|

|

|

|

|

#1 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: '55 International Metal/Body/Paint Work

It's all in the details....Awesome work

__________________

Robert |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Apr 2012

Location: Beaver, Pa.

Posts: 197

|

Re: '55 International Metal/Body/Paint Work

You never cease to amaze!

|

|

|

|

|

|

#3 | |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

Quote:

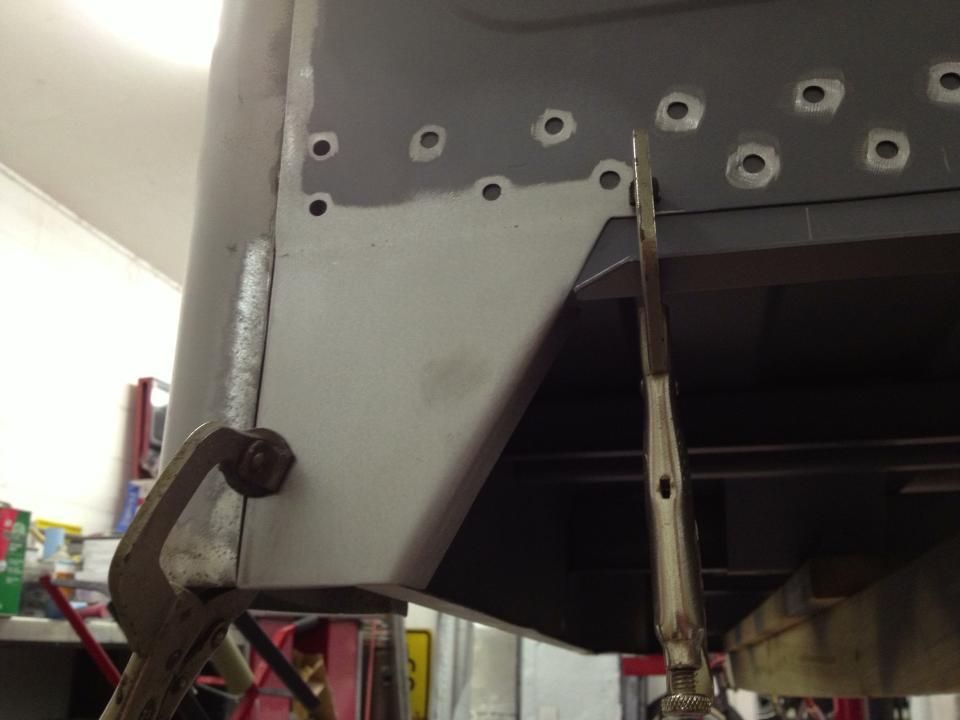

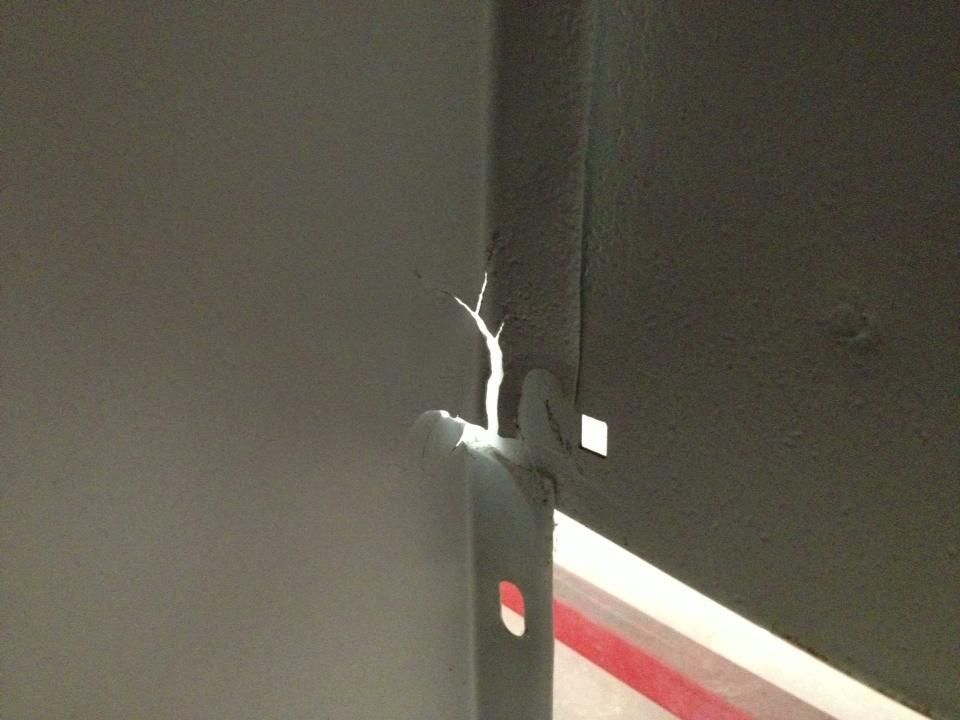

Thanks! With the header panel roughed in I needed to get the bed sides squared to the floor. Easier said than done!! The front 8" of the passenger bed side was twisted inward at the top, right where the stake pockets were. Everything was bent and there were cracks in the corners of the pockets.    I had to cut the corner brace out, ground out the cracks to prep them for welding (gets rid of the fatigued metal), then use the porta-power and a six foot long piece of tubing to have enough leverage to pull the corner back straight.   After rough shaping and welding the cracks.   New corner brace.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

