|

|

|

|

|

#1 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

Agree with Bomp!!! dug

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys. Bomp, that has been one of my best finds.

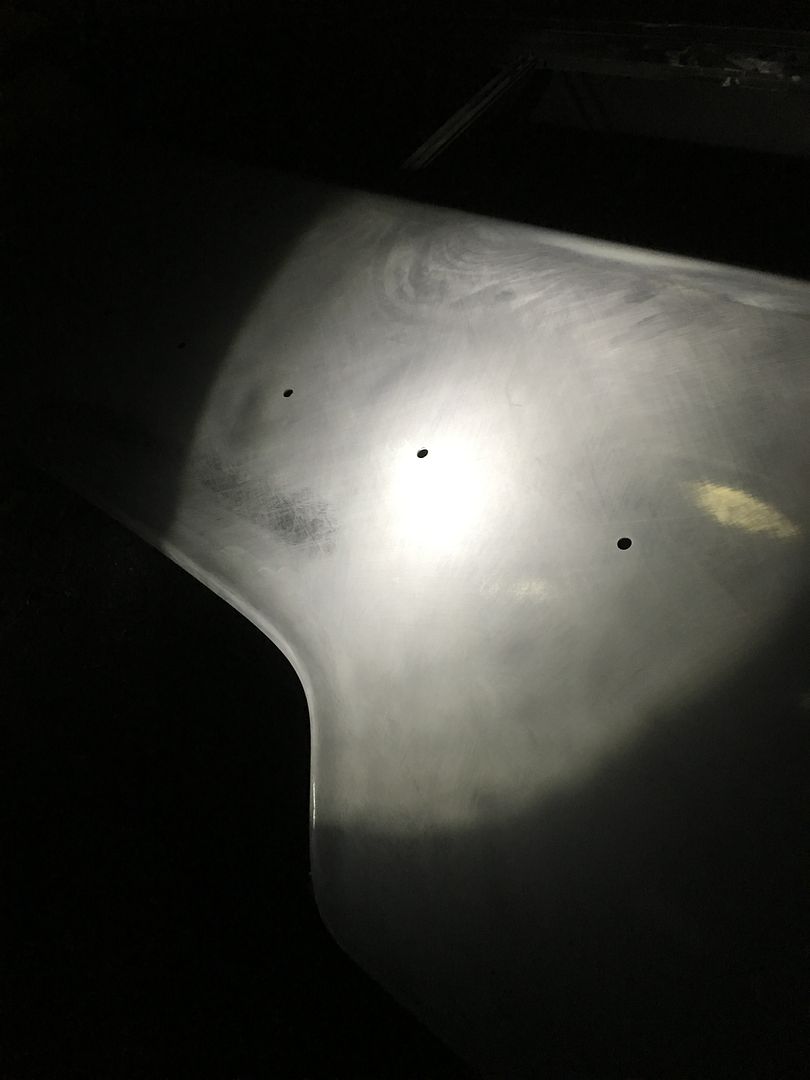

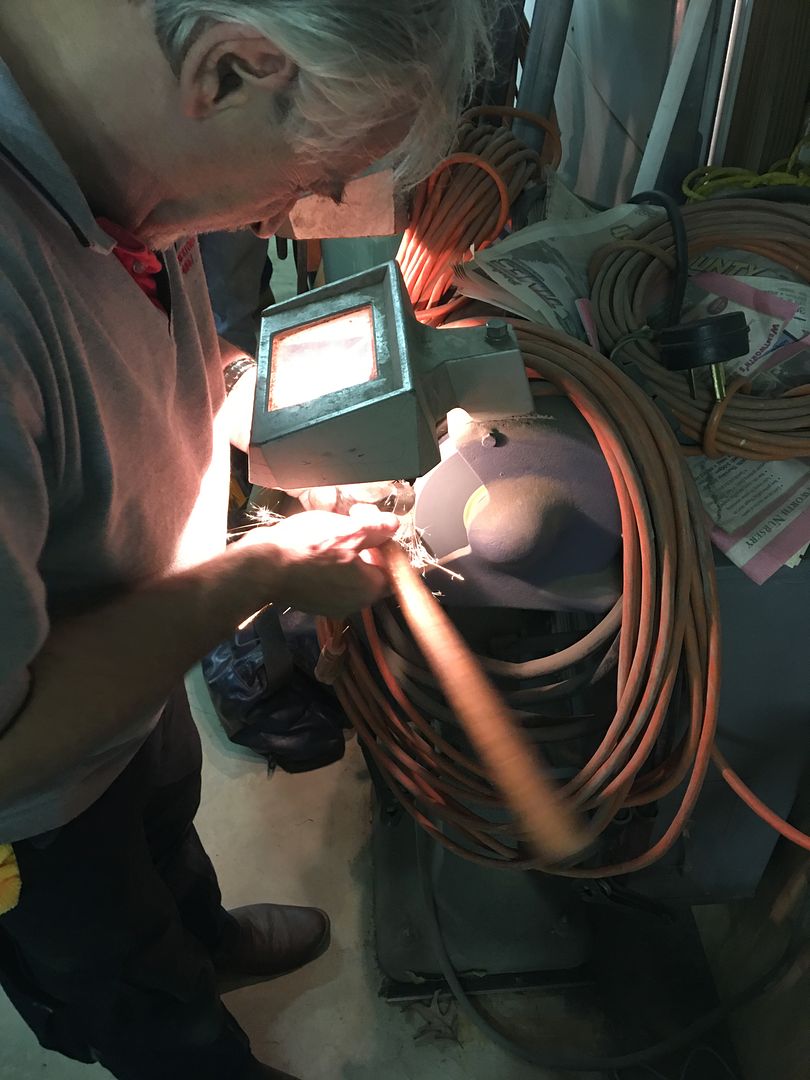

Made our table slightly larger to better hold the panel level for punch depth consistency..  More holes for screws added to keep things snug  A few holes to fill, we'll get the other side done and weld them all in one sitting.   Motion picture version: https://www.youtube.com/watch?v=KCIv27b4dPs .

__________________

Robert |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Nov 2011

Location: West Plains Missouri

Posts: 2,088

|

Re: 55 Wagon Progress

Super nice Robert!

Mark...

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=645774 Project Orangepeel 52 A.D. http://67-72chevytrucks.com/vboard/s...d.php?t=653337 John's LS 49 dodge http://67-72chevytrucks.com/vboard/s...d.php?t=655780 Blake's 67 GMC LS stepside http://67-72chevytrucks.com/vboard/s...d.php?t=690527 Reed 78 FJ40 Rebuild http://67-72chevytrucks.com/vboard/s...d.php?t=733259 Barger's 78 FJ40 |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks Mark!

