|

|

|

#1 |

|

Account Suspended

Join Date: Jul 2014

Location: NH

Posts: 280

|

Need New Radiator

So my radiator is steaming a little from the middle somewhere. I need to replace it sooner than later and all the replacement radiators I see have the nipple on it for one of the heater core hoses but my radiator in my truck now doesn't have that. The heater core hoses go to the intake and waterpump.

So what do I need for a radiator? |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Wisconsin & Arizona

Posts: 4,852

|

Re: Need New Radiator

The earlier trucks of this generation had the hose to the intake. The later years had it to the radiator. You should be able to plug or cap the nipple. The radiator may even come with what you'd need. Another option may be to have yours re-cored if your tanks are good.

|

|

|

|

|

|

#3 |

|

Account Suspended

Join Date: Jul 2014

Location: NH

Posts: 280

|

Re: Need New Radiator

Ok, thanks. I just ordered a Champion 3 Core aluminum one off of ebay for $190 shipped. Wish me luck!

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Apr 2007

Location: Foster Rhode Island

Posts: 1,176

|

Re: Need New Radiator

The radiators usually come with a rubber cap on that nipple if you don't need to use it. Another option you could try is thread the nipple out of the water pump and screw in a steal pipe plug. You could get one at the depot or any hardware store its just a regular pipe thread in there. Then just get a longer heater hose and run it to the radiator. I don't know why that wouldn't work just fine.

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Feb 2011

Location: Modesto, CA

Posts: 2,189

|

Re: Need New Radiator

Which number did you order. I got cc367 and it's about 2-3 inches narrower than stock. They have a different one that's stock width.

|

|

|

|

|

|

#6 |

|

Account Suspended

Join Date: Jul 2014

Location: NH

Posts: 280

|

Re: Need New Radiator

I thought I ordered the cc367 but the invoice said cc369. I got it off ebay and it just said 67 C10 pickup with 283.

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Feb 2011

Location: Modesto, CA

Posts: 2,189

|

Re: Need New Radiator

You ordered the correct one then.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: Need New Radiator

I'm running this in my 72. Good price and it has side tanks which resemble the factory originals.

http://www.speedcooling.com/1967-197...r/prod_38.html

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i |

|

|

|

|

|

#9 |

|

Account Suspended

Join Date: Jul 2014

Location: NH

Posts: 280

|

Re: Need New Radiator

So this radiator doesn't fit. It's too wide.

|

|

|

|

|

|

#10 |

|

Junior Member

Join Date: Mar 2007

Location: Hideaway, TX

Posts: 4,950

|

Re: Need New Radiator

Oriellys part#433369 is a 4 core replacement without the outlet for the heater hose.

__________________

71 Suburban 350/700R4 Project Trixie 72 CHEVY,Highlander,SWB,396,T400 |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Apr 2014

Location: Southern California

Posts: 200

|

Re: Need New Radiator

I just put in the Oreily unit and out of the box it has 3 pin holes. I ordered it online with free shipping and when I went into the local store to inquire about warranty exchange they told me I had to pay shipping from back east. TOTAL BULLS#IT!!!

$200 of crap if you ask me FYI the the stock upper radiator brackets also wont fit the tank. |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: Need New Radiator

See post #8 above. Direct fit, American Made, priced right, and I've been running it since March of this year. Made it through Texas heat this summer with out a problem.

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Feb 2011

Location: Modesto, CA

Posts: 2,189

|

Re: Need New Radiator

The 3 row uses the 4 row mounts. You probably have the stock 3 row mounts. I'm having problems with mine as well but as I said, mine is narrower than yours.

|

|

|

|

|

|

#14 | |

|

Junior Member

Join Date: Mar 2007

Location: Hideaway, TX

Posts: 4,950

|

Re: Need New Radiator

Quote:

__________________

71 Suburban 350/700R4 Project Trixie 72 CHEVY,Highlander,SWB,396,T400 Last edited by BB72CHEVKT; 10-28-2014 at 04:58 PM. Reason: spelling |

|

|

|

|

|

|

#15 | |

|

*************

Join Date: Apr 2005

Location: Pensacola, FL

Posts: 17,858

|

Re: Need New Radiator

Quote:

__________________

Rob - https://www.instagram.com/hart_rod_c10 As Iron Sharpens Iron, So One Man Sharpens Another. Proverbs 27:17 FOR SALE: DBW pedal bracket - http://67-72chevytrucks.com/vboard/s...d.php?t=651123 FOR SALE: Hood Brackets http://67-72chevytrucks.com/vboard/s...d.php?t=679945 1987 Silverado SWB - 34.5K original miles http://67-72chevytrucks.com/vboard/s...d.php?t=801834 1969 SuperBurb - http://67-72chevytrucks.com/vboard/s...d.php?t=200387 1968 Farm truck - http://67-72chevytrucks.com/vboard/s...d.php?t=358692 1968 SWB - http://67-72chevytrucks.com/vboard/s...d.php?t=551258 1948 Chevy - http://67-72chevytrucks.com/vboard/s...=122164&page=3 |

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Jun 2014

Location: Bushwood, MD

Posts: 510

|

Re: Need New Radiator

So I'm having the opposite issue - I need the radiator with the nipple for the heater hose and all I can find are the ones without...

RP |

|

|

|

|

|

#17 | |

|

Registered User

Join Date: Jan 2011

Location: Chattanooga, TN

Posts: 2,165

|

Re: Need New Radiator

Quote:

__________________

'83 K20-TPI '73 C10 '79 C10-ex-diesel(SOLD) '07 Tahoe(Son driving) '14 Suburban-DD '71 C10-current project |

|

|

|

|

|

|

#18 |

|

Account Suspended

Join Date: Jul 2014

Location: NH

Posts: 280

|

Re: Need New Radiator

Well, I emailed the seller of the Champion radiator I bought and sent him pics of my old one and he said that the radiator I have was a modified one from a 73+ truck and that someone welded or soldered on the angled collar for the lower hose. And he was right. He is having me return the new Champion radiator at his expense and is shipping me out a new one from a 73+ truck and having the shop tig weld a collar on it like my old one. And he's swapping it out to a two core one instead of the three core they sent me. Said it will fit like a glove. Here's hoping.

|

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: Need New Radiator

Quote:

