|

|

|

#51 | |

|

Registered User

Join Date: Jun 2009

Location: harris mn

Posts: 126

|

Re: Simple TBI build

Quote:

dont get that dorman part for the o ring gaskets for the oil cooler adapter. the big o ring that seals the adapter to the block is to thin. go to the dealer and get the gm kit for it, its like 5 bucks cheaper at the dealer. if you get the parts store kits youll have a nasty oil leak that you cant get to seal up... i tried the dorman kit on my tbi 350 started leaking oil as soon as i pulled it out of the garage. |

|

|

|

|

|

|

#52 |

|

Registered User

Join Date: Jun 2009

Location: harris mn

Posts: 126

|

Re: Simple TBI build

also what are you going to do for controlling the 4l80? doing a standalone controller or are you switching ecms to a newer one? im kinda curious

|

|

|

|

|

|

#53 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

I had a 1991 computer but was lacking the correct harness so i decided although the TCI/fast controller. It is expensive but i thought it would save a lot of headaches and i can have different setting for towing and regular driving. http://www.summitracing.com/parts/tci-302820 I am waiting for the SYE for the 241. should be here by Friday and i hope to have it running by March. Chris |

|

|

|

|

|

|

#54 |

|

Master Hater

Join Date: Apr 2006

Location: Temple,Tx.

Posts: 402

|

Re: Simple TBI build

I hate to see someone install a flat tappet cam into a roller engine and then say they want efficiency , The main reason GM went to roller cams was reduced friction. Plus, you have a brand new engine, and as someone before said Id hate to see your engine ruined buy running a lobe flat. Thinking of a flat tappet cam going bad keeps me up at night. Im to the point now I don't even look at flat tappet blocks anymore, I love roller cams. I am looking for the same results for my 85 though, I have a set of LO5 heads that are looking for a New home, but Ill keep mine carbed for now,

__________________

1997 C1500 ECSB 4.3/NV3500 8.5 3.42 "This evening, all of you bleeding hearts... why don't just go ahead and hug yourself for the next 20 minutes or so, because there's a really good chance you're gonna be offended".- Captain Owen Honors |

|

|

|

|

|

#55 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

Truth be told, I have seen many more roller failures than flat tappet. I am currently running flat tappets in my 78 f250, 67 camaro, both 80 CJ7s. In 30 years of building motors I have never personally seen a flat tappet failure. I know oil has changed but without enormous spring pressure i feel the risk is very low. I hope to have it running in a few weeks, I am waiting for the slip joint eliminator for the 241 |

|

|

|

|

|

|

#56 |

|

Registered User

Join Date: Jun 2012

Location: Minnesota

Posts: 509

|

Re: Simple TBI build

I'm not understanding the concern with using a flat tappet cam. They require proper prelube and break-in, but aside from that what is the concern with lobes going flat? Are cams not made of the same material anymore that this is all of the sudden a big problem? Yea a roller setup would be best, but this isn't a high RPM build, its a low-mid RPM build. I'd think the ROI for roller to be minimal unless there's something new about flat tappets that make them scarier?

|

|

|

|

|

|

#57 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

There are millions of flat tappets cams running today without any issue? But as for this build you are correct about the ROI. The TBI heads have a very small intake runner that increases the air/fuel velocity at low RPMs. The correct Lob Sep and exhaust is probably more important that anything. I will agree that the roller would open the valve a little sooner but not sure if it would make big hp gains. I think a lot of people look at the roller/flat lobes side by size and the roller looks a lot more aggressive. The reality is the contact area of the lifter reacts differently and they open relatively the same. The roller does have an advantage. http://www.lunatipower.com/Tech/Cams...tOrRoller.aspx |

|

|

|

|

|

|

#58 |

|

Registered User

Join Date: Oct 2015

Location: Allen, TX

Posts: 63

|

Re: Simple TBI build

I'm not sure if your set on the TCI controller or have already purchased it, but I was recently looking for a controller for my 4L80E and settled on using a MicroSquirt controller. They are fairly new. I was not familiar with them, but the transmission builder used them himself and convinced me I would have no issues with it. The biggest plus for me is that it was almost $200 cheaper than the TCI. If you have the harness for the transmission and more time than money, you can save another $100 by just buying the controller without the transmission harness and wiring it up yourself.