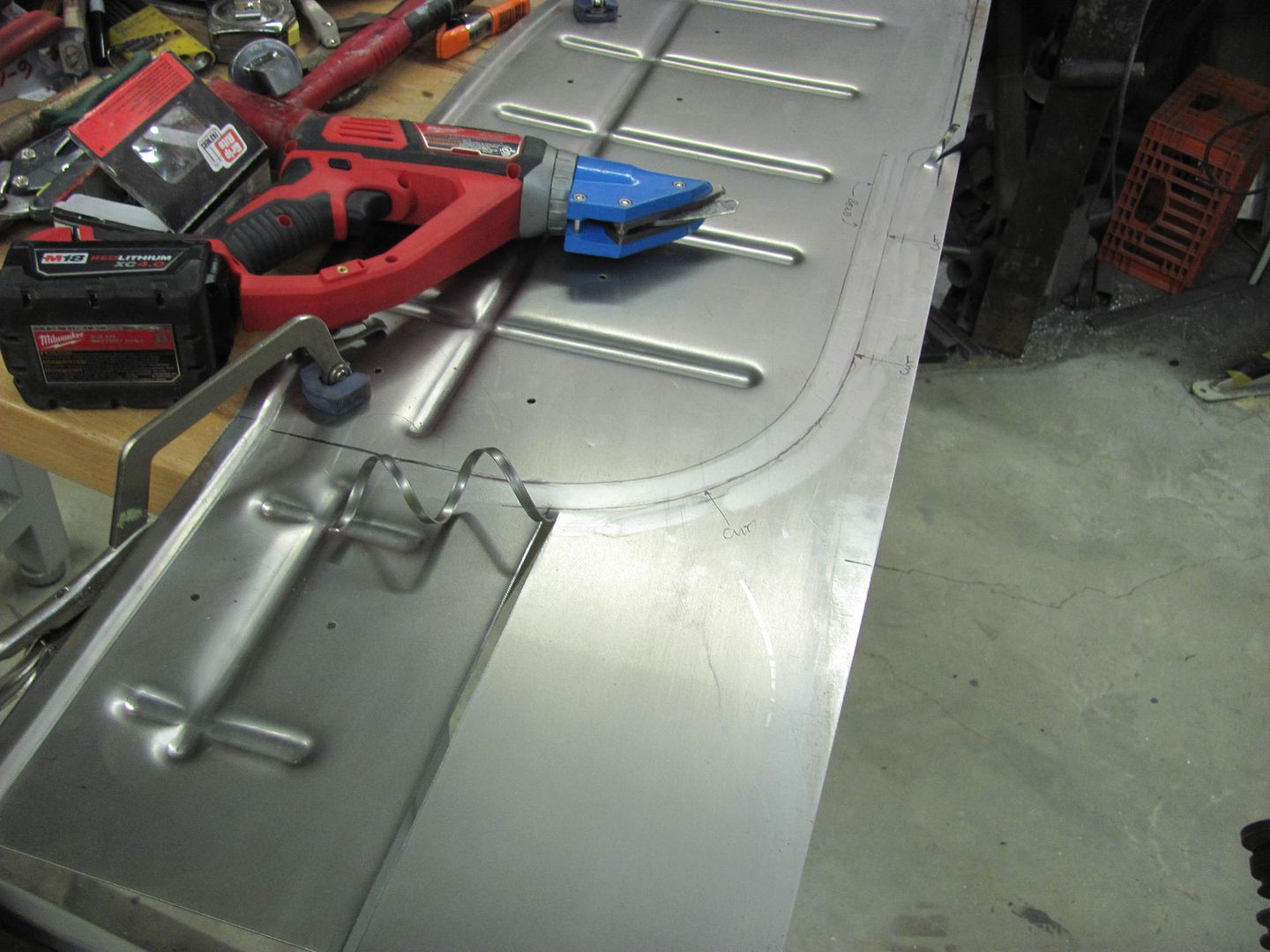

Last night we used the poster board template to check the fit of our pattern to the passenger side. Only a slight shave in the middle for a good snug fit. Then we test fit the repop front section of wheel well, which was horrendous. if we were to trim it to fit there wouldn't be enough step flange left over for the seal. So, Kyle added a 1/2" strip of 18 gauge cold rolled to the outside so we will have enough to trim for a proper fit. Still needs to add that corner on this side as well. https://www.youtube.com/watch?v=DNiSM9Oyp2s While he was welding away, I trimmed the second panel for the passenger rear wheel well, used the Lennox with the tipping die to add the step flange for the seal, and got it prepped for the bead detail work, which we'll get to on Saturday.