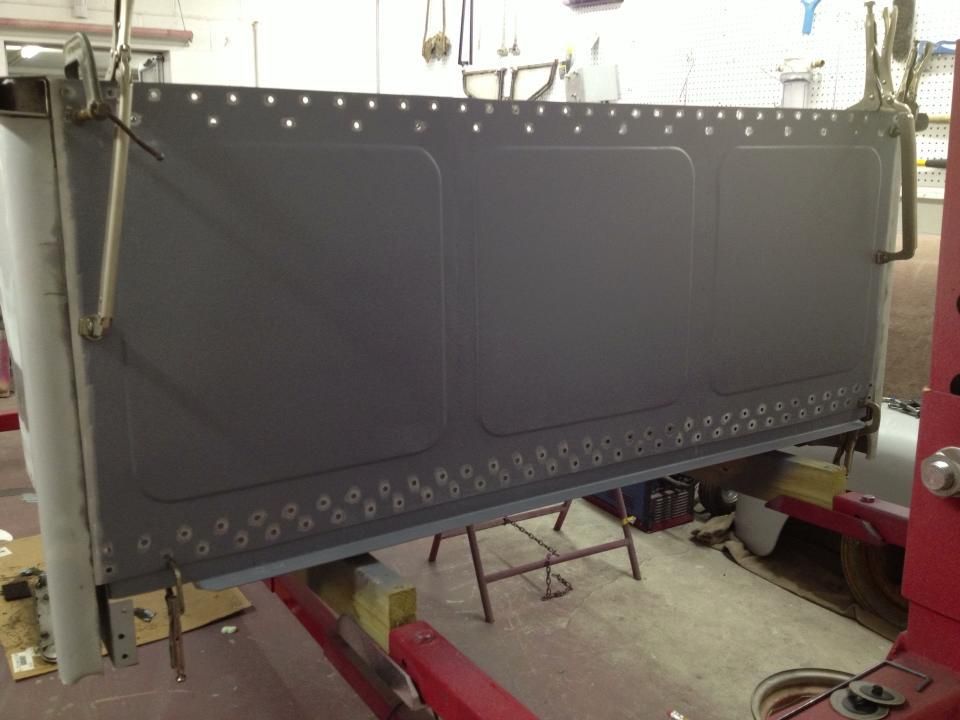

Once the front of the bed sides were straightened and squared I fitted the header panel, primed it, and drilled holes for the plug welds.

The original header panel had extended bottom corners that I needed to replicate.  The corners fill in these gaps on either end of the header.  New pieces welded on.   With the bottom corners finished it was time to weld the header in place. I started from the bottom center and worked outward, keeping clamps on either side of each plug weld spot while welding.  The sides were butt welded to the bed corners.  And a tube was welded across the top to replicate the boxed section on the original header. The gap between the floor and header will be seam sealed just like the bed sides were. .

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Feb 2010

Location: Hartselle, Al.

Posts: 466

|

Re: '55 International Metal/Body/Paint Work

Excellent work!

