|

|

|

|

|

#1 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Any chance there are oval ones that have the functionality you are looking for? If they exist, how would two look installed in the dash vertically?

Buddy building a 52 Buick is using round vents from a Chevy Sonic. Suprisingly they look right in that car. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

round

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

I think round looks more in tune for the year of the ride.

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jul 2012

Location: Rosenberg, Texas

Posts: 3,506

|

Re: 55 Wagon Progress

I'd definitely go round over rectangular. There really aren't any crisp lines on a tri-five. I mean in an overall sense.

__________________

-Duane C/10 Club Texas member 1971 Chevy C10 "Brutus" SWB Fleetside 2016 6.0L (L96) 6L90E (driver/project) 1965 Pontiac GTO "Royal Goat" 400/TH400 w/AC (my baby) |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

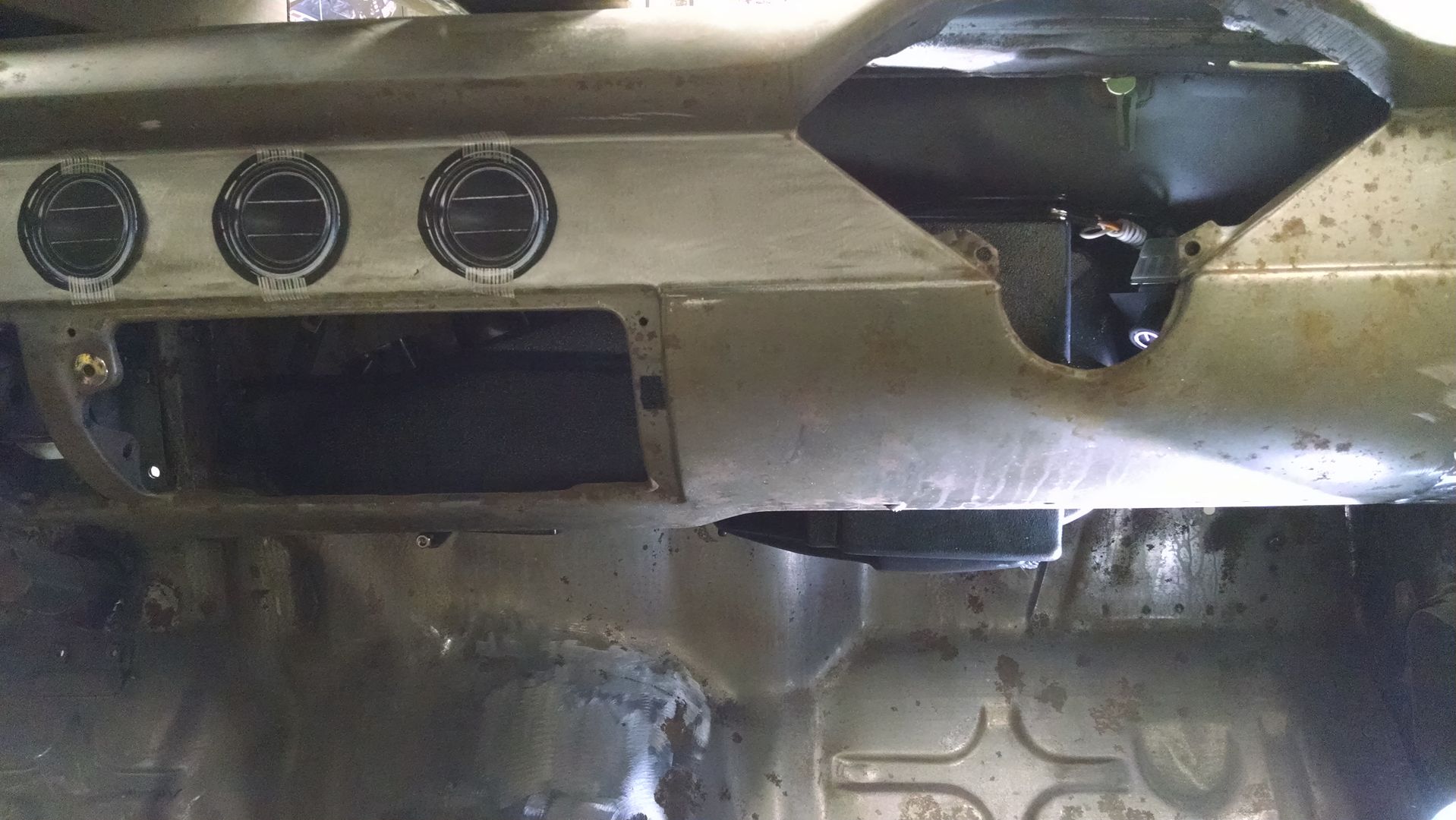

Went to a metal shaping workshop this past weekend, and just in case we needed a project to tackle, I took along one of the round vents so I could make some "buckets" in case we were going to mount them in the lower outside corners of the dash. To prevent scratching, I covered the chrome with painters tape. As it turned out, we had plenty of other projects going on, and I never got to the vents. Removing the tape when we got home resulted in this:

So be forewarned, don't use tape to protect the chrome on the plastic vents from Vintage Air. Also made a Xerox copy of the vents to be able to lay them out and test a pattern before cutting any holes. Thanks to all for the input on vent selection. Here is the 5 round pattern that the owner has decided on...

__________________

Robert |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Well that chrome didn't hold up very well! Vent pattern looks good.

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Can't believe chrome came off that easy...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

