|

|

|

|

|

#1 |

|

Senior Member

Join Date: Aug 2005

Location: tulsa OK

Posts: 3,070

|

Re: LFD's 4dr Tahoe Build

kevin what do you use to bend the DOM tubing? i saw where you post the lazze bead roller, hopeing you could share this info too...also are you still working full time, and this is a 'hobby' still?

|

|

|

|

|

|

#2 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Quote:

I have been full time at home for the last 2-3 months but I will be headed back to work (my union day job) in the next few weeks. Work got slow so I took a leave so some of the other guys could keep working knowing I had plenty of work here to pay the bills. But they just landed two good size framing jobs so it is back to being 60 hour a week baby sitter  For the DOM and HREW I have a hydraulic tube bender designed for doing roll cages and tube chassis. It is a JD squared model-3 on juice. I started building dune buggies chassis when I was 14 or 15 and have always had tube benders around. The one I have now I bought about 15 years ago and turned it to a full hydro unit about 6-7 years ago. Once I have the body off and start doing the rest of the chassis I will show more on tube bending and chassis work. Kevin LFD Inc. |

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jun 2009

Location: Puyallup, WA

Posts: 337

|

Re: LFD's 4dr Tahoe Build

You are the one that keeps my motivation going on my suburban. I don't have a bad ADD problem yet but distractions won't leave me alone. May need to start my own build thread so other member will urge me to stay focused.

__________________

Travis Travis2005 K2500 Duramax (hauls the junk home) 1967 Chev C10 (hauls a$$) 1970 Suburban (Yukon XL 4 door) 1968 GMC 3/4 ton (sheetmetal only, chassis gone) 2005 Malibu (wife's car, still a Chevy) Project Family Hauler New Home for Chevys (Moved in and working) |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

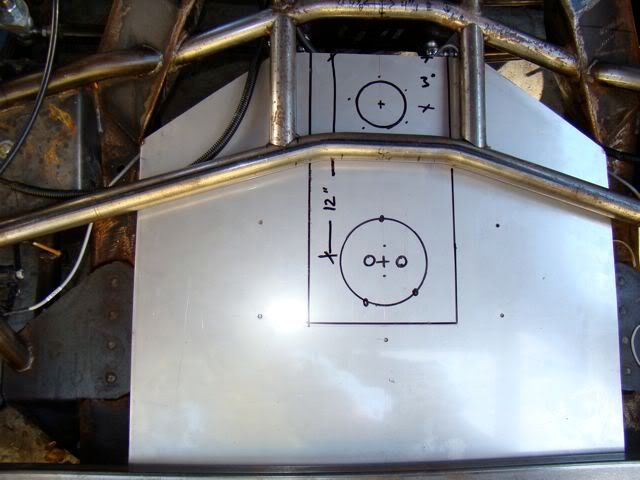

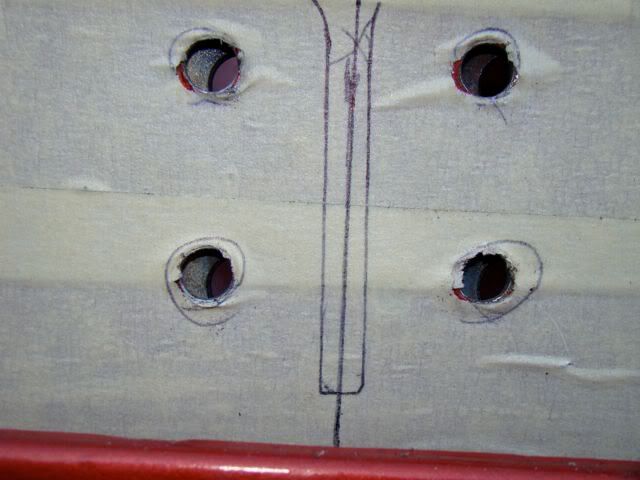

Rock Valley Antique Auto Parts Inc. I gave Rock Valley a call today to see if they could help me with my in-tank pump and sending unit. I spoke with a guy name Chris about what I wanted and I had a few questions for him as well. He had me fax him a drawing of my tank with dimensions and any key point. Then in about 1 hour he called me back and faxed the sheet back to me. We went over what he felt was the best set up and placement for my baffles as to not get in the way of the sending unit or pump. They are going to build a mounting plate that will hold the in tank pump, fuel resivor and sending unit. The mounting plate will be set 1" below the top of my tank (so the lines will clear my tube work) and the lines will exit out the front of the tank. Great company to deal with and if you need a tank or just parts to build your own I highly recommend them. I am looking at about $425 plus shipping for what I bought and I will have the tank ready for it to drop right in and Tig up. I made my tank out of .070 SS and it is right around 27 gal. That should give me about a 500 mile cruising range. With my rear floor and frame I had a lot of things to deal with in the over all size and shape so that I could get the largest tank possible to fit and stay out of the way. Here are a few pic's of what I ended up with. I still need to figure out what size fill tube I want and how I will be mounting it all up. Kevin LFD Inc. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