I have not had a chance to install my 4l80 yet so I cannot comment yet on how it works out. The transmission builder was nice enough to leave my transmission on the dyno so he could show me the software and tuning process in action. Looks simple enough to me. Anyway, here is a link if anyone is interested. I'll post up my thoughts after I get it installed in about two weeks. http://www.efisource.com/shop/micros...transmissions/ |

|

|

|

|

|

#59 | |

|

Registered User

Join Date: Nov 2013

Location: Fowler California

Posts: 140

|

Re: Simple TBI build

Quote:

For what its worth, here are some GM part numbers useful for the cooler adapter 10244495 Oil cooler adapter seal 25013759 Oil cooler bypass valve 14102025 Oil cooler gasket

__________________

1967 CHEVELLE MALIBU 427/700R4 1971 CHEYENNE 10 350/350 1983 GMC K3500 454/400/205 1987 R10 TBI 350/700R4 2014 CRUZE 2.0 TURBO DIESEL |

|

|

|

|

|

|

#60 | |

|

Registered User

Join Date: Nov 2014

Location: Alameda, CA

Posts: 877

|

Re: Simple TBI build

Quote:

A friend of mine had a 350 wipe a lobe which trashed a lot of the engine. Ever since then, he's made sure to run oils with enough ZDDP or additives... it's bad for catalytic converters, which is why most modern oil doesn't have much. With roller lifters you can run whatever.

__________________

1973 C20, 350/350 |

|

|

|

|

|

|

#61 |

|

Registered User

Join Date: Jun 2012

Location: Minnesota

Posts: 509

|

Re: Simple TBI build

The cam & lifter kit is only part of the formula. You'd also need the keepers and spider, cam retainer, and to drill and tap the bosses for the retainer and spider. It'd be riskier to drill and tap a partially assembled engine and hope you catch all the pieces than to break in a flat cam with some care. Not arguing the roller cams are not generally better, they just aren't always necessary.

|

|

|

|

|

|

#62 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

Drill and tap the front of the intake for the AC bracket.  I shortened my brake booster line and used the first step in a double flare to give me a small bulb at the end of the steel line    The fuel lines are still in the way of the rear vacuum port. I am thinking of plugging it and using a 3/16th tee off of one of the lines from the front. It only runs the heat/ac stuff inside. I will see if it throws a code when the if the vacuum spikes in that little line. I might end up making custom lines because my original link had a kink and i found a set at the junk yard but i am not sure how decent they are to run. |