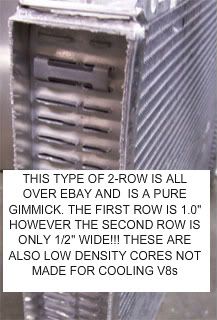

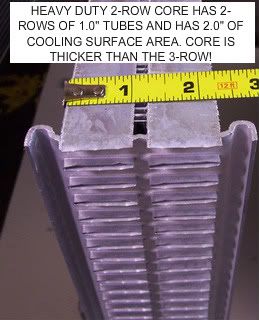

Also a little long, but interesting read about cooling. I found it insightful. There is considerable misinformation regarding what makes a radiator transfer heat (so take what you read with a grain of salt). Ill try to make a short radiator and heat transfer for dummies post Heat is transferred from the coolant to the radiator mass, and from the radiator mass to the airflow. The temperature difference at each transfer junction (coolant to metal, and metal to air) drives the quantity of heat transferred. Aluminum weighs less, and the lower mass allows it to transfer heat more quickly than brass. The steady state heat transfer between the two materials (aluminum and brass) is very similar, but aluminum reacts quicker to a change in the temperature difference of the coolant fluid (like when you are on the throttle) because the heat transfer takes less time heating up the mass of the radiator itself before establishing the temperature difference between the radiator and the airflow. The fact the aluminum experiences an elevated surface temperature quicker allows it to reject the heat into the airflow quicker. When the radiator is underdesigned (to reduce weight or fit a poor location) this rapid thermal response provided by aluminum can make a difference in overheating (or not) after a brief period of WFO travel (like in racing). When the load is steady state (a fixed industrial engine or a long crawl up a grade towing), the response time benefit is insignificant because while the brass takes longer to respond, having the proper area for heat transfer is more important (both radiators eventually reach the same steady state temperatures and the same heat transfer rate). Sizing the face area of a radiator core to have one square inch for every cubic inch of displacement has been around for a long time (400 ci. engine matched to a 20"x20" radiator). This rule of thumb does not work everywhere (dry deserts need more face area) so some add 10% or more extra face area. Core thickness is an airflow restriction on the air side (bad for heat transfer), and more tubes (one tube per core) increases surface area (good for heat transfer) on the coolant side. Multicore radiators are great for getting the radiator metal hot, but not always great for getting that extra heat into the air, and the hot air away from the radiator. The coolant to metal transfer is fairly efficient, because both materials (coolant and metal) have significant mass to store the heat being transferred. The heat transfer junction, the required wetted area of the tubes inside the radiator core, can be calculated with fairly good accuracy. The surface area can be accomplished with more small oval tubes (1/2" and 5/8" typical of brass radiators) or with fewer larger tubes (typical aluminum 1" and 1 1/4" tubes). Go with the most tubes (cores) for the greater surface area, if the fan drive can handle the airflow restriction. The aluminum radiator core manufacturers already take any credit for the more rapid thermal response of aluminum when calculating the tube surface area, they use the minimum surface area they can design, so further reducing the face area of the core (to try and squeeze even more efficiency from the aluminum construction) is risky unless the design can be tested and adjusted (if the budget allows doitagain engineering). I advise against reducing the face area of the core, and any thinking that the material choice allows a discount factor to the heat transfer potential, unless you are racing to shave weight and the load is transient. The coolant side of each core tube sees the same temperature coolant flow and the same rate of heat transfer from the coolant to the radiator core metal. The result is the radiator metal is almost always the same temperature with minimal gradient front to back. The coolant to metal heat transfer is the same for each core (what heats the radiator metal is the same), and the coolant temperature leaving each core (to be delivered to the engine) is nearly the same, but the air side of the radiator is not so simple. The discount factor for heat transfer on subsequent cores is only on the airflow side. The face cores experience unheated air, and subsequent cores experience air at a higher temperature. The best heat transfer occurs where the greatest difference between the air temperature and the radiator metal is found, the face or entering side of the radiator. If you want the best heat transfer, increasing the face area of the radiator metal that sees cool air will gain you the most impact for your effort (a larger radiator face will beat more cores nearly every time). The construction of the radiator fin design is important to the increase in temperature through subsequent cores in series, and is related to a "bypass factor" that models how much air bypasses heat transfer from direct contact to the surface area of the fins. The mass of air that can squeeze between (bypass) the fins without picking up heat mixes with the mass of heated air that does make contact, and the result raises the air temperature of the downstream cores. In reality, without getting into math or fin designs, the elevation of air temperature between cores is less than 15%. If the airflow temperature is raised from 70dF to 170dF through a four core radiator, a 100 degree increase, 45 degrees (~45%) of the temperature rise (and heat transfer) is in the air to metal contact in the first core, and a lower percent from subsequent cores (something like ~30%/17%/8%). The aluminum radiator guy's are right that two cores are more efficient (nearly 80% of the cooling is from the two front cores), but if the total surface area of the coolant to metal, and metal to air, contact is less ... the net result is not so great of a design (just like ricers 100 ci 4-banger @ 3 hp/ci is good, but nothing like a 302 @ 1 hp/ci: there is no substitute for more surface area in a radiator unless you want to spend a lot). The actual area of the core face that experiences the high air to metal temperature difference is more important than the calculated face area. People tend to forget that the radiator face is not working to transfer heat, unless it's moving air. What makes air flow through a radiator core (through a restriction)? Pressure drop (static pressure) or the momentum of the air mass (velocity pressure) through the core establishes the airflow, and the resulting heat transfer. Most people with a cooling problem try to increase the mass of air blowing through the radiator by increasing the velocity pressure acting on the core. They add a round fan (usually electric) in front of the radiator (a pusher fan). When an unshrouded fan is used, a puller with no shroud or a pusher, the core area experiencing the airflow (and temperature difference) is limited to only that is the direct path of the high velocity air. A 20x20 (400 sq.in.) radiator face with a 16" diameter fan blade, without a shroud, is little better at heat transfer than a radiator with a 16" round (201 sq.in.) face area. Adding a 16" pusher in front of this radiator, with the unshrouded 16" puller, gains almost nothing in air side heat transfer effect. How do you get the entire entering face of the radiator to work transfering heat? You try to get airflow across the entire face of the radiator core. Try many small fans (fit lots of round high velocity airstreams in a square area)? It can work, but it's looks complicated (and is probably expensive). It's easier to make a static pressure difference across the radiator core work to move air through the entire face of the radiator, by using a puller fan and fitting a shroud on the suction side of the core. You only need one fan, and it can motivate airflow across the entire face area of the radiator core, just by adding a shroud to contain an area of negative pressure on the leaving air side of the core. The problem with using static pressure to draw airflow through a radiator is that it takes a significant increase in power to generate pressure (research fan laws). Using a multicore radiator core that is thick and restrictive on the air side requires that it be matched with a fan and shroud that can generate a static pressure difference great enough to overcome the restriction. Replacing a two core with a more airflow restrictive four core can sometimes work against you if the fan clutch is weak, or it is combined with a swap to an electric fan. Most electric fans cannot develop significant airflow at higher static pressures, because the power draw must be limited to protect the wiring. Compare an electric fan to a high flow (and pressure) mechanical fan. The blades of the electric are narrow, and the blade pitch is shallow (compared to the mechanical fan), both design aspects limit the potential of an over-amp condition. Yes, electric fans are great to gain power on the end of the crankshaft, because to generate a significant negative pressure behind the radiator sometimes takes three to five horsepower (the gains we read in the electric fan advertisements). Use electric fans when you can, when the radiator is overdesigned for the power and transient heat transfer required, and use a shroud. Just do not expect a 1/4 hp electric to pull the same airflow and pressure drop of a fan drawing 3 hp off the front of the engine. I read that fans have little effect to gain airflow at speed ("airflow is going through the radiator on the highway because you are going faster, so adding a fan or shroud to cool the engine on the highway is not going to solve the problem.") We read it all the time. It's BS. What is difficult to understand is that most vehicles generate a high pressure area under the chassis at speed (the air above and to the sides of the vehicle is high velocity/low pressure, but underneath it's low velocity and high pressure). Yes, the pressure in front of the radiator can be higher (conversion of the velocity pressure to static pressure) but the pressure behind the radiator can increase with speed as well. Betting that the converted high velocity air in front of the vehicle radiator can overcome the pressure under the vehicle (the pressure on the leaving side of most unaided radiator cores), to motivate airflow, is almost like betting that you can piss up the inside of the airhose of your compressor with 20 psi streaming out the end. You still need a fan and shroud to eliminate most radiator airflow problems at highway speeds, because you still need to establish a pressure drop across the radiator core (and sometimes it's more difficult at 60 mph, than when parked at the curb). Crossflow vs. downflow design is not as important as where the radiator cap pressure relief is located. The cap should be on the low pressure side of the water pump, something that is easier to package and service with a crossflow core. I hope this helps (I have had enough internet tech for the week)? In summary: if the budget demands a choice between a high dollar aluminum radiator, or a brass radiator and a well fitting shroud, get the system with the shroud (and use a mechanical fan drive with a fan blade that has some pitch angle to the blades, and a clutch to save power when it's not needed). Happy Trails!"

