|

|

|

#26 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Well, I got the clearance I was looking for from the CPP member. All it took was acetylene and a ball peen hammer.

Even had a shot at welding the member in place, but had a learning experience instead. Lesson 1: welders need to be maintained. Things like tip cleanliness and ground clamp condition matter. A lot. Lesson 2: It's important to close the $%^ shielding gas bottle when not in use. This one was my co-worker's mistake, but it drove home the lesson for me. Lesson 3: This one is yet to come, but it is in the proper use of grinding & cutting equipment for getting the X member back out, cleaned up, & put in correctly. The silver lining is that my buddy Korwyn might be willing, for a few bucks & a few beers, to tune up the welder & burn the cross member into place competently while I'm working on customer cars some time. I'm learning to weld, and I'm glad to, but I'll be even gladder to get the engine into place & move on. So, all in all, things are going damned slowly at the moment but hey, my first build. I'll try and cut myself some slack. |

|

|

|

|

|

#27 | |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: Project: Over My Head

Quote:

then comes when you have withdrawal when you don't have a project then comes when you have withdrawal when you don't have a project  then you get like me then you get like me

|

|

|

|

|

|

|

#28 | |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: Project: Over My Head

Quote:

then comes when you have withdrawal when you don't have a project then comes when you have withdrawal when you don't have a project  then you get like me then you get like me     if you have seen my steering column in my build thread you know what i mean. if you have seen my steering column in my build thread you know what i mean.

|

|

|

|

|

|

|

#29 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

I got the motor in place today. A friend, Corwin, came by & welded in the cross member after I got it clamped in place & double checked my measurements. Triple checked, in fact.

From there it took ~10 minutes and the engine was in its new home. [IMG]  [/IMG] [/IMG]Turns out that with the stock trans cross member in place you can get everything in there, but you can't point the trans towards your rear axle. Pan clearance or driveline angle - can't have both with that cross member in there. So, I formulated a plan & tomorrow, if it's slow at work, out comes the sawzall (cutoff wheel?) and I'll post pictures of the modified member. I wound up putting my CPP member's mounting plates 26.25" back from the frame rail's tip, as high as I could stuff them inside the frame. I wouldn't recommend their parts especially but with an angle grinder, a torch & a hammer they work just fine. Additional tech notes: no way you can get a stock steering box in there with stock headers. Probably not even with block huggers. I am going with the CPP power steering kit, which moves the steering gear forward and outside the frame rail. The motor could be moved further back but only with a lot of trans tunnel massaging, which I wanted to avoid in order to keep life simple. This setup is still lightening the truck, I think, and moving weight rearward for sure. Oh, and the tie rod: stock beam axle steering leaves precious little room between tie rod and oil pan. I couldn't get them to touch when I bounced on the front of the chassis, though, so it may be that extending bump stops is good enough. I may wind up going with a different axle regardless. Moving the engine further back, though, you could get the oil sump clear of the steering. Or switch to an F-body pan & call it a day - though I haven't measured to see that an F-body pan would def. work. Ultimately, I decided that despite the tie rod clearance issue that my motor placement offered the best compromise of space ahead, space behind & space underneath. Both cross members and the firewall are working against this swap but with a new oil pan or some extended bump stops, it can be done pretty easily. Last note: I used CPP's 3" forward LS conversion plate. So if you do something similar, take that into consideration w/ your mounts. Last edited by yossarian19; 12-05-2012 at 09:14 PM. |

|

|

|

|

|

#30 |

|

Registered User

Join Date: Mar 2010

Location: Piper, KS

Posts: 683

|

Re: Project: Over My Head

Nice progress. Keep it up.

|

|

|

|

|

|

#31 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Project: Over My Head

Looks good. I remember how good I felt once I got mt engine tacked in place.

Kim |

|

|

|

|

|

#32 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Lighting was too poor to bother posting the picture I took, but on my lunch break I sawzalled the old cross member out. I think with the right combination of motor mounts and firewall trimming I could have gotten the driveshaft angle I wanted without cutting, maybe, but in my case the cross member had to die.

