|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#51 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

It started out so simple; one of the straps retaining my rear u-joint had light between the strap and the u-joint cap. I have been chasing an intermittent bump-induced driveshaft vibe for months now, so I figured I may as well check out/fix the strap to make sure the cap isn't walking around in the yoke. Easy job, which should have taken no more than 30 minutes.

You want to know how to make God laugh? Tell Him your plans  So I pull the bolts retaining the straps. Now, having had them on and off a few times, and using Loctite each time, means the threads were gummed up. No biggie, I had a 6mm tap hot and ready to go. Oops... turns out they are 8mm, not 6. And I don't have an 8mm tap (mental note: add 8mm tap to my next MSC order). Fortunately, I DO have a set of Snap-On thread chasers, so I'm still in business. I throw the straps and bolts in a paint mixing cup and add a little acetone to degrease and de-Loctite the parts, then I crawl under the truck with the thread chaser and a 1/4" drive ratchet. I get about half way in, and I can feel the thread chaser getting mired in the goo. I back it out, clean it off, and run it back in. It's still gooey, so I lean on it a bit. Did I mention I'm using a 1/4" drive ratchet? There's only so much torque a mere mortal can apply to a 1/4" drive ratchet, and it ain't much. One moment I'm removing Loctite goo, and the next moment the ratchet suddenly spins really easy. Didn't even make a sound, just twisted the shank of the Snap-On thread chaser clean off. Using a 1/4" drive ratchet. Did I mention that part?  Now, I have seen my share of broken $#!t, so I noticed two things. Snap-On's Sooper-Dooper thread chasers are maybe grade 8. They felt more like grade 5 when it broke. They are definitely not any kind of tool steel. Second, the shank could have been much larger. It was only maybe 1/4" diameter or so. Now, I have seen my share of broken $#!t, so I noticed two things. Snap-On's Sooper-Dooper thread chasers are maybe grade 8. They felt more like grade 5 when it broke. They are definitely not any kind of tool steel. Second, the shank could have been much larger. It was only maybe 1/4" diameter or so.So there I sat, junk in one hand and a broken thread chaser in the other. And, of course, the rest of the chaser stuck in the yoke, which is firmly bolted to the pinion in my rear axle. Swell. Imake a phone call to my buddy Todd, who just happens to own a machine shop, and after a bout of laughter on his end he says that there are no jobs set up on the manual mill. Cool beans, I'm in business! I figure I will pop the yoke off, drill out the busted thread chaser, and while I'm at it I will machine the yoke to use u-bolts instead of the crappy straps. I bust out the 1/2" drive impact and a suitable socket buzz the yoke nut off, and try to slide the yoke off the pinion. It doesn't budge. I get on it with a plastic-faced hammer and it still doesn't move. Interference-fit splines. Swell. Not a problem, I figure. My rear axle happens to be an AAM 14BFF, which has a drop-out pinion support. I zap out the 6 bolts holding the pinion support, tap it with the plastic hammer, and it slides right out. I jump in a borrowed beater and make haste to the shop. Ended up having to use a press to get the yoke off the pinion. Oh yeah, this will be a ball of laughs to re-assemble. I put that out of my mind as I examine the off seal arrangement AAM uses on these later model axles. Apparently, they really, REALLY don't want them to leak. I press off the dust cap and something that looks like a thick speedi-sleeve with an integral outer seal so I can machine the yoke. A carbide drill bit made quick work out of the broken thread chaser, after which I drilled out the holes to .394" for the 3/8" u-bolts. Then another half-hour of machining with a .750" end mill and the yoke was ready to go. Now comes the fun part. I go to put it back together only to find out that the outer pinion bearing doesn't want to slip over the pinion shaft. WTF?!?! I fuss with it some more, and bigger than $#!t I manage to pop the garter spring off the seal  WTF, is Mercury in retrograde or something? Of course, there is no way to re-install the spring with the seal in place, so I say eff it and remove the seal. At least now I can remove the outer pinion bearing from the support assembly and see what the deal is. Simple answer: it is a light PRESS FIT onto the pinion shaft! WTF, is Mercury in retrograde or something? Of course, there is no way to re-install the spring with the seal in place, so I say eff it and remove the seal. At least now I can remove the outer pinion bearing from the support assembly and see what the deal is. Simple answer: it is a light PRESS FIT onto the pinion shaft!    By this time I am swearing a littany of curses at the engineer who took a perfectly good design (the original GM 14BFF) and decided to "improve" upon it. By this time I am swearing a littany of curses at the engineer who took a perfectly good design (the original GM 14BFF) and decided to "improve" upon it.Since I don't have a shop manual for this new "improved" 14b, experience tells me that I will have to heat the bearing to 250°F and slip it down until it seats against the crush sleeve, then install the new seal, then heat the yoke to 250°F and tap it in place against the bearing. Then I can install the new nut and set preload. Nice. Now all I need is a new seal, since I destroyed the old one removing it. At least they don't appear to be too expensive.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." Last edited by MaxPF; 02-04-2017 at 03:48 AM. |

|

|

|

|

|

#52 | |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

Quote:

Cliff notes for those who have assembled D60' and D70's, 10b's and 14bsf's; if you think the crush sleeves on these axles are a bish to compress, you haven't had the pleasure of working on a 14bff. Now granted, Snap-On air impacts are a bit weak-sauce compared to an Ingersoll-Rand unit, but mine (1/2" drive) has always been able to crush D60, D70, 10b, and 14bsf sleeves. The brand new sleeve in the 14bff just laughed at it. I ended up having to break out the 3/4" long-handle ratchet with a cheater bar and reef on it for a half hour to get it crushed to the specified preload. This thing was a stone bich that I have no desire to repeat. IF I have to do another one in the future I guarantee I will pre-crush the sleeve in a press to within .020" of final length to safe a lot of grief. Or, borrow a 3/4" drive impact. Anyway, got it running now. I'm hoping it fixes the vibe problem, but I'm not holding my breath...

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

|

#53 |

|

Registered User

Join Date: Nov 2010

Location: Alabama

Posts: 740

|

Re: A K5 Cummins Conversion: The saga continues...

Sounds like fun. I've got a Dana 60F and Dana 70HD rear I'll be getting into soon.

|

|

|

|

|

|

#54 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

Dana axles are my least favorite to set up. If you want to save yourself a lot of grief, either buy or make setup bearings for the carriers and inner pinion bearing. And buy, rent, beg, borrow, or build a case spreader. And never, EVER spread the case more than .010".

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#55 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Cool I have been throwing around the idea of a cummins swap in my '87 K5 Jimmy that we bought in Mesa 3 years ago.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#56 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

If you choose to do so, plan on boxing or otherwise reinforcing the frame from at least the front body mounts forward and replacing your axles with one ton units.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#57 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Yes sir. Good idea. They are a very heavy motor.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#58 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

It's not just the weight, it's also the torque. A p-pump engine using the stock turbo and a few basic mods is easily capable of over 700lb-ft.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#59 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Yes very true.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#60 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

Back when I replaced my pitiful Zoner alternator with a real alternator, I also mentioned that I had removed my AC blower/evaporator stuff from the engine compartment as well as the stock under-dash AC crap. This is getting replaced with a system that will fit entirely under the dash. Of course, I could have bought a system from Classic Air or Vintage air, but that wouldn't have been any fun. Besides, I wasn't really happy with their stuff. That being the case, I elected to roll my own.