__________________

Robert |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

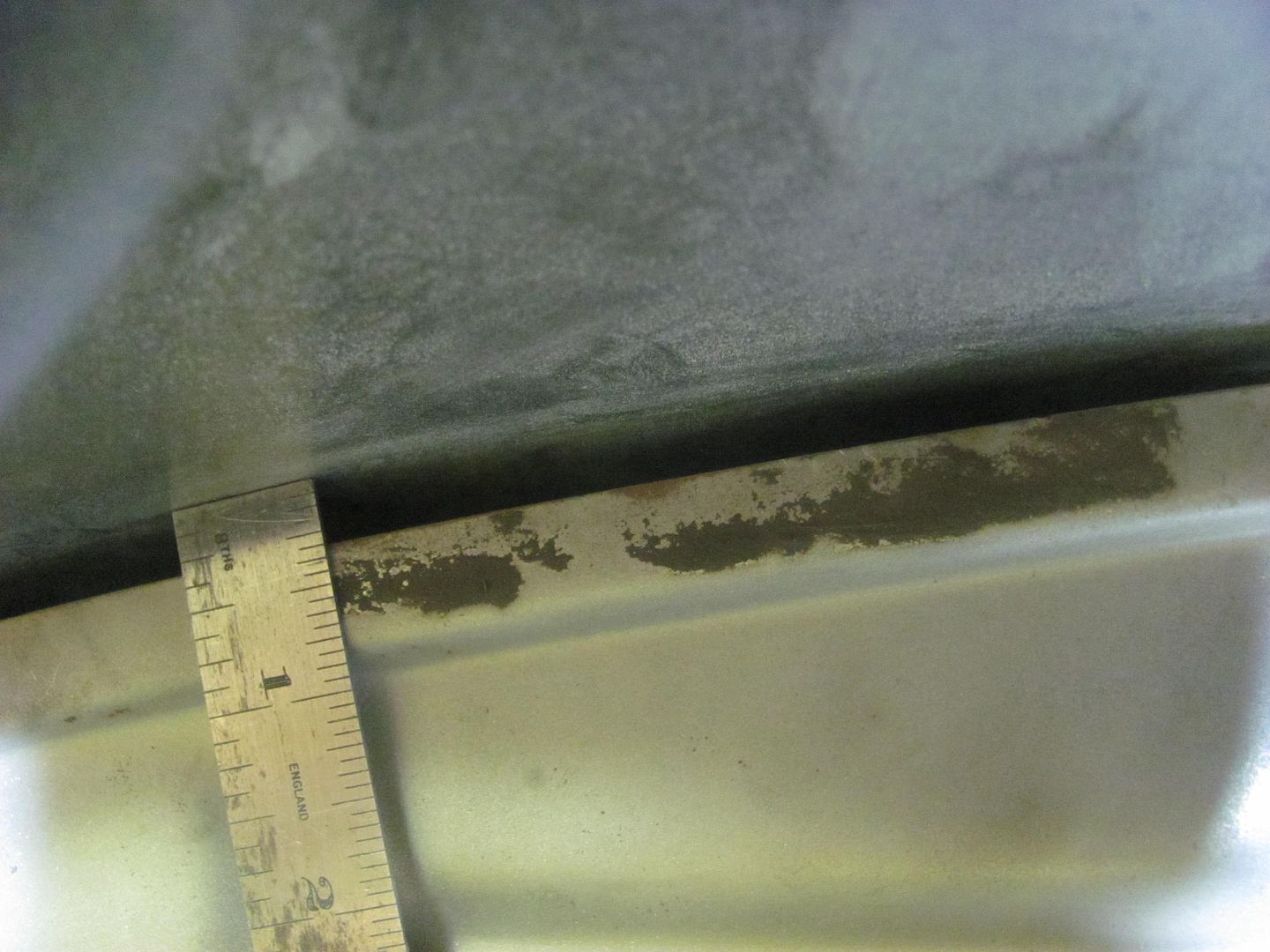

Here's a test fit of the reproduction wheel well for the 55, this is the front section. Note the poor fit to the rear side of the quarter panel. I don't know if these are an EXACT reproduction of OEM, but have heard others having similar "gaping hole" issues with their original cars.

