|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Feb 2012

Location: JBLM, WA

Posts: 153

|

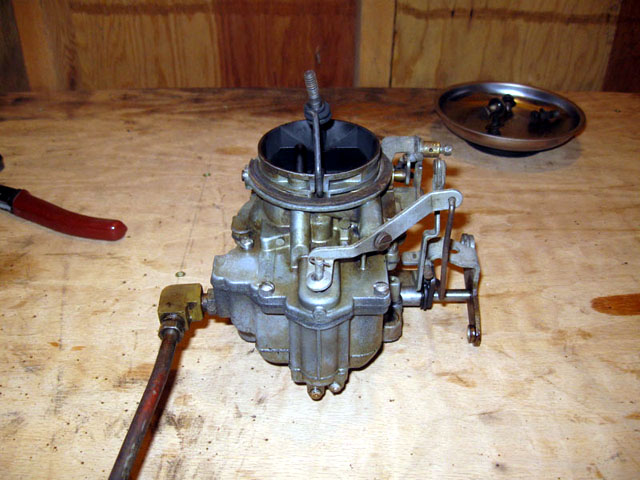

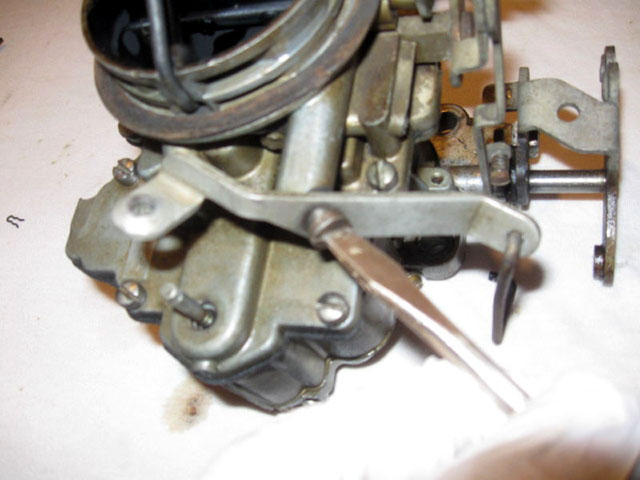

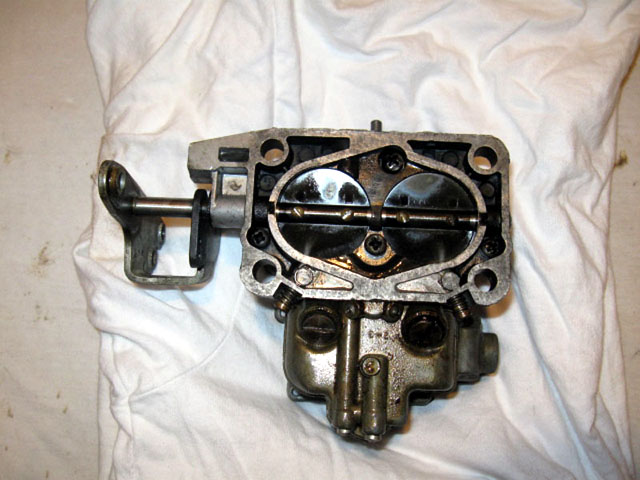

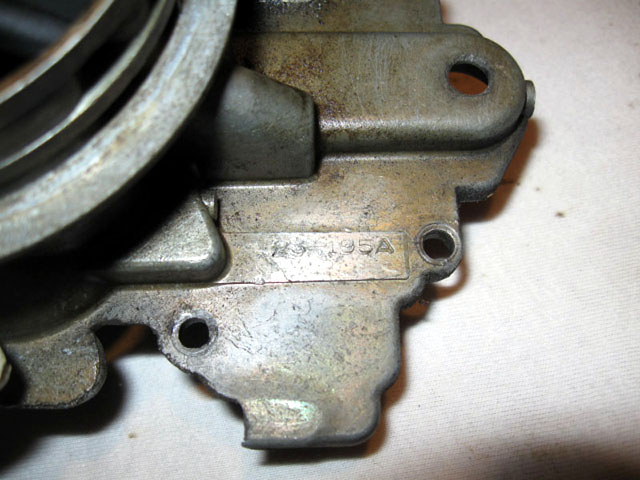

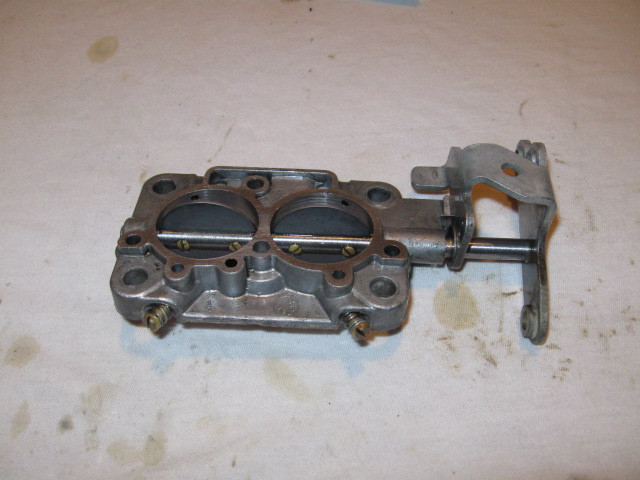

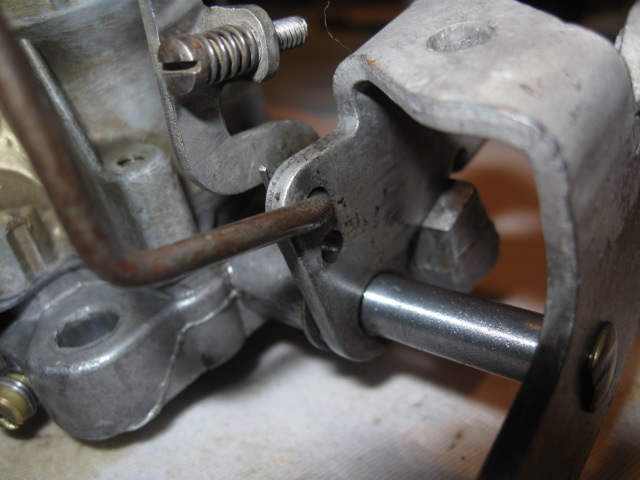

1968 GMC C20 305 V6 Bendix Stromberg Model WW 2bbl - 23-195a When I purchased the truck, the PO said the carb needed a rebuild, and after my last couple fill-ups I was getting 7.9-8.4mpg. It was hard to start, hesitation off idle, flooring it didn't do anything, sometimes it caught. It was wet off the base of the carb, at the front. Not all of this is just the carb, it needs a full tune up, but I wanted to start here. This will never get good mpg, but high 7s is not good, I'm hoping to average 10 when I'm done, hopefully a bit more when I complete a full tune up. This is temporary at that, I do plan on the HEI and Holley upgrade, but until then, the money I'll spend on the carb kit will pay for itself in a couple fill ups, if I get my 10mpg. Keep in mind, I'm averaging 8mpg, driving like an old man. There's no hot rodding a BB V6 with SM465  Took me a bit, but finally I found a carb kit at Mike's Carburetor for about $37, spent another $40 on carb cleaner and compressed air cans as I have no air compressor. I'm no expert on carbs, I'm sure there's a lot I'm not doing right, I have no manual other than the