|

|

|

|

|

#1 |

|

I'm just glad to be here!

Join Date: Jan 2008

Location: Longview, TX

Posts: 4,788

|

Re: The Official John Lee Jr Thread

Here is a site that I have had good service from in the past. I have gotten my rod ends form them and they are top quality. Looking over the site I found this page for the rigid rods that are drilled and tapped on each end for Male threaded rod ends. I chose 3/8" size because that rod looks about that diameter in your pictures and from what I remember from my '65.

If you know or can measure the distance betwen the centers of the ends of the current rod, you can find the cut rod that is would work on this table... http://www.midwestcontrol.com/series.php?id=98 Here are the rod end options for that rod: http://www.midwestcontrol.com/part_family.php?id=8 They also offer the jam nuts too. I put together this package with a 12" rod (13.58" to 15.126" center to center) and came up with a total of $34.20 for steel parts. The jam nuts are real high at over $5 each, but givent he way it would be installed a single right hand regular nut would work on just the one end and not allow the adjustment to change...: http://www.midwestcontrol.com/cart.php

__________________

Karl  1965 Chevy Stepside(Grandpa's Old Blue) and (July 2015 Shop Build!)(2020, the Saga Continues) http://67-72chevytrucks.com/vboard/s...d.php?t=372424 The LST Challenge: http://67-72chevytrucks.com/vboard/s...=1#post7812257 Korbin's 1st Square: "Sunburn" http://67-72chevytrucks.com/vboard/s...d.php?t=418618 1985 GMC Sierra: "White Trash", Korbin's 2nd now... http://67-72chevytrucks.com/vboard/s...d.php?t=632305 Henry - 1984 Chevrolet, Owen's 1st Square |

|

|

|

|

#2 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Yer blog has a straight stick added on to the S10 shifter. Looks like a decent temp solution if it'll clear a bench seat. Gives me time to look around and fab up some stuff after the trans is in and I can drive it while fabbin.

|

|

|

|

|

#3 | |

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,927

|

Re: The Official John Lee Jr Thread

Quote:

I see no reason why you couldn't remove the shifter shaft with the Hurst style bolt connection from a FORD assembly, then swap it into the S10 assembly. You'd then have the correct base plate for bolting onto the S10 tailhousing. Basically a hybrid of the first 2 links below. Forget the cutting and drilling of the FORD baseplate. Just reassemble with an S10 baseplate. Don't forget, you are NOT putting FORD parts into your Chevy - No . . no . . no! . . . . it's all Borg Warner stuff. I've included a pic of my $9 salvage yard shifter handle that I pulled from a 67-72 Chevy truck. It will replace the straight S10 shifter you saw on my T5 page. Tech article showing how to make your own short throw shifter. H.A.M.B. thread for modifying a FORD T5 short throw shifter. Aftermarket Short Throw Shifter for $94 T5 shifter that's been straightened in a shop press.

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

|

|

|

|

|

#4 | |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Dayum, that's the shape, just havn't decided flat or round stock.....but don't Borg Warner parts have cooties on em after bein in a ford? Sorta like my grandkids grabbing cookies outta the jar after pickin their noses, I don't eat the cookies, boogy fingers ya see. But yep, might be the easiest.

So, the big question, Tom put in a short throw shift...what is that, the bolt on shifter lid or something inside the trans case? If its in the length of the shifter rod that's on there now, based on the postion of the cross pin, I'd be inclined to mod that rod vice replace it with one that might have a longer throw. PS how tall is that 72 and up shifter and whats the thickest diameter....I might could beat one into shape and weld on the top of the old shifter for the taper and the threads, or just cut some threads. Quote:

|

|

|

|

|

|

#5 | ||

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,927

|

Re: The Official John Lee Jr Thread

Quote:

Quote:

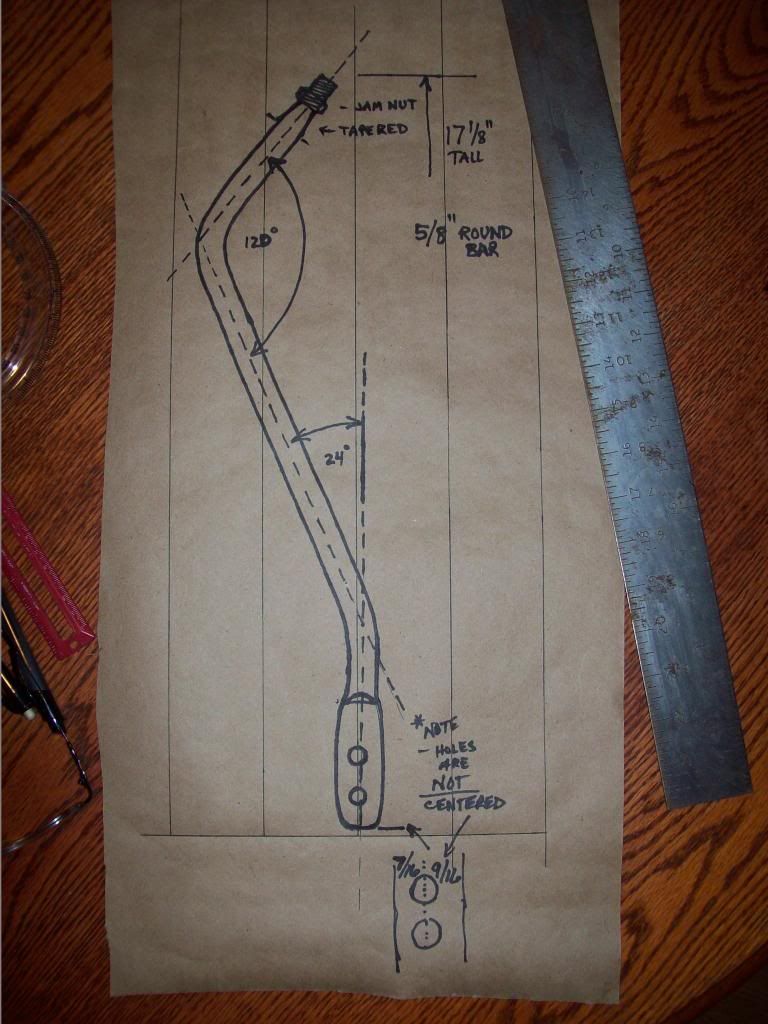

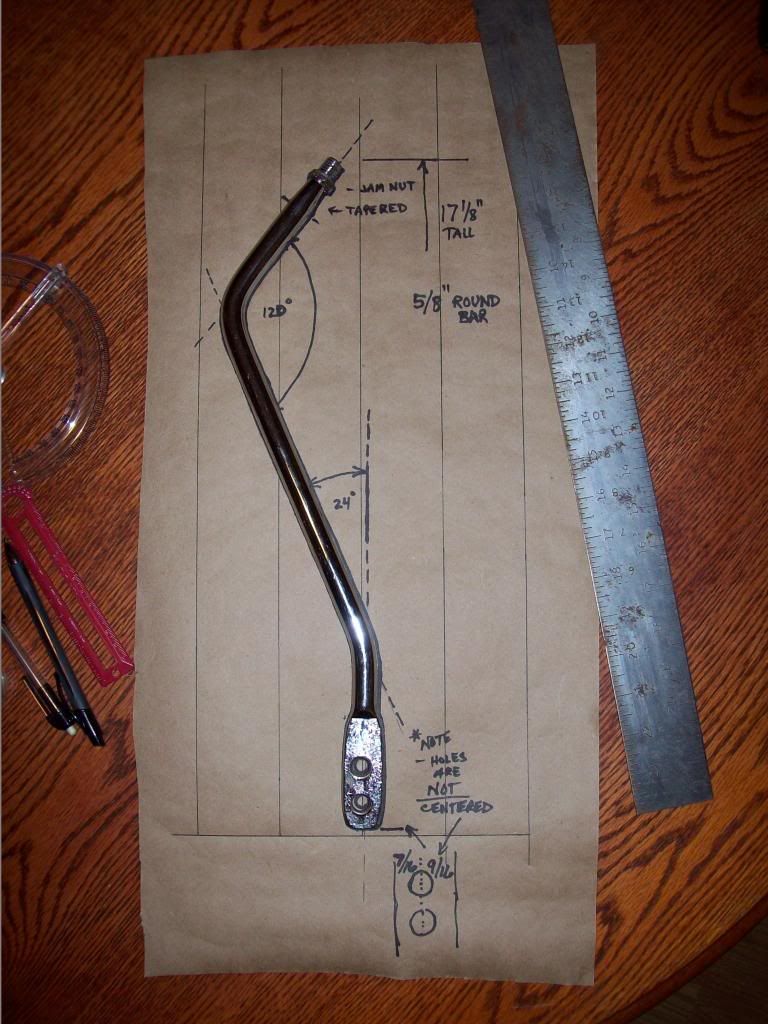

My shifter diameter is 5/8" round and 17" tall without the ball and 18.25 with ball. The flat part at the bottom is 1" wide by 3" tall and 5/16' thick. The shaft starts a gentle taper just about an inch below the threads for the knob.

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

||

|

|

|

|

#6 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Well then, I will have to buy it. Does it use the original winged nut at the fork?

Thanks for the feedback. |

|

|

|

|

#7 | |

|

Registered User

Join Date: Aug 2012

Location: Tooele, Utah

Posts: 327

|

Re: The Official John Lee Jr Thread

Quote:

I thought about making my own as well but it came down to lack of time and motivation.

__________________

1936 Chevrolet 1/2t 1964 Chevrolet C10 1964 Chevrolet C10 (sons) 1965 Chevrolet K10 Suburban 1969 Chevrolet C10 1937 Plymouth P4 |

|

|

|

|

|

#8 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Cool I'll have to look it and the other link over and decide what to do. Might could mod the linkage now and have those bugs out of it before the T5 install.

|

|

|

|

|

#9 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Done, 5/8 bar steel or Alum is easy to bend and flatten and drill and tap! I can use my RCBS reloading press and sometime anvil. Woo Hoo! Thanks. I'll make one I think, no sense in me messin up Mr Langdon's good work by swapin in more parts and tryin to figure it out on the fly.

|

|

|

|

|

#10 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Done, 5/8 bar steel or Alum is easy to bend and flatten and drill and tap! Woo Hoo! Thanks.

|

|

|

|

|

#11 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

But then again, I don't have to flatten out the S10 shifter.....just trim it to length and make a concavity in the lower shaft of the new stick.....that could be forged or even ground in. Forging might be loads of fun....it involves fire and hammers and beer and as long as I got a fire goin I could heat it up for the bends and get some smooth curves. Hmmmm, I gotta go find my Redback Spider shift knob.

|

|

|

|

|

#12 | |

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,927

|

Re: The Official John Lee Jr Thread