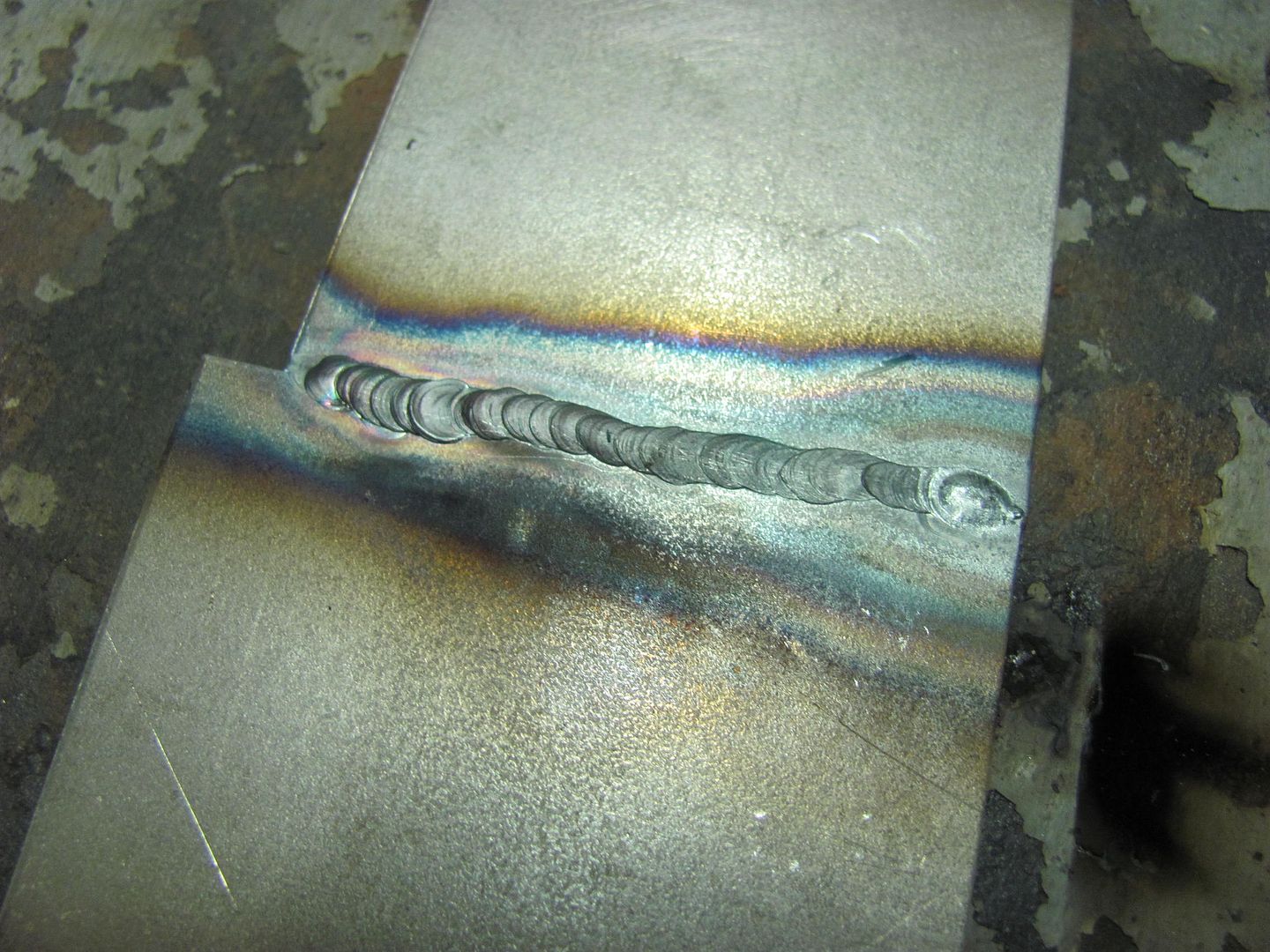

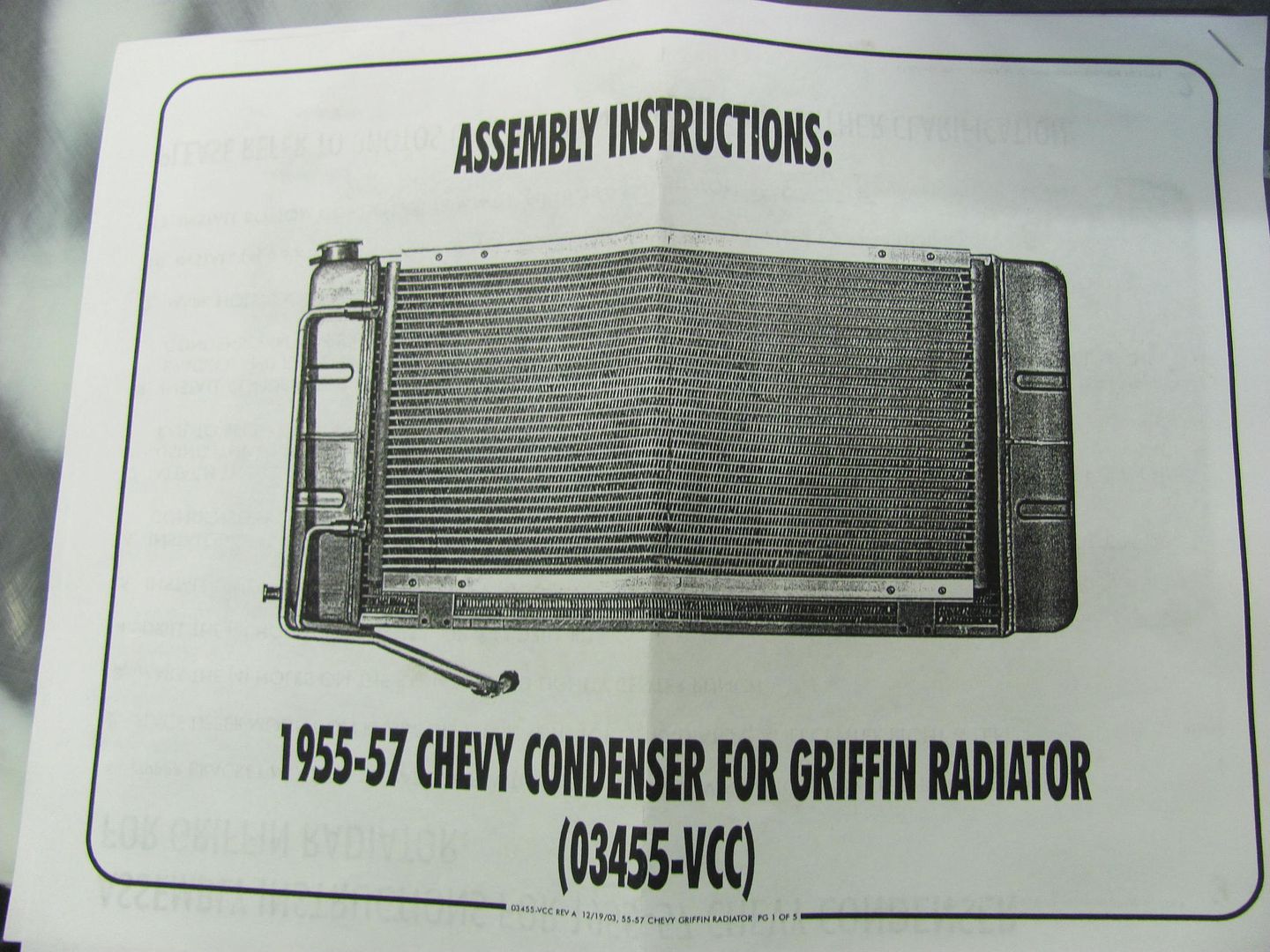

At about $10 ea, I think that's one of those got your money's worth things..

