|

|

|

|

|

#1 |

|

I have no time for this

Join Date: Dec 2002

Location: Fort St John B.C. CANADA

Posts: 434

|

Re: 55 Wagon Progress

It seems a shame they didn't have you fix the scrape ahead of the wheel while yo were at it.

__________________

1986 Chevy short box ( PROJECT ) 1994 Chevy Blazer lifted 6" 2009 Gmc 2500 HD 1999 Hugger orange Camaro SS 2007 BMW X5 Sport |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

Yes, but this wasn't an insurance job, nor was the previous incident when that dent was added. With the cost being paid by the owner, sometimes a line is drawn in the sand as to what is worth the cost of repair.

__________________

Robert |

|

|

|

|

|

#3 |

|

I have no time for this

Join Date: Dec 2002

Location: Fort St John B.C. CANADA

Posts: 434

|

Re: 55 Wagon Progress

I hear ya I did collision repair for 15 years. Nice work on the bus always top notch

__________________

1986 Chevy short box ( PROJECT ) 1994 Chevy Blazer lifted 6" 2009 Gmc 2500 HD 1999 Hugger orange Camaro SS 2007 BMW X5 Sport |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

Thanks!

Dropped it off before work, picked it up afterward.  After about an hour in the driveway with an air hose, the flow of trapped media is scarce, but I'm sure there's still some there. We'll get some SPI epoxy sprayed tomorrow night...