Quote:

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

|

|

|

|

|

#13 | |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Quote:

Here, I found the short thro part of the shifter, nice towering big doughnut of a metal thingie on toppa the trans.....  And here's Mr. Redback, sent to me from Down Unda and first installed on a T5 car I bought back in 1994, my first ever Ford Mustang.....many a shift under that spiders butt....I think I can get the Ford cooties off it for install in John Lee. Bad Ass Spider Blues now!  Over the years his, well actually her red stripe faded and is white now but takes on the yellow cast from the resta the knob from time to time and depending on angle. But still pretty cool. GoodWife hates it and refused to drive the stang, so....maybe it still has majic in there.  Well, that's two tranny swap parts acquired....tranny and shifter knob....about a bazillian parts and ideas to go. Sure glad its not a tomorrow morning project.

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Jan 2013

Location: Columbia, SC

Posts: 1,927

|

Re: The Official John Lee Jr Thread

Quote:

Jay

__________________

My 65 C10 build: www.lugnutz65chevystepside.weebly.com Want to know more about T5 transmissions? My website has a T5 Info Page and a Step by Step T5 rebuild. |

|

|

|

|

|

#15 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Nice, got out the FFF compound for spiffing up gunstocks and polished my knob. All them old scratches are gone and it looks brand spankey new.....Ol Redback butt just a shinin and ready for shiftin.

|

|

|

|

|

#16 |

|

Registered User

Join Date: Aug 2013

Location: Payson, AZ

Posts: 3

|

Re: The Official John Lee Jr Thread

<- Stupid jealous...can't wait till I get further along w/ Patsy to play with the big boys...

|

|

|

|

|

#17 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Awesomeness! Now I'm cookin. Might not grind away on my shifter, just shorten and sleeve. Top cover on the short stroke shifter is welded on and so no easy disassembly at this point, at least not unless some significant repair is indicated. So, I'm thinkin a two diameter sleeve, 3/4" id for the T5 spud, cross drilled/pinned and drop in the shank of the 5/8" shifter rod....also pinned....

