn" http://67-72chevytrucks.com/vboard/s...d.php?t=418618 1985 GMC Sierra: "White Trash", Korbin's 2nd now... http://67-72chevytrucks.com/vboard/s...d.php?t=632305 Henry - 1984 Chevrolet, Owen's 1st Square |

|

|

|

|

#16 | |||||||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Quote:

Quote:

Quote:

Quote:

Quote:

Here's Nuke's http://67-72chevytrucks.com/vboard/s...48#post3867748 Quote:

Thanks El Campo! Quote:

Thanks Karl!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|||||||

|

|

|

|

#17 |

|

Registered User

Join Date: May 2012

Location: Lima, Ohio

Posts: 103

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Great work thanks for sharing.

|

|

|

|

|

#18 |

|

Elev8r Man

Join Date: Aug 2010

Location: Glendora, CA

Posts: 835

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Excellent info, thank you for sharing this. I will be starting my body work soon.

Posted via Mobile Device

__________________

1955.2 C4 Carry-all / Suburban  ---> 55.2 Build Thread!! ---> 55.2 Build Thread!!1958 Fleetside SWB ---> 58 Fleetside Build thread 1939 2 door sedan My F.B. project page. |

|

|

|

|

#19 |

|

Registered User

Join Date: Aug 2013

Location: Wildomar Ca

Posts: 274

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Thanks for the great details I will read this again when ready to block sand.

|

|

|

|

|

#20 |

|

Here kitty kitty kitty

Join Date: Aug 2010

Location: Perrysville, IN

Posts: 548

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

mcbassin just sent this link to me. it is great info! thanks for sharing the knowledge and thanks to mcbassin for pointing it out.

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jun 2011

Location: Richmond,Va

Posts: 2,934

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Marked for reading when I'm not so tired and my attention span isn't suffering. Thanks for the info. I've got my 67 down to bare metal, doing all the things required before I lay down the epoxy primer. Block sanding the high build primer has me a little nervous when it comes to the detail work.

__________________

Nick Carter 1967 C10 Short bed Fleetside Project Cheap Thrills! 2WD C10 Modern/Performance Alignments Easiest Alignment Ever! |

|

|

|

|

#22 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Thanks for the comments dudes, glad that it's a help!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

#23 |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

It has been a help for me just this last weekend:

Not as clean as your pro work but I really like the results so far.    I do have one question, you mentioned using slick sand above; Have you used Z-chrome high build rust defender? How does it compare to slick sand? they are both polyester based. I have noticed it takes a bunch of it to build but it sands out smooth. I think it may be better than the old urethane primer I used to use. |

|

|

|

|

#24 |

|

Registered User

Join Date: Mar 2013

Location: Houston Tx

Posts: 218

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

is there any pros to blocking out metal rather than primer or was that just your personal preference? that looks like some mighty fine body work also!

edit: wow, thought it was metal ha! I didn't bother reading :/ |

|

|

|

|

#25 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Re: How To Detail Sand Body Panels, Edges, Corners, Etc.

Quote:

Yeah, it's Slick Sand primer, not bare steel. You can block bare steel to show the high/low spots though, it's really helpful to find everything before you start the bodywork process!

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|