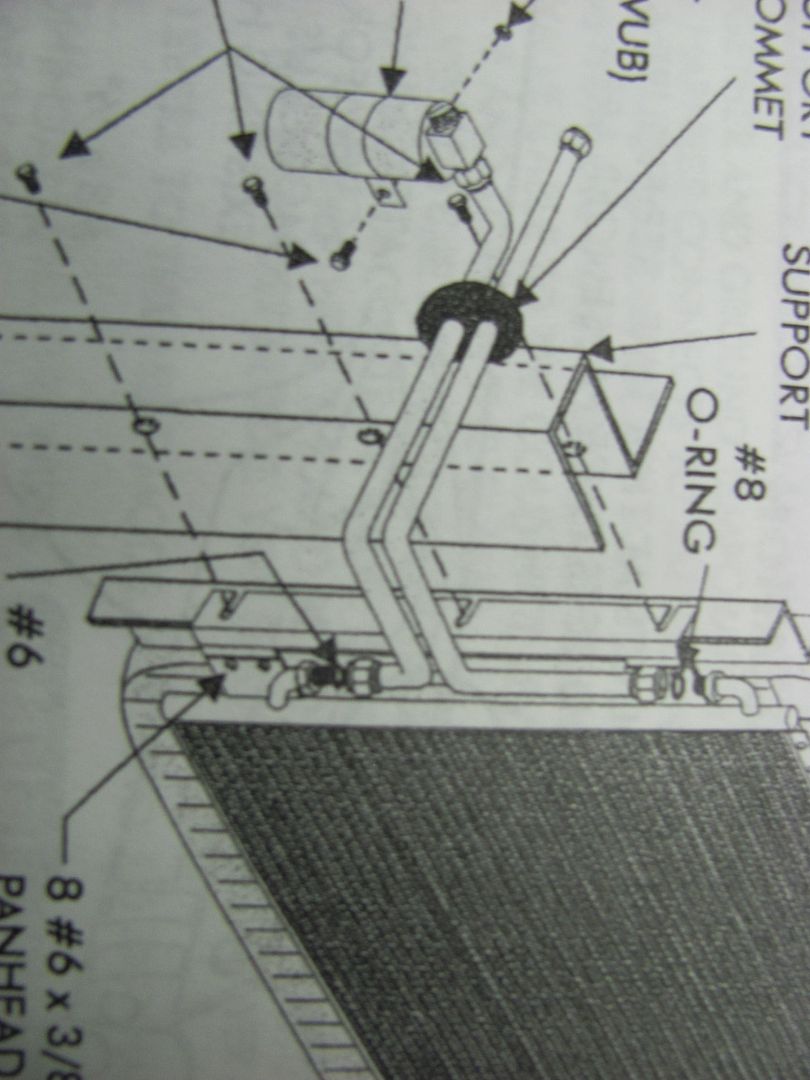

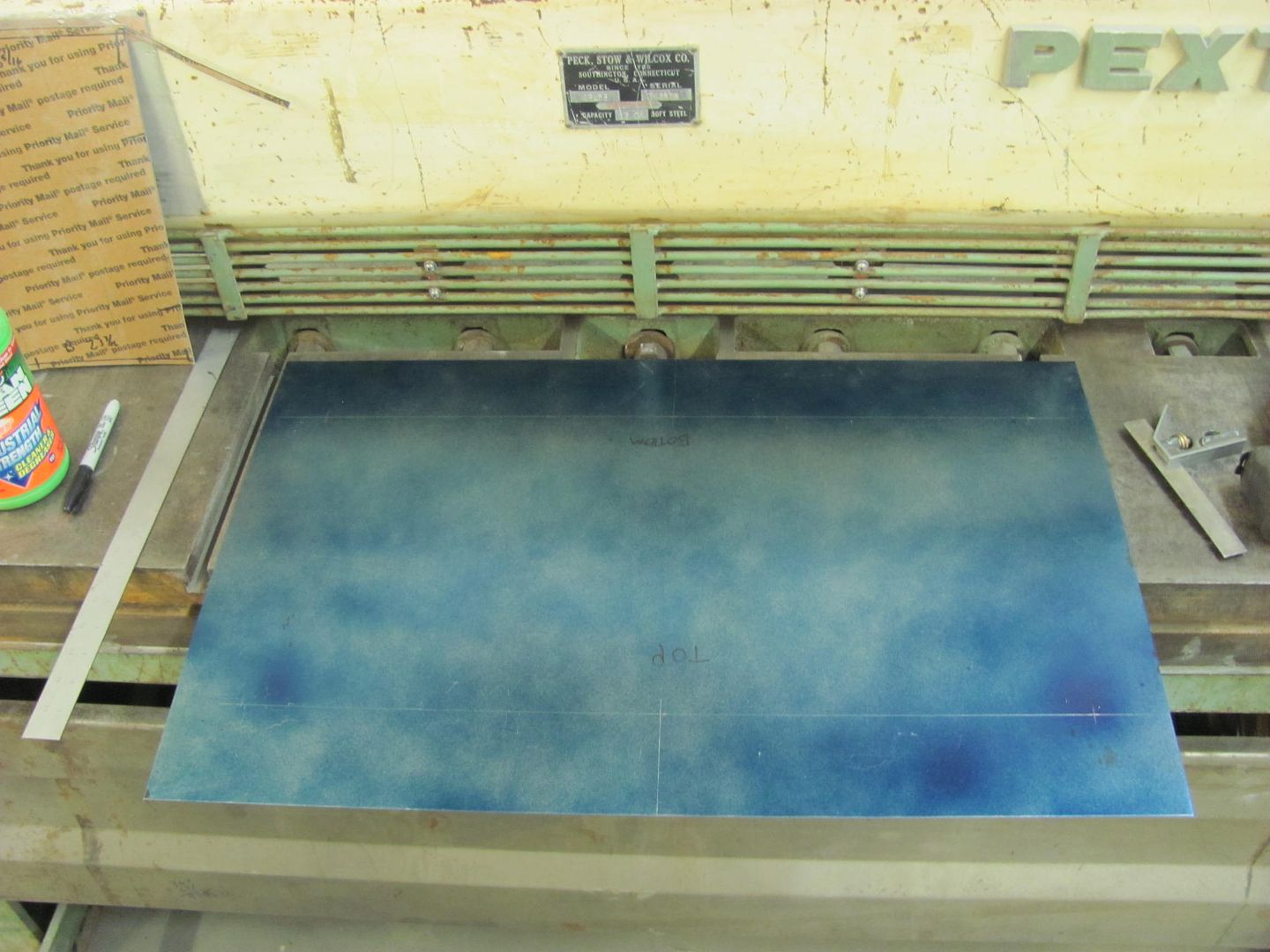

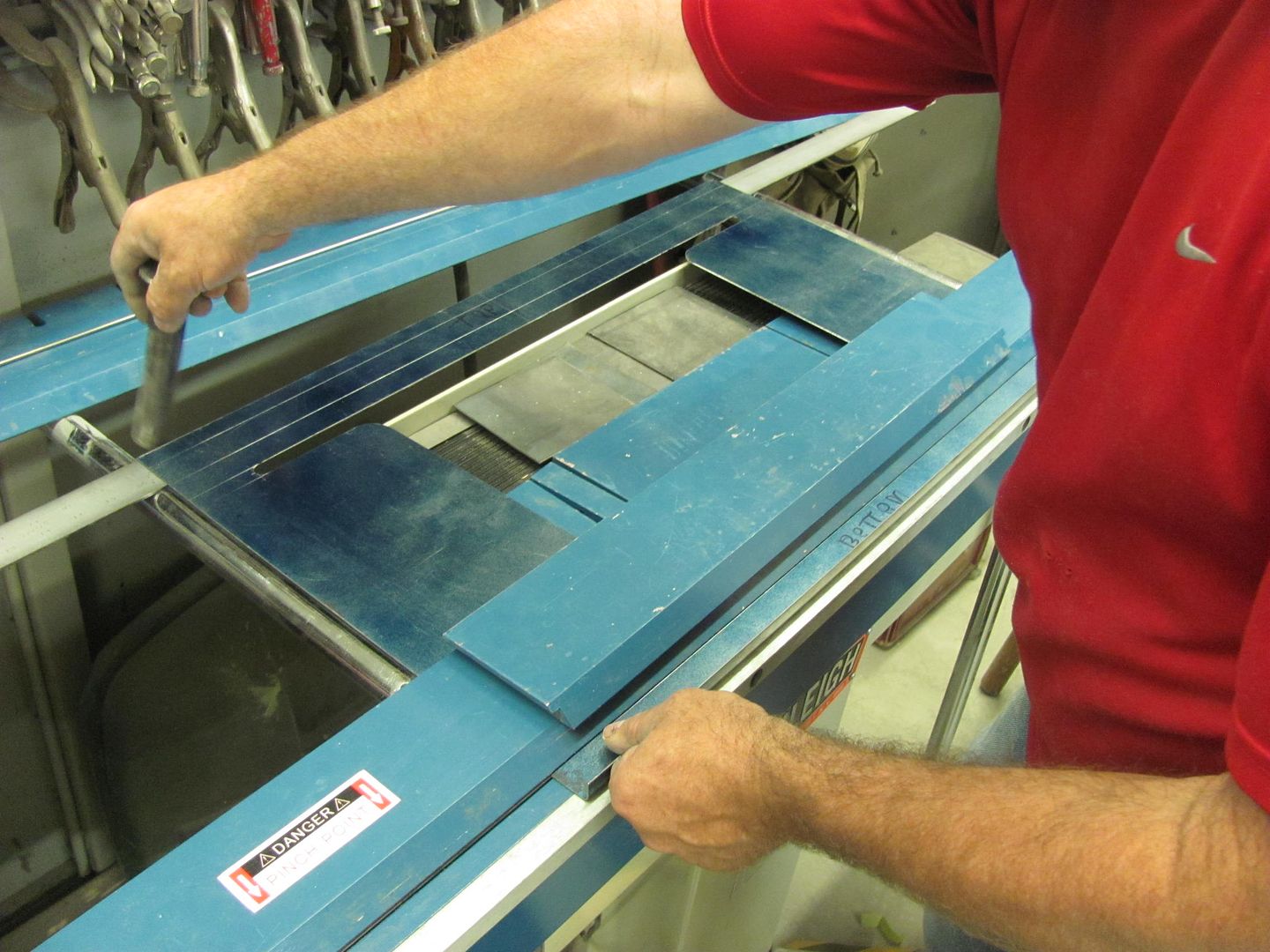

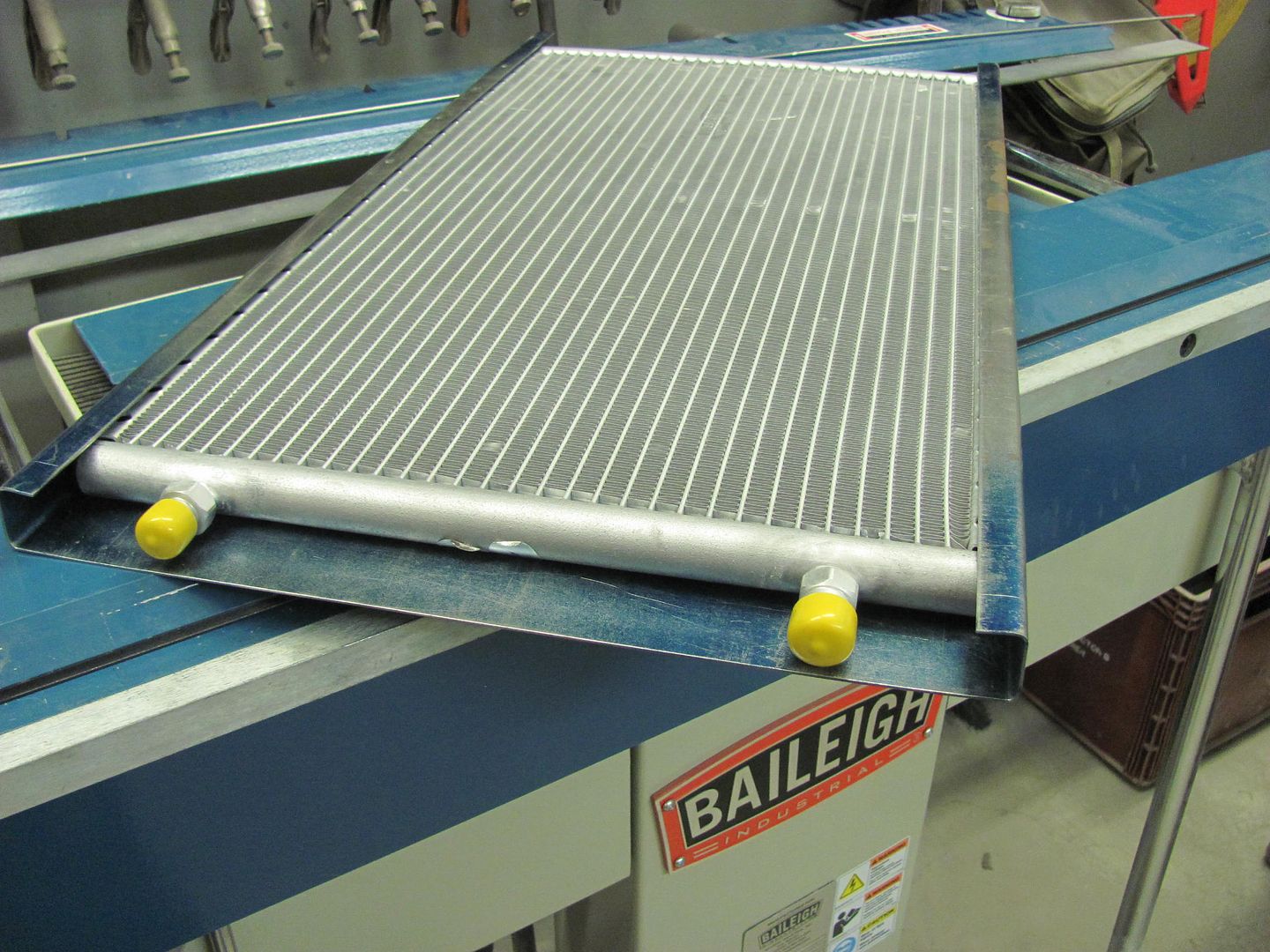

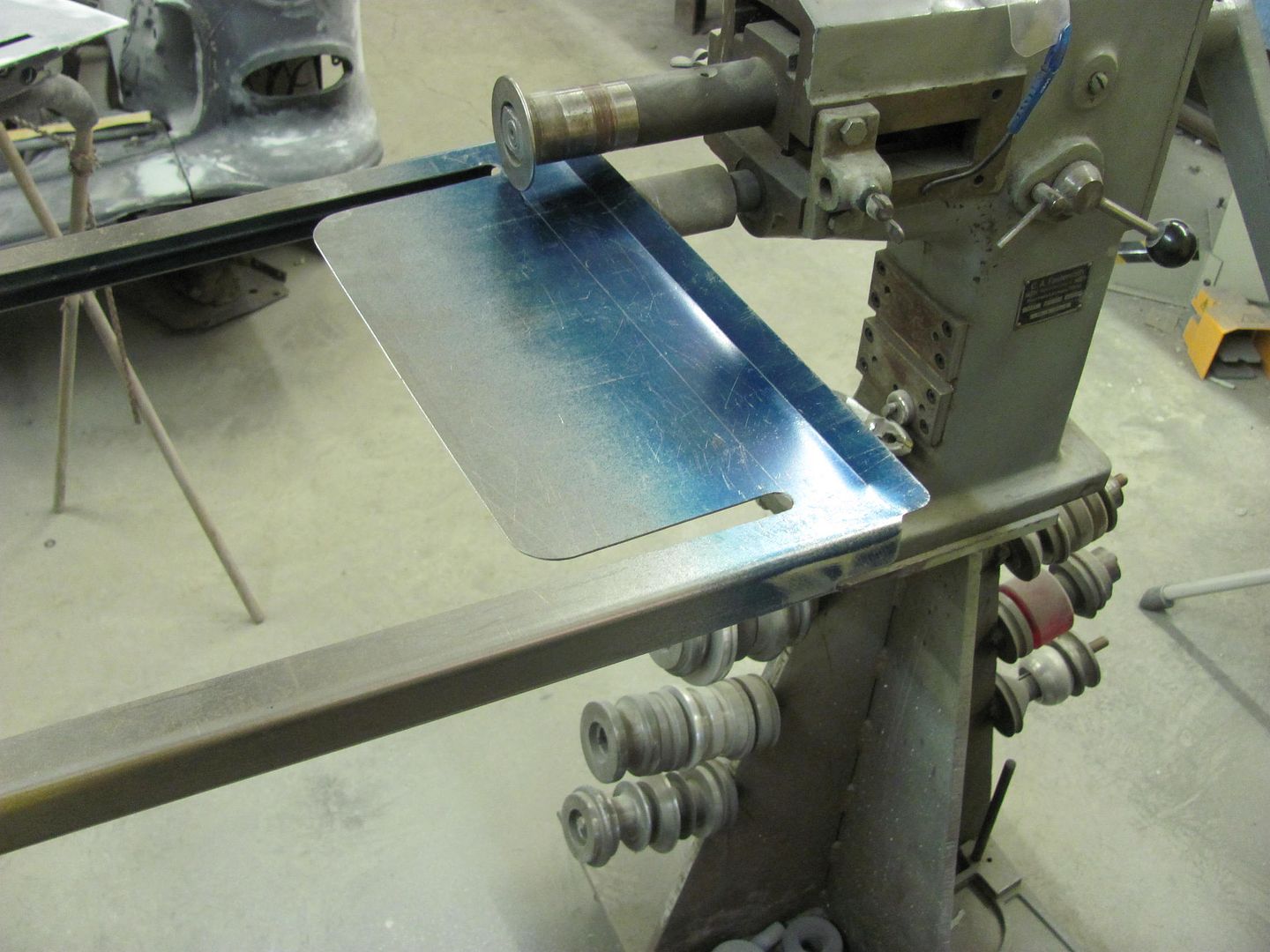

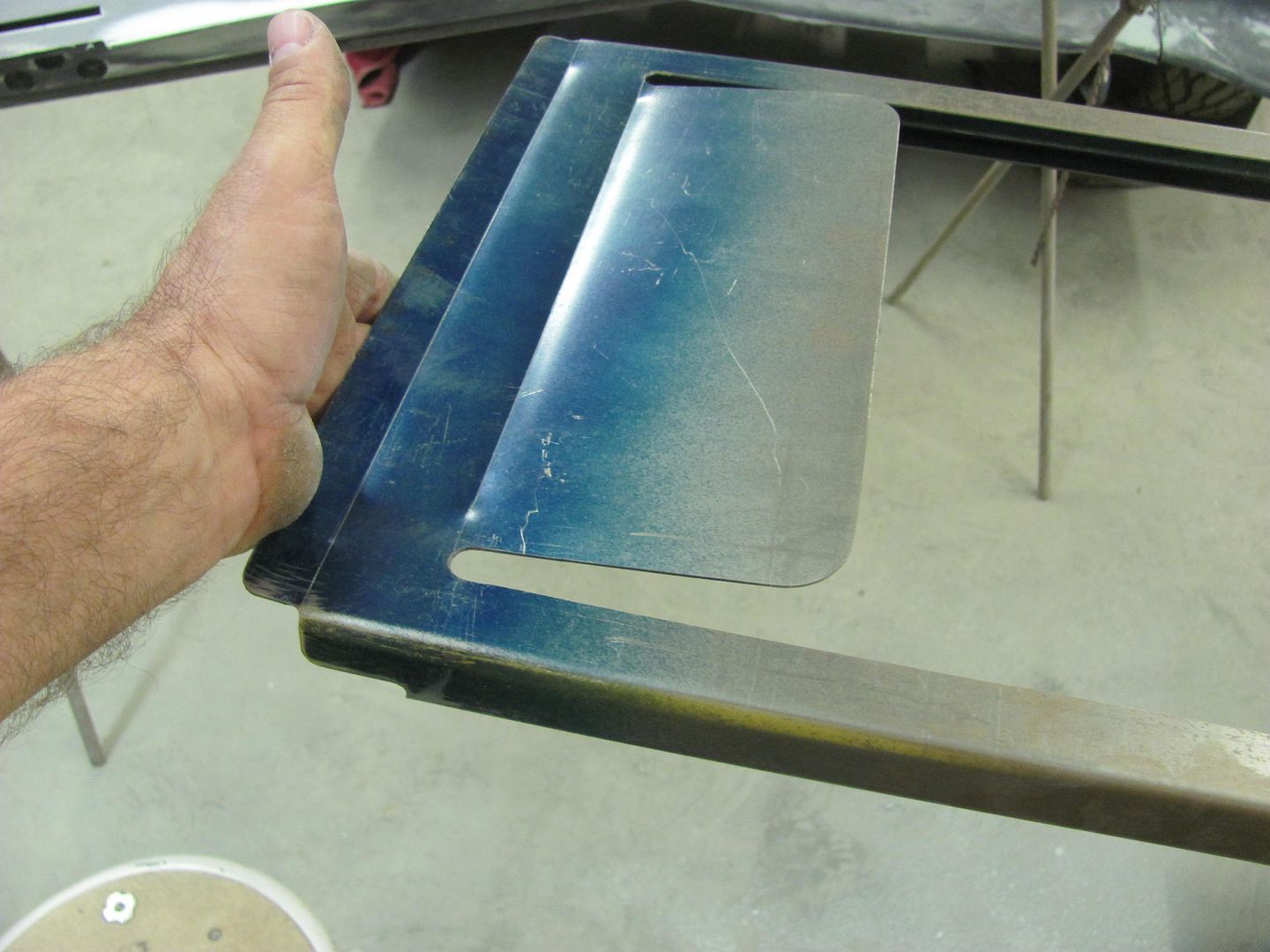

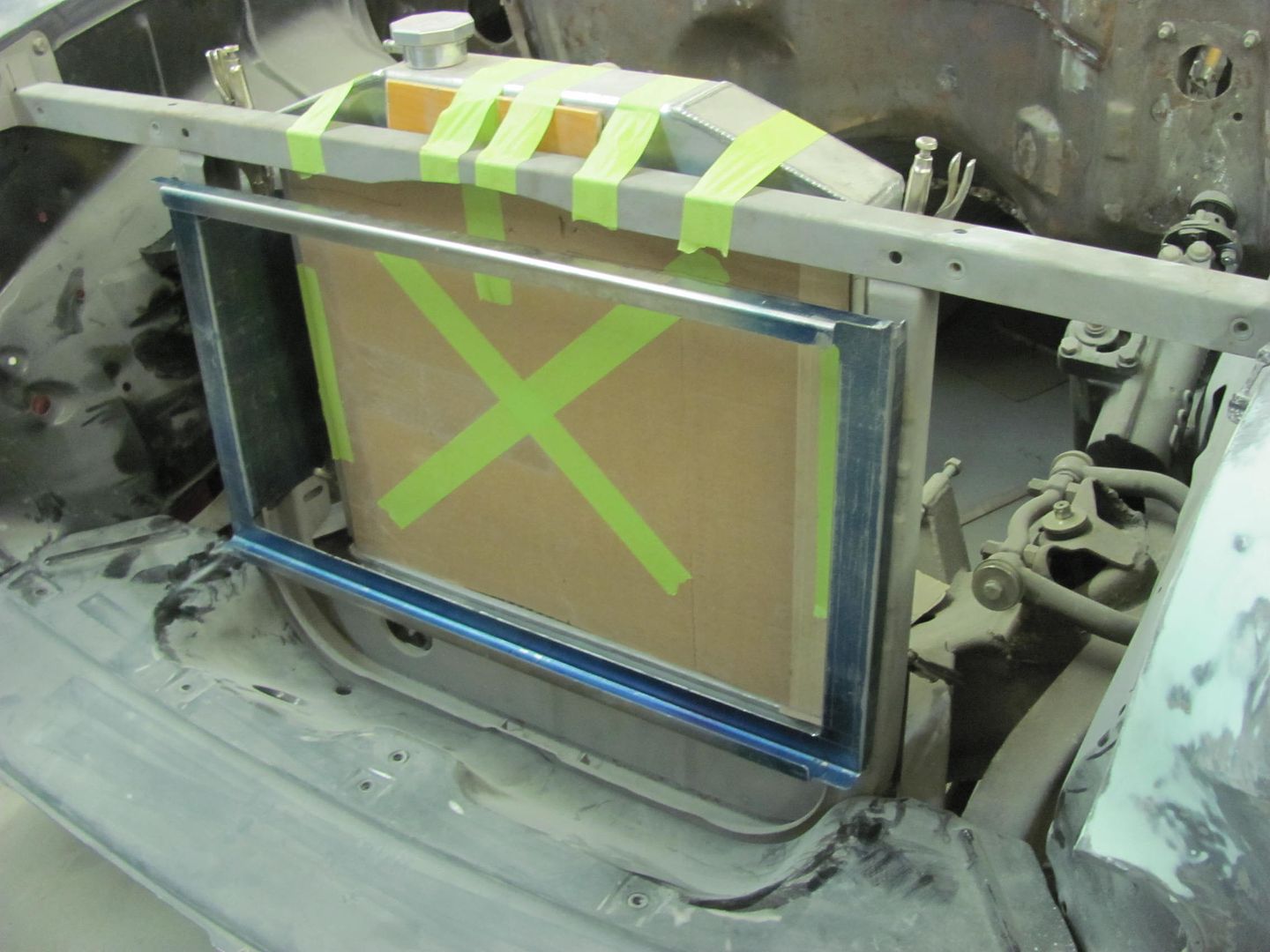

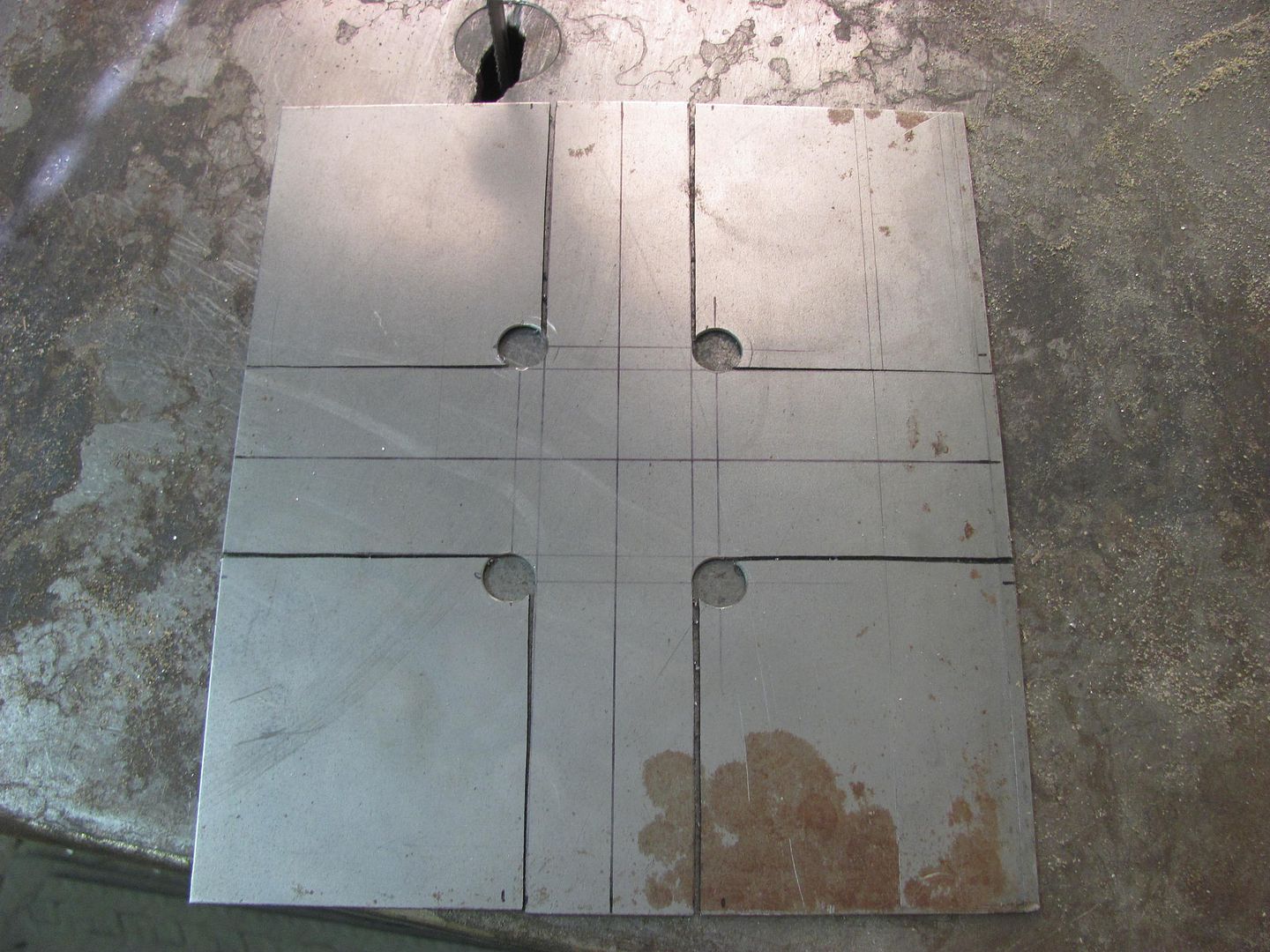

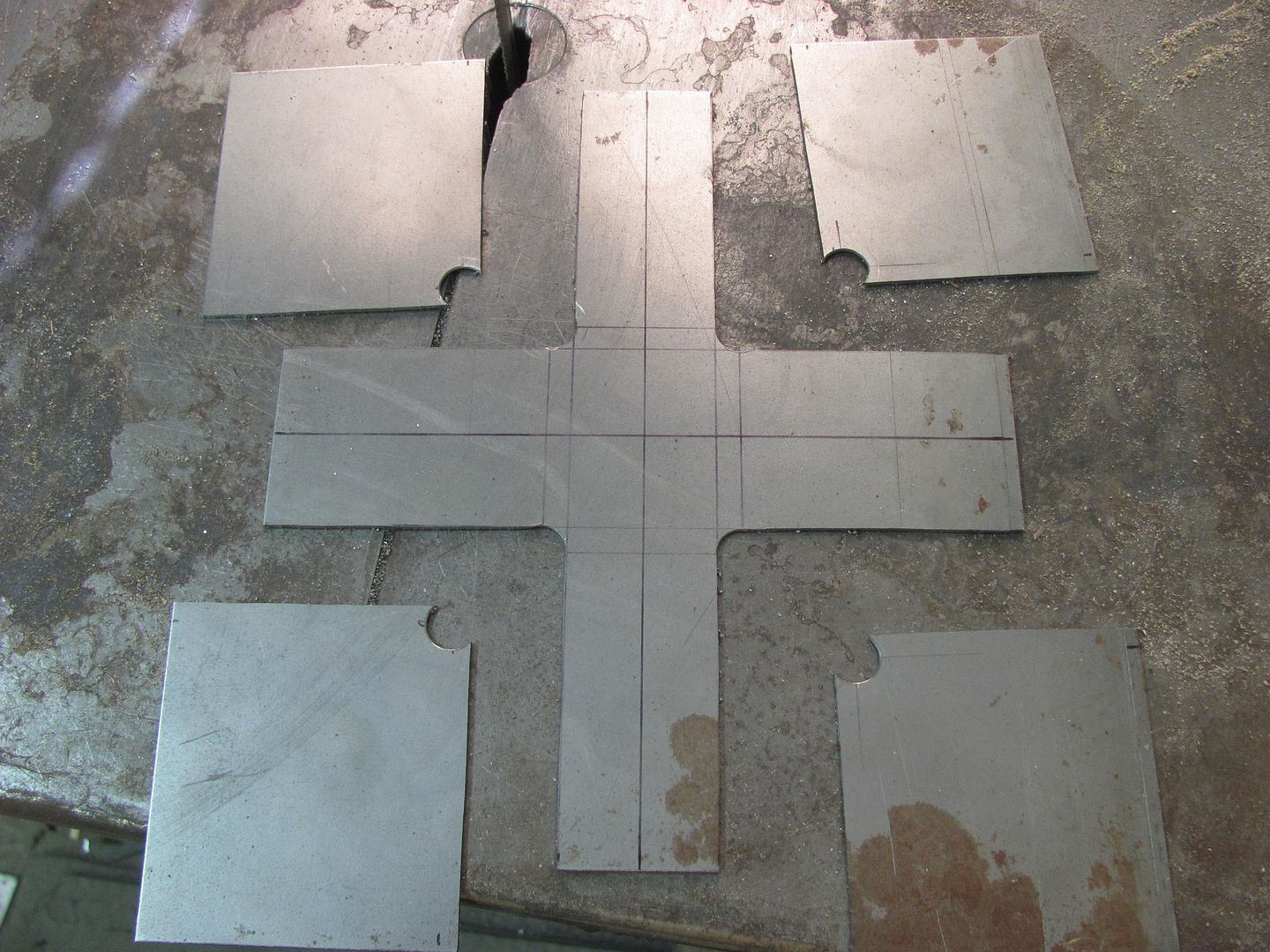

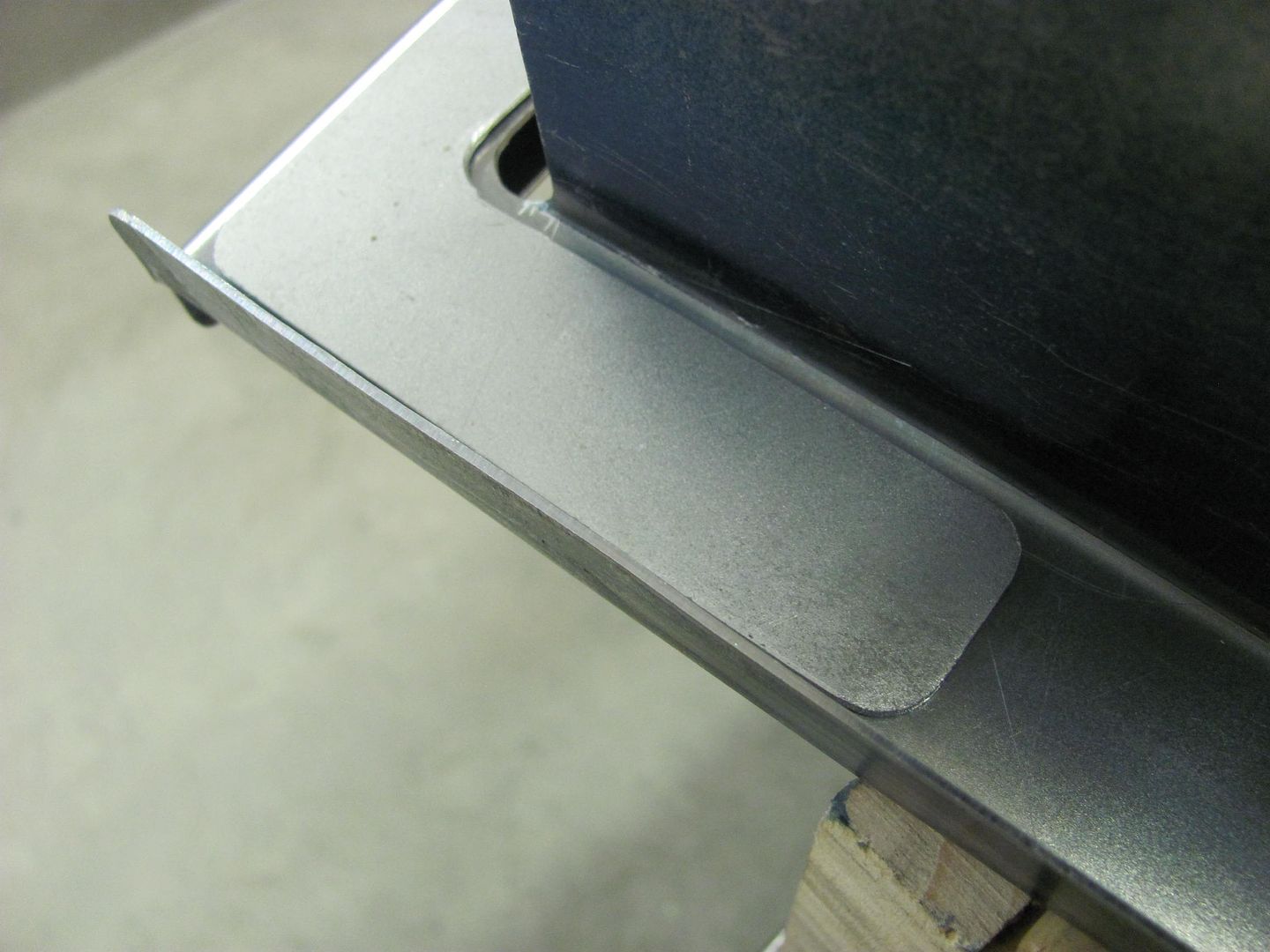

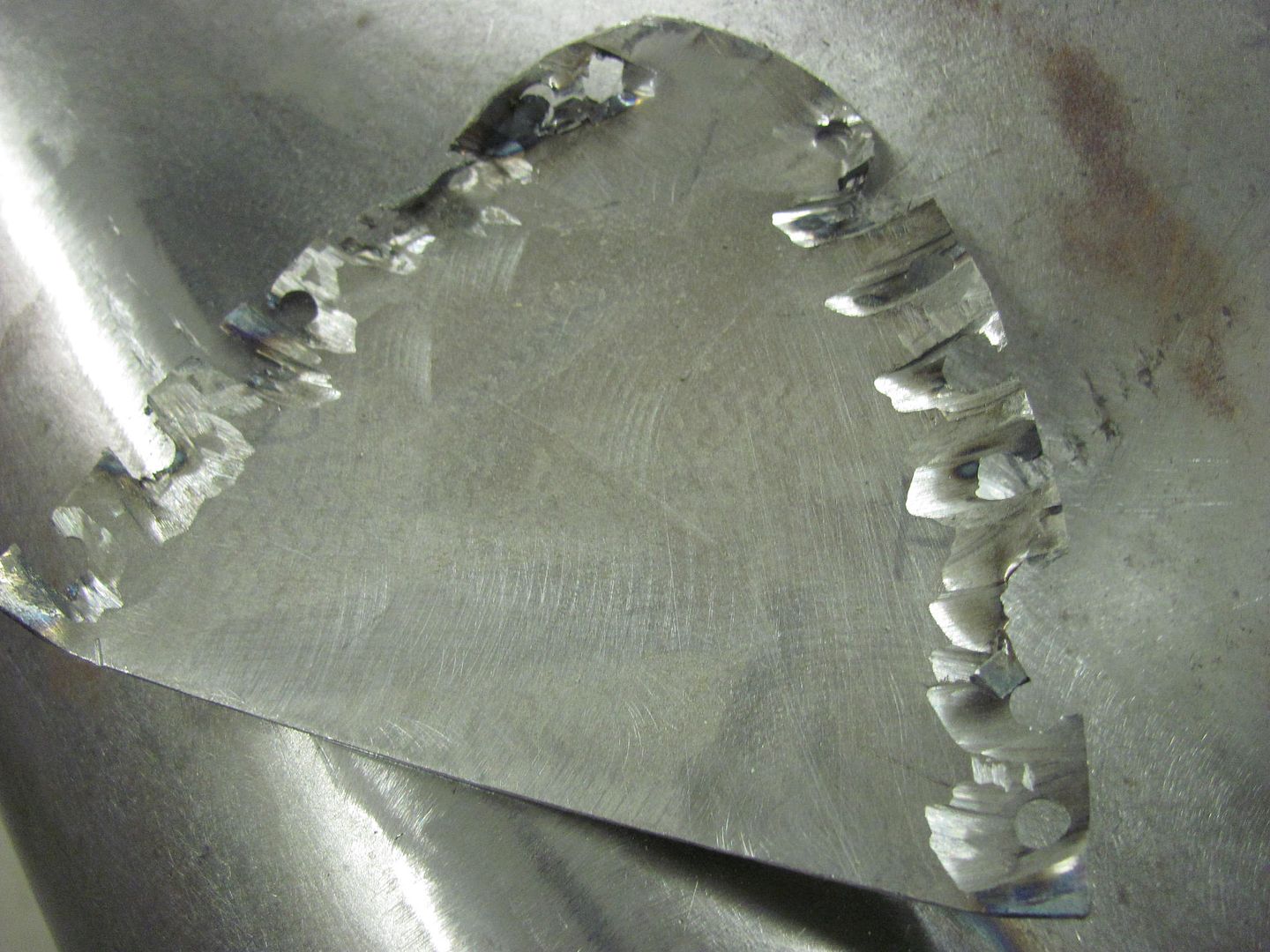

Well, the past couple of shop nights we've had some detours and some back up and punts. Where to start.. Started with a test fit of the power antenna the owner had bought, installed somewhat easily and even clears the door hinge when closed by 1/4". But this trim ring on top is just......obnoxious. Anyone use a power antenna that is a bit easier to hide?  Next, lets get the VA unit under the dash to see how much room we have to work with on a radio..   