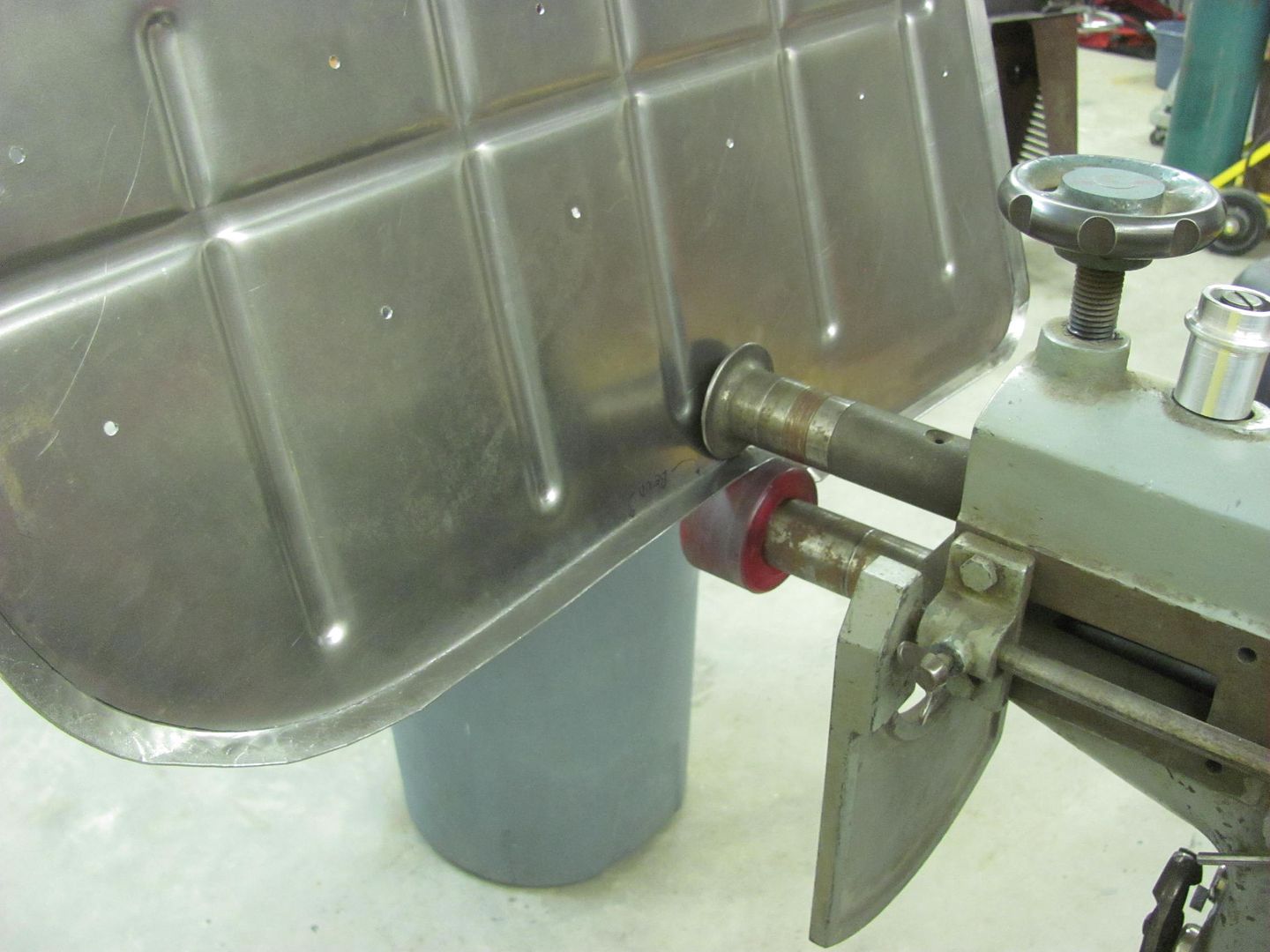

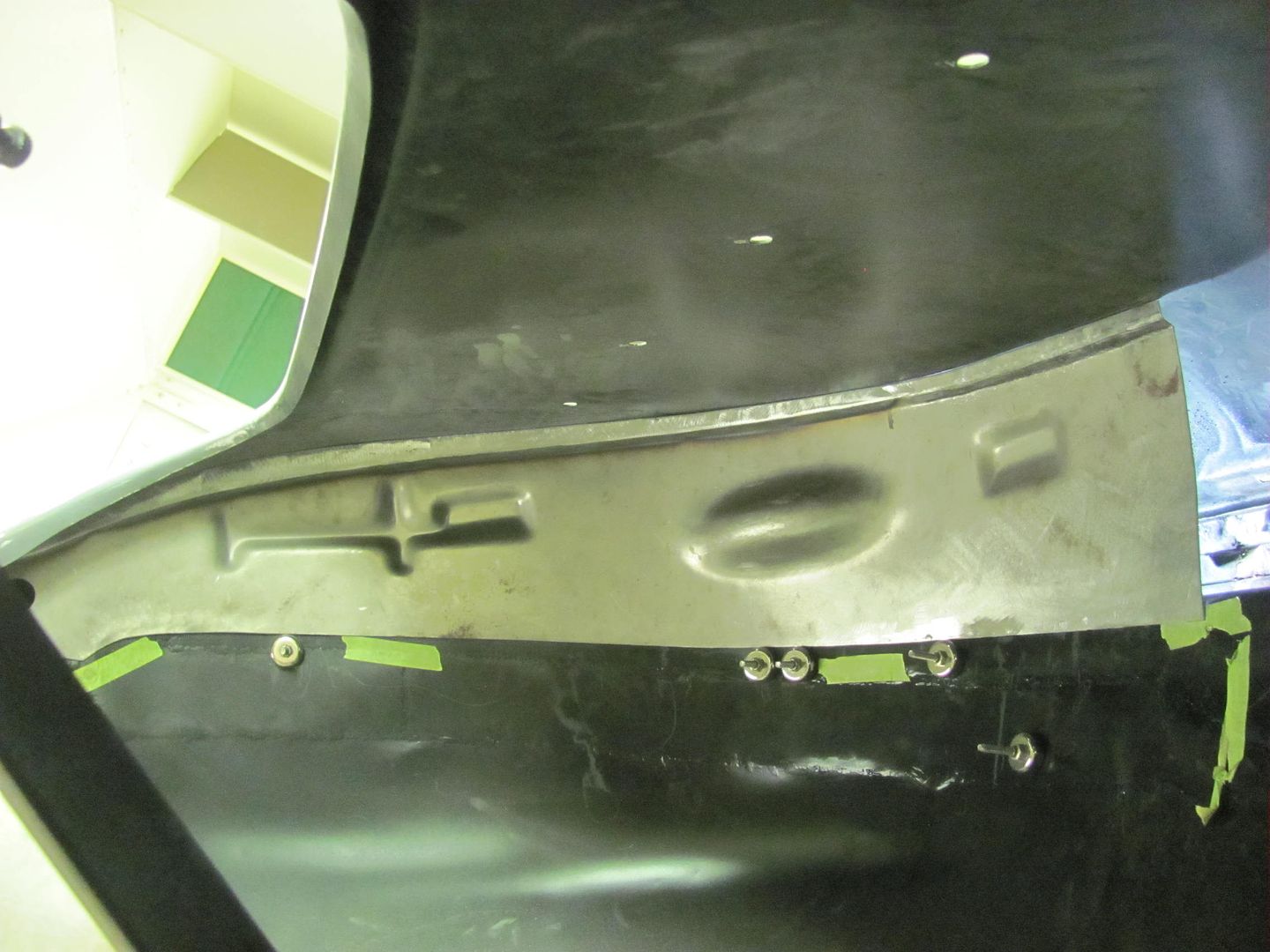

This is the driver's side:   video version.... https://www.youtube.com/watch?v=WiSaQXkkowc This is the passenger side we modified Thursday, adding a 1/2" filler strip and then trimming to fit to the quarter panel....  .......and shown here with seal in place...  Here Kyle is adding the 1/2" filler strip to the driver's side reproduction wheel well. https://www.youtube.com/watch?v=penIygidVUc With the rear section not available in reproduction (blessing in disguise), here is the final layout and trim of our version..  Flanges are tipped using the Fasti swaging machine..  Test fit of the driver's side wheel wells. The front reproduction piece has the filler strip added but still needs trimming, the rear section is a much better fit than what came out from the factory..     Video version: https://www.youtube.com/watch?v=9BvNqdKQf3U Once the front section has been trimmed for proper fit, we will butt weld the front and rear section together to eliminate another overlap rust trap.

__________________

Robert |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Finishing up on our drivers side wheel well today. The front "modified" reproduction is trimmed and fitted. A light is put behind it to check for gaps...  The baffle that sits above the wheel well is made differently as well, this time using a piece of 16 ga cold rolled steel, and trimmed to fill the void. We left a slight gap that we plan on sealing with seam sealer.  Shown here with bulb seal against the quarter....  The trouble with the factory version of sealing above the baffle is that the expanding foam encapsulates the surrounding area, to include surrounding the slot for trim hardware. It is here that water intrudes, and is held against the quarter causing rust.  