What brand of seam sealer do you use? Steven

__________________

“Life is and will ever remain an equation incapable of solution, but it contains certain known factors.” - Nikola Tesla Matt. 6:27 "Who of you by worrying can add a single hour to his life?” http://www.67-72chevytrucks.com/vboa...=507266&page=2 |

|

|

|

|

|

#6 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

Thanks! I use SEM 39377 two-part on normal seams like the bed floor. For drip rails I like to use Fuzor Self Leveling two-part sealer.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#7 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: '55 International Metal/Body/Paint Work

I think you really have a calling to become a teacher.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#8 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

It would have to be teaching adults, I don't think I could deal with the attitudes that most high school or tech kids have for very long. I'd have to kick most of them out so I could actually spend time teaching the ones that wanted to learn instead of herding the ones that are just there to pass a class. Or atleast that's the way it was when I went to Greenville Tech- 20-25 in a class and 5-8 that really wanted to learn it for a career. It has crossed my mind though.

Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#9 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

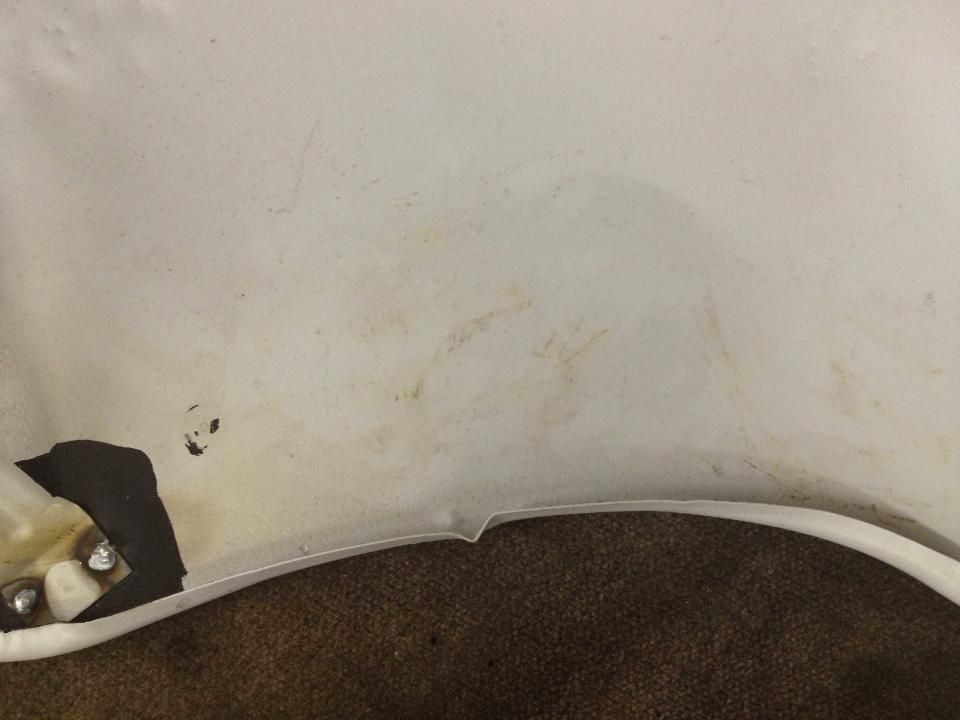

Since the metalwork on the bed is mostly finished up I moved to the fenders.

The left fender had a few cracked areas that I cut out and replaced. I also had to drill out the brace and fix it.     Old metal cut out, new metal ready to be welded in.   Fixing the other cracked spot.      Brace welded up, backside of brace and inside of fender coated with etch primer before welding.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#10 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

The right fender was in worse shape, nearly the whole back edge had to be cut out and replaced. There were tons of cracks/splits that had been reinforced with sheetmetal riveted in place.