Doh! We had planned on a single DIN chassis, so it appears the radio will need to be 4" deep, or go back into the dash, or go in a console. She did buy a console with the bucket seats, they all came out of a late model Monte Carlo. Let's give that a go.  Not much room for installing a single DIN chassis, but even worse the console tapers in at the bottom where the trans tunnel is spreading outward. So it looks like its teeter tottering. Doesn't match the car at all. So this looks like something else to add to the list, perhaps a custom made console is in order.. Since we're not doing too well inside the car, let's shift gears and move to the outside. We had a couple more parts to add to the pile awaiting powder coat. The side baffles of the core support had some hole alignment issues, must be off a 57 or something.... so we'll fill those in and get them re-drilled correctly. Next, we need mounting brackets for the radiator. These were made from some 16 gauge cold rolled steel..      We do now have much better clearance around the radiator petcock with the new improved version of the lower baffle..   Kyle had learned some Tig welding this past weekend at GatorMeet, from Gator's boy Dakota. Dakota is quite accomplished for his youth, having won the state competition for welding. Here Kyle runs a couple of practice samples to get the machine dialed in... Seems he forgot his long sleeve welding shirt this evening.     I had shown him how to tack without using filler, and gave him more aspiration by showing him a no-filler fusion weld. All in due time.. Practice aside, here is the hole filling effort in the baffle panels...  While Kyle worked on filling the holes, I had directed attention to the condenser and the holes we would need to add to the passenger side baffle prior to powder coat... just as shown in the book..  ....only Murphy had other plans, it appears our condenser was intended for a cross flow radiator...    