Our version will leave this hole unobstructed so that any water intrusion that may occur will pass on through. Now to fill in our screw holes that held together the "MDF Sandwich" that we used for beading the panel. A piece of 1/4" thick X 1" copper flat bar is used as a backer, I find it leaves the back side of the weld much cleaner than using flattened copper pipe.   Video version: https://www.youtube.com/watch?v=H2k5_RqRnzc  With the front and rear sections having been fitted and trimmed for a butt weld, next we tack the panels together with the TIG..    Now we have a one piece wheel well, no overlap joints to trap moisture and start rust, as the originals had done.   One piece wheel well test fitted using the bulb seal.... https://www.youtube.com/watch?v=ViIPhYNsEb0 Moving on to the passenger side, both front and back are trimmed and test fitted. Some minor tweaks and we will be ready to trim for a butt weld and TIG these together next time..

__________________

Robert |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, that is some super nice work, looks great...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Nov 2011

Location: West Plains Missouri

Posts: 2,088

|

Re: 55 Wagon Progress

As usual really nice Robert!!

Mark...

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=645774 Project Orangepeel 52 A.D. http://67-72chevytrucks.com/vboard/s...d.php?t=653337 John's LS 49 dodge http://67-72chevytrucks.com/vboard/s...d.php?t=655780 Blake's 67 GMC LS stepside http://67-72chevytrucks.com/vboard/s...d.php?t=690527 Reed 78 FJ40 Rebuild http://67-72chevytrucks.com/vboard/s...d.php?t=733259 Barger's 78 FJ40 |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

