|

|

|

#51 | |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

Quote:

These weigh alot more than 10-12 lbs. Theres absolutely no way they weigh less than 50 lbs a set. You have to remember they have crossbars, the bushing sleeves, the inner sleeves, balljoints, etc. thats alot of weight. |

|

|

|

|

|

|

#52 |

|

Registered User

Join Date: Jan 2009

Location: Columbiaville, MI

Posts: 8

|

Re: Control arms

This is a copy and paste from taylor on another forum

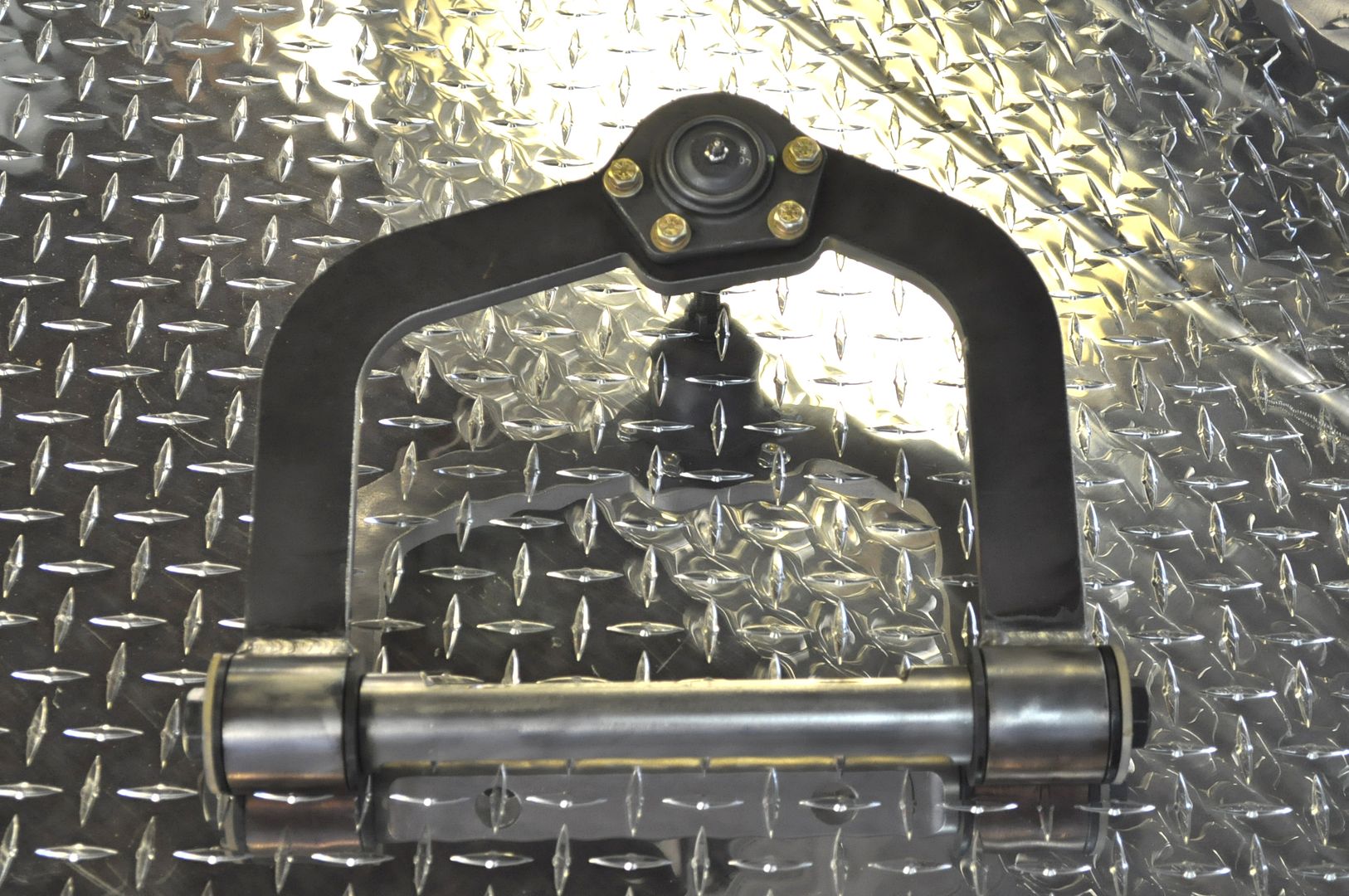

Here are the basic entry level uppers. They include X-Shafts and all poly bushings. These arms will be similar in design for the Jeebus Joint version as well, just got an order for that version today, so I will be showing pics soon. The arms are about 1" wider than stock total. they weigh 5lbs more than stock as well, with the HD x-shaft. Fully tig welded, and made from .500 plate 1018 Steel.

|

|

|

|

|

|

#53 |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

I like the uppers. I bet the lowers weigh alot more than stock. stock lowers weigh a bunch, especially with the crossbars.

|

|

|

|

|

|

#54 |

|

Registered User

Join Date: Aug 2010

Location: New Hamburg, Ontario

Posts: 220

|

Re: Control arms

not everything aftermarket is heavier than stock.

|

|

|

|

|

|

#55 |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

I agree, an aluminum intake is lighter....