|

|

|

|

|

|

#63 |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Reaf suspension

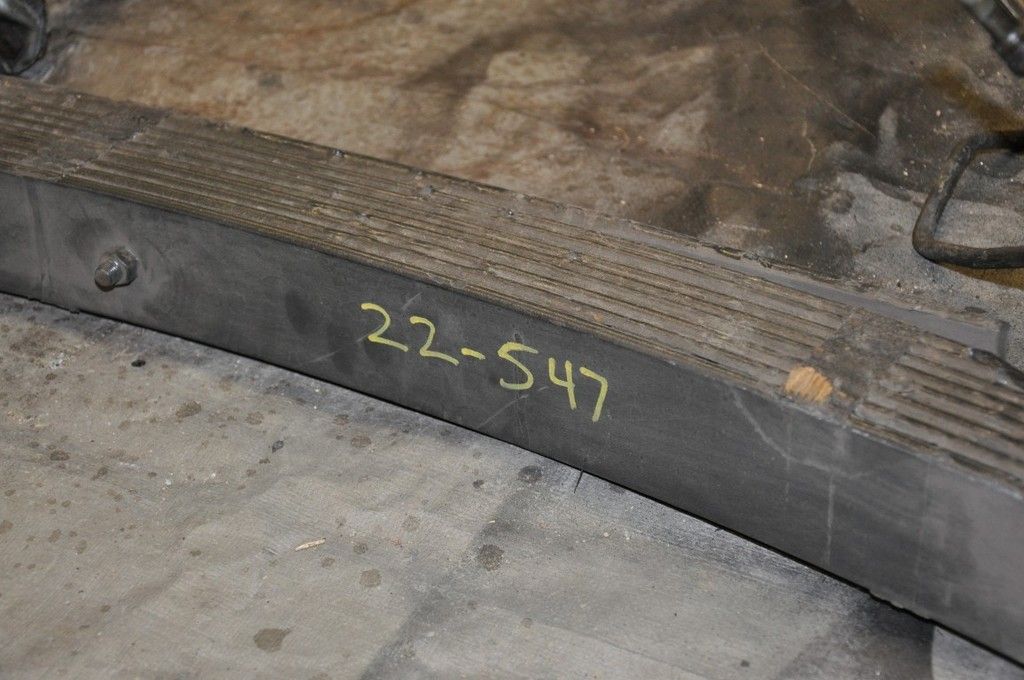

On a different subject,,

I started on the rear springs tonight. I bought a set of factory springs for a one ton truck. The arch is two inches greater and the capacity is 2600 vs my OEMs 2300 I was running a 2 inch block but with the new spring i sit the same height without the block so it looks like the free arch holds up with the weight of the truck. I assume it will settle some so the block may go back in in the future. Part number 22-547 http://www.generalspringkc.com/product_p/22-547.htm ( i bought local but the link gives you the specs)

|

|

|

|

|

|

#64 |

|

Registered User

Join Date: Apr 2011

Location: greenville sc

Posts: 558

|

Re: Simple TBI build

What is the hp rating of this engine with stock intake etc? don't see it listed on their site like the other engines.

|

|

|

|

|

|

#65 | |

|

Registered User

Join Date: Jul 2013

Location: minneapolis, mn

Posts: 28

|

Re: Simple TBI build

Quote:

|

|

|

|

|

|

|

#66 |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

I might run this down to a local shop and dyno it for fun after it is complete. I think it will be a shock to see how little gets to the wheels compares to the flywheel.

Right now i am hung up on the SYE kit. I reinstalled the front have of the t-case tonight so i could get on with driveshafts and exhaust. If anyone has pics of exhaust and clocked T-cases,, please share. Chris |

|

|

|

|

|

#67 |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

converter dust cover solution

|

|

|

|

|

|

#68 | ||

|

Registered User

Join Date: Oct 2003

Location: Carmichael, California

Posts: 3,005

|

Re: Simple TBI build

Quote:

Quote:

As far as the roller cam goes, you don't need to have a high rpm engine just to use one. Every production engine uses one today. Most of the roller failures I've seen are from using OEM or cheap retro lifters on on a high performance camshaft. And most of the blocks should be dried these days. Not all did back in the day but I would think they are now. Finding a spider and dog bones isn't hard. Used is just fine for these and they are all over ebay. And using g GM lifters with a OEM roller core camshaft will certainly keep costs down. With that said, the OP has decided to keep it a flat tappet and clearly has the engine buttoned up so no sense in diving into it now.

__________________

Anthony |

||

|

|

|

|

|

#69 |

|

Registered User

Join Date: Jun 2009

Location: harris mn

Posts: 126

|

Re: Simple TBI build

When you say clocking ring do you mean your reclocking the transfer case or just getting a new adapter? The one from the 400 is the same as the 4l80 just the tranny mount bolts are farther forward on the 400 adapter which you'd need to trim the mount to clear the oil pan.

I'm just using the one from my 4l80 since there in the center of the adapter. And since the passenger drop 208 mounts the same as the drivers drop 241 that was behind the 80e. |

|

|

|

|

|

#70 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

Since i am running only a 2 inch lift i don't think it will affect my front drive shaft at all. My only concern is it leaking. I read a lot of post about the ring leaking and that would drive me insane. I do not know if it is a real concern or not. I spoke to ORD and he said that they do like to leak but can be sealed if installed properly. I just found this link to a guy that make a DYI clocking adapter. Waiting for a call back. http://www.pirate4x4.com/forum/motor...ngagement.html I will take a few pics this morning and post. Chris Last edited by chris989; 02-23-2016 at 11:59 AM. |

|

|

|

|

|

|

#71 |

|

Registered User

Join Date: Jun 2012

Location: Minnesota

Posts: 509

|

Re: Simple TBI build

I guess I'm out of the loop on cam failures due to newer motor oil additive formulations. I haven't seen nor heard of an alarming number of failures. Just guys reporting they know a guy who's brother in law damaged a camshaft and they surmised it must have been the oil that caused it because SN can't be as good as the old SD was.