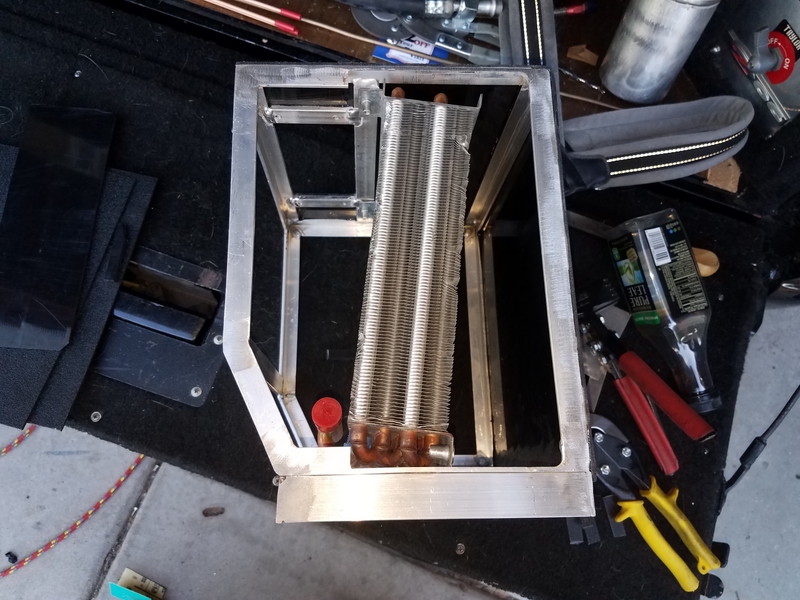

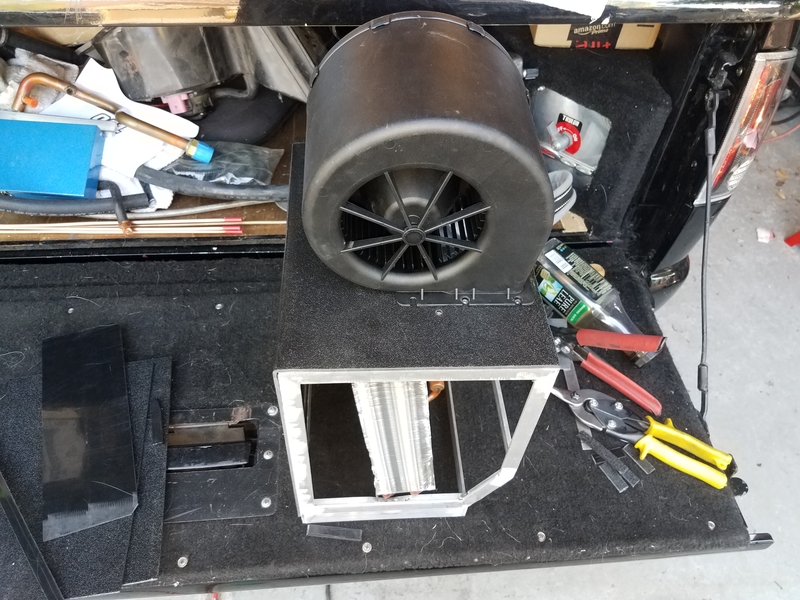

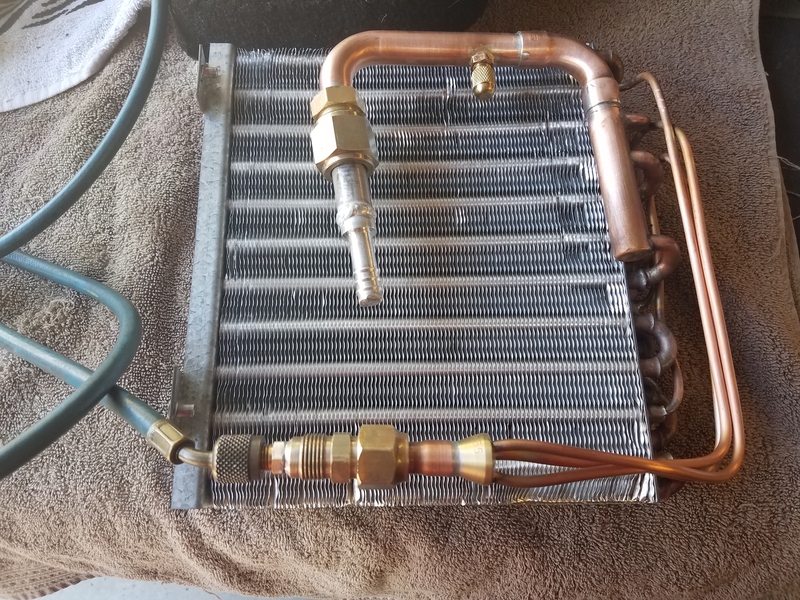

One of the things I didn't care for with the Classic and Vintage systems was the meager evaporator size of these units. I got an evaporator from a mid-2000's Navistar application that was the right size, but needed some plumbing mods. I cut off most of the suction pipe and un-brazed the distributor tubes from the core, and then after much measuring and thinking I built an aluminum skeleton for the evap housing:   This part fits where the glove compartment resides, with the side with the beveled edge going against the firewall. It will be entirely enclosed with ABS. The blower will blow the air into the back perpendicular to the flow through the core. The air will then flow 90° through the core before changing direction 90° again and flowing out through the side. This will be easier to see once the enclosure is completed. At that point the air will enter a separate, attached enclosure that will house the heater core and the various doors and duct outlets. Because I wanted the engine bay as free of clutter as possible AND I wanted my AC to be as efficient as possible, I chose to use a thermal expansion valve (TXV) instead of a simple orifice tube. This eliminates the accumulator, which would have to go under the hood on the firewall, and provides actual refrigerant control. Back in the good ol' days, automotive TXV's were made by outfits like Parker and Alco, who also made TXV's for stationary AC and refrigeration. However, they were simple, rudimentary designs built to a price point. Nowandays, all automotive TXV's are made in China, and the quality and reliability has gone down. While they get the basic job done, they tend to be quite variable from sample to sample and they usually "hunt" badly at low evaporator load (i.e. when the blower is on low speed), alternating between starving and flooding the evaporator. Sometimes the flooding is severe enough that liquid refrigerant makes it back to the compressor. At high loads they often run somewhat starved, with resulting high superheat and less than stellar vent temps. Knowing this, I chose to use a real AC/refrigeration TXV from an American manufacturer. The distributor that came on this coil was designed for an automotive TXV with an o-ring sealed output, while the Sporlan TXV I am using has SAE flare fittings. That combined with the fact that the stock distributor was in the wrong physical location for my needs and not easy to relocate is why I removed it and it;s tubes. Because there are so many different configurations of distributors they are not something that HVACR wholesalers typically stock. Fortunately, I found a seller of surplus NOS