|

|

|

|

|

|

#6 |

|

low n' slo

Join Date: Mar 2009

Location: rosenberg, texas

Posts: 5,172

|

Re: LFD's 4dr Tahoe Build

thats a great looking tank man...hey..are you gonna have a floor behind the rear seats? i think it would be kinda cool to leave a plexiglass window on the floor so you can see all the tubing work you did

__________________

67 1/2 ton Suburban - Project DRGNWGN. Build thread  -_--_--_ _________ _--_-_ -/____|__|__\__ ,.,,,.,.,,.,|_O _______ O_] |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Thanks but it has a full floor for the 3rd row seats. I have put way too many hours into keeping this floor as low as humanly possible and still be able to lay frame with a 31.5" tall rear tire. How many C10's have you seen with the frame rails on the ground and only a 2" step in the floor! Also this tube work is nothing compared to what the rest of the frame will look like. It will have a photo shoot before getting the body placed back over it and they will be in the build book to see.

Kevin LFD Inc. |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: LFD's 4dr Tahoe Build

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Sep 2009

Location: Medford, OR.

Posts: 207

|

Re: LFD's 4dr Tahoe Build

|

|

|

|

|

|

#10 |

|

Rods

Join Date: Nov 2002

Location: Bryan, TX

Posts: 1,398

|

Re: LFD's 4dr Tahoe Build

As a non structural weld im thinking i can use a spool gun on the tank.. Not sure how the baffels ill go though

__________________

Just keepin it simple.  1965 C-10 Ext cab build. 350??(Does it count at 2 truck if I had to cut one up?) 1966 C-10 lwb 283 auto 1970 Suburban in pieces 1971 Blazer 4wd....restore someday. all factory CST 1972 Blazer 4wd parts truck still a roller 1972 GMC Sierra Grandee 1998 Chevy ext driver. 2005 F**D the wife drive...(cant fix women) |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Well I had an hour to kill between honey do's for tomorrow so I made the first 2 mounts. They are 8" long and centered on the sides of the tank front to back. Their are 2 braces per side, the one you can see facing down and one just like it facing up and welded to the first one. This just gives a good "grab" on the side of the tank and a lot of support on the tank in both up and down directions. Next I will do 2 straps running front to back also out of SS. The rear will pin into bracket that will be on the top of the front edge of the trailer hitch and the front mounts will hang off the tube work and have a T-bolt that will tighten the tank up against 1/8" rubber straps between the tank mounts that will go on top for the tank to tighten against. But with just these two side mounts I can stand on the top of the tank with out flex. I used 7/16" bolts with a large square nut welded in side the frame rails.

The first pic is with the system at level 3 (90% up). Second pic is level 2 (ride height 50%) with 8" of tank clearance. Third is level 1 (10%) up and the last is aired out but the front still has 1 1/2" to come down after we put the new front top arms in so that will raise the tank another 1/4"+ or so. But all in all I feel it will work out great! Kevin LFD Inc. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

|

|

|

|

|

|

#12 |

|

Still Learning

Join Date: Jul 2009

Location: Central Oklahoma

Posts: 10,108

|

Re: LFD's 4dr Tahoe Build

That is a nice looking tank! I think it will work very good. Keep the pictures coming. How much is the kit for the tank going to set you back with the pump and all? I may be interested in one too. thanks,

Mike |

|

|

|

|

|

#13 |

|

high-Tech Red Neck

Join Date: Feb 2008

Location: Livingston, MT/On my boat WA/BC/AK

Posts: 2,294

|

Re: LFD's 4dr Tahoe Build

Kevin, how hard is it to tig that stainless? I have been wanting to learn, but just havent got off my bum and done it.

__________________

"He used to be a pretty nice feller, now he's a welder!" |

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Jun 2007

Location: Netherlands

Posts: 191

|

Re: LFD's 4dr Tahoe Build

Quote:

The only thing i experience is the warping of the material. But that is with every material you weld.

