|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#26 |

|

Registered User

Join Date: Feb 2012

Location: Ruskin Florida

Posts: 4,566

|

Re: 59 truck with axle flip and removed load leaves. Major axle hop!

I do have a lead foot! Even in my 4x4. She loves the carbon blow out. Will spit it sideways easy. Still want to know about the bolts.

__________________

70 swb 4x4 406sbc 700r4 203/205 d60/14blt locker yadda yadda http://67-72chevytrucks.com/vboard/s...88#post6935688 Yeller 72 Blazer 2wd conversion project "No Daggum Money" http://67-72chevytrucks.com/vboard/s...d.php?t=550804 LS1-T56 3.73 LSD super budget build Blanco-2014 Sierra SWB https://67-72chevytrucks.com/vboard/...d.php?t=810350 |

|

|

|

|

|

#27 | |

|

Registered User

Join Date: Aug 2012

Location: Salem Mo

Posts: 656

|

Re: 59 truck with axle flip and removed load leaves. Major axle hop!

Quote:

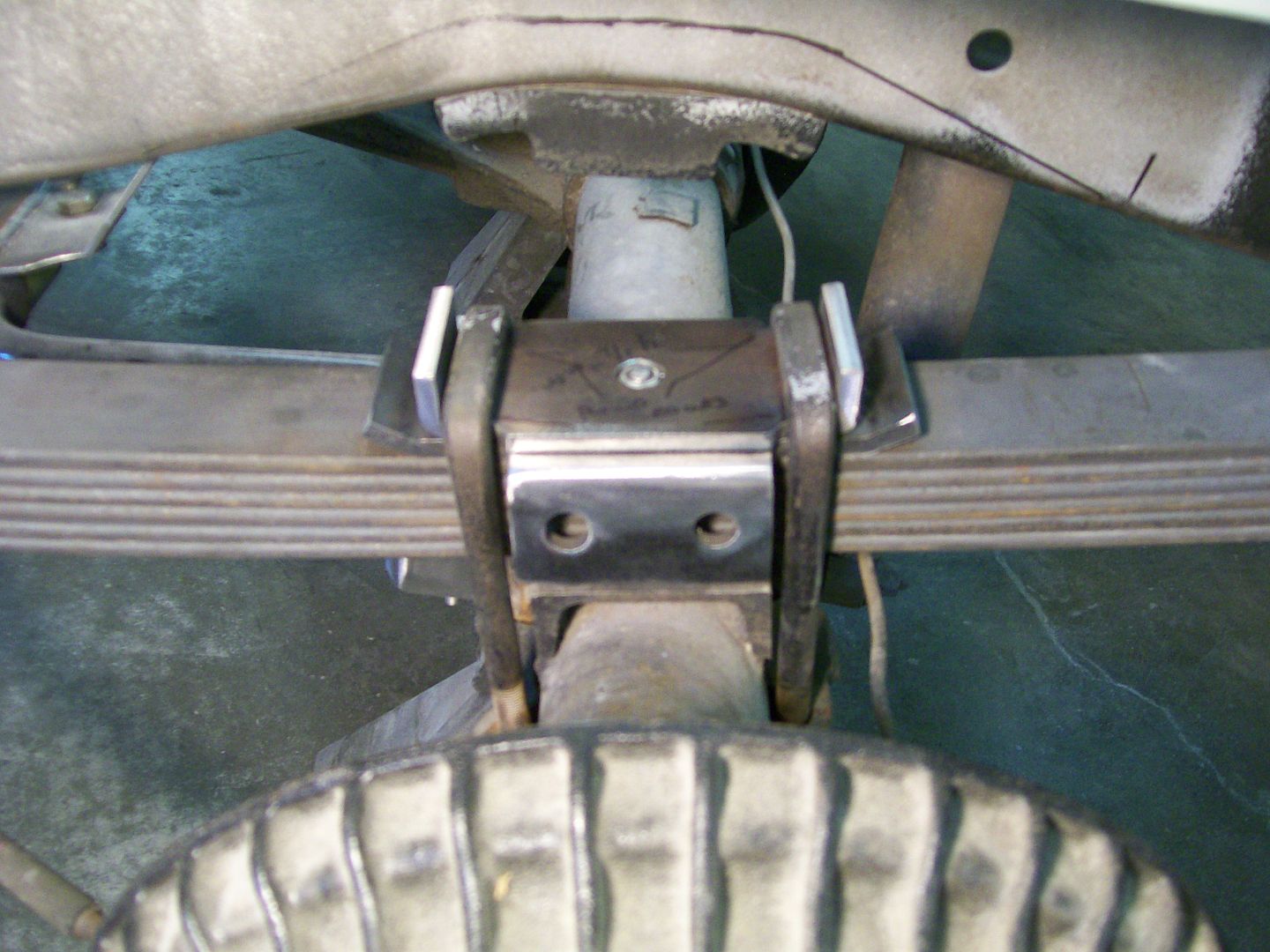

In the above pic you can see my top plate. I found this next picture that has better detail.  Ok, the two bolts, plus the two on the other side goes through a drop plates that comes down from the top plate that goes against the top of the springs when the axle U bolts are tightened. I left just enough space between the leaf spring and the side plates for the head of the bolts to fit. The idea was, as mentioned by OrrieG, I like to have about a 1/2 to 3/4 inch between the rubber snubber and the leaf spring. Using the two bolts on each side allowed some adjustment to get this clearance. In the final set-up I assembled the whole truck for the proper sitting height, then used these bolts to adjust for the rubber snubber clearance, then removed the traction bar and welded the top spring plate to the main traction bar side rails. I felt that regardless how tight these bolts were, since there was no solid spacers or locking devise, the torque of the engine could cause these bolts to loose grip under load. So a full weld once the traction bars were set to their proper setting, is holding everything solid now. Thanks for asking jjzepplin, I'm happy to answer.

__________________

My 57 Chevy truck build.http://67-72chevytrucks.com/vboard/s...d.php?t=541132 Last edited by Stepside Jim; 04-27-2017 at 11:28 PM. |

|

|

|

|

|

|

#28 |

|

Registered User

Join Date: Feb 2012

Location: Ruskin Florida

Posts: 4,566

|

Quote:

Posted via Mobile Device |

|

|

|

|

| Bookmarks |

|

|