It was kind of crazy - at some point the member had caught a stump or a rock hard enough to collapse in the front wall of it. That caused enough bind to snap a sawzall blade at the attachment point when I hit the bound-up area. So, Corwin claims to have a 4l60E yoke laying around. Methinks I'll use the original two piece driveshaft & have the trans-side section shortened & the yoke put on. Add new U-joints & a spin balance & call it a day. Unless the driveline shop wants to build me one cheaper than they'll modify the old stuff, that is. Slow progress but things are getting done. Now that work is busy again I'm down to just a couple hours a week I can work on the truck. Of course I'm getting paid for 8 hours a day again, so I can afford parts. |

|

|

|

|

|

#33 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

I trimmed ~1/2" off either end of the CPP cross member & got it to fit well enough to hang the transmission on. I still need to finalize the angle & firm it all up later on, but for now, it keeps me from having to keep a support leg under the truck.

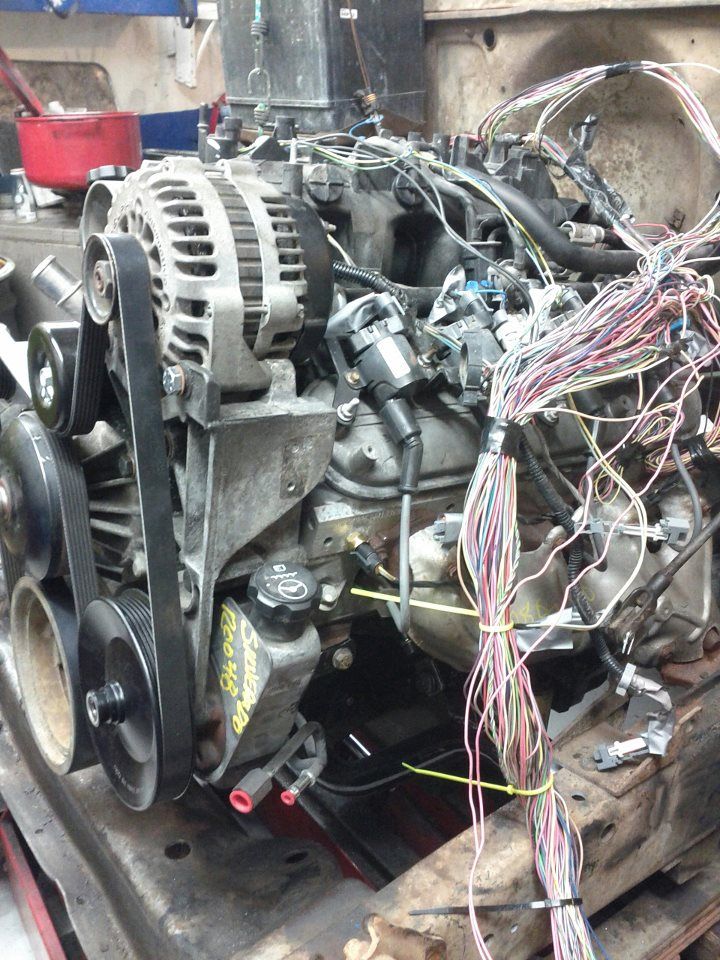

[IMG]  [/IMG] [/IMG]Then I got the coil packs re installed, along with fresh plugs & wires. Put in the engine coolant temp sender, too. [IMG]  [/IMG] [/IMG]Not pictured, I also got the driveshaft support bracket re-installed with 3/8"-16 hardware and got the original parking brake hooked up again. I'm super glad to be able to retain the stock hand brake, I think it's a really cool bit of retro (is it still retro when it's actually old?) and pretty darn practical. I'd removed it when I wasn't sure how it would fit with the motor. I was about to tear into the front axle when I discovered that the lift the truck is on is malfunctioning - the suspension lifts don't work, only the drive-on section. So when the time comes to install steering & brakes, I'll be getting creative with all of that. Or just roll it onto another lift, I guess... Blew through everything I'd hoped to get done, so now I have to make up a new to-do list. No shortage of work, just need a plan... |

|

|

|

|

|

#34 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Project: Over My Head

Looking good.