Progress from this past week.. Kyle got started on media blasting the drivers side wheel well and I "assembled" the two components for the passenger side..    We plan on epoxy primer on these prior to installation, so the media blasted surface will give a good bite for the primer. Here's the test fit of the assembled passenger side wheel well...   Next, the road trip on Friday.. To preface, a couple weeks ago someone had posted a link showing a Baileigh English wheel on eBay (the big one). In the background was one of the Baileigh power hammers. So I called the contact number in the ad, asked if the hammer was available, which he said yes. He gave me a price, asked for a deposit, and this past Friday was the pick up day. I left the house at 1:45 am, picked up my nephew Chris, and drove to CT. Got it loaded up, made it back to the house by 10 pm, quite a long day. Wait....it's supposed to rain tomorrow, let's unload! So we got it off the trailer and inside by 11. Saturday, after sleeping in, was spent locating a spot for the machine, hooking up power, and trying it out on some scrap metal..  Excited to have this additional capability in the shop.

__________________

Robert |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2012

Location: Oblong, Illinois

Posts: 7,028

|

Re: 55 Wagon Progress

Very nice work on the wheel wells Robert! The power hammer was a nice find and will be useful with your fab work.

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Was working on finishing blocking roof and quarters Saturday when the high winds took out the power for a couple hours.. Not to be deterred, the Milwaukee flashlight comes to the rescue...  Power came back on just after lunch and we got the next dose of Epoxy applied. These sure are some long quarters, I think I'll try a Yugo for the next project, shouldn't need anywhere near the paint prep...   or the video version: https://www.youtube.com/watch?v=06HesZWWT5I .