But if the lowers are 3/4" like I suspect then they are much heavier. I deal with laser and plasma cut plate steel in all shapes and sizes all day long. I work at a place that builds armored vehicles, like cars, suburbans, Mercedes, SWAT vehicles. So an armored vehicle with thicker steel is heavier and in this case arms with thicker steel are much heavier. The stock lowers are what 1/8" or 3/16" thick? then you replace that with at least 1/2" and probably 3/4"?? we have a CNC plasma that will cut plate up to 5' wide and 12' long. we use up to 3/4" thick and cut everything ourselves. Then on top of that I also make arms and I know what the bushing ends weigh, the balljoint cups weigh etc. Im looking at making some flat plate uppers for a buddy right now. The uppers can be 1/2" and be good but the lowers probably need to be 3/4" and that means they will be very heavy. I dont have a problem with heavy. I like the flat plate arms. I wish I had a laser so I could make some. But I know they are heavy. |

|

|

|

|

|

#56 |

|

Registered User

Join Date: Aug 2010

Location: New Hamburg, Ontario

Posts: 220

|

Re: Control arms

agreed.

|

|

|

|

|

|

#57 | |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

Stock upper arms weigh 11lbs 4oz with the stock x-shafts, and ball joints. My flat plate arms weigh 13lbs 6oz made from .500 steel and 1.4375 cold rolled bar stock for the x-shaft. the lower arms will weigh in the ball park of 6lbs heavier than stock with x-shafts. You remove metal from non weight bearing areas of the arm to lighten them up and make them a bit more easier to move around. On the average, from my flat plate arms that i produce , and stock arms, usually the uppers i make weigh no more than 3lbs heavier than stock, if they are heavier than that, i re-design them. The lowers, i leave a bit more room for weight addition, i will accept up to a 10lb increase in weight on the lowers, just because they are usually a bit beefier! I weighted a few other sets of aftermarket arms, there all heavier than stock as well.... so im not sure what the issue is i suppose, its going to be expected unless someone starts producing a stamped steel lower arm..... Taylor Last edited by N2TRUX; 11-05-2010 at 10:33 AM. |

|

|

|

|

|

|

#58 | |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

The blue webbed arms weight 12lbs 8oz. they are a fair amount heavier than the stock arms, but the stock arms on a dodge ram truck are made from .4375 thick cast aluminum...... so i was not trying to match that hahaha. Taylor |

|

|

|

|

|

|

#59 |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Whats so great about any arm then? nothing if you look at it from that perspective. Its just a aftermarket control arm, that will help your truck lay out on larger wheels, and get more travel than a stock arm, and be stronger while doing it. There not here to change the world, its just a part i make. No claim has been made to any greatness lol. I take orders from people, and make them parts, they use them on their trucks.... the world goes round... Taylor |

|

|

|

|

|

#60 | |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

Uppers are 1/2 inch flat plate, 1018 mild steel. Lowers are 3/4 inch flat plate mild steel. I have built arms for everything from 1ton dually trucks to mini trucks using that method.... never had an issue. Been driving on the same set of .750 plate flat arms on my personal 1500 Ram QC for 4 years now. good guessing tho! |

|

|

|

|

|

|

#61 | |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

Nobody else sells them! The jeebus joint is something machined in house, to each vehicle application. On a truck like this, you would only need jeebus joints on the uppers. the lowers can be ball joints and still get plenty enough travel to make they lay out on anything you would need to. Taylor |

|

|

|

|

|

|

#62 |

|

Happy to be here

Join Date: Mar 2000

Location: Cypress, TX

Posts: 39,021

|

Re: Control arms

Taylor (Jeebus) welcome to the forum. We appreciate you taking the time to set the record straight on your product.

Can you give us more insight on the benefits of the Jeebus joints over a standard balljoint?

__________________

Follow me on Facebook and Instagram @N2trux.com Articles- "Jake" the 84 to 74 crewcab "Elwood" the77_Remix 85 GMC Sierra "Scarlett" "Refining Sierra" |

|

|

|

|

|

#63 |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

I was wondering is the weight and what thickness. thats the biggest determining factor. I like the arms Taylor, ive said that. so why you have to post a comment about "millions of years" ??