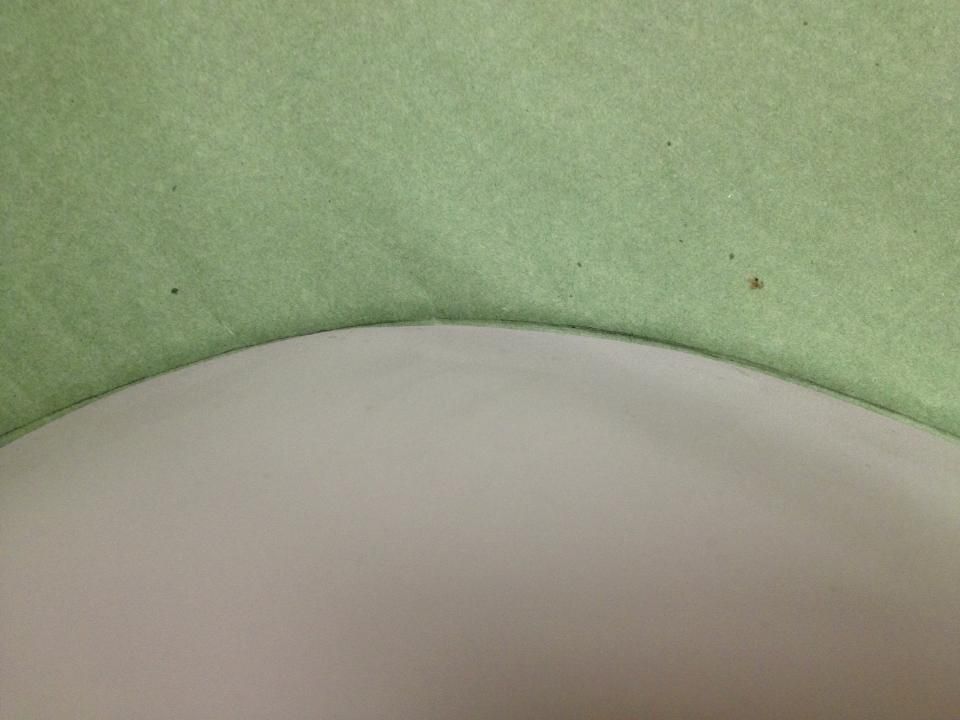

"Pat. Apr. 13 1920" on the patch!    Matching the rounded edge on the patch to the original fender lip.  Patch welded in and smoothed.  New corner brace just like the original.  Test fit the brace and prepped it for welding.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#11 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

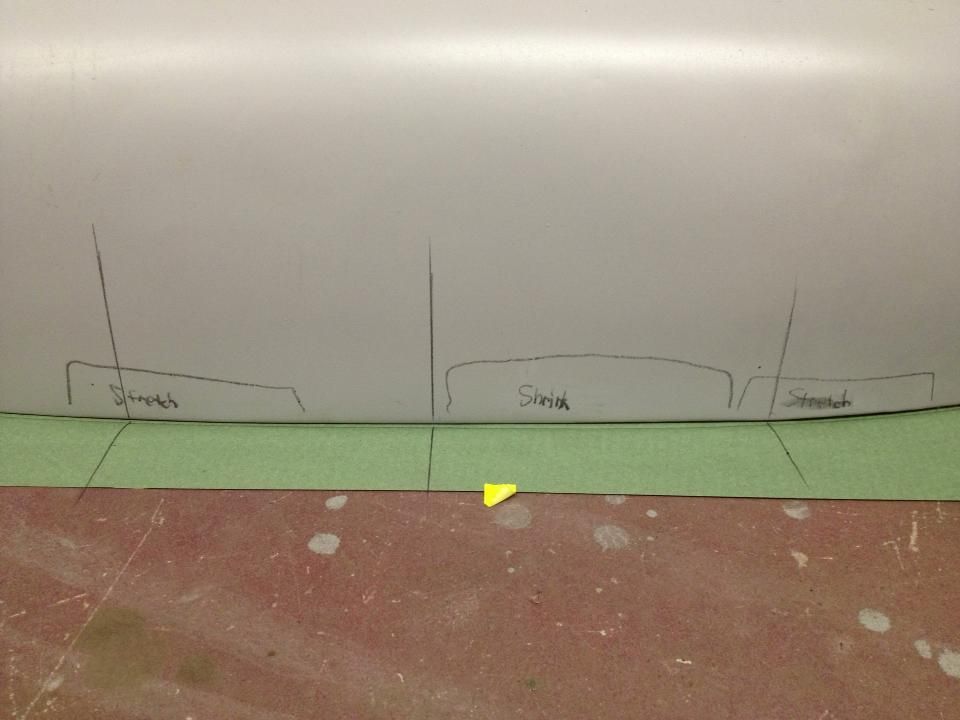

The right fender didn't fit the bedside stamping, there were dips and waves around the mounting flange.

Made a template of the stamping shape.  Made reference marks to line up the fender to the template.  Dips show up against the template.   Game plan for straightening, I'll use the shrinker/stretcher.  Set up a stand with the shrinker/stretcher inside.   Dip gone from the top after a few rounds of shrinking/stretching.  Test fit on the truck, still need to work on the corners and allow room for the fender beading.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc Last edited by theastronaut; 02-26-2013 at 10:39 AM. |

|

|

|

|

|

#12 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

After reshaping the right fender edge, test fitting with the fender beading. Even gap and the beading fits flush against the bedside.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Feb 2010

Location: Hartselle, Al.

Posts: 466

|

Re: '55 International Metal/Body/Paint Work

Very nice!

