|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Account Suspended

Join Date: Sep 2009

Location: High Plains of Colorado

Posts: 2,485

|

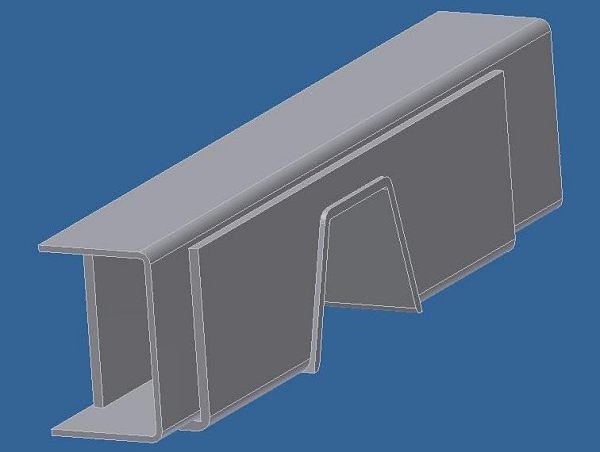

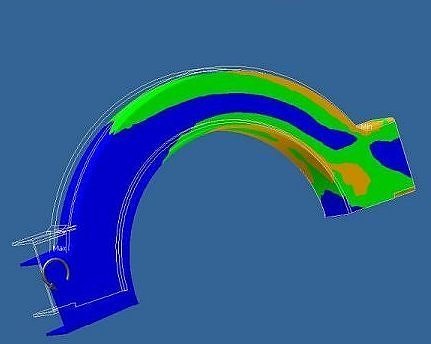

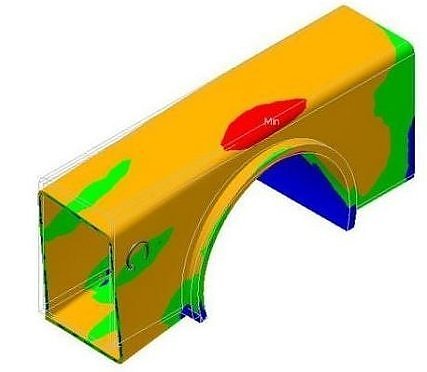

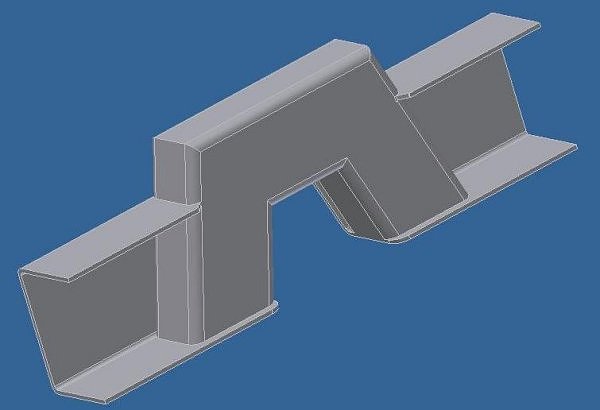

Frame Notch Based On Strength

To discuss this topic go here- LINK

I reviewed this thread and was concerned that some of the information that was posted would be taken out of context and misused. To prevent this from happening I deleted my posts and reworked the data into the following: Frame Notch Based On Strength Frame Notch Based On Strength A lot of guys are notching their frames to lower the trucks stance. As a Mechanical Engineer some of the photos these guys have posted on various websites reflect notches that are scary. Please note that I don’t have a dog in this hunt; I am not selling anything. Don’t shoot the messenger, I am merely trying to help. How you notch your truck frame should depend on its original factory design and how it will ultimately be used by you or any future owner. My personal philosophy has always been any change to the frame should restore the original strength, but that is me. I always assume that just because I may never push the envelope of my truck to its rated capacity doesn’t mean the next owner won’t. Things to consider: How do you plan to use the truck? If those plans include hauling loads in the truck or pulling a trailer with the truck the frame will see these loads and frame strength will be very important. Long bed trucks load the rear frame section more than short bed trucks. A look at various designs using Finite Element Analysis A Stock Frame (based on a 65 C10) is the baseline for all of these designs. The FEA assumes a factory stock standard coil spring / trailing arm type suspension, circa '65 (I have been told that the suspensions from 63-72 were all very similar) and assumes a bending moment from hauling and towing loads. Worth noting is that if hauling and towing loads are not present the trailing arm suspension style frame has almost no load at the rear axle, only the weight of the frame itself and the truck bed. A Stock Frame (based on a 65 C10) is the baseline for all of these designs.  Commercially Available Notches Bolt In This model replicates the popular bolt in notch, it gains you about 3-1/2" additional clearance. It captures the bottom and the outside of the frame and is ¼” thick. The frame is not boxed. FEA reveals the frame is 80% weaker than stock. Bolt In Type Notch  Add a welded in boxing plate to the back of this design and the FEA reveals the frame is still 60% weaker than stock.  Weld In (Dim. data was taken from this website: http://www.*****************/notches/...step-notchkit) The half circle notch is slightly stronger than stock (about 10%) and gives about 8" more travel. Half Circle Notch FEA  The Step Notch is slightly weaker than stock (about 10%) and gives about 8" more travel. Step Notch FEA  DIY Weld In Notches Pipe Notch. This yields 2" more travel than stock and is as strong as a stock frame. It utilizes a 3/8" reinforcing pad and a 1/4” boxing plate to accomplish this. Pipe Notch FEA  Deep Pipe Notch. I saw this being done on one of the websites. It was a boxed installation and it is about 76% weaker than stock! Deep Pipe Notch FEA   Step Notch made from rectangular tube. Here is one I developed that is made from mitered 3-1/2” x 2-1/2” x ¼” wall tubing. It is about 10% stronger than a stock frame and gains you about 3-1/2" additional clearance. Tube Type Step Notch FEA  Tube Type Step Notch as viewed from inside  Summary If you want the frame to be as strong as stock and you want a frame notch deeper than the 2" there is simply no substitute for adding some sort of truss structure, or replacing the frame section with another structural member that has the same or greater section height as the original frame. Whenever someone starts talking about a deep frame notch (> 2” nom.) and state that just by adding thicker plates to the sides of the frame rails this makes the frame stronger than it was in its original condition, yet they are and not adding vertical height, they do not understand beam analysis. Some final thoughts The implementation of any design affects its strength. The final fabrication can only be as good as the welder – fabricator performing the work. I have yet to see a bolt in notch that will restore the strength of the frame to the factory condition. I have not seen any manufacturers “certifying”, via a signed document, the strength of their notch kits. The information posted here is for reference only. Results will vary based on actual dimensions, materials used and the quality of the implementation and fabrication. Last edited by N2TRUX; 04-03-2011 at 10:49 AM. |

|

|

| Bookmarks |

|

|