__________________

Robert |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

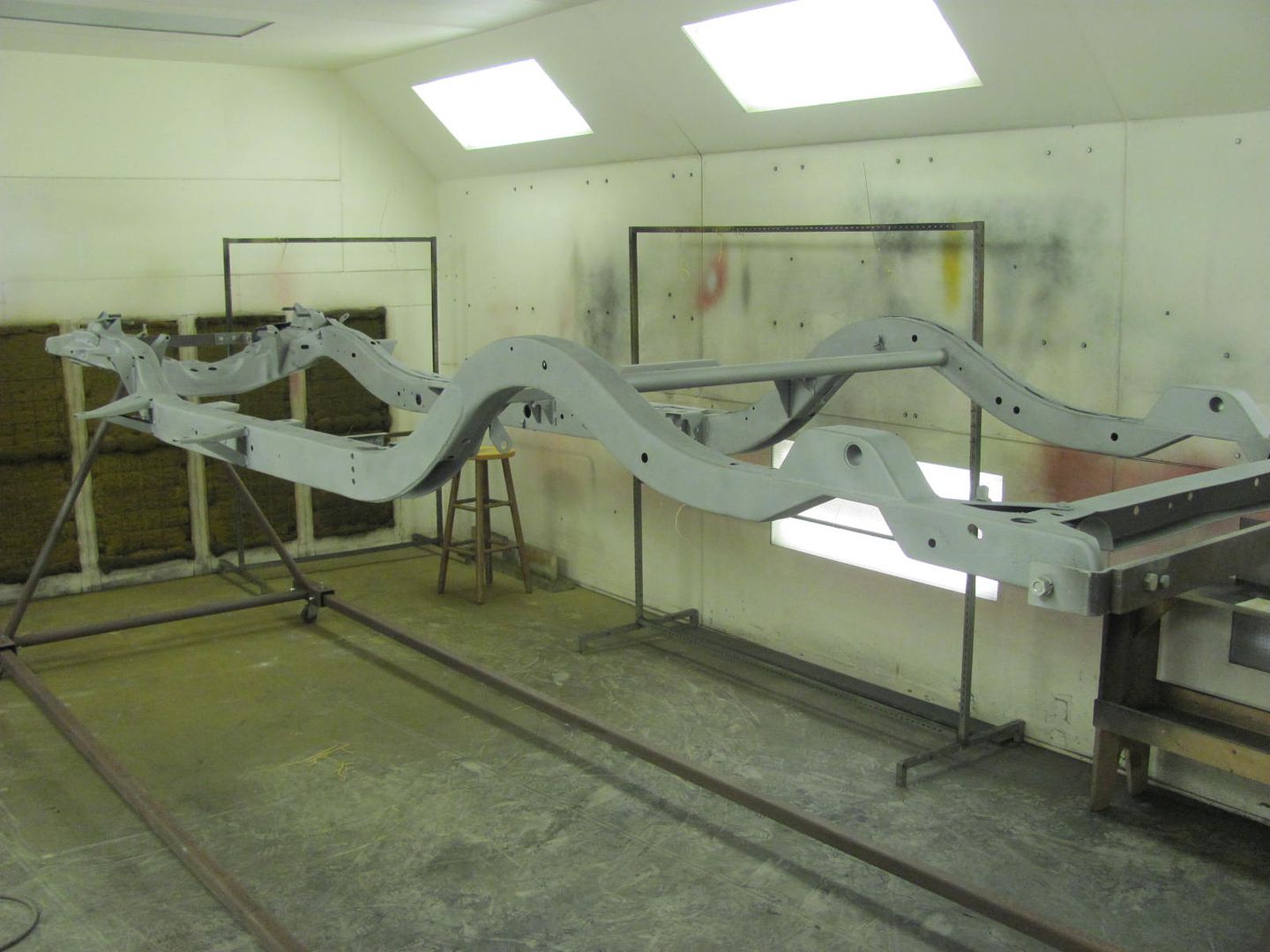

That frame is a thing of beauty,

Quality of work is second to none. Even on a school bus no short cuts are taken. When Im out in the shop I reflect back to this build and it makes me try that much harder. Thanks for posting, even the small stuff. Merry Christmas and Happy New Year. |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Apr 2003

Location: Indep, MO

Posts: 5,893

|

Re: 55 Wagon Progress

OOOO Cleeeeean! Gotta love some blasted metal.

__________________

Boppa's Old Yeller Truck Build, Old Yeller's New Heart! Project Buzz Bomb Flyin' Low! |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,555

|

Re: 55 Wagon Progress

Nice turn around time, frame looks great...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