__________________

Anybody can restore a classic, takes a man to cut one up..... http://www.arnoldscustoms.com |

|

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Quote:

The mounting plate (8w x 15.5L x 1" deep) correct pump for my LSX motor and the sending unit for my gauge was $425 + shipping. The pump mount is done in SS and has the locking ring like the 73+ tanks do and the Sender is drilled and tapped for easy mounting. Kevin LFD Inc. |

|

|

|

|

|

|

#16 | |

|

high-Tech Red Neck

Join Date: Feb 2008

Location: Livingston, MT/On my boat WA/BC/AK

Posts: 2,294

|

Re: LFD's 4dr Tahoe Build

Quote:

I think it should be easy enoguh to do using a tank selector for a 70's model with saddle tanks, seeing as how the wrecker has an external fuel pump. Did you fab the lock ring, or did it come with the kit?

__________________

"He used to be a pretty nice feller, now he's a welder!" |

|

|

|

|

|

|

#17 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Quote:

Kevin LFD Inc. |

|

|

|

|

|

|

#18 |

|

Registered User

Join Date: Sep 2009

Location: Medford, OR.

Posts: 207

|

Re: LFD's 4dr Tahoe Build

Hey Kevin, Happy Thanksgiving! Thought I'd wave as I went by. I just passed Winters on my way to Modesto.

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Nov 2006

Location: Springfield/Kansas City

Posts: 1,842

|

Re: LFD's 4dr Tahoe Build

Wow! Those seats turned out really nice, almost like they're supposed to be there.

|

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Quote:

Your truck sure is looking good but one questions for ya. Did you get to keep the color matched guitar from the music video? That was just too cool! Kevin LFD Inc. |

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Aug 2005

Location: Hillsboro Oregon

Posts: 6,449

|

Re: LFD's 4dr Tahoe Build

That looks really nice.

|

|

|

|

|

|

#22 |

|

low n' slo

Join Date: Mar 2009

Location: rosenberg, texas

Posts: 5,172

|

Re: LFD's 4dr Tahoe Build

they do look nice..maybe one day..

i was lookin at my moms 96 explorer today and it looks like the hinge setup is similar..i just glanced at it. i didnt really look into it much but it looks like it folds into the firewall too.

__________________

67 1/2 ton Suburban - Project DRGNWGN. Build thread  -_--_--_ _________ _--_-_ -/____|__|__\__ ,.,,,.,.,,.,|_O _______ O_] |

|

|

|

|

|

#23 | |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

Quote:

Kevin LFD Inc. |

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

PorterBuilt's DropMember Hood Hinges How-To LFD style So I have been killing my self setting my hood on and off during my 72 Tahoe build. With a 30.5" tall front tire little things like hood hinges kind of get in the way. So my thoughts are that since Nate from PorterBuilt street rods is the reason I am so low and can not run a stock hinge that he should be the one to fix the problem as well! And now he has!! What Nate has come up with is a cowl mounted Hinge kit that really works. Not like the others that only let your hood open half way or the $1K scissor type that are hard to set up right then they still are not real stable (side to side) when they are up. This install took me about 4 hours to complete and the results are out standing. Easy to install with basic tools (plus a welder), the hood opens up 7" higher then stock hinges, way more solid and firm then any hoods I have dealt with. Also since these are a single pivot point style hinge un-like the factory hinges you will not have to push the rear of the hood down for it to close all the way. It will line up the same way every time you open or close the hood. Their were a few snags and we will get to that as they come up in the install. Lets get to it! Ok first thing to do is remove the hood, cowl and stock hood hinges. Then you need to find the center point of the front of the cowl area and put a piece of masking tape their that you can write on. Then from this center mark you will go left and right 23" each way so the hinges will be 46" from center to center. I used masking tape to make all my marks on so it is easy to change if you make a mistake and also it will help protect the paint for the painted guys. Ok so once you make your two hinge marks 46" apart from each other you are ready to make a templet so you can transfer the hinge mounting holes and center slot. So the first step is to mark the hinges for Passenger and Drivers side. Take the hinge box's and set them side by side so the top of the box's are touching like in the pic and not the bottoms. Once you have done this put a P on the left one for Passenger and a D on the right one for Drivers side. [IMG]  [/IMG] [/IMG]Take one of the hinges and place it face down on a piece of poster board and trace the out line of the hinge box, center slot and the 4 mounting holes. Now their is a P and a D to this templet as well so put a mark showing what is what. After I cut this out I placed the box back over it and used a transfer punch to get exact centers for the holes. [IMG]  [/IMG] [/IMG]Then take the templet and place it so the 46" marks you made are in the center of the slot you cut out and that the bottom of the templet is tight to the bottom of the wire gutter. I used 2 small magnets to holt it in place while I transferred the mounting holes with a center punch. and marked the slot with a pen. [IMG]  [/IMG] [/IMG]Then I drilled out the the 4 mounting holes with a 5/16" bit but I did not cut the slot out yet. First I set the Passenger side box over the area where it will go and marked out the area I needed to remove so it could slide into the cowl. Only remove as little as you have to so it will fit. Then slide it into place and install 4 bolts just to locate it in the correct spot. It should be sitting flat to the bottom of the cowl at this time. I then used a C clamp to hold it tight so I could mark and drill the 2 bottom holes that will go through the cowl in to the cabin. Note! At this point I chose to use regular hardware for all my mock up because SS is great but does not lend it self well for going in and out too much. So I will keep the SS in a bag and when I am ready for final assembly I will set it all with the regular hardware, tighten it all down and then when I am happy with it I will remove 1 bolt at a time and install the SS with a bit of anti-sieze. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Then I marked for the (2) 3/8" holes for the center slot. The first one went at the bottom of the marked out slot but 1/4" up. The top hole will be for now right on the corner of the top of the cowl. After they are drilled I removed the tape and scribed 2 lines from top to bottom of each hole. I marked mine just inside the lines of where I thought it would end up then I cut out the section. I then clamped the box back in place using the bolts to align it once again. I then took a die grinder and gently remove the rest of the metal around the slot until it was just flush with the slot cut in the box. By doing it this way you end up with a very clean hole that just looks right. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Kevin LFD Inc. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Jul 2005