sheet that came with the rebuild kit with an exploded view, and a few adjustment sections. I'd much prefer a book, like when I did my 4bbl Rochester. Oh well. So lets start. Kit number 651 from Mike's Carburetor. Didn't know they were right here in WA. Ordered Sunday, got it in the mail Tuesday.   Remove the Accelerator Linkage, Return Spring, and Choke Cable  Remove the Fuel Line, mine was stuck, I had no line wrench, so I removed it at the hose from the fuel filter, took it apart once I got it on the bench.  Remove the Vac. Line to the Distributor. Behind the carb you can see the other holder for the choke cable, the bracket remains on the carb.  I took the fuel line off by removing the fitting at the carb, then put it in my vise and got it off the rest of the way after PB blasting it.  Remove the fuel fitting, you can see the needle poking out the carb.  Remove the choke cable bracket, this one screw is one of the screws to remove the air horn.  remove the screw to the bracket, the front goes to the pump plunger and is held by a clip, the screw was reverse thread. The other part of the linkage is hooked by a small cotter pin, both pins come with the kit. I removed it all at once.   Remove the rest of the linkage, note the small spring that has to be removed.  Remove all the screws on the air horn.   Remove the Pump Plunger Assembly.  Under the Plunger is the larger of the two check balls.  You can see your float, needle, and the spring that retains the float.  