|

|

|

#226 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

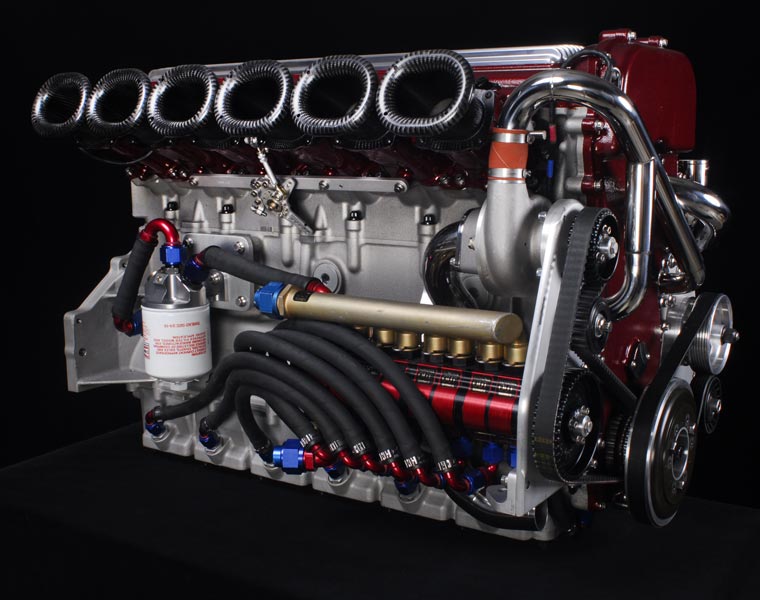

Cored sand cast gets a little more complicated in that you need to be able to suspend the core, where you split the cast has to be taken into consideration, the angles of flanges and such need to be tapered so that the material can flow right and that it can be removed, the shrinkage rates differ from inside to outside, anyway, a lot more complicated. There will probably be great advances in 3D printing in coming years and there will also be splits in the different technologies being developed. The really cool tech is the laser reactive powdered media printing where the part just grows out of a powdered media instead of the tech that is currently being consumerized which is more like laying down media with a tiny controlled caulk gun. The reactive media printing is the one that can actually print out of more industrially useful materials like metals from the get go, very very expensive at this point though. If I didn't have friends with access to the printers. the printing would actually cost me more than the casting at this stage, so it's not cheap. Also the down side of 3D printers is that they are not exactly smooth. I may end up doing some post print smoothing to make the cast look more like a traditional cast. I've also considered doing a inverse print and making foam cores, since that is what the Atlas block is and it would continue the "look" into the manifold. If you look at the Atlas block it looks like Styrofoam. Anyway it's posted elsewhere in the thread but here's the manifold design again: |

|

|

|

|

|

|

#227 |

|

Registered User

Join Date: Nov 2014

Location: shreveport, louisiana

Posts: 28

|

Re: Project Madera: A Jimmy GT

you seem like a guy with a lot of know-how and excess funds. I wonder how much more difficult and costly a DOHC conversion would be than what you're already doing. I'm wondering how much it would cost for a 292/250, if it would be marketable, if there's demand for such a thing...but if I'm COMPLETELY honest, the only reason I wonder if it would ever make good business sense is just to fund the project so that I could have it for my c10. Oh pipe dreams...

|

|

|

|

|

|

#228 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: Project Madera: A Jimmy GT

i know they did a 32 valve conversion on the old big block still using the stock camshaft and pushrods and some realy trick rockers

arias made a set of billet 32 valve heads for the small block too both where somwhere in the eighties it turned out you can actually get better flowing heads with two valves per cilinder and some extensive development work wish is the reason the LS engines still have 2 valves per cilinder maibe this will help : http://www.69pace.com/6shooters.htm theres one that made an aluminium inline 6 head by lopping of one combustion chamber of a set of good flowing aluminium v8 heads and weld them together

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#229 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