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i |

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Dec 2011

Location: acworth georgia

Posts: 890

|

Re: Need New Radiator

Z10 has GREAT points about radiators, and is a great educational tool for those trying to learn about cooling.

If you end up needing another, we are a forum sponsor here and we make hand-built aluminum radiators here in the USA for your truck that are a bolt-in, and we offer a discount for forum members. http://67-72chevytrucks.com/vboard/s...d.php?t=590670 |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jun 2011

Location: ventura, california

Posts: 24

|

Re: Need New Radiator

For your consideration, i just tried the Oreillys radiator, it comes close in dimension, but the mounts will Not work with OEM mounts, also seems low quality. sending it back, still looking for affordable replacement, with quality build.

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Dec 2014

Location: washougal, wa

Posts: 3

|

Re: Need New Radiator

Z10 disertation should be pinned!

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: Need New Radiator

Thanks Jayelder. Not my write up but it sure helped me when I was working through my cooling.

Also, as an update. I've now had my cooling system up and running for 5000+ trouble free miles. The truck made it through a hot West Texas summer and is now working fine in a colder than usual winter. See my build for more info.

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i |

|

|

|

|

|

#24 | |

|

Registered User

Join Date: Jun 2011

Location: ventura, california

Posts: 24

|

Re: Need New Radiator

Quote:

By chance, was it an all metal radiator? The ones I got from oreillys was plastics tank alum core. I need a radiator, but oe style is what I want. |

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Aug 2012

Location: Midland, TX

Posts: 1,267

|

Re: Need New Radiator

See post #8. All metal, styled like original.

__________________

1969 RS/SS Z10 Camaro Pace coupe 1972 GMC Short Step buildhttp://67-72chevytrucks.com/vboard/s...=1#post6356218 1979 Mazda RX7 1979 Pontiac Trans Am WS6 & 1979 Pontiac Trans Am 10th Anniversary 1999 Honda Valkyrie 2006 Corvette Z06 2010 BMW 650i |

|

|

|

|

| Bookmarks |

|

|