|

|

|

#551 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

Ive done a bunch of stuff with a mig, and er70s2 is pretty decent filler for mild to cast too. i am always skeptical until i prove myself. still never had any parts come back cracked. i still prefer to use the heliarc if i dont use the nickel rod for a little better heat input and control. but i think these manifolds are pretty good castings, and that also helps.

|

|

|

|

|

|

#552 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

Nothing real exciting lately.

i decided to pull the backing plates off the dana 70 and put them on the 80. the 80 only had backing plates, nothing else when i bought it. yanked the whole set up off, hauled it to the carwash and gave it a good washing. then painted the outsides black  new seals!  got to the other side and found that the bearings felt a little icky. decided to run a different hub i had laying around because this one was ugly. not real sure it would have mattered but hey, whats the use of spare parts anyhow.  back together. ill have to pull the wheel cylinders but i havent ordered them yet. hopefully i can do it without totally disassembling everything. i also need to order some new drums  today i crossed over.

|

|

|

|

|

|

#553 |

|

Junk Yartist

Join Date: Jul 2009

Location: Greeley, CO

Posts: 2,203

|

Re: 72 k20 project

Oh man! Now you're ready for colored transparent speaker wires, wire nuts, and a twisted ground wire under a sheet metal screw!!

Posted via Mobile Device

__________________

-Jeremy YOU ONLY FAIL IF YOU STOP TRYING 70 Crew Cab Build Link 70 GMC Suburban 4X4 build thread 95 Yukon Daily Driver Rebuilding an NP205 |

|

|

|

|

|

#554 |

|

Enjoying left field

Join Date: Jun 2008

Location: Dillon Montana

Posts: 900

|

Re: 72 k20 project

I just caught up on your thread, looks awesome. I have a question about cast welding though. On my 6.5TD, the turbo manifold has a straight section about 4" long near the inlet.

If I can cut that section out, then my turbo downpipe will fit past it. My plan is to put a good bevel on the cut, preheat the manifold in the barbeque, and tig weld it with nickle rod. Hows that sound? What about using the cut out cast metal as filler? |

|

|

|

|

|

#555 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

that will work well. let it all come up to temp. only needs to be 200 or so. weld it and put it back in the barbeque. cool it slowly. do not attempt to use the cast material as filler. it wont work worth a ****.

|

|

|

|

|

|

#556 |

|

Junk Yartist

Join Date: Jul 2009

Location: Greeley, CO

Posts: 2,203

|

Re: 72 k20 project

Ryan, Did you make that dash bling? If so, how about some pictures.

__________________

-Jeremy YOU ONLY FAIL IF YOU STOP TRYING 70 Crew Cab Build Link 70 GMC Suburban 4X4 build thread 95 Yukon Daily Driver Rebuilding an NP205 |

|

|

|

|

|

#557 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

No, i bought it. a member here, Mahanian sells them. great deal for the money.

Ryan |

|

|

|

|

|

#558 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

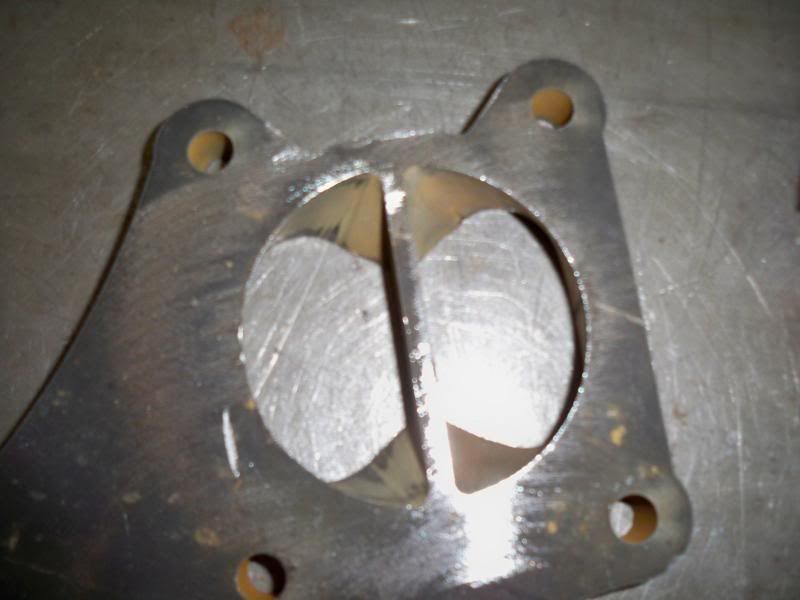

tacked the hot pipe flange on the new plate i bought. and cut the turbo mount flange