parts that had a distributor from a Rheem R-22 heat pump of a suitable size with suitable feed tubes already brazed on, and it was cheap. When I got it, it turned out that the distributor was a Sporlan branded part. Cool! The feed tubes were 3/16", which are a bit smallish for an R-134a system, but the Sporlan software tool showed the pressure drop to be acceptable for my overall system design. I went ahead and brazed a 1/2" SAE flare fitting to the distributor inlet for attachment to the valve. Here's the TXV and distributor assembly, ready to be brazed/assembled onto the evaporator once I figure out exactly where I want to put it:  When I pulled the OE HVAC unit out of my truck I salvaged the heater core from it. I had replaced it several years ago, and because I rigorously maintain my cooling system it was still in excellent shape. Well, excellent shape other than the somewhat crushed tubes that happened while I was trying to remove the heater hoses  Still, the tubes are easy enough to straighten out if I so choose. I also got a new all-aluminum heater core. I am still undecided as to which core I want to use. The aluminum core is obviously more restrictive to airflow compared to the copper/brass unit, while the copper/brass unit has the disadvantage when it comes to transferring the Cummins' meager engine heat to the air flowing through it. If I was running a gas engine with a 195° thermostat the choice would be easy, but with the Cummins' 180° thermostat and limited waste heat production I am leaning toward the aluminum jobbie. Still, the tubes are easy enough to straighten out if I so choose. I also got a new all-aluminum heater core. I am still undecided as to which core I want to use. The aluminum core is obviously more restrictive to airflow compared to the copper/brass unit, while the copper/brass unit has the disadvantage when it comes to transferring the Cummins' meager engine heat to the air flowing through it. If I was running a gas engine with a 195° thermostat the choice would be easy, but with the Cummins' 180° thermostat and limited waste heat production I am leaning toward the aluminum jobbie. Finally, there is the blower. Here, the choice of manufacturer was easy. In the pic below you can see two blowers. The smaller one is the one that Classic and Vintage use in their units. The big sumb***h is the one I am going to use! I figure I have the space to fit it, and I can always limit the speed of the big blower whereas I can't add more speed to the small one. Plus, for a given airflow the bigger blower is quieter.   That's it for now. Stay tuned as the AC-from-scratch adventure continues!

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#61 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