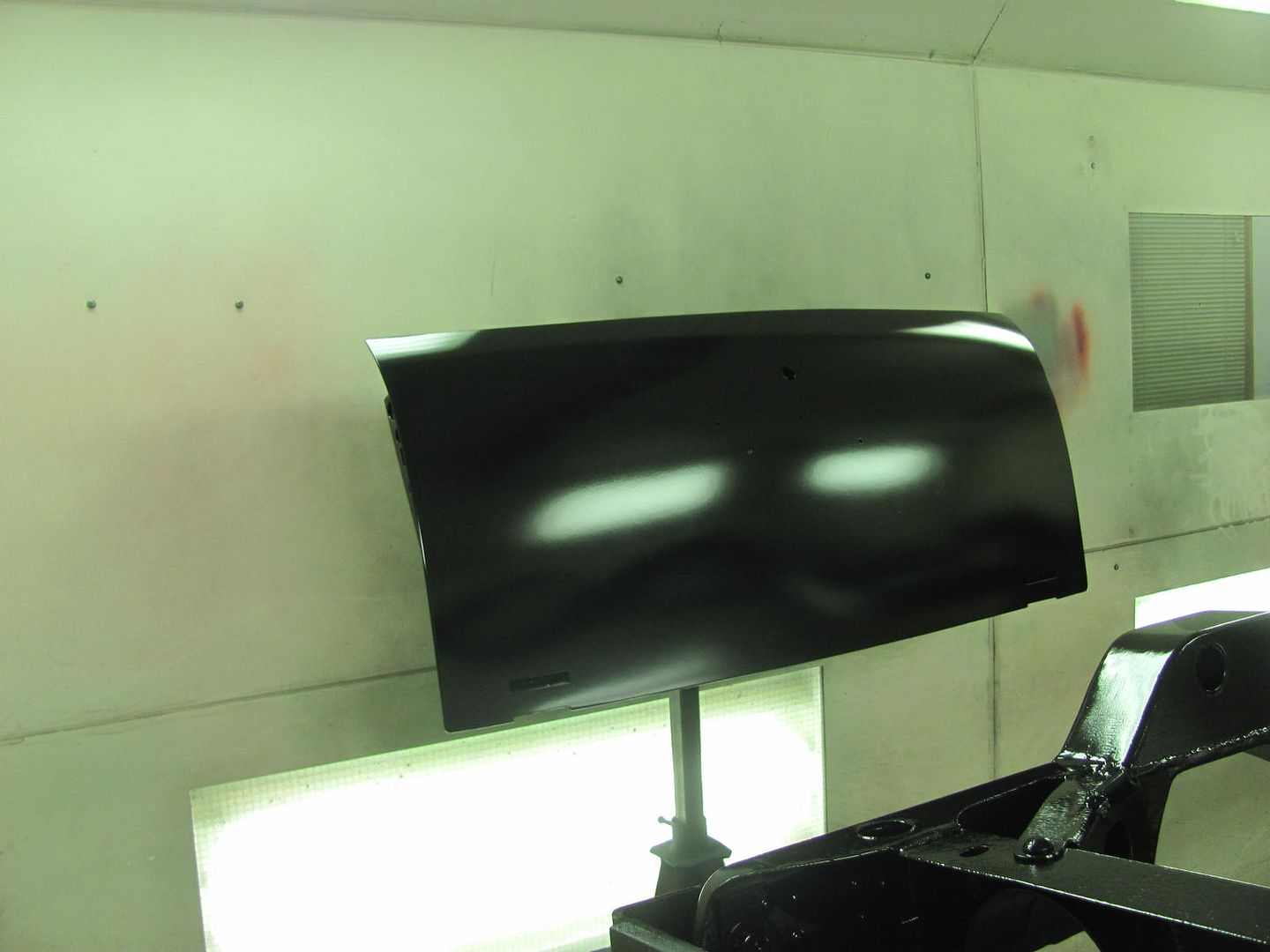

Thanks for the comments fellas..

55 parts everywhere....  Two coats of SPI epoxy....   Had some left in the paint gun so a couple of extra pieces were moved in...   Oh yeah....the "new" trailer wheels were all blasted and ready to go, so they got a couple coats on the back side...

__________________

Robert |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

The frame had some slight pitting so the sides were hit with the DA to flatten things out a bit, and some Evercoat 416 used to address some of our plug weld grinding marks on the frame plates...

Here's the "winter" heating method for spraying in cold temps. 170,000 BTU aimed at the air return, and the air handler fan turned on constant to circulate the heat. Open window for air intake..    After three coats of primer, the sides of the frame are looking much better than before...    Also got some more primer on these parts as well, should be ready for blocking in a few days.

__________________

Robert |

|

|

|

|

|

#10 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: 55 Wagon Progress

Have a Merry Christmas

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Nice and Clean.

Merry Christmas |

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

Thanks guys. Merry Christmas everyone!

__________________

Robert |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

The other day when we primed the frame a second time we also did the front side of the trailer wheels..

and today I mixed up some Centari that has been sitting on the shelf a few years.. It sprayed pretty decent...   And more blocking.....

__________________

Robert |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

Made another trip to the car wash tonight. Tire soak, high pressure soap, and a rinse...

While Kyle was media blasting, I used the 36" AFS to block the tail gate.  This had been blocked a couple times before and never seemed to come out right. Of course, I was using a shorter block as well. The 36 really did the trick in getting things nice and flat...   .....and getting things ready for another epoxy session...     Moved these out of the way, closer to the door so we can get tires on this weekend. Order trim rings today, now for some baby moons that fit... I swear they get brighter every time I look at them..

__________________

Robert |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Looks great.

How many times, or what's the deciding factor from laying down epoxy vs primer or high build primer? Must forgive my questions,,, I'm in class here learning from the master. : ) |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

I used slick sand on the last car we did, the 65 Fairlane:

http://www.garagejournal.com/forum/s...ad.php?t=86935 It does have a couple spots that look like some shrinking took place. One of those I see it but the owner doesn't but I need to improve the next one kinda things. I think the epoxy will give a much better base than the slick sand as epoxy doesn't have the porosity that the SS does. So other than some spots of evercoat 416, most everything on this build has been epoxy. Just wanted to try it and see if it held up any better.

__________________

Robert |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

Picked up some 400 grit PSA paper yesterday, used it this evening to get the tail gate finished to 400 grit, next week we'll wet sand to 600 grit.