top of the flange  bottom of the same piece of metal  in position... sort of.   there are few things to consider, but its going to be mounted like this. i biffed and cut the part an 1/8th of an inch thinner than it was programmed for, so its getting re-cut to make my inlet flange pattern match better. i need to cut a relief in the frame rail for the primary compressor housing. i need to do some machining on the mount plate to allow for an external gate. i have to figure out exactly what i am doing with the gate on the primary. it can be done a few different ways. |

|

|

|

|

|

#559 |

|

Carpe manana

Join Date: Dec 2010

Location: Eau Claire, WI

Posts: 12,424

|

Re: 72 k20 project

Looking real good! It must getting warm up there also. Come down for a visit if you get time. Pete

__________________

1972 K5 CST Highlander Blazer: http://67-72chevytrucks.com/vboard/s...d.php?t=708547 1972 K20 Cheyenne Super: http://67-72chevytrucks.com/vboard/s...d.php?t=528308  Members met: ORANGBLAZ, 2003 silverado, MikeCofield, BB72CHEVKT, Duncan&Son, Sameyrasmea72, THENEWMEXICAN, HotRod C/10, brianthelion02, Sport/Truck, ryanroo, michael bustamante, Dirt's72, Already Gone, WestButteTruck, 57taskforce, Moreyel, painterljp, AASmedic, SoCoC10, Lumaestas, carbuff382, Chevyland Members met: ORANGBLAZ, 2003 silverado, MikeCofield, BB72CHEVKT, Duncan&Son, Sameyrasmea72, THENEWMEXICAN, HotRod C/10, brianthelion02, Sport/Truck, ryanroo, michael bustamante, Dirt's72, Already Gone, WestButteTruck, 57taskforce, Moreyel, painterljp, AASmedic, SoCoC10, Lumaestas, carbuff382, Chevyland

|

|

|

|

|

|

#561 |

|

6>8 Plugless........

Join Date: Sep 2007

Location: Prairie City, Ia

Posts: 17,139

|

Re: 72 k20 project

Looking pretty nice. When you coming over to weld up my rear suspension and frame?

__________________

Ryan 1972 Chevy Longhorn K30 Cheyenne Super, 359 Inline 6 cylinder, Auto Trans, Tilt, Diesel Tach/Vach, Buckets, Rare Rear 4-link and air ride option Build Thread 1972 GMC Sierra Grande Longhorn 4x4 1972 Chevy Cheyenne Super K20 Long Step side tilt, tach, tow hooks, AC, 350 4 speed 1972 C10 Suburban Custom Deluxe 1969 Chevy milk truck 1971 Camaro RS 5.3 BTR STG3 Cam Super T10 1940 Ford 354 Hemi 46RH Ford 9" on air ride huge project Tired of spark plugs? Check this out. |

|

|

|

|

|

#562 | |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

thanks!

Quote:

anyhow, i didnt get my replacement flange plate cut tonight, but i scrounged a bit of tube to weld in the frame where i have to clearance for the compressor housing. AND... i got my jeep running correctly for the first time since mid april last year! already got one dirty look just cruising up the street in my neighborhood.

|

|

|

|

|

|

|

#563 | |

|

Registered User

Join Date: Nov 2008

Location: mitchellville, ia

Posts: 282

|

Re: 72 k20 project

Quote:

__________________

1996 Dodge 2500 Ext Cab Long Bed P24V Cummins Turbo Diesel 5 speed 4x4

"STOCK" ASSEMBLY THREAD |

|

|

|

|

|

|

#564 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

ill do my best. not exactly sure what my schedule is. i am actually flying in and out of chicago and riding to IA with my older sister and her family. not sure yet what my schedule will be

|

|

|

|

|

|

#565 |

|

Registered User

Join Date: Aug 2007

Location: Kentucky

Posts: 828

|

Re: 72 k20 project

wahoo!!!

|

|

|

|

|

|

#566 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

so, i re-cut my turbo flange. it now fits the inlet on the Hx55 much better. outwardly it looks no different, so i didnt take any pics of the new one. i have a little machining to do to it then it'll be done.