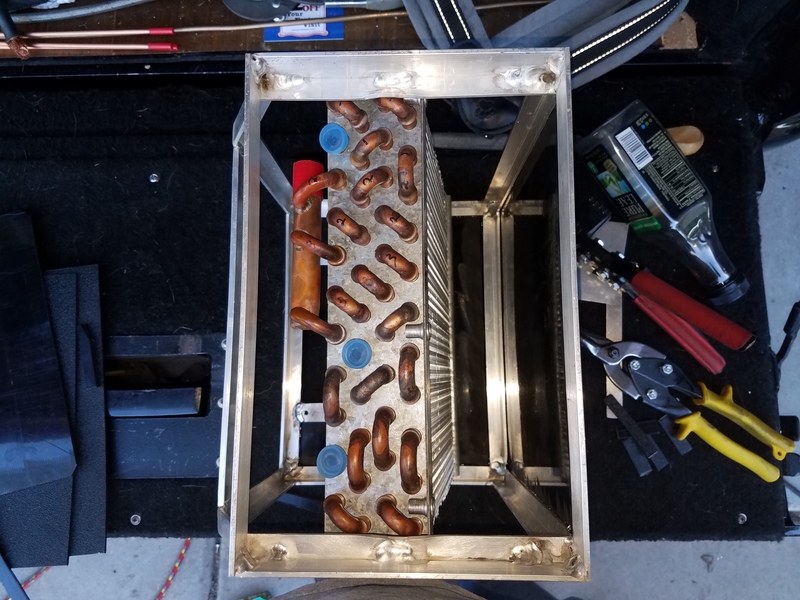

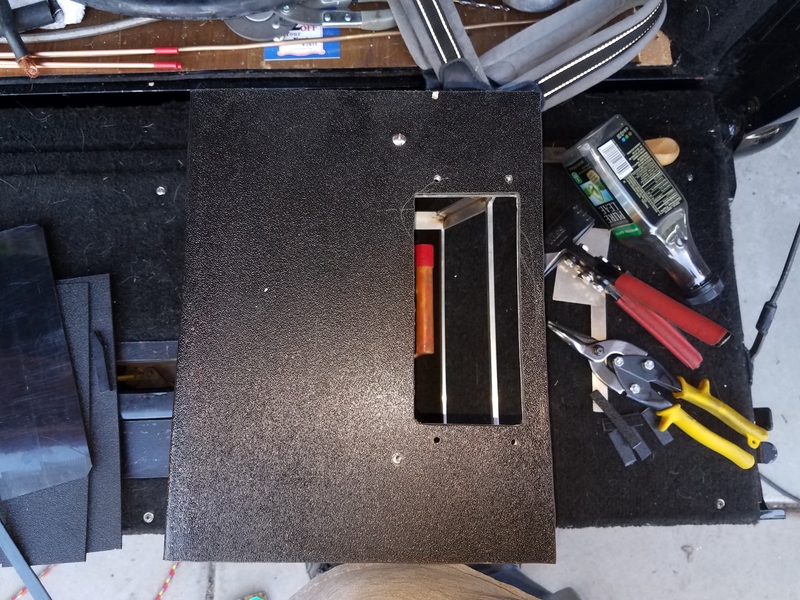

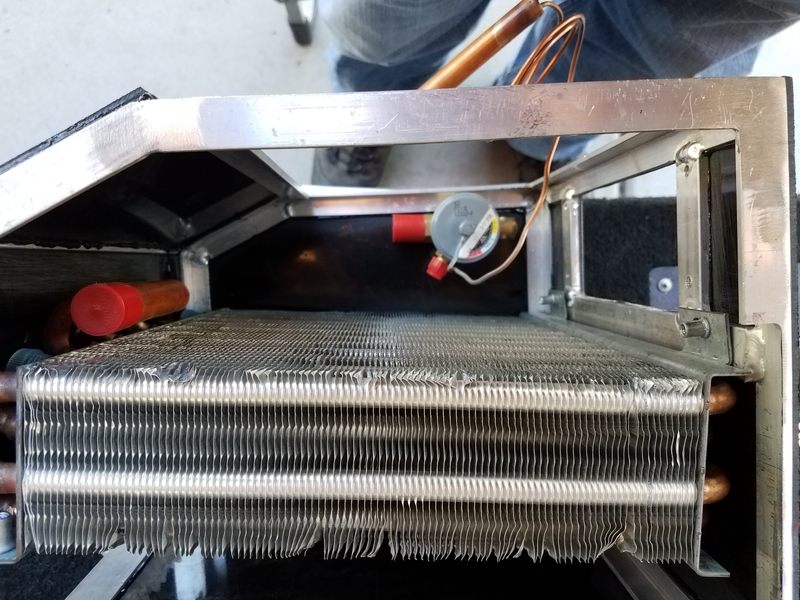

Still working on the evaporator housing. I made a few mods to the initial design. I found that mounting the evaporator at a slight angle gave an increase in room behind the evaporator for the expansion valve without reducing the outlet area, which is A Good Thing™:

Here's a view of the firewall side. On the bottom, which is actually the left side if you were viewing it installed in the cab, you can see the outlet extension. This is what the housing containing the heater core and distribution doors will slide onto:  Top view. You can see that I already have ABS glued to the front and right side:  This is a view looking into the outlet extension. The face of the evaporator on the right is the outlet. The end of the evaporator will be covered by more ABS and will be on the inlet side. The little blue caps cover the open tubes where the three distributor tubes will eventually be brazed. The black crud in the corner welds is where I dipped the tungsten into the weld puddle because I was welding by sense of smell at that point  I have discovered that welding is a perishable skill. If you don't do it often you lose the muscle memory and your skills deteriorate. Unfortunately, so does your eyesight as you age. My welding skills, especially on aluminum, used to be MUCH better than they are now. I have discovered that welding is a perishable skill. If you don't do it often you lose the muscle memory and your skills deteriorate. Unfortunately, so does your eyesight as you age. My welding skills, especially on aluminum, used to be MUCH better than they are now. This is the right side. The square hole is where the blower blows into the housing:  What it looks like with the blower in place:   I now reached the point where I needed to glue two more ABS panels on before I can proceed further, so as of tonight it is sitting with panels clamped in place letting the adhesive fully cure overnight:   This is the adhesive I am using. The place I buy from has a good assortment of products by 3M, Norton, and SEM. Of the products, this one was recommended by the manufacturers literature for bonding metal to metal, metal to plastic, and plastic to plastic. It's a 2-part urethane adhesive. It's not as strong as the epoxies, but the epoxies weren't recommended for use on plastic:  After I glued the first panel on and let it cure overnight I tried to rip the glued seam apart and it just laughed at me, so I think it is strong enough for an AC housing  I also got a tube of moisture-curing urethane seam sealer for sealing gaps and especially for sealing the condensate tray. It's half the price fo the two-part urethane adhesive and thicker. I don't want air leaks, and I really don't want a condensate leak! I also got a tube of moisture-curing urethane seam sealer for sealing gaps and especially for sealing the condensate tray. It's half the price fo the two-part urethane adhesive and thicker. I don't want air leaks, and I really don't want a condensate leak!That's it for now. Stay tuned for the next exiting episode!