Hmm..... don't think this is going to work. So to back up and punt, the plan is to make a mounting bracket that will hold this universal condenser to a top flow radiator all while hiding those ugly holes that scream "I'm a universal fit". Then we'll have to get some new hard lines made up that fit correctly.  Layout of the mounting bracket...  Don't try this at home, it was done on a closed test track...    The ears inside will be folded inward to use the same bolts on the side of the radiator.. Here we are making the top and bottom folds in the magnetic brake, this design will help to hide all those holes..    ....and we'll finish the mounting flanges next time..

__________________

Robert |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Nov 2011

Location: West Plains Missouri

Posts: 2,088

|

Re: 55 Wagon Progress

Looking really good Robert..

as the story goes with Hot Rodding Nothing goes as planned  On the power ant. maybe french it? (don't know if that will blend with the look your going for, but just a thought.) Mark...

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=645774 Project Orangepeel 52 A.D. http://67-72chevytrucks.com/vboard/s...d.php?t=653337 John's LS 49 dodge http://67-72chevytrucks.com/vboard/s...d.php?t=655780 Blake's 67 GMC LS stepside http://67-72chevytrucks.com/vboard/s...d.php?t=690527 Reed 78 FJ40 Rebuild http://67-72chevytrucks.com/vboard/s...d.php?t=733259 Barger's 78 FJ40 |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Murphy fights me about every day in the shop....my end result isn't nearly as good as yours though I keep trying!

Nice work guys! |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

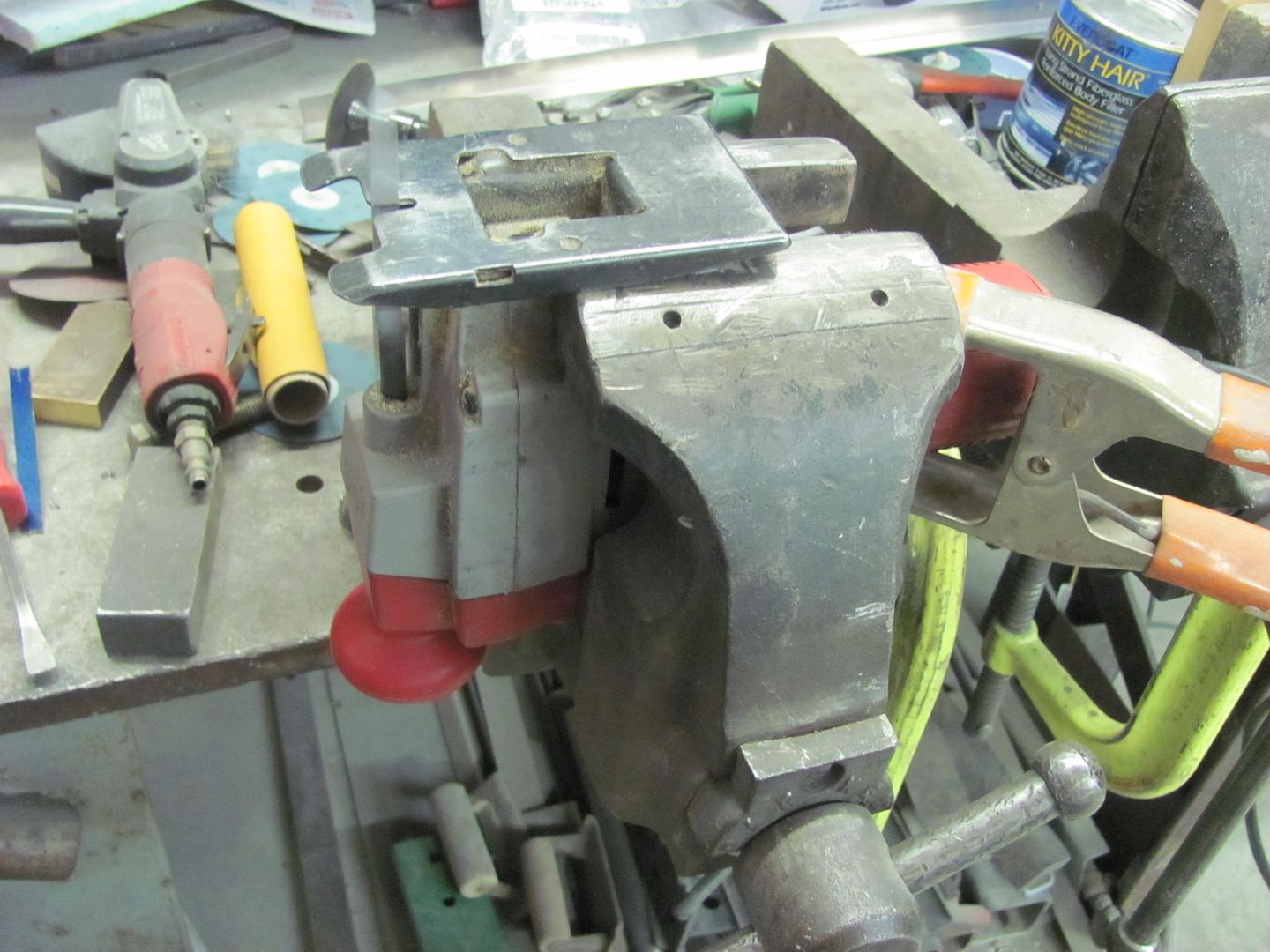

Too funny! Awesome Baileigh equipment and your band saw consists of a jig saw clamped in a vise. Nice work!