Maybe making a flat crank V8 out of two DOHC fours might be worth it, or maybe a modern double six based on two Buick or 4.3l Chevy V6s with a common crank. Just not getting the gain of a new head for the 250/292, I can't see where it would be dramatically better than the Pontiac OHC six that already exists and is already based on the 250. |

|

|

|

|

|

|

#230 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

|

|

|

|

|

|

|

#231 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: Project Madera: A Jimmy GT

i know the aj8 24 valva heads will fit a jag v12

https://www.youtube.com/watch?v=peJznOKmEKs the later jags where 5.0 i believe not sure if theres a stock inline 6 head with the same cilinderspacing , if there is it might be cheaper to adapt the deck of a inline 6 chevy to bolt that head on

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#232 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

|

|

|

|

|

|

|

#233 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: Project Madera: A Jimmy GT

i later on read some more about it , it seems its not as eazy as slapping them on , only the cilinderspacing is the same but the block isnt rigid enough for the head to be fitted without extensive welding to the decks , sorry about that

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

|

#235 |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Waiting on Porterbuilt at this point, my chassis, engine, and all that are in Arizona. In the mean time I've been working on my parts taxi, the '03 Sonoma. I keep walking around with a tape measure and a set of digital calipers but I have nothing to measure

. I've also decided in the mean time that I'll be getting a lost media friendly 3D printer in 2015 to design parts, this technology has really hit a stride in the last year or so, and well frankly I'm getting tired of resources disappearing on me and plan on trying to be a lot more self sufficient on this project going forward. . I've also decided in the mean time that I'll be getting a lost media friendly 3D printer in 2015 to design parts, this technology has really hit a stride in the last year or so, and well frankly I'm getting tired of resources disappearing on me and plan on trying to be a lot more self sufficient on this project going forward.

|

|

|

|

|

|

#236 |

|

Registered User

Join Date: Feb 2009

Location: Calgary, AB, Canada

Posts: 156

|

Re: Project Madera: A Jimmy GT

Subscribed. Not sure how I missed this. I'm building my 68 GMC with the same engine and transmission combo.

|

|

|

|

|

|

#237 |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

|

|

|

|

|

|

#238 |

|

Registered User

Join Date: Apr 2007

Location: Acworth, GA

Posts: 441

|

Re: Project Madera: A Jimmy GT

Any progress on the build?

|

|

|

|

|

|

#240 |

|

Senior Member

Join Date: Jun 2011

Location: Washburn, IA

Posts: 600

|

Re: Project Madera: A Jimmy GT

I've been away awhile. That rendering looks pretty trick. Ever thought about have it laser or hydro cut out and tig welded together?

|

|

|

|

|

|

#241 |

|

Registered User

Join Date: Sep 2006

Location: New Haven, MO

Posts: 1,243

|

Re: Project Madera: A Jimmy GT

Love the build. You are going at this from a completely different angle than any other truck or blazer than I have seen or heard of. I would not have the intestinal fortitude to go for a build anywhere close to this caliber. What do you do as a day job?

__________________

-Lincoln 1987 GMC S15 (soon to be a chevy clone)  2.5l, 4 speed, no ps, no pb, no ac Silence is golden, but duct tape is silver.  Spoken by Cletus the hillbilly I like stickers... a whole bunch. |

|

|

|

|

|

#242 |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

OK, so I've been kind of a slack about updating this thread.

My chassis has been at Porterbuilt for almost a year now so they could get their stuff to actually fit the 4WD frame. It's supposed to be completed this month, but then again I've heard that several times before. The delays in the chassis have halted everything else, and I've stopped shopping vendors for the rest of the project right now because I've gotten too many interested in parts of the project only to have these delays cause the resources to evaporate. So until I have a rolling chassis to work with I am kind of stalled out, it's very aggravating and makes me look like a total flake. I do really appreciate all the encouragement on my project, to answer your question Abe, I am a computer infrastructure architect, I design large scale computing systems but I am currently between gigs so cash flow is a bit lacking at the moment anyway. In the meantime I plan on starting to develop some of the electronic controls soon using these little Raspberry Pi microcomputers: I plan to use several of these to control various things in the truck like the seats, windows, and well, stuff. The cool thing about these is that there is many display options for them from simple indicators to small little text displays and full color displays from small cell phone sized to your typical SatNav sized. I also haves several of these: ...which are a simple little spinning turn dial that essentially acts like an up arrow and down arrow on a keyboard and when you push it it's like the return key or a mouse click, meaning you can use it with a real simple webpage running on the controllers to create simple interfaces with a cool spinning knob. |

|

|

|

|

|

#243 |

|

A guy with a truck

Join Date: Sep 2005

Location: Germany, for now

Posts: 5,921

|

Re: Project Madera: A Jimmy GT

Cool ideas here. The wait from PB will be worth it. The rest of Blazer owners will appreciate you as well, when there is a true 2wd conversion available.