Easy piezy and I can swap out as simple as bending up a new shifter or changes by makin up new adapters, like a round to flat, etc. We'll see, brains just a cookin..... |

|

|

|

|

#18 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

My idea for a simple (steel tubeing/no weld/no grind the shifter stub) shifter adapter for the S10 T5.

Cut off the T5 stub where ya want it. Bend up the shifter rod the way ya like it. Slip the large end of the adapter on the T5 stub....cross drill and tap or just add nuts. Slot the top half of the adapter tube.... Install the 5/8 diameter shifter lever just made...cross drill and pull the leaves of the adapter up tight with bolts. Paint. Add shifter knob. Go drive.... Get tire of the shifter shape/height, bend up a new one and install in top of the adapter. Love the shifter? Weld it to the adapter.

|

|

|

|

|

#19 |

|

Registered User

Join Date: May 2012

Location: Salinas, Ca

Posts: 299

|

Re: The Official John Lee Jr Thread

Sounds fine to me, more than one way to skin a cat.

Posted via Mobile Device

__________________

1966 C10 250 with 3 on the tree Build Thread Bunch of other cars no one cares about

|

|

|

|

|

#20 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Got my first windshield crack. A shotgun blast of gravel to John Lees face on the way home yesterday. Mudbogger Boy darted around me (I was 65 in a 55 zone and in the right lane), guess I wasn't fast enough, but, his RR tire decided to unload a double handfull of mud and river rock into the driverside of my windshield. I seem to recall seeing at least 5 stones hit the windshield in my line of sight, nice circular shotgun blast pattern.

I wound up with one bullseye and 1/2 inch crack in the 11 oclock position of my vision, just at the bend of the windshield from flat face to piller. Oh well, Off to Oreillies for the Permatex Small Crack Repair kit and we'll document its use here...and in about a month we'll see how it holds up goin from warm garage to cold driveway. I spect it'll crack again eventually and give me the impetuous to replace the windshield with an upper tinted one and slide out that frosty back glass for a Slider Window. But, maybe it'll buy me just one more season with the original glass. |

|

|

|

|

#21 |

|

Registered User

Join Date: May 2012

Location: Salinas, Ca

Posts: 299

|

Re: The Official John Lee Jr Thread

I hate that, its happened to me many times and it seems to suck just a little bit more when its a new car. I think I have the most gravel damaged 3 yr old car in this part of Cali.

When windshield replacement time comes will you do it yourself or have it done?

__________________

1966 C10 250 with 3 on the tree Build Thread Bunch of other cars no one cares about

|

|

|

|

|

#22 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

This havin limited GoodWife (she's off takin care of Mother in Law for the week+) leaves me lots of opportunities to eat Taco Bell and work on guns and trucks and stuff. Tonight was truck night....and what a night it was.

First, fixin or at least patchin up a bullseye and crack in my ancient windshield after yesterdays MuddBoy Gravel Shotgun Blast to the face.....Coulda gone to Safeglass or whatever they are called but that's no fun....so, bought a crack fix kit at Oreillies...$12 instead of an estimated $150. Lets see how it works. From the inside, heres the crack, bout 11 oclock just outside my straight ahead vision area...(by the way, out of coke tonight but Dr Pepper and Jack Daniels is a pretty tasty reward for a hard evenings work).  I cleaned the glass, pretty good with Zeiss lens wipes and dry paper towels. Been putting TurtleCrap Ice on the windshield and wanted to get that mostly gone for the fix....three Zeiss wipes and break out the contents of the repair kit.  Per the instructions, pick out broken glass bits with the enclosed tack and I cleaned it with another Zeiss wipe.  Stick on the vacuum thingie centered over the bullseye in the glass.  Stick the syringe holder thingie to the vacuum thingie...  Pour fixer sauce into the syringe holder thingie and put in the syringe and draw a vacuum for at least 10 minutes....  After 10 minutes, remove the syringe, let in air, compress the syringe to create pressure for 20 minutes.  Remove all the other stuff, put a drop on the yellow pad thingie and stick it to the windshield....move out into direct sunlight for 15 minutes or cloudy days 1 hour for the whole mess to cure....  After one hour on a cloudy day remove the yellow thingie....sauce has cured by UV light in and on the windshield....  Scrape off the excess sauce and though it don't show in the photo, the chip out is smooth and about 80% disappeared...much less noticeable than the bugs on the glass and with luck sealed up enough I'll get another season or two outta the glass.