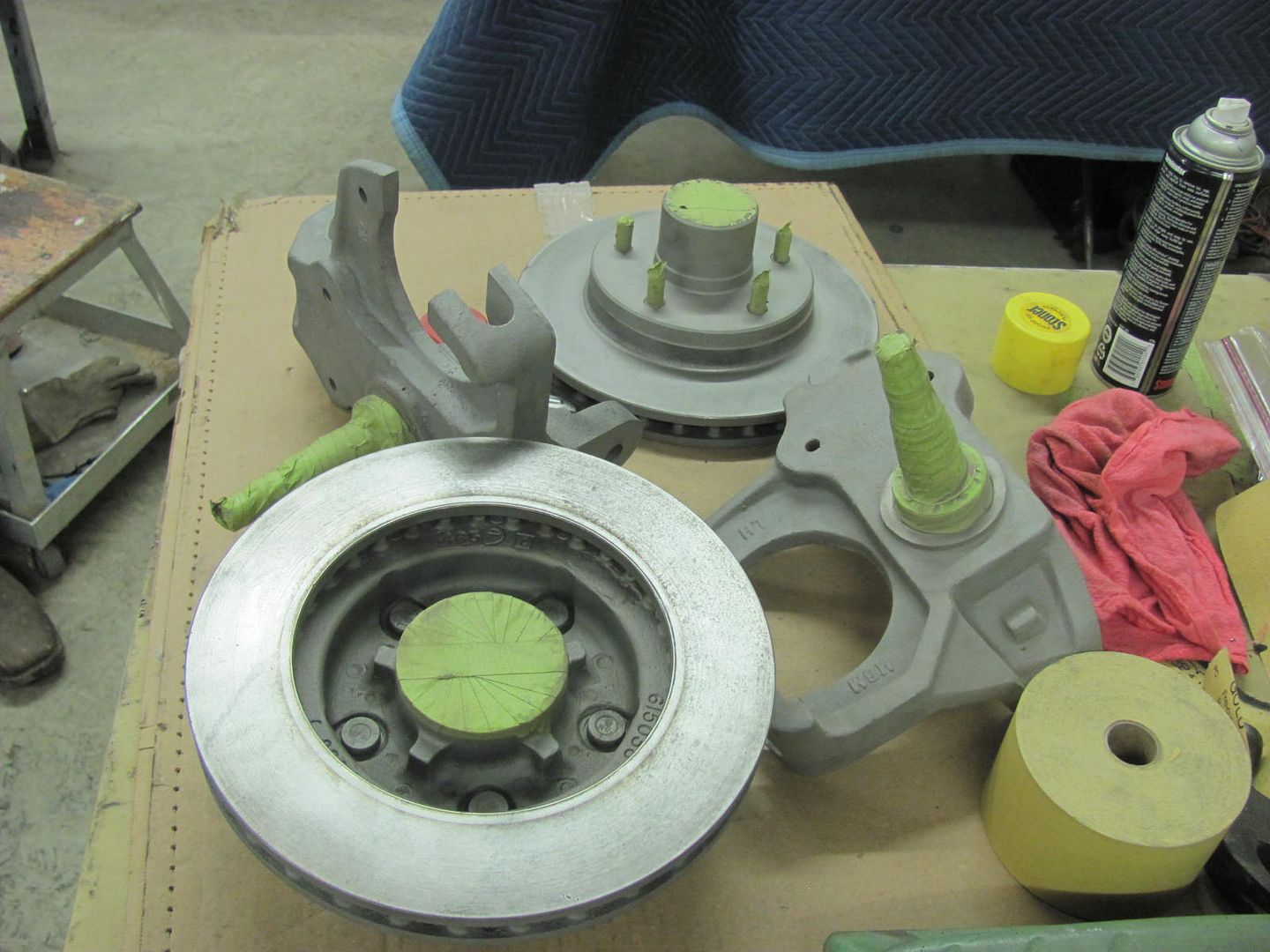

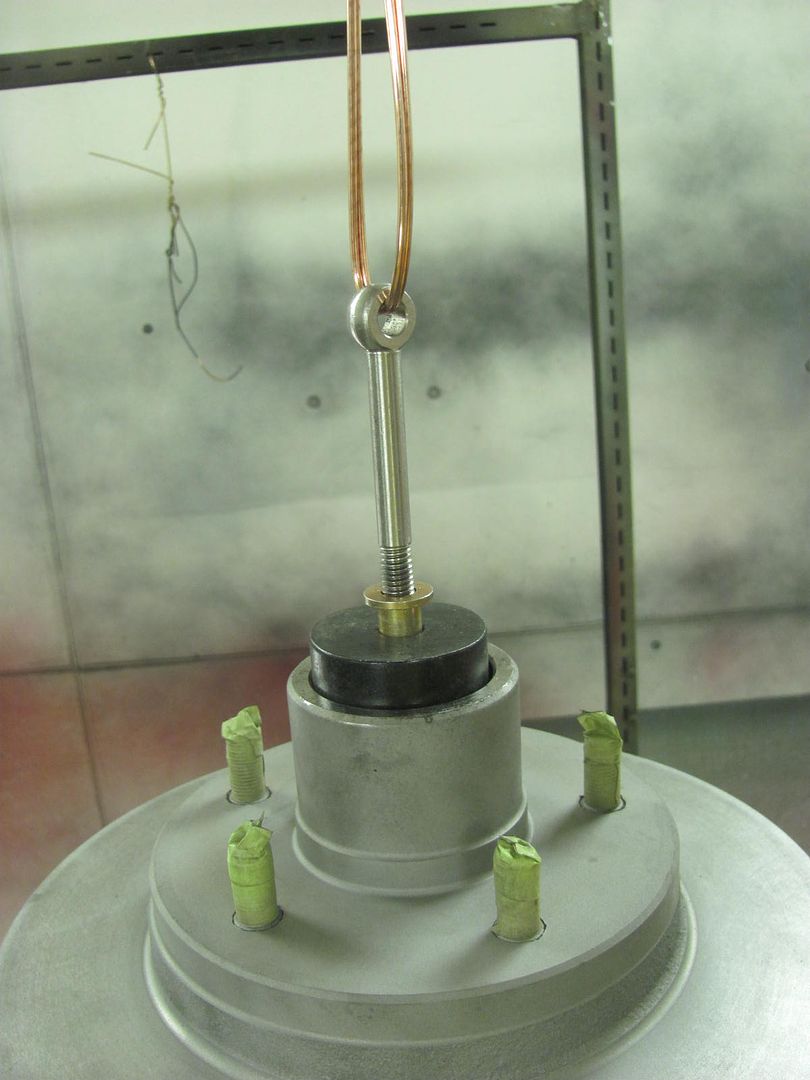

Nephew Chris came over and helped Kyle and I get the frame off the rotisserie and back on the floor..   With the rotisserie freed up, we now have a new paint fixture...   Parts prepped for epoxy primer tomorrow...    While I was getting these parts taped off, Kyle started blowing apart the rear end for media blasting..

__________________

Robert |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,026

|

Re: 55 Wagon Progress

I like the way you have tied off the small pieces side to side so they don't move around when painting. A simple yet great idea.

Progress and parts are looking really good. |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

yeah, that's one thing I can't stand is parts spinning around while you're trying to spray them..

Today Kyle worked on getting the axle pads welded on....   .....while I was spraying some SPI epoxy....    .....and while I had some epoxy mixed, we poured some inside the tailgate to seal the inner and outer skins ..    Axle pads done, then heated the opposite side to counter the weld shrinking...     It's real close, just a little more straightening to do... other parts from the booth today....   ....and then sprayed some silver metallic Imron on the A-arms..

__________________

Robert |

|

|

|

|

|

#20 |

|

Registered User

Join Date: Sep 2013

Location: Glendale, AZ

Posts: 289

|

Re: 55 Wagon Progress

Imron!!.......... ACKKkkkkkk......... I use to paint Aircraft with that... yuck!

(Great Product though) |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,555

|