The spring was a PITA to get out, a hooked pick would have made it easier, I mangled mine, after I saw a new one comes in the kit   All three pieces removed, you can see the little spring mangled up. I soaked the float to see if it had leaks, as of right now, it doesn't. The float of course does not come in the kit, but the float retaining spring and needle do.  A bit crudy in there, its worse than the photo shows.   Flip 'er over and start removing the Throttle Body Assembly, retained by 4 phillips screws.   Flip 'er back over again and Unscrew the Pump Discharge Nozzle. Ya I do things bass ackwards.  Pointing at the gasket below it, wish I had a better picture, it's a triangular piece. Below it, where I'm pointing is your 2nd check ball.  The underside of the Main Body, remove both Main Discharge jet plugs. Note both have a crush washer  Oh ya, forgot to take the vac line fitting off.  Remove the Power by-pass jet. I believe the gasket was not put in the last time this was rebuilt.  Remove both Idle Needle Valves from the base of the Throttle Body Assembly.  Here's everything in order, from the top left, laid out like you'd read a book.  Model Stamp 23-195a   A blurry picture of the Vacuum Power Piston Assembly. This does not get removed, just take care of it.  You can see it's stamped/sealed.  Now get to cleaning! I'm soaking the parts, and I'll be using air duster cans, since I don't have an air compressor, to blow out all of the passages.