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#62 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Wow nice maybe you could give Vintage air some pointers. Your not the first one I have heard is not impressed with there stuff

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#63 | |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

Quote:

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

|

#64 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Do you work with HVac for a living?

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#65 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

I used to do refrigeration and HVAC,but now I only do side jobs for family and such. I may go back into the refrigeration field though since I got laid off at the first of the year. Service work is always available, and I hate being an office rat.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#66 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

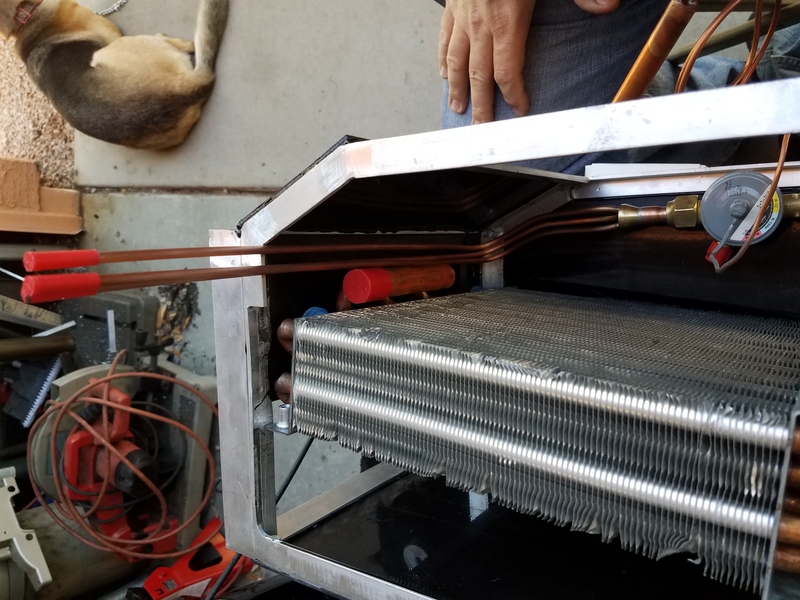

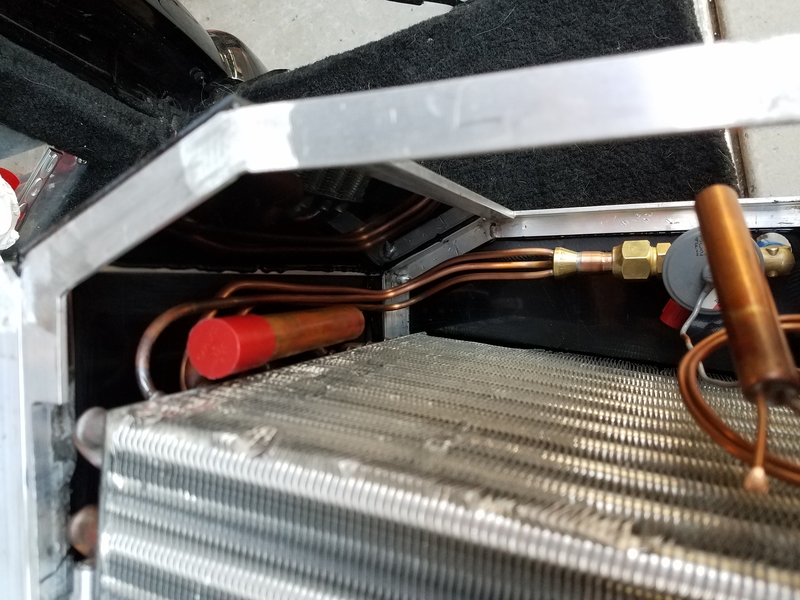

So the AC is still a work in progress. I wanted the adjustment stem on the TXV to be accessible without having to remove a bunch of crap and without mounting the TXV in the engine bay. I decided to mount the TXV with the adjustment stem poking through the bottom of the housing. I had to drill a hole for both the stem cover/body of the valve as well as the inlet fitting. This is what I ended up with:

This mounting arrangement does have the drawback that the liquid line will also exit the housing, but I will be able to make a tight u-bend and send it back up the firewall-side. Since there is a roughly 1" gap between the back of the housing and the firewall for sound insulation running the liquid line up the back of the housing presents no issues. The next thing to do was fit the distributor/tubes and route them into the evaporator. This started with running the tubes along the bottom, then making a few judicious bends to turn them up toward the top inlet:  Then more bending and head scratching to fit the tubes into their respective circuits in the evaporator. In order for the distributor to work properly the tubes to each circuit must be equal length, so the tubes going into the lower circuits have to make u-turns and head downwards to their respective inlets. Once I got it all fitted, I hooked up my CO2 bottle, started a slow flow of purge gas, and started brazing the tubes in. I got the second one brazed up when I realized no gas was flowing. A quick check of the gauge showed my Co2 bottle was flat  I had to load it up, schlep over to the welding supply joint, and get a refilled bottle just so I could braze up the last tube. But I gotter done, and here is the result: I had to load it up, schlep over to the welding supply joint, and get a refilled bottle just so I could braze up the last tube. But I gotter done, and here is the result:  Here's an underside view of the finished product:  The cap covering the adjustment stem will be readily accessible but safe from being hit by errant feet. You can also see the condensate sump that I was able to mold into the bottom cover. Unfortunately, the back side of the sump got a bot thin and a couple holes developed. Rather than try to make another one (this was already attempt #2) I sealed up the holes with the urethane adhesive. I still need to drill a hole in the sump and install a suitable drain fitting. That will be a post for another day.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

#67 |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

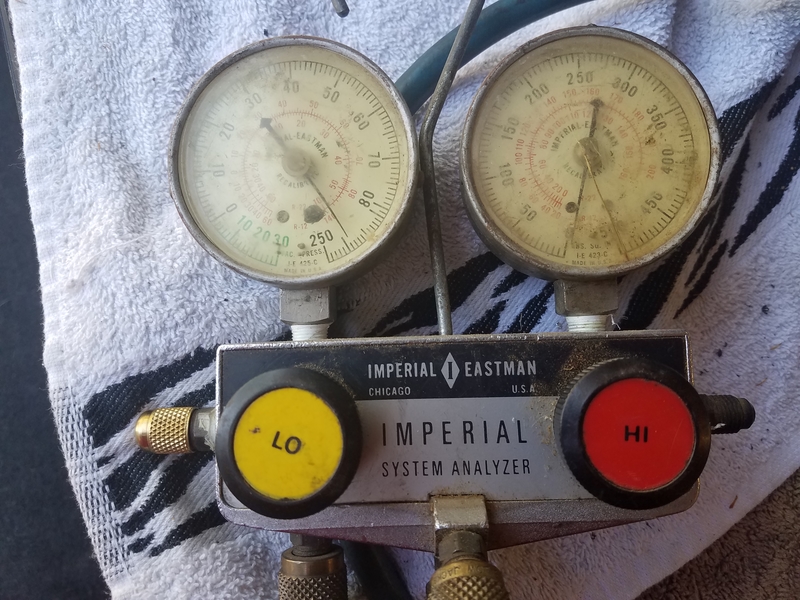

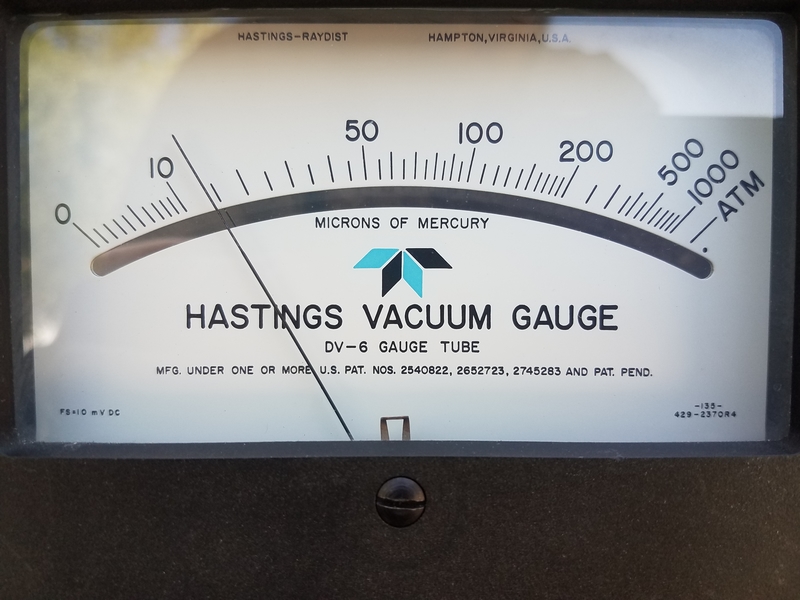

I neglected to mention earlier that I have a new family member!