I used the same CPP trans cross member in mine. Kim |

|

|

|

|

|

#35 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Well, I tore into the wiring harness today.

The trouble is, I found several sections where the junkyard cut off connectors. We'll see what / which they were as I'm able to identify them. Really don't know if I'll be able to use the harness. Worst case scenario, I've spent 2-3 hours today practicing for my next harness mod. Best case... I've got almost all the fat trimmed out of the harness & am almost ready to start adding fuses & relays. Gotta look for a connector picture for o2 sensors... I think everything else is accounted for on the harness. |

|

|

|

|

|

#36 |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: Project: Over My Head

colored spagitti. Rats now I am hungry!

|

|

|

|

|

|

#37 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Well, I went over things & reviewed a few diagrams. All I'm missing, it turns out, is the male connector for my driver's side o2 sensor. I'll buy a 4-pin Weatherpack connector for $3 and move on when I get back to work in early January. Progress to date:

[IMG]  [/IMG] [/IMG]Massive slowdown at work means I'm not going to be spending any / much money on this for a little while, though I think I can afford to finish the wiring harness by mid January and hopefully be back to full time work by then. After that... front axle swap? Steering fab? Dunno. |

|

|

|

|

|

#38 |

|

Registered User

Join Date: Jul 2011

Location: Auburn ca.

Posts: 2,886

|

Re: Project: Over My Head

Massive slowdown at work means I'm not going to be spending any / much money on this for a little while, though I think I can afford to finish the wiring harness by mid January and hopefully be back to full time work by then. After that... front axle swap? Steering fab? Dunno.[/QUOTE]

There are a million and one thaings to do that don't cost anything or a couple bucks.I know I have been working on mine steady for two years and have less than $1000 into it |

|

|

|

|

|

#39 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Well, I haven't bought it yet but christmas present to myself is going to be some wiring supplies to finish up this part of the project with fuses, relays, harness wrap & split loom. I think I'll also set up a push button start and some sort of covert fuel system interrupt to minimize chances of anyone joy-riding the truck, since it's going to have a dirt-simple ignition system and 1957 locks.

|

|

|

|

|

|

#40 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

I still need to solder the injector positive wires together & build the fuse blocks, but first I need a soldering iron. Here's how far I've gotten with the wiring:

[IMG]  [/IMG] [/IMG]What I need to know now is whether I can get rid of the PNP switch. I think I'd read that you can, plus the GM rep at SEMA told me it wasn't needed. I don't remember what if anything you have to (ought to) do if you aren't going to use the trans mounted switch, though. I don't care about neutral safety nearly so much as I care about idle quality / in gear vs neutral. Then again, as long as it runs well, I don't think I care about 100 rpm at idle one way or the other. Thoughts? |

|

|

|

|

|

#41 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Well, I struggled a bit and determined that the 2002 LS1 Camaro tank I had bought isn't going to work for me. This is the "better" outcome:

[IMG]  [/IMG] [/IMG]Had to chop a cross member out with the sawzall & remove the (old, ugly, "custom" ) rear bumper to get even that much clearance. So, I think I'm in the market for a Mustang tank or a Blazer tank or whatever can be easily / cheaply made to work feeding the 4.8 with a return line. Thoughts, anyone? The good news: I finally organized the SAE tools handed down from both my grandfathers & my dad into Grandpa Buyer's box:  So, I'm calling tonight's effort an educational experience and moving on. I might put the body work back on & finish up the fuse / relay wiring while I figure out what to do with the fuel system. I'm grateful to be able to say that at least the wiring harness's cut / layout / rewrap phase has been completed. |

|

|

|

|

|

#42 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Project: Over My Head

Sorry for your tank troubles. I know guys have used the mustang tanks under the bed. It shouldn't be to much trouble to plumb a return line into one of those.