__________________

-Chris Instagram _elgringoloco_ '70 Short-Wide How to: Ruin a perfectly good C10 ‘70 Blazer ConversionHow To: Ruin a Perfectly Good 4wd '72 Highlander How To: Ruin a Perfectly Good K/5 (SOLD) '72 Blazer 2WD How to: Ruin a perfectly good Blazer (SOLD) '05 Yukon Daily Driven (not so stock) Yukon (SOLD) ‘07 Yukon Denali (daily) Members met list: SCOTI, darkhorse970, 67cheby, 67cheby'sGirl, klmore, porterbuilt, n2billet, Fastrucken, classicchev, Col Clank, GSFMECH, HuggerCST, Spray-Bomb, BACKYARD88, 5150, fine69, fatbass, smbrouss70, 65StreetCruiser, GAc10boy |

|

|

|

|

|

#244 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: Project Madera: A Jimmy GT

found this glass dash for in a car it includes everything a normal dash has like the oilpressure warninglight indicator hi beam handbrake brake warning indicators that other systems needs to have leds added for

https://plus.google.com/+VenatorDashboard/posts guy uses android a small anolog to digital box and some software he builds himself and these tft screens with a tft to vca adapter  the russian car computer website has a lot of info and most of the program on it and once you hit google translate you can understand most of it , you might want to look intoo it contacted him a while back and he just about ready to sell the stuff in beta/kitform with the pull down menu's in english the price he quoted me was between 500 and 600 dollar

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts Last edited by watahyahknow; 07-19-2015 at 05:49 AM. |

|

|

|

|

|

#245 |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

The display dash is pretty cool stuff, probably a bridge too far for me though. I do want to keep the actual gauges a traditional needle and dial affair, though I do realize that the gauges I plan to use (Speedhut) are still microprocessor controlled, so the reality is that they are really sort of the same deal as electronic.

Dakota Digital makes a little all in one vacuum fluorescent display for motorcycles that I am planning to incorporate into my cluster. The DD unit has a graphical tach, digital speedo, odometer, signal and high beam indicator, and a speed vs rpm based gear indicator as well as a clock, fuel gauge, and some programmable idiot light functions. Though I plan to have all the gauge functions repeated as "analog" gauges. I do not plan on using the casing at all. It really has to do with the gear indicator and odometer than anything else, The Speedhut speedometer has, like most electronic speedometers these days, a cheesy LCD display for the odometer and since they do custom, my plan is to have them do one dial face with the LCD area open so I can set the gauge up the first time and another without the window and just bury it under the dial. Having a Vacuum fluorescent odometer incorporated into the cluster but separate from the gauge, to me, feels a bit more OEMish. Also my 6 speed 4L80E and paddle shifter doesn't really lend itself to anything other than a speed based or some TCU programed method of indicating gear and I really want to have an indicator that tells me what gear I'm in vs. what is selected. The dash is a whole thing unto itself which I've not gotten into in this thread much. I plan on doing a machined gauge cluster with the gauges mounted behind a single pane of acrylic in a layered array. I've measured it all out and I should be able to squeeze 2 4.5in gauges, speedo and tach, with the tach a reverse wind, and both with rotated faces so they land with the needles pointing at each other. With the corners slightly tucked under the 2 big gauges I should be able to fit 3 2.25in gauges outside of those and another 3 slightly tucked under those on each side. This gives me a total of 14 gauges in the cluster, 6 of which (on the left) will be individual calibration vacuum gauges for the individual throttle bodies. The center of the dash and falling into a center console will be modular panels so the electronics can evolve over time, each panel I am planning to be about 1"x9" or some multiple of that (2"x9", 3"x9", etc..). This way I can put in DIN and Double DIN pieces, or switch panels, or AC controls or vents, or whatever. Parking brake will be an electronic unit as will the main P-R-N-D selector with the paddle shift manual override. The selector is a standard piece from Powertrain Control Solutions, the same company that makes the 6 speed TCU I'll be using (they also made the valve body). Here's a pic: ...and the E-Stopp electronic parking brake which simply pulls the parking brake cable when you push a button: I think I've also mentioned in this thread somewhere that the exhaust will be incorporating an internally by-passable muffler and I'm using the Ridetech Select series coilovers which are also electrically controllable. |

