|

|

|

|

|

#1 |

|

Under Construction

Join Date: Oct 2007

Location: Midlothian,TX (DFW)

Posts: 4,555

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

sweet progress as usual Don.....

__________________

Heath subscribe to the board here: http://67-72chevytrucks.com/vboard/payments.php http://67-72chevytrucks.com/vboard/s...d.php?t=157669 FAQ how to's 1956 Chevy Apache 1967 C10 SWB FleetSide (under construction) 1969 K10 SWB FleetSide (Future Build) 1972 C10 SWB Stepside (Future Build) 56 chevy truck : http://www.cardomain.com/ride/2955823/1 67 truck build: http://www.67-72chevytrucks.com/vboard/showthread.php?t=281357/1 69 k10: http://67-72chevytrucks.com/vboard/s...d.php?t=389470 |

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2009

Location: Kansas city, mo

Posts: 134

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Thats the look of the dash I am thinking. Nice job.

Subscribed too. Keep us posted. Bill |

|

|

|

|

|

#3 |

|

Registered User

Join Date: May 2009

Location: Kansas city, mo

Posts: 134

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

ok,

Im back. I have to say I am very jealous of the out come of this truck. I finally talked the misses into lowering the suspension last night on out 68 stepper swb 1/2 ton 2wd. I have a few questions. Im sticking with the 350/350 auto to keep the budget in tack, and want to keep the 10bolt rear. Now here is what I would like to know. One is there a wireing diagram so I can start going thru the stock wiring and figure out the issues, or would it be much better to start fresh witha after market, and if so what are your suggestions with the one you went with, or will it be overkill for stockish 350 carb setup? two would you guys have suggestions for a lowering setup for my truck that can be up graded to do like you did here with the front cross member,and ride height sensors? I would like to bagger, but think with all I am about to get into it might get to be a very expensive setup off the bat. Suggestions, and links with part numbers maybe? Also, The cab heat that came with my truck, is such a rig job, and finding parts will get up there to do it stock, so thinking vintage air, what are the differences in cost and spacing for the 2nd vs. 4th gen you guys talked bout earlier in the thread. Next, brakes. I would like to go with at least disks in the front, and 5 bolt chevy setup, would I be best to find a stock setup,and axles, or is there a budget minded setup suggestion? I do not have poser boosted setup, so might need to source that also. If I an looking to go to something like 2-3 front and 5-6 drop in back with 8x18-19 front, and 8-9x20" on back will I need to consider the large step notch for rear frame, or? Maybe Iam just dreaming, maybe I am asking too much, but hate to do things twice, and am willing to learn. If there are any local guys that have done alot of this to thier trucks, pm me and lets get together so we can chat. Im not in any big hurry to get this truck back on the road, wanting to make a keeper, so I am starting with the second cab I found, fixing rust, and then going to front clip, then bed, so I will have most of the summer on just that, and will then get into the chassis, and electrical this winter (hopefully), then paint next spring,and get here back together next summer if all goes well. Im going to start by shaving the firewall as you did. What gauge sheet stock did you use? I have plenty of 19 gauge from strret rod work, but can get 16 or? soon if needed. Thanks in advance,and hope I did not ask toooooooo many ?'s. P.S. LOVE THE TRUCK! P.S.S. the misses asked me last night Y We did not just go looking for a finished truck? I showed here the jesabell thread (bad speller)and showed her that you would never know what was there if you did not have documentation from the builder, and was hoping not to get something that was some roofers way of fixing sheet metal. two I did not like the idea of buying some one else unfinished or rigged nightmare. 3 just the pride of knowing you did most if not all the work, spells WINNER in my book. We currently own two other custom cars, one I built and another getting rebuilt due to past owners horrible body work,and rig jobs. I am also modifying a newer one owner diesel truck I like, making it my own. Alot of this is new to me,and I appreciate finding this site and all the proud owners that make it a little easier than me just winging it looking thru mags, trying to get a clue. Thanks again for all the great posts and answers, not just to this thread but all the others that help a guy like me get a truck that I can call my own. BILL Bill H. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Nov 2007

Location: dallas Tx in front of you

Posts: 182

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Man you know your stuff nice work on the dash

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

ok, i jumped off the dash for a bit and started working on the underhood sheetmetal....we wanted a very clean, "WOW" engine compartment, when the hood was popped.....here is what ive got so far, also the intake is gonna be changed out to something more suitable/matching to the engine compartment.....got my templete of what the inner fender was gonna look like, by bending a little peice of scrap metal....then cut and rolled the new peice to look like the templete... also clearenced around the steering column....after i got it ruffed in, i did the same for the other side

Last edited by 68 short step; 05-30-2009 at 12:03 AM. |

|

|

|

|

|

#6 |

|

Under Construction

Join Date: Oct 2007

Location: Midlothian,TX (DFW)

Posts: 4,555

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

lookin good Don!!