Location: Winters Ca. 95694

Posts: 4,843

|

Re: LFD's 4dr Tahoe Build

I then did the same for the drivers side but had to do a bit more trimming to get everything in place. After the face holes were drilled and the top of the cowl was cut to get the box inside I found that the holes did not line up. The box was tight against the left side of the opening in the cowl and as you can see in the pic it still has to go over a bit. So I trimmed more off the one side of the cowl until it lined up then I found I need to do a bit more for the bolt head to clear as well.

[IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Next it was time to install the hinge arm before bolting in the boxes! If you bolt the box in first you will not be able to slide the bolts into place to hold the arms. Now their is a P and a D to the arms as well. The angle on the end of the mounting plate of the arm will slope in towards the center of the cowl. So imagine a line going from the head light to the center of the cowl and the angle in the arm will follow this same line. Note If you are already painted or going to be driving it for some time you will want to paint these parts and seal up the bottom bolt holes with silicone. To do this put a large amount of silicone under the box around the two holes and then put some more in the holes before inserting the bolts. Yes this is a bit messy but better that then water or rust coming through later. So I assembled the arms on the boxes with everything setting in the cowl openings. Once the arms were bolted in I went ahead and started the 4 front bolts but before tightening them up I dropped the other 2 bolts in place going into the cabin. Then tighten them all up starting with the 4 in front and moving on to the 2 on the bottom. Now that the boxes are tight you can set the tension on the hinge arms. What I did was tighten them up just so the arm will stay up and require a very small amount of force to lower. What this does is makes everything nice and snug and does not allow any slop in the operation of the hinges. Next you will want to adjust the up travel of the hinge arms so they are even with each other like in the pic below. [IMG]  [/IMG] [/IMG]To do this you will take your die grinder or file and adjust the top of the slot so the arms will come up to the same point. You may want to sit the cowl back in place and see where the front edge is location to the top of the slot. You do not want the slot to go into the cowl panel so make a mark at the front edge and work towards that. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Once you are happy with both sides you can bolt the cowl panel back in place and start on the hood. Note The very first thing you want to do is make sure all the bolts can be screwed all the way into the mounting plate. If you have any problems you should run a tap through the hole first. I had one that did not go and found out after it was welded in place. I have already spoke with Nate about this and he is fixing this so it will not even be a possible problem on later kits. Also note their is a passenger and a driver side to these plates as well. The angle on the plate will follow the angle on the hood brace. So find a good place to lay your hood up side down and grab your tape measure. You will once again want to find the center of the hood along the rear brace. Their is a factory hole that is almost exactly center but double check it before moving to the next step. Once you find center you will want to measure out 23" each way just like on the cowl. This again is the center of the hinge mounting plate but since these plates are 2 1/2" wide now measure to one side 1 1/4" so you have a good mark to line the edge of the plate up with. Put the plate down and trace around it withy a pen then remove the plate and clean all the paint off this area so you will get a good weld in a later step. Now re measure and place your marks one more time (don't forget the 1 1/4" offset line) and using a framing square you will want to make sure these plates are square with the rear of the hood and 1" in front of the back of the brace. This should also be about 2 1/2" from the very back edge of the hood. Once you have this I recommend just doing one tack weld per piece first. After both sides are tacked re-check your 46" number to make sure it is correct then finish welding. I only did about a 1" weld in each corner and I feel that is more than enough to secure the hood for good. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Kevin LFD Inc. |

|

|

|

|

| Bookmarks |

|

|