Last edited by kalbert; 02-23-2016 at 12:05 PM. |

|

|

|

|

|

#72 | |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Quote:

Someone correct me if I am wrong,,, Doesn't Cumins Diesels still run flat tappets? |

|

|

|

|

|

|

#73 | |

|

Registered User

Join Date: Oct 2003

Location: Carmichael, California

Posts: 3,005

|

Re: Simple TBI build

Quote:

__________________

Anthony |

|

|

|

|

|

|

#74 |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

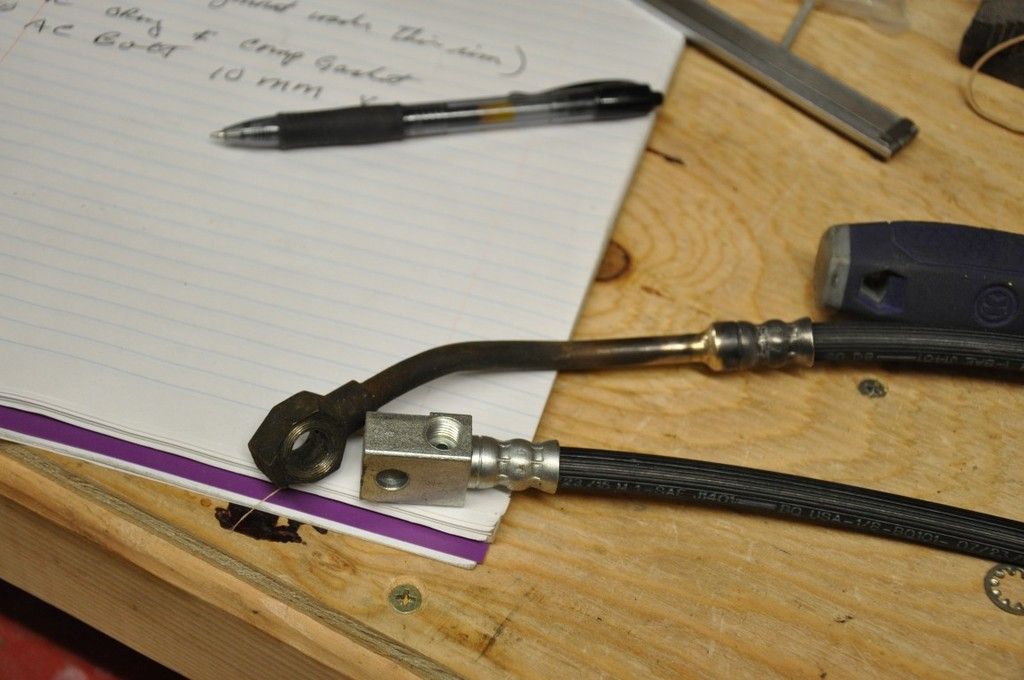

brake lines

Just about ready to fire this motor sometime next week, All of the small details suck up so much time.

I have been meaning to share info about custom brake lines. Some of you will love it, some will be skeptical. I ordered longer lines from a vendor once and threw them in the trash. It was a braided hose with a handful of fittings to make them adapt. I then found a local company that will make DOT approved lines exactly like the OEM or from braided and at whatever length you want. The beauty is it is cheaper than the junk for sale. Now that i live 500 miles from them they still did my work, I sent them in a flat rate box with a return label inside. Take a look.  braze the OEM banjo to new MADE IS USA line   new ends  I run them on all of my projects (ford and jeep have smoked braided stainless) and couldn't be happier. The company is ALLhose on Post rd in Las Vegas. They normally do not do mail order stuff but if you called them ahead I am sure they would make them for you. Or you could PM me and i could tell you who to talk to. MOD=== this is not an advertisement, please do not delete. It might help some members for a custom project. Thanks, |

|

|

|

|

|

#75 |

|

Registered User

Join Date: Dec 2011

Location: Boise, Idaho

Posts: 582

|

Re: Simple TBI build

Need a little help

I am getting ready to fire this thing up and I have no power on half my fuse block. I have traced it to the same wire as the alternator. The wire diagram show the the wire feeding the panel and also running back to the battery. It indicates to ring terminals but it could also be a slice somewhere within the wire loom that is now all buttoned up tight. If anyone has a truck in this era, do you have two main wires from the alt. (one to bat and one to fuse panel? If I run a jumper, everything powers up as it should. I either lost the wire to the battery or i have a break in the single/splice wire somewhere. Thanks in advance, Chris |

|

|

|

|

| Bookmarks |

|

|