__________________

Heath subscribe to the board here: http://67-72chevytrucks.com/vboard/payments.php http://67-72chevytrucks.com/vboard/s...d.php?t=157669 FAQ how to's 1956 Chevy Apache 1967 C10 SWB FleetSide (under construction) 1969 K10 SWB FleetSide (Future Build) 1972 C10 SWB Stepside (Future Build) 56 chevy truck : http://www.cardomain.com/ride/2955823/1 67 truck build: http://www.67-72chevytrucks.com/vboard/showthread.php?t=281357/1 69 k10: http://67-72chevytrucks.com/vboard/s...d.php?t=389470 |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

also made the front cover peice....this peice will act as a radiator hold down,fan shroud, and really smooth things out/ clean up the engine bay, for that smooth clean "WOW" look were after....

started measureing and cut a peice of metal, then bent it, cut the top part so i could 'bend' it to match the contour of the factory core support... tacked it in place, then welded it from the backside (still need to finsh weld/grind the front/top side tho)....and set-it in place to get an idea of how it looks. but first i had to remove the factory, 'bumps' in the core support (they will be smoothed up later)

|

|

|

|

|

|

#8 |

|

VA72C10

Join Date: Mar 2008

Location: Midlothian, VA

Posts: 25,269

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Very nice work!

__________________

Looking for a 67-72 swb or blazer project in or around VA.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Let me be the first to say WOW

it really does look great. I have spent halve my drive time this week working on my engine bay and hood hinges for our Tahoe (in my head at this point) and I know it takes allot of thought to get to the point you are at. Maybe I missed it but what are your plans for hinges? Also what did you change on the pulleys? I to want to ditch the truck intake (little close to the top of the fire wall with the C4 DM) but I have been told I need to change my entire engine accessory set up so I am looking for less expensive ideas. it really does look great. I have spent halve my drive time this week working on my engine bay and hood hinges for our Tahoe (in my head at this point) and I know it takes allot of thought to get to the point you are at. Maybe I missed it but what are your plans for hinges? Also what did you change on the pulleys? I to want to ditch the truck intake (little close to the top of the fire wall with the C4 DM) but I have been told I need to change my entire engine accessory set up so I am looking for less expensive ideas.Kevin LFD Inc. |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Quote:

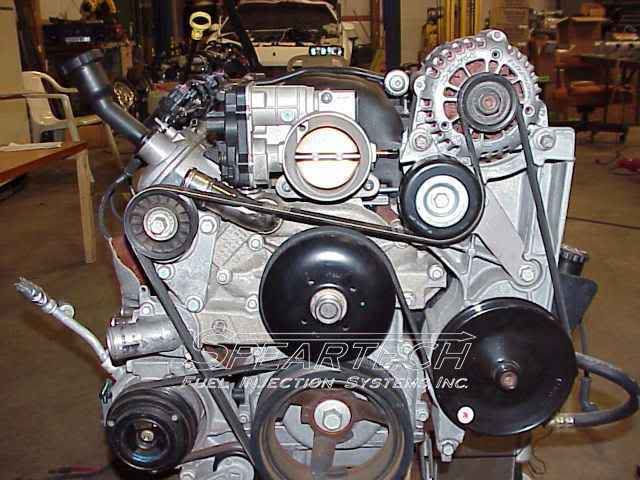

as for the pullies, quite a bit of work went into this system, to keep the VVT feature.....all the pullies had to be spaced out, and the alt. had to be raised and clocked 20* from the factory position.....for a cheap alternative to run a car intake inplace of the truck one, you simply need a idle pulley relocation bracket (this moves it from the factory location more outboard, to clear the TB on the lower intake) here is what im talking about

|

|

|

|

|

|

|

#11 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Quote:

Ok I will look into a few different options if I decide to change over to the car intake. Few more questions for you if you don't mind. 1) who did you get the alt relocate kit from and what is the ball park price? 2) did you have a clearance problem with the sensor on the top rear of the truck intake at the fire wall and if so what was your fix? 3) I was told my 05 5.3L was a VVT motor but a few of the wire company's have told me they did not make one in 05 but you sent me a link showing they did. How can I tell if it is a VVT motor or not? I would like to keep this function but I am having no luck so far. Thanks for the info and again you are doing a sweet job on the engine bay. Very well thought out. Kevin LFD Inc. Last edited by Rokcrln; 05-31-2009 at 11:49 AM. |

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jun 2007

Location: DFW (Forney)

Posts: 1,529

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Lookin spectacular, keep it up!