__________________

Robert |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

This is the first sprayout sample... we'll view these again tomorrow in the sunlight to see the true colors...

Chrysler pewter over H/K organic green. https://www.youtube.com/watch?v=4GniinTcVDw https://www.youtube.com/watch?v=GgDecIZdv04

__________________

Robert |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2016

Location: Australia

Posts: 1

|

Re: 55 Wagon Progress

Hi Robert....I've only recently been lucky enough to have stumbled onto your post's, & are enjoying every single one.

This question is back-tracking a bit, as it relates relates to cutting to open up particularly the door & trunk gaps. Do you mark your actual cutting line at 5/32", or do you cut a little more to allow for grinding the welds. So the finished gap size is at 5/32" Thanks Brett |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Brett, IIRC, it was just a touch more.

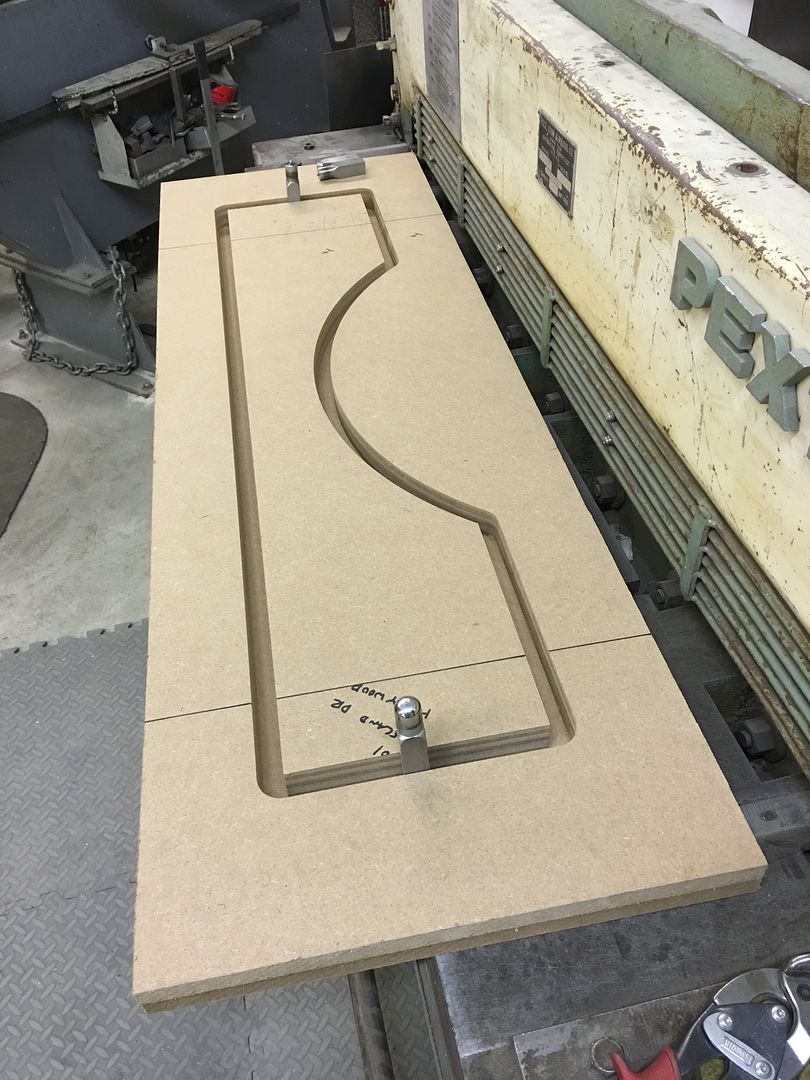

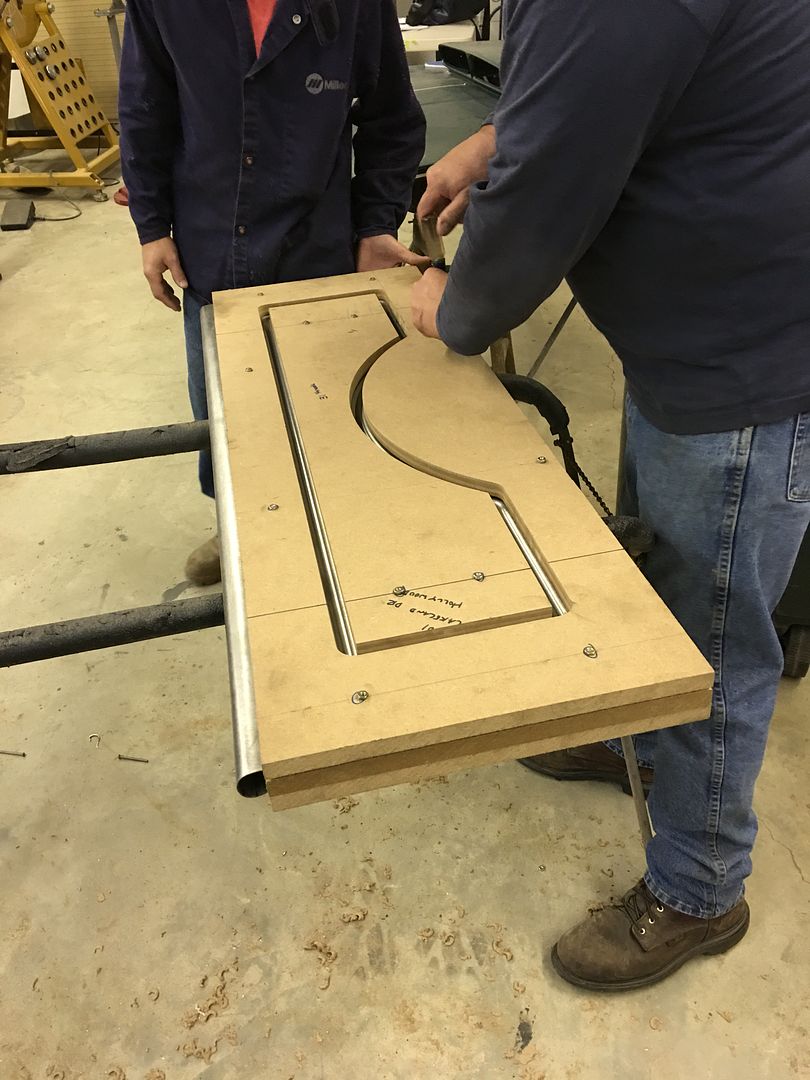

Sorry for the lack of posts, we've been cleaning the shop for the 2016 MD Tommasini Metalshaping Class. Here is a new sand bag we made up for the class, made from a full cow hide, it measures 40" x 24" x 4" high. We had some loose leather left over, so the top was wrapped to provide additional protection from any sharp metal... This uses just over four 5 gallon buckets of saved blast media to fill the bag, so we don't need any holes letting all that pour out on the floor!  Some of the projects include duplicating these repro BMW saddlebags in aluminum, and this Mopar hood in aluminum......   Here Peter shows using the stump for tuck shrinking  Here Peter modifies the heel of a ball peen hammer for less marking while tuck shrinking...  Here it is in use.... https://www.youtube.com/watch?v=plpfX1aPAI0 Duplicating the hood....    A local source was used to CNC a template for bead detail on some Model A p/u bedsides....  Bead added....  Motion picture version: https://www.youtube.com/watch?v=CSD_RUh6bMg  Close-ups of the results...   