I do know where the stress on an arm is and about what one weighs made from whatever material. The guessing as to weight depends greatly on material thickness and where the big open areas are. Im just curious as to the weight and thickness. Last edited by N2TRUX; 11-05-2010 at 10:34 AM. |

|

|

|

|

|

#64 | |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

Quote:

|

|

|

|

|

|

|

#65 |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

One more thing, The stock lowers with crossbars are pretty heavy so that should help. So what thickness do you make the lowers with?

Keep in mind Taylor that I said I like these and I think this is where the arm industry is heading. Its simpler and allows for more cool looking designs than just tube. Last edited by DHPmike; 11-05-2010 at 10:02 AM. |

|

|

|

|

|

#66 |

|

Registered User

Join Date: Jan 2009

Location: East Texas

Posts: 1,047

|

Re: Control arms

|

|

|

|

|

|

#67 |

|

Happy to be here

Join Date: Mar 2000

Location: Cypress, TX

Posts: 39,021

|

Re: Control arms

Guys I did a little editing so we can stay on topic. Lets share the knowledge, and leave the BS out of it.

__________________

Follow me on Facebook and Instagram @N2trux.com Articles- "Jake" the 84 to 74 crewcab "Elwood" the77_Remix 85 GMC Sierra "Scarlett" "Refining Sierra" |

|

|

|

|

|

#68 | |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

Well, the majior advantages are the amount of travel it provides. From a stock C-10 Ball joint, the jeebus joint gets 14 more degres of travel. And, to be honest, thats quite a bit when it comes to laying a truck out on huge wheels. Another often over looked advantage is its stregnth. The cycle rating on these 100% sealed, teflon lined stainless steel bearings is nearly 10x more than any ball joint, when used on street trucks. Bassicly, its just a much much stronger alternative to the boring old ball joint that everyone else has. |

|

|

|

|

|

|

#69 | ||

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Quote:

Quote:

I did state this earlier in the thread, but i will do it again for ya. In most cases, The upper control arms are made from 1/2" Flat plate 1018 Mild Steel. And lower arms are made from .750 plate 1018 Steel. On rare instances, i will produce a upper arm from .750 plate, is the person intends on beating the snot out of it or soemthing like that. Usually, the design i use, in addition to the plate steel thickness is far more than sufficant to replace an control arm. Most of the stregnth is in the design. Last edited by N2TRUX; 11-05-2010 at 11:19 PM. |

||

|

|

|

|

|

#70 | |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

Quote:

But dont tell someone you have to have something like that on an upper arm to lay out big wheels. You just need the balljoints to utilize their complete amount of travel. Just look at 90% of the trucks at a show layed out and the balljoints are not maxed. thats wasted travel and theres no way to say its not. Its simply wasted and that allows for less up travel. Dont get me wrong I prefer something like the joints you make or any of the alternatives but lets not scare people into buying them because they think their truck wont lay out without them. as I said the look makes them worth it. I like the look of them with the center pivot at an angle like it would be when a truck is layed out.. |

|

|

|

|

|

|

#71 | |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

Quote:

I agree that on certain really large wheels you would need drop spindles or this. But lift is not lost by installing drop spindles. |

|

|

|

|

|

|

#72 |

|

Registered User

Join Date: Sep 2010

Location: Bakersfield,Ca.

Posts: 340

|

Re: Control arms

So who has the best deal on Control arms?

__________________

57 Chevy shortbed,327,Muncie 4 speed,12 Bolt rear end(current project) It's your ride build it the way you want !!!!!!!!!!

|

|

|

|

|

|

#73 |

|

Registered Cruiser

Join Date: Mar 2010

Location: Mesa, AZ

Posts: 918

|

Re: Control arms

Porterbuilt makes a nice tube arm with a little extra drop integrated, quality stuff!

Last edited by JNJchev77; 11-05-2010 at 02:05 PM. |

|

|

|

|

|

#74 |

|

Registered User

Join Date: Nov 2010

Location: Michigan Metal Works

Posts: 122

|

Re: Control arms

Yea, porter built arms are really nice! I had a customer here in the shop with a set and they were very well put together. I was not too fond on their upper arms, i just dont like the look or layout of them, seems like there are better options, but they were very well put together, and the welds were beautifull!

the thorbeke brothers arms we a good choice as well! They are very high quality! Taylor |

|

|

|

|

|

#75 |

|

Registered User

Join Date: Jul 2009

Location: Wylie Texas

Posts: 91

|

Re: Control arms

The answer to your question on arms is to decide what you want to do with the truck and find the best arms for that purpose that you can afford.

Wheel and tire size as well as how low and your budget are all things to consider. Then as stated in this thread you can choose between tube and flat plate arms. pay attention to what bushings are used in each and what style balljoint. If your running very large wheels it pays to look into the style joints Taylor makes. If your not running very large wheels, like say 22s or smaller then you can run a stock replacement style balljoint. |

|

|

|

|

| Bookmarks |

|

|