__________________

'58 SWB Fleetside...Front & Rear Porterbuilt Dropmember, 6.0 LS /4L60E. Accuair E-level, 20 Billet Specialties (Vintecs) '63 Buick Riviera ... AccuAir E-level, 20" Billet Specialties (Vintecs) http://67-72chevytrucks.com/vboard/s...=528853&page=5 |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Quote:

its all GM stuff too......we got it from scoggin- dickeys parts http://www.sdpc2000.com/ 2) the sensor you're talkin about is the map sensor, i see in your thread how you have it taken off to clear the recess in the firewall.. a simple fix for you that may work, is turn it around (so the pulg is faceing forward)...... but, no, i did not have this problem, in 05 they used a diffrent intake design, that located the map sensor more forward on the intake (you may have a late design 04, early model 05 engine/intake)...here is a pic of that intake (the sensor with the masking tape on it, is the MAP sensor, about 2" forward of the fuel rail crossover)   3) in 05 they didnt have the VVT engine.... the VVT (variable valve timing) engine has a cam phaser on the front engine cover that addvances or retards the cam on the fly..... it does this for either gas mileage or for power, pending on where your foot is on the gas pedal  in 05 they did have a DOD (displacement on demand) engine.....there is a few ways to tell if you have a DOD engine 1) the cam position sensor is in the front engine cover ( instead of the back of the engine by the oil presser sesnsor) 2) if the valley cover has isnt flat, and looks like a valve body of a tranny(see #2 pic above) 3) what style of computer you have, if its a E40 with a seperate transmission control module, then you may have a DOD engine... 4) if the MAP sesnor is in the front of the intake Last edited by 68 short step; 05-31-2009 at 03:34 PM. |

|

|

|

|

|

|

#14 |

|

Under Construction

Join Date: Oct 2007

Location: Midlothian,TX (DFW)

Posts: 4,555

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

nice work....

__________________

Heath subscribe to the board here: http://67-72chevytrucks.com/vboard/payments.php http://67-72chevytrucks.com/vboard/s...d.php?t=157669 FAQ how to's 1956 Chevy Apache 1967 C10 SWB FleetSide (under construction) 1969 K10 SWB FleetSide (Future Build) 1972 C10 SWB Stepside (Future Build) 56 chevy truck : http://www.cardomain.com/ride/2955823/1 67 truck build: http://www.67-72chevytrucks.com/vboard/showthread.php?t=281357/1 69 k10: http://67-72chevytrucks.com/vboard/s...d.php?t=389470 |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Nov 2006

Location: Springfield/Kansas City

Posts: 1,842

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Very nice work! That looks really good!

|

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jul 2007

Location: Charlotte, NC

Posts: 350

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Did you make that coil pack cover? It's pretty hot.

__________________

70 CST, 6.0/ 4L80E in the works. *Custom harness by 68 Short Step* |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Mar 2004

Location: Boiling Springs, PA

Posts: 391

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Oh man the engine compartment looks awesome!

How did you role the inner fender and what did you use for cutting? |

|

|

|

|

|

#18 |

|

PROJECT 7DEUCE

Join Date: Dec 2002

Location: GRANTS PASS OR

Posts: 21,594

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Holy sh!t that is bad arse.....

__________________

GO BIG GREEN  GO DUCKS GO DUCKSMEMBER #6377 72 k-5 daily driver 6'' lift 35'' 350-350-205 slowly getting rust free. Project "7DEUCE" check out my build http://67-72chevytrucks.com/vboard/s...d.php?t=267665 Tim Powell..R.I.P EastSideLowlife..... R.I.P.. |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

thanks everyone....i used a 4.25" OD roller on one radius of the fender and a 3" OD roller on the other (lower) radius.....the fan shroud, i used a brake.....

i used a combo of cutting tools, one was a plasma cutter and the other was a cut-off wheel Last edited by 68 short step; 05-31-2009 at 10:42 PM. |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Quote:

What kind of a roller do you use, Got any pics? Kevin LFD Inc. |

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Oct 2005

Location: Strathroy, Ontario, Canada

Posts: 108

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

wow, that is some of the nicest fab work I've ever seen, could be my weak spot for these trucks, but yours is what will be fillin my dreams tonight lol

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Nov 2007

Location: dallas Tx in front of you

Posts: 182

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

Nice work under the hood ...

|

|

|

|

|

|

#23 |

|

.....I am working on it.....

Join Date: Jul 2007

Location: Anaheim Hills, Ca

Posts: 960

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

WOW!! Awesome build!!