Re: 55 Wagon Progress

Man, I thought they quit making that years ago, guess not...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

this gallon can has been sitting around for quite awhile (going on 20 years). Can't bring myself to throw it away, for things like these a-arms it gives a tough as nails finish...

__________________

Robert |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

I am curious on the heating of the opposite side of the perches, was there a visible amount of warpage after welding or was this step more just precautionary?

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,637

|

Re: 55 Wagon Progress

OK, here's the backwoods method of checking the rear for any weld distortion. Bolt everything back together, including wheels. Rotate the wheels to insure they are indeed NOT BENT. Now raise the rear up in the air and place tires down on top of a couple milk crates. Now grab the third member and rotate around, looking for any wobble in the wheels. Typically with the welding process causing some shrinking, you will notice a wider area opposite the pads. We used a tape measure between the wheel edges, and notated the dimensions taken after rotating the axle in 90 degree increments. Heat up the long side to add some shrink there. Let manually cool and check again..

__________________

Robert |

|

|

|

|

|

#25 | |

|

Registered User

Join Date: Oct 2007

Location: Spanaway

Posts: 8,451

|

Re: 55 Wagon Progress

Quote:

__________________

Mike. Swamp Rat build thread : http://67-72chevytrucks.com/vboard/s...d.php?t=595019 72 3/4T 4X4 4" BDS Lift 33" BFG's |

|

|

|

|

|

| Bookmarks |

|

|