i did take a short video of the 3D flow in action for those interested  just so you all know, it is .750" plate steel the mounting holes for the secondary turbo are cut at .385" .010" oversized for the the fastener (.375") with studs threaded into all 4 holes on the manifold flange the waterjetted part slips over the studs with 0 clean up after cut. awesome. Last edited by ryanroo; 05-09-2013 at 07:51 AM. |

|

|

|

|

|

#567 |

|

Registered User

Join Date: Jun 2010

Location: Pittsburg, KS

Posts: 953

|

Re: 72 k20 project

Twin setup is looking really good bud! That waterjet is sweet

__________________

1980 K10 - 6.2L Diesel/SM465/NP205 Build Thread 1984 K30 CC Dually - "The Tank" 12V Cummins/Nv4500/Np205/D60/D70HD 4" lift & 37's Build Thread 1960 C-60 Dump Truck Make it road worthy! Thread |

|

|

|

|

|

#568 |

|

Junk Yartist

Join Date: Jul 2009

Location: Greeley, CO

Posts: 2,203

|

Re: 72 k20 project

Why did you buy the outlet plate and not cut it yourself out of curiosity?

__________________

-Jeremy YOU ONLY FAIL IF YOU STOP TRYING 70 Crew Cab Build Link 70 GMC Suburban 4X4 build thread 95 Yukon Daily Driver Rebuilding an NP205 |

|

|

|

|

|

#569 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

it was 18 bucks. all i needed to do was get out the credit card. i was already ordereing from the place i got it, so i just did it. seemed easier than reinventing the already round wheel. after getting it and finding out how well it fit, or didnt. i would have rather drawn and cut my own. but, its on there now, so all is well.

|

|

|

|

|

|

#570 |

|

Enjoying left field

Join Date: Jun 2008

Location: Dillon Montana

Posts: 900

|

Re: 72 k20 project

Is that a 5 axis waterjet? COOL! I programmed a little for a local guy with an older Flow waterjet.

Posted via Mobile Device |

|

|

|

|

|

#571 | |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

Quote:

it can do some really cool stuff but its way slower than the plasma for sure. we are waiting for the Flow guys to finish up on the laser mapping device/software. right now it doesnt have any way to locate the surface of the material so if you have a sheet with a little hump in it, it can blow the water back into the abrasive and clog the crap out of it. hopefully they get that stuff done sometime soon. we cut some cedar with it the other day, that was pretty interesting. |

|

|

|

|

|

|

#572 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

so i cut some slots in the turbo plate for the external wastegate.

you can see how the cut matches the flange better now that it is the correct thickness  just to show how the wastegate ports are  got a 90 degree silicon elbow. it will probably need to be trimmed, but it is the best way to make the corner quick and stay out of the alternator. it is also a 4"-3.5" reducer. also the downpipe flange is on there. it will need to be grafted to an ell very close to the exhaust housing, but it fits!

|

|

|

|

|

|

#573 | |

|

Enjoying left field

Join Date: Jun 2008

Location: Dillon Montana

Posts: 900

|

Re: 72 k20 project

Quote:

|

|

|

|

|

|

|

#574 |

|

Junk Yartist

Join Date: Jul 2009

Location: Greeley, CO

Posts: 2,203

|

Re: 72 k20 project

So was your first stage originally an internal waste gate? If so how did you close the port? Is the external going to dump pre or post secondary turbo?

Posted via Mobile Device

__________________

-Jeremy YOU ONLY FAIL IF YOU STOP TRYING 70 Crew Cab Build Link 70 GMC Suburban 4X4 build thread 95 Yukon Daily Driver Rebuilding an NP205 |

|

|

|

|

|

#575 |

|

Senior Member

Join Date: Apr 2004

Location: sw colorado

Posts: 2,720

|

Re: 72 k20 project

we already have about 4 guys and the owner who can operate it, so you are welcome to try, but i dunno if they'll bite. right now its more of a toy than a money maker. i assume that will change as we get better at programming and all that. they were looking at new 3D software yesterday, so who knows.

both turbos are internally gated. i will be blocking off the internal passages for the gates in one way or another. most likely i will be tapping the ports and using a pipe plug. depending on how this set up runs and if i feel like it will spool with it, i may step up to a 14cm exhuast housing on the 35. they are not internally gated, so i will be ready for that. according to my friends at low budget diesel, i probably will not need a gate fro the primary. if i do, it will be an easy add on. the gate on the secondary will dump into the hotpipe to help drive the primary. |

|

|

|

|

| Bookmarks |

|

|