Couple of questions that I may have missed: 1. What headers are you using? 2. Please explain to me the parts used for your lines to and from your power steering box and the pump. I like the braided lines. Nice work man!! Last edited by sandking; 06-03-2009 at 08:42 AM. |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

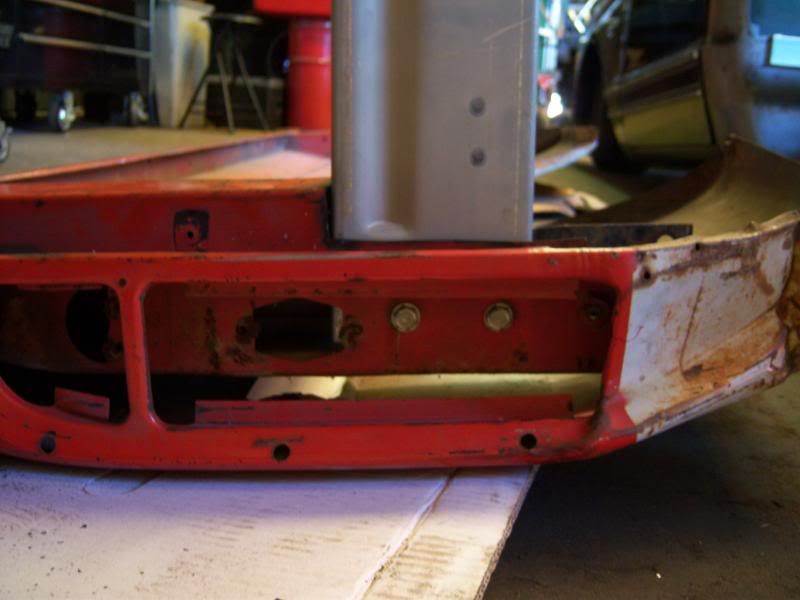

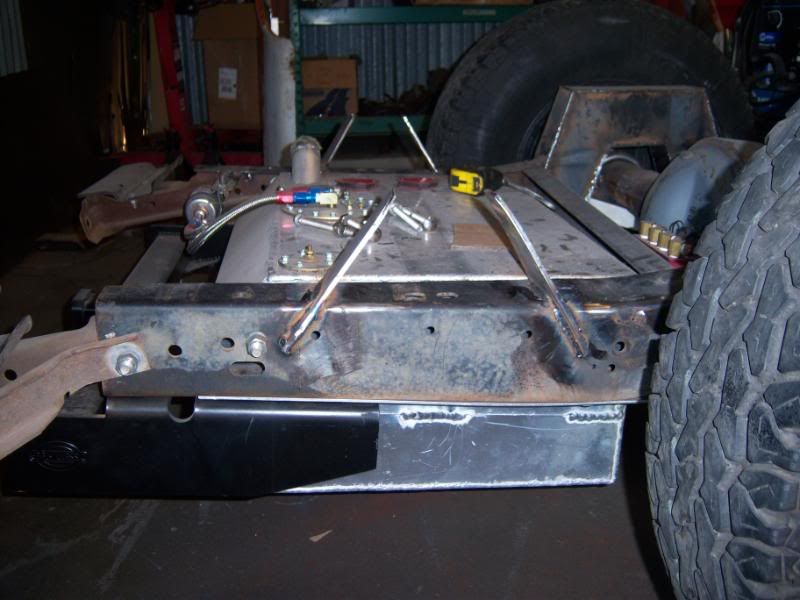

the headers are for a 99-02 firebird/camaro........

im working on the bed, i had to raise the bed floor 4" to clear the notch.....also we're converting it to a wood floor..... started by clearancing the rear most crossmember, and raiseing it 4".....then i bent up some new angles, measures up 4" from the bed floor, made my cuts, trimmed my angle to fit, clekoed angle in place, and repeated the same process for the other side.......once that was done i started with raseing my bed mounts..... i made a simple raised mount, that happened to turn out looking like alabama......then i welded my alabama bracket in place.......thinking my alabama bracket looked to plain/square (altho i doubt this would easily be seen), i added a few curves for the other bed mount bracket, further up on the frame.....this bracket came out looking like the lockness monster head comeing outta the water (so i was happy with this one  ) )then i welded the lockness monster in place, then proceeded to make alabama look like lockness, so they would match......the rear tubs are in the design process, and will be more of a round design, rather then the stock 'square-ish' design..

Last edited by 68 short step; 06-14-2009 at 09:01 AM. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: project INCREDIBLE HULK 6.2L with 6L80E

|

|

|

|

|

| Bookmarks |

|

|