|

|

|

|

|

#246 |

|

Registered User

Join Date: Nov 2014

Location: shreveport, louisiana

Posts: 28

|

Re: Project Madera: A Jimmy GT

Yikes. You're not supposed to talk about that on a car site. Because it's all subjective, right? None of this is worth it really. I mean why go with an inline six when a v8 would be fine? Probably cheaper and more aftermarket support. But is that old truck worth it? Why not just buy a sports car? The "what's the point" or "is it worth it" argument is to be avoided at all costs. It's the only reason my grandpa's truck isn't scrap metal already.

Still looking forward to updates on this very cool project. |

|

|

|

|

|

#247 |

|

Collector of Projects

Join Date: Apr 2003

Location: Las Vegas

Posts: 3,106

|

Re: Project Madera: A Jimmy GT

I wanted the E-STOPP brake system, but I heard it takes (relatively speaking) forever to engage... almost 10 seconds. Its about $500. too....

|

|

|

|

|

|

#248 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

I understand that this engine was actually loosely based on the 292, though there isn't much left of it. This engine carries a starting price of $45,000 and does have a bit more potential than the Trailblazer engine, but not as much as you'd think. GM used both of them in the Baja trophy trucks as well as for Pikes Peak hill climb racers. The Falconer L6 I think caps out around 5 liters and the Trailblazer could probably be pushed to 4.4 liter by using the sleeves from the 3.7 Liter I5 Canyon engine and maybe a bit more with a stroked crank, but not much. In the Trophy Trucks, they ran 5.0 and 4.2 respectively both 24 valve DOHC and both turbo charged and the Trailblazer engine in race trim was lower in HP but actually slightly higher in HP/liter. |

|

|

|

|

|

|

#249 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Project Madera: A Jimmy GT

Quote:

My plan was maybe to just auto engage them when the ignition was off. My father drilled into me that the parking brake is either something you use every time or absolutely never use at all, because if you don't use it every time the cable gets sticky and doesn't disengage all the way and wears out your rear brakes. So if I did use the electronic version it would probably either be a button I never push because it engaged automatically, or a button I never push because I simply don't use it. Is it worth $500 if that is the case? I don't know, but it just seems like not having a parking brake at all just seems wrong, no? Especially since I already have all the parts at the wheels to make them work. |

|

|

|

|

|

|

#250 |

|

Registered User

Join Date: Jul 2006

Location: the netherlands europe

Posts: 4,335

|

Re: Project Madera: A Jimmy GT

you could look around at wheelchair adaptations for cars , some of them allso have these sort of thing for when the person operating it doesnt have the strength or feet to operate the lever

from wat the picture of the system shows its nothing more than a linear servo , you could add one to under the dash mecanicly pressing the brakepedal lever above the footpad with a small roller , prolly can use a smaller less powerfull servo for that retracted it doesnt mess up the pedal feel and extended it keeps all four wheels locked it does put some force on the hydraulic lines and stuff but it would brake better than a emergenc brake does i would still keep the original emergencybrake setup incase the hydraulics let go

__________________

i got a job again and having fun at it too idea's for the trucks and the order of things to do are taking shape and get closer to being realized , a few more months and i be able to start building for real i complete 2 of the trucks intoo running fashion one custom and one basicly stock the thirth will be sacrificed for parts |

|

|

|

|

| Bookmarks |

|

|