Question: What are you using to roll the edges? I am starting to look at metal working equipment so I can stop using a vise, sandbag and hammer for everything.  Steven

__________________

“Life is and will ever remain an equation incapable of solution, but it contains certain known factors.” - Nikola Tesla Matt. 6:27 "Who of you by worrying can add a single hour to his life?” http://www.67-72chevytrucks.com/vboa...=507266&page=2 |

|

|

|

|

|

#14 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

The brake I'm using is adjustable to make different radius edges; you move the upper clamp part (don't know the technical name) back to make the roll bigger. On the bigger radius edges I have to make them by hand using tubing and a hammer.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Apr 2012

Location: Beaver, Pa.

Posts: 197

|

Re: '55 International Metal/Body/Paint Work

Fantastic job, I always look forward to updates on this truck! The picture taking and documentation is first class and I know it's gotta slow you down at times. Much appreciated.

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Aug 2007

Location: Redwood City, CA

Posts: 1,174

|

Re: '55 International Metal/Body/Paint Work

X2^ - it's all in the details isn't it? your attention to detail, vision and skills are exemplary.

__________________

66 GMC Suburban Custom 66 Chevy K10 Suburban |

|

|

|

|

|

#17 | |

|

Senior Member

Join Date: Nov 2003

Location: Calgary Alberta

Posts: 1,936

|

Re: '55 International Metal/Body/Paint Work

Quote:

Posted via Mobile Device

__________________

67- 72 Parts collecter |

|

|

|

|

|

|

#18 | ||

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

Quote:

Quote:

My buddies shop has one but it's so big that it won't make a small enough radius for fender edges or that kinda stuff. I have used one before though and they're pretty neat! Made a rear shelf panel for a Nova that curved into the backrest and console using a slip roll.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

||

|

|

|

|

|

#19 |

|

Registered User

Join Date: Oct 2009

Location: canton ga

Posts: 12,728

|

Re: '55 International Metal/Body/Paint Work

Amazing attention to detail ,its going to be very nice .

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: May 2010

Location: Shreveport, LA

Posts: 115

|

Re: '55 International Metal/Body/Paint Work

Any new updates? And what's up w/that Nova?

__________________

81 GMC C15 RC SWB 5.3L 4L80E project

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

The Nova was another shops project car. Dad took it in to do the interior but the owner had to stop progress due to health issues last summer. Not sure when or if we'll get to finish it.

On the '55, I've got the left fender straightened and prepped for epoxy, will be spraying it and a couple of the wheels today. Dad took in a '66 F100 for a full restoration so I'm having to split my time up now.     Posted via Mobile Device Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#22 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