|

|

|

|

|

#23 |

|

Registered User

Join Date: Mar 2013

Location: Southern Oregon

Posts: 10,384

|

Re: The Official John Lee Jr Thread

Nice truck and awesome that you were able to fix your windsheild!

__________________

1966 Chevy C10 "Project Two Tone" http://67-72chevytrucks.com/vboard/s...d.php?t=596643 1964 GMC "Crustine" semi-build:http://67-72chevytrucks.com/vboard/s...d.php?t=665056 My youtube channel. Username "Military Chevy": https://www.youtube.com/channel/UC_h...fzpcUXyK_5-uiw |

|

|

|

|

#24 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Well, that's it....US Government Shutdown. I am free to drive my truck all day and go hunting. Happy joy. Bastards in DC....

|

|

|

|

|

#25 |

|

Account Suspended

Join Date: Oct 2012

Location: here

Posts: 2,408

|

Re: The Official John Lee Jr Thread

Shifter adapter prototyping time. So, picked up 3 feet of 5/8" round bar....will bend it up later for a shifter handle.....and try to taper it in the drill press for addition of a knob...but....

If you look at the photos of the shifter on the T5, the Chevy shifter is a 3/4" dia round bar....for shifters are half round and the handles bolt on. Most folks cut off the Chevy shifters and weld their custom shifter on. I don't wanna weld it...I might want to change shifters like GoodWife changes shoes....so...options. I could cut off the excess chevy shifter, grind one side flat and drill it to accept any of the ford style shifter bars. I might still do that but for now, I want to try something perhaps a bit easier....a nice tapered round adapter that slides on and cross bolts to the T5 stub I'll be leaving behind after cutting off the excess. So, 5/8" thin wall steel tube slips over the 5/8 rod I bought...so far so good, one end can be mounted with minimal work...but its thin wall. 3/4 inch steel gas/water pipe is a bit over 3/4" ID and as it turns out, perfect. So...first, get the other end of the thin wall sized up so it'll accept the 3/4" diameter stub of the T5 chevy shifter. Grease, Smasher Wacker and a variety of sockets to slowly expand one end of the thinwall pipe....sorta tapered opening.  Lemmie tell ya, this ain't an easy job...but I got plenty of thin wall to practice with. One end of the thin wall roughly tapered to accept the 3/4" shaft and the other end left alone to accept the 5/8" shaft...now I grease up the OD of the thin wall and drive it into the gaspipe and get after the inside with the sockets again to improve the shape of the thin wall and its taper.....the gas pipe acts as a hollow anvil.  I split the gas pipe a bit, shape on the installed thin wall sleeve, slit the pipe some more, shape the thin wall installed in the pipe and finally slit the gaspipe thru and drive the sleeve out, the gas pipe retains the taper. "I meant to do that." Lucky me.   The sleeve installed in the gas pipe....the shifter in the top of the sleeve...ready to cross drill and bolt. If it all fits the T5 shifter when rough assembled, I'll set up the lower half of the adapter for two cross bolts to attach to the shifter. From there I can bend and shape my shifter shaft, install the ball and if really industrious, get out my arc welder and some hangers and weld the adapter to the shifter shaft. (Or get my boy to Mig it for a couple Tacos from Tacos El Primo)

Last edited by Sharps40; 11-13-2013 at 06:38 PM. |

|

|

|

| Bookmarks |

|

|