The old tools are cool. Kim |

|

|

|

|

|

#43 |

|

Senior Member

Join Date: Aug 2010

Location: Shasta Lake, CA.

Posts: 1,619

|

Re: Project: Over My Head

The '67 Mustang tank drops in with just a little trim of the frame rail.

I found this pic on this site. |

|

|

|

|

|

#44 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

I'm guessing the mustangs use a mechanical fuel pump that draws from the bottom of the tank, making a Walbro inline pump easy to use. Then just have a return line nipple put on up top & figure out the level sender.

Sound correct? Also - you say "trim" the frame - how so? What's the procedure? |

|

|

|

|

|

#45 |

|

Registered User

Join Date: Apr 2011

Location: Caldwell, Idaho,United States

Posts: 143

|

Re: Project: Over My Head

I have the same set up ,I used a late model pump assy. from a tahoe, bought the install rings from vetteworks ,(could have made them but saved time) ended up with a stock type pump assy ,easy to replace on the road and easy to plumb in. my build has more info.

__________________

Learn to deal with reality, or reality will deal with you. |

|

|

|

|

|

#46 |

|

Registered User

Join Date: Apr 2011

Location: Caldwell, Idaho,United States

Posts: 143

|

Re: Project: Over My Head

oh ,and if you set the tank between the rails you have to trim 1/2" or so from the top rail to allow it to set in place.

__________________

Learn to deal with reality, or reality will deal with you. |

|

|

|

|

|

#47 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Rick, you have a link to your build thread?

Looking closer at the pic, it looks like you used a Mustang tank and, as you say, used Vetteworks adapter rings to use a stock Tahoe (w/ LS engine) fuel sender. Correct? |

|

|

|

|

|

#48 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

Been a while with no substantial updates. Basically, I've been short on time & money. However:

I got myself the Vetteworks rings & a mustang tank. Today, with a fractured shoulder, I began to trim out the frame to take the mustang tank. The rearmost 12" or so are now wide enough on the bottom rail to let the tank slide between. I'll have the lip around the tank resting on the bottom of the frame rail, shove it forward till it stops against the shock mount cross member, then add 2 cross members (removable, so I can someday remove the tank) to replace the one I took out. Bolt the tank to the frame, take it all back apart, add the Vetteworks rings & my LS1 pump, and start making the fuel lines. I was getting ready to spend the next few days doing this at the shop, since I'm on sick leave, when my boss reminded me that my fractured upper arm / shoulder joint needs rest and that he needs me healthy. So I put down the sawzall and went home to the couch, where I am now. |

|

|

|

|

|

#49 |

|

Registered User

Join Date: Aug 2007

Location: Corona, California

Posts: 7,998

|

Re: Project: Over My Head

It sucks being laid up.

Hope you have a speedy recovery. Kim |

|

|

|

|

|

#50 |

|

Registered User

Join Date: Sep 2011

Location: Nevada City, CA

Posts: 908

|

Re: Project: Over My Head

At long last, I got the tank mounted.

It was made more difficult by having the bed on the truck & roughly 600 lbs of crap in the bed whlie I was working. You really want as much space as you can get working on these things... My results so far: [IMG]  [/IMG] [/IMG]And from the side:  What I did in the end was to cut the lower horizontal piece off the frame's C channel for the rearmost 8.5", remove the rearmost cross member and narrow the frame by 3/8" or so on the bottom rails. Total cost of mods: $10 worth of sawzall blades and cutoff wheels. If I'd had the bed off the truck, I could have gotten the tank in without cutting the rearmost lower "C" section. I could not have dropped the tank with the bed attached, though. I'll have to fab a removable cross member (or 2) and finish running lines & power, but I think the worst of it is done as far as my fuel system goes. All with a fractured arm! |

|

|

|

|

| Bookmarks |

|

|