__________________

68 GMC C2500 - 305 V6 - 4spd Last edited by augie; 05-08-2012 at 01:30 AM. |

|

|

|

|

#2 |

|

Registered User

Join Date: Feb 2012

Location: JBLM, WA

Posts: 153

|

Re: Bendix Stromberg WW Rebuild

Ok Lets put it all back together

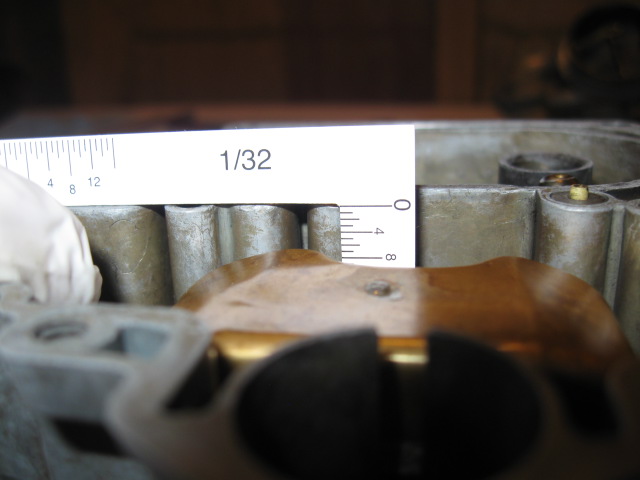

Put your idle screws back in. I went all the way in until lightly seated, and back out three full rotations, as a base to start.  I was wrong, it did have a gasket, but it was rock hard until I soaked it over night.  Put it back in.  Didn't forget the fitting this time.  Put your new crush washers back in. These in the kit were not a great fit, but they work. One note though, you can see the main jets. I WOULD have taken those out and cleaned them. But I can't find my tool for it. I bought a kit when I rebuilt my Qjet, but I can only find one of the bits (for adjusting the idle screws on the Qjet), which of course didn't work. I would have tried needle nose pliers.. but didn't see the point in asking for trouble.  Here's a better picture of what I was talking about earlier, don't forget to put your checkball in first!  And it's in.  Put your 4 screws back in, the left/right are a different size than the top/bottom. I forgot to take a picture of the gasket, but scroll up if you forgot.  I put the picture up earlier, but forgot to give a description. But I did take out and clean the idle tubes and clean them. Put those back in.  Put your float, needle, and float retaining spring back in. Good news is the spring goes in way easier than getting it out.  Screw the fitting/needle seat back in.  Check your float level and adjust if needed. 3/16. I was provided a 1/32 gauge, so even though the picture doesn't show it perfectly, it's at 6/32 (3/16).  Paper says to soak the plunger for a few minutes in oil. I did it, spray paint top works very well   Don't forget your checkball first!  Drop in your plunger  Put on your gasket.  Put on your air horn, tighten your screws. One is longer than the rest, this is for the bracket for the choke.  And put back on all your linkage. The rest is just a bunch of pictures of various spots. I know I had to re-look at my pictures.        Don't forget to clean up your intake before you put the gasket on.  All back on!  Now take a minute before you make adjustments.

__________________

68 GMC C2500 - 305 V6 - 4spd Last edited by augie; 05-08-2012 at 01:14 AM. |

|

|

|

|

#3 |

|

Registered User

Join Date: Feb 2012

Location: JBLM, WA

Posts: 153

|

Re: Bendix Stromberg WW Rebuild

Alright I'm done for the night. I do have a problem though. First start up, after the bowl filled, it fired right up. I didn't pull the choke and try to get it running, just wanted to fill the bowl and check it. Glad I did it was gushing fuel out of the top of the air horn at the plunger, and the vacuum tube at the very top of the air horn. After many 4 letter words and dinner, I took it back off, took the air horn off. I BELIEVE the float was sticking. Well I know it can stick, as I was playing with it. Gotta figure out why it's occasionally sticking. The body of the float itself, at the end, or far right of it is getting stuck in the bowl when it's all the way down. I'll figure it out tomorrow. And I'll continue with my idle adjustments, pump rod adj, etc.

Thanks for looking, hope to help someone one day. This was sooooo much easier and faster than the last carb I did. Helps when you only have 2 barrels. Hope I don't have to get a new float. If anyone knows my Hg of vacuum for the 305 V6, that'd help when I go to adjust the idle. Otherwise if I can't find it online, I'll set it to 21'ish or by ear

__________________

68 GMC C2500 - 305 V6 - 4spd |

|

|

|

|

#4 |

|

Registered User

Join Date: Feb 2012

Location: JBLM, WA

Posts: 153

|

Re: Bendix Stromberg WW Rebuild

Well the float was stuck down (open needle) which is why fuel was gushing out. Figured as much. The body was physically stuck in the bottom of the bowl. No idea why, poor design, previous re builder installed wrong float? Who knows. I also read that it should be set a 32nd of an inch lower (7/32) instead of the 3/16 the factory says. Reason being according to what I read, is that the old fuel (lead?) was more dense, so the float was more buoyant I suppose. Not sure if this is gospel. I did these things, it's just fine. No idea if you can set the idle screws by vacuum gauge, can't find info anywhere. So I did it by ear, screw it in till it sounds bad, and back a half turn.

All in all it was fun, learning experience I guess. Still can't wait to do the Holley upgrade. If I notice any real mpg increases, I'll post back. But it'll be a few weeks or more, I don't drive it all that often.

__________________

68 GMC C2500 - 305 V6 - 4spd |

|

|

| Bookmarks |

| Tags |

| 305 v6, model ww, rebuild, stromberg |

|

|