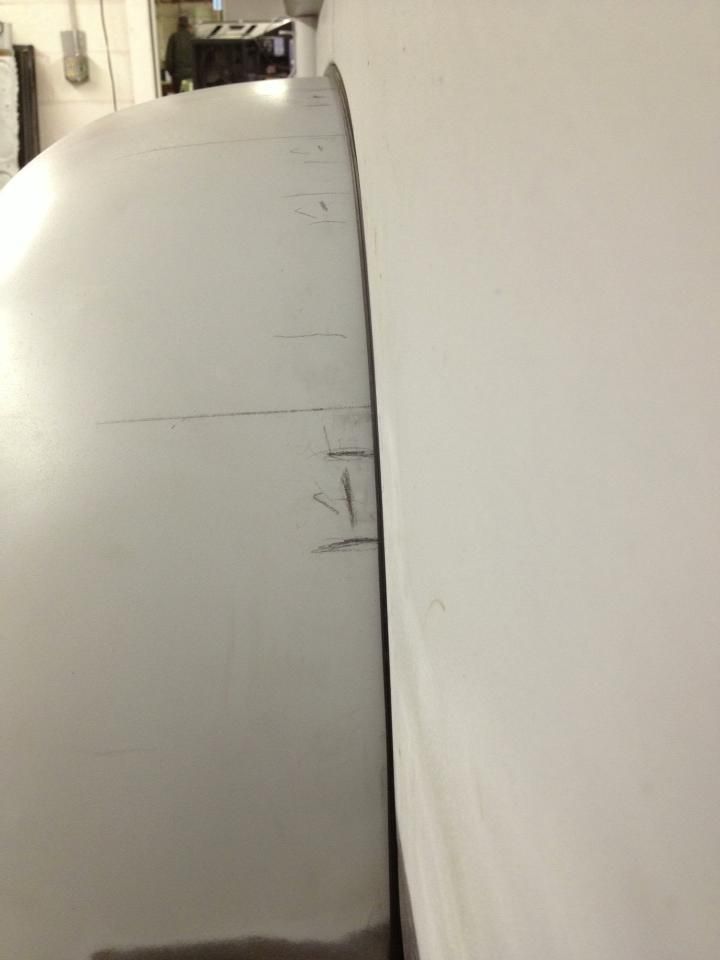

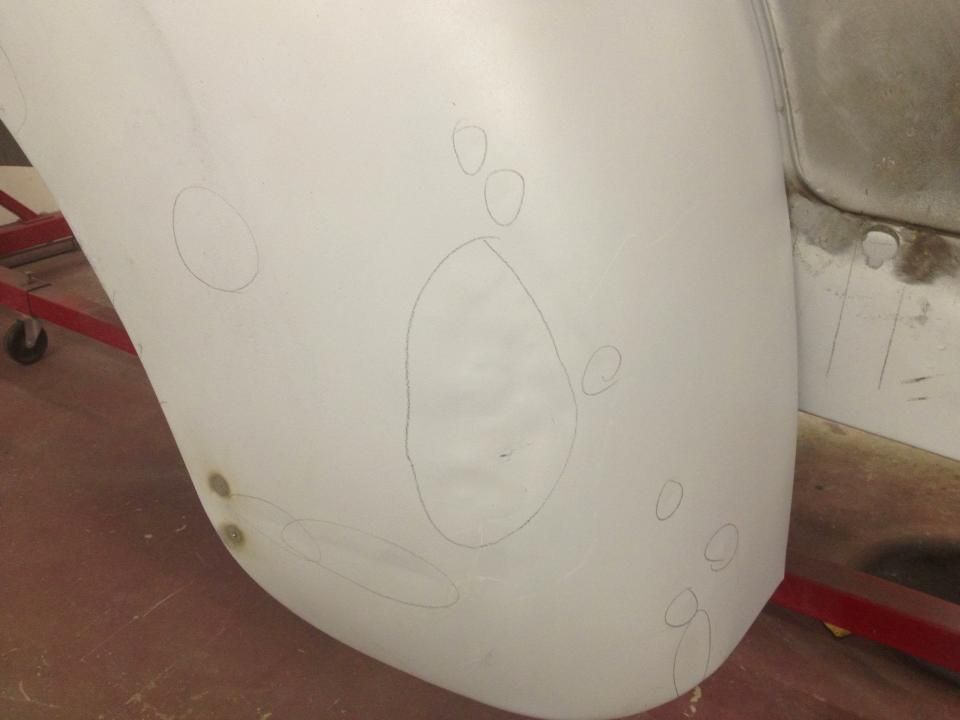

Been awhile since I updated this, I'm still working on it though progress has slowed a bit since taking more restoration projects at the shop. We started on a '66 F100 about a month ago, and that's been taking up a good bit of time.

Here is the process to straighten the driver side fender. The wheel opening was crushed in on the back edge and there were dents everywhere.    Comparing the shape with the flexible straight edge, shows about a 1/4" gap.  Kink in the inner flange.  Kink straightened.  Working out the crushed spot.   Dents marked... I had to sharpen the pencil a few times to get them all      Overall shape of the crushed spot is back where it should be.  Dents fixed, metal shaping done and ready for epoxy and skim coating.   This angle shows the wheel opening shape pretty good.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#23 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

I sprayed a couple coats of PPG DPLF and let it sit overnight, then scuffed it and skim coated the fender with 3M Platinum. Platinum is pretty thin so its great for skim coating large areas and making sure it goes on thin- only about 1/16".

Starting to block the filler down.   First round of Slick Sand after blocking the filler with 36/80/180.  Second round of Slick Sand, ready for final blocking and shooting with tinted K93.  Here's a vid of me skim coating the front fender.

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#24 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,870

|

Re: '55 International Metal/Body/Paint Work

I had two of the wheels blasted so I prepped them with PPG DX metal cleaner and metal conditioner, then shot them with PPG DPLF epoxy.

Had a couple spots that needed filler.  Shot with three coats of PPG K36 and guide coated.  Wetsanding with masking tape to protect the center from stray sanding gouges.  And painted...

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc |

|

|

|

|

|

#25 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: '55 International Metal/Body/Paint Work

So where's the thread for the other resto projects.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

| Bookmarks |

|

|