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

We've got a Lockformer bandsaw with a 24" throat, but no blade welder to be able to cut out the middle of a panel.

__________________

Robert |

|

|

|

|

|

#13 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,139

|

Re: 55 Wagon Progress

Great work as usual! Thanks for the countersinking trick! I've got the same flairing tool and I can use that trick later on!

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Always glad to see your post, excellent work...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks for taking time to post fellas.

More progress on the condenser mount... The flange fold marks are run through the tipping wheel to better show the bend location. I've found that when using the press brakes this helps to "feel" when the upper die is located properly, less guesswork with the eyeballs where it's harder to see in the press brake dies..   Clamped in place for a test fit..  The side folds add some stiffening as well as hide the bolt heads for the core support baffle plates.  Test fit of the condenser...      Radiator brackets got a nut welded in the bottom hole, the condenser mount will get nuts welded in place for the top 2 sets of holes, so everything will bolt in from the outside in..   Making the slots for the radiator brackets, used a cone shaped burr....  Found that this cutter had less chatter when the cutting edge was perpendicular to the hole opening...

__________________

Robert |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

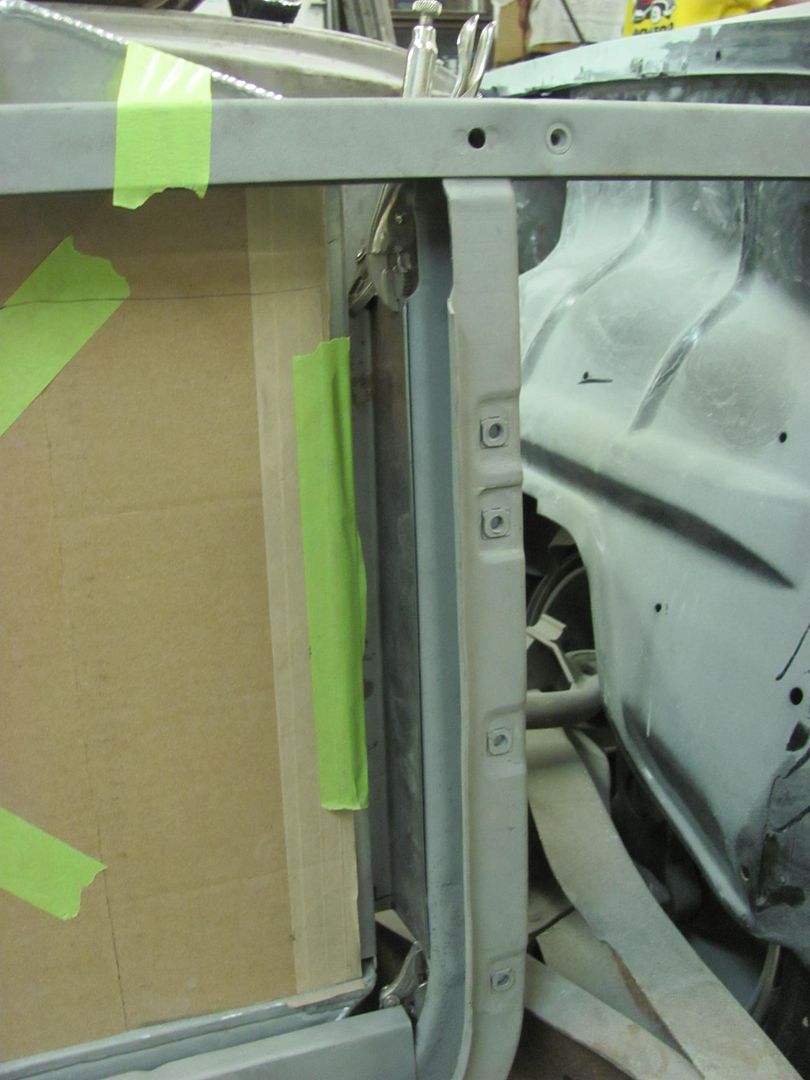

Some more details to iron out on the condenser mount, the corners seemed to "roll" a bit, so some corner braces are in order..

Using 16 gauge cold rolled, holes drilled to provide an inside radius to help prevent stress cracking..     Plug welds to hold things together..   Bob Heine over on GJ suggested using a Corvette antenna as they use an escutcheon with a flush fit, so I had a Corvette part delivery over the weekend, size of the business end is rather larger than the aftermarket one we had. As this fit in the void behind the A pillar (see in background between cowl vent and A pillar) and also needs to dodge the hinges closing, this did cause some interference. Dan thought this was from a late 80's/early 90's..  The biggest issue with the universal power antenna we have is that the top of the fender is considerably rounded, and the antenna escutcheon is designed for flat. So we are also looking at the factory piece, to see if we could adapt (drill hole larger) to use with the power antenna.

__________________

Robert |

|

|

|

|

|

#17 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

modify and use the stock one

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

More progress on the condenser, used some machine screws to attach to the bracket, and some AVK style rivet-nuts in the frame of the condenser to act as a captive nut.

Bolted in place...   Meanwhile Kyle ties up some loose ends, finishing the weld across the remaining "shaved" lead seam on the passenger quarter.. It does need some grinding on the underside of the weld still but we'll wait for the car to be on the rotisserie for easier access.     Fitment of the Driver's side tail light... this was even worse than the passenger side in fitment, and we did need to make a relief cut at the top, but after some massaging, it's getting close. A few more tweaks to get this done and then the headache of installing the motorized tail light pivot for fuel fill access..

__________________

Robert |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2012

Location: Eastern Ontario, Canada

Posts: 1,041

|

Re: 55 Wagon Progress

Awesome as always.

__________________

1952 Canadian Chevy 1300 C4 IFS & D44 IRS 5.3 HO L33 My Build: http://67-72chevytrucks.com/vboard/s...d.php?t=632938

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Sid!

Sorry for the slight hiatus, been in UK and just got back this past weekend. Time to catch up on what we had done before I left and what Kyle did while I was gone to take up my slack.. Part of our fitment issue with the passenger tail light was that we are installing the "hidden fuel fill" which required the removal of the brace welded in the opening. Next, when the old quarter was cut off and the new one installed, without the brace in place both pieces tended to wrap to the right, which can sort of be seen in the following picture, where its flush above the inside corner and rotates to the right upwards of that. The outer quarter was rotated in a similar fashion. We weren't having much luck in resolving the issue with the top weld seam remaining, so a relief cut was added, a restraint device employed to make use of some off dolly bumping to eliminate some of the right rotation. I didn't get a good picture of it, but you can see where the inner quarter comes in considerably upwards of the tail light right corner..  Anchor  Off-dolly bumping...  Then some shrinking was used to pull in the inner quarter, and a 16 ga plate used to hold things in place while the top seam was re-welded.   Kyle got the seam welded closed...  And temporary brace removed...  Much better, almost ready to tackle the "fuel door" pivot...

__________________

Robert |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jul 2012

Location: Rosenberg, Texas

Posts: 3,506

|

Re: 55 Wagon Progress

That's a lot of work to straighten a tail light opening. You're all very skilled and talented to be able to figure that out and make it happen. I'm impressed more and more when I read this thread. Keep up the good work.

__________________

-Duane C/10 Club Texas member 1971 Chevy C10 "Brutus" SWB Fleetside 2016 6.0L (L96) 6L90E (driver/project) 1965 Pontiac GTO "Royal Goat" 400/TH400 w/AC (my baby) |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

It was going to be a challenge getting it to line up with using the hidden gas fill behind the tail light, so we wanted to get it fitting correctly to the sheet metal before starting that fiasco...

__________________

Robert |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Got another care package in the mail... The new escutcheon for the antenna looks like it will work, the hole size matches the nut on the antenna and we'll just need to get rid of the flat spot/keyway in the hole. Only I don't think we'll be using this one. Between a recess under the chrome and visible scratches in it, this one's going back.

On to the next new pieces, hopefully these fit better, Reproduction headlight buckets..... wanted to test fit all the headlight and turn signal pieces before re-priming the fenders..  Decided to use some AVK rivet nuts over the u-clips..      Parts fitted..

__________________

Robert |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Well this isn't much of an update, but since Kyle was busy media blasting some parts I had torch and hammer duty.. So to have a place to drop the torch quickly, bent this up:

When the top seam was welded we had a slight bulge just in from the tail light. So some dime sized spots were heated and then hammered with glancing blows to bring things down a bit.. The fit of the tail light is much better now, and we've started the fitup of the motor assembly's mounting plate. Should get that welded in tomorrow..

__________________

Robert |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

That torch holder looks pretty handy. I remember one of the guys selling a torch hanger that would shut off the gas when you hung it up, then would restart the gas and light the torch when you picked it back up. Just don't remember where.

Nice work on the tail light housing. Curious, have you kept track of how many hours on this one build so far? |

|

|

|

|

| Bookmarks |

|

|