Her name is Freya, and she does an excellent job of holding down the floor while I work:  She is a 3-½ year old German Shepherd who was at a rescue shelter. She is great with kids and cats, and she has a good sense of people and she has definitely become protective of her new family. She is also very intelligent. I am looking forward to taking her camping with us. I think she will really like hanging out in the forest. Unfortunately, the weather is heating up fast, and when she rides in my truck her attitude is "Dude! Get me some AC goin' in this thing!" With that said, I got the evaporator finished. I was originally going to run the suction line out the back as one piece, but I quickly realized it would be impossible go get the evaporator in or out of the housing. I ended up running a horizontal section of suction line long enough to accommodate the TXV bulb then turning it down and putting the -12 brass female o-ring fitting on the end. With the exception of the Schrader fitting, which is brazed on with 56% silver braze, all of the suction piping is soldered together with Harris Stay Brite silver solder. Stay Brite is designed for HVACR service and because it takes much less heat to melt there was no danger of accidentally melting the braze joints between the header and the three tubes exiting the evaporator. After I got it soldered and brazed, I used my pressure test fittings to plug up the inlet and outlet and pressurized the whole unit:   I found my old Imperial gauge set and chose to use it to pressure test the system. Despite being over 35 years old, the manifold doesn't leak. My JB manifold leaks, and my Yellow Jacket manifold has a broken low side gauge. They are both on my to-do list to fix. Whether they will get fixed depends on if I decide to invest in a Testo 550 or a Sporlan SMART tools setup to attach to the Imperial manifold. Anyway, I digress. Here it is holding ~190psi pressure:   The problem with this gauge set is that it was designed for a better, vanished time. It has saturated temperatures for R-12 and R-22, and the gauges start to retard after 80psi, at which point they're not very accurate or responsive. I tried running my JB manifold with brand new R-410a gauges that read to 250psi on the low side with no retarding, but then I discovered that the low side valve seal leaks. I ended up putting the Imperial set back on and pressurizing the evaporator to 75psi. It has now been a couple days and the gauge is holding pressure, so I think I can pronounce the evaporator coil leak-free. I also got myself a new micron vacuum gauge. Back when I got into refrigeration and AC nobody had micron gauges because they were expensive. Turns out they are still expensive, but cheaper than they used to be. After having seen how different two new digital gauges from the same manufacturer can read on the same line, I chose to go with a laboratory-type instrument. If I get a cheap, compact digital gauge I can use this instrument to sanity check it. I decided to use my new gauge to see how low of a vacuum my over-20-years-old vacuum pump can pull. Here's the gauge tube attached to the pump:  I tried initially with the oil in the pump, and was only able to pull 180 microns. I dumped the oil and filled the pump with some old (but unused in a sealed bottle) oil I had lying around. The pump holds a quart, and I had 3/4 quart of VERY high quality and very expensive Inland 45 synthetic pump oil in the cabinet. I poured it in the pump, and topped it off with ¼ quart of cheap Robinair vacuum pump oil that had been kicking around in a cabinet for 10 years. The Robinair oil is nowhere near the quality of Inland 45, but the pump still managed to pull a very respectable vacuum:  14 microns! It actually pulled down to 11 a few minutes after I snapped that pic, at which point I shut it down. For a relatively inexpensive refrigeration service pump that is an excellent vacuum. Assuming the AC system doesn't leak I should have no problems pulling down to 250 microns. That's all for now. Hopefully the next update will be to show the evap housing mounted under the dash.

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." Last edited by MaxPF; 04-21-2017 at 03:06 AM. |

|

|

|

|

|

#68 |

|

Registered User

Join Date: Oct 2014

Location: Kitchener, Ontario, Canada

Posts: 3,254

|

Re: A K5 Cummins Conversion: The saga continues...

Always good to have a friend in the shop with you then you will never talk to yourself. Rescue thumbs up.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=648459 https://67-72chevytrucks.com/vboard/...d.php?t=769441 1951 MG TD 1967 Jeep CJ5 1.9L TDI 33X13.5X15 Mud Grapplers. 1952 GMC 9700 p/u 7.3L diesel on air, dually |

|

|

|

|

|

#69 | |

|

Registered User

Join Date: Jan 2016

Location: Mesa, AZ

Posts: 60

|

Re: A K5 Cummins Conversion: The saga continues...

Quote:

__________________

1991 V1500 Blazer (Silverado), 5.9L 12V P-pumped Cummins (5x .012 sac injectors, #6 fuel plate, WH1C with external 38mm wastegate running 30psi), NV4500 with 1-⅜" input shaft, SBC Con-O clutch, NP205, HAD, 4.10 D61/14BFF spinning 37" Nitto Exo's  "I got a shotgun, a rifle, and a four wheel drive and a country boy can survive." |

|

|

|

|

|

| Bookmarks |

|

|