1937 Dodge coupe door repairs... the lower inner and lower door skins are fabricated...   A complex architectural piece that was shrunk, stretched, planished, and reverses added, all with the same hammer...   Saddle bags in process... https://www.youtube.com/watch?v=Fnapwrq0lzw after wheeling...  Some other efforts of shrinking, blocking, and planishing in making a fender profile and rear corner of a T-bucket in aluminum...    Two days in the books, two to go!

__________________

Robert |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Mar 2011

Location: Arizona City

Posts: 353

|

Re: 55 Wagon Progress

Awesome! Hoping to read in detail! I am a amateur and am getting ready to do my first exterior panel replacement on a rather beat up 57 Chevy.

__________________

I pity the fool with only 2 headlights!

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks!

Here's our paint sample with some sunlight added. The incremental lines to make the radius really show up, but quite a bit of pop in the sunlight.. https://www.youtube.com/watch?v=lAZFi78fngA

__________________

Robert |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Mar 2011

Location: West Plains, Missouri

Posts: 7,559

|

Re: 55 Wagon Progress

Robert, love seeing the stuff made in your shop...Jim

__________________

my build thread: http://67-72chevytrucks.com/vboard/s...d.php?t=459839 Jimbo's long bed step build:http://67-72chevytrucks.com/vboard/s...t=464626<br /> |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

Incredible work. Thank you for sharing. I soak it up like a sponge.

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Thanks guys!

The final two days of the Maryland Tommasini Metalshaping Class. We had two stumps that we gave to students to take home, here is the final version carved.... https://www.youtube.com/watch?v=5yH-M21yUok I had some requests to show the mammoth sand bag with the loose cover removed... It saw quite a bit of use and came in handy!  More repair parts were made for the 37 Dodge doors...       The crease or "swage" at the top center of the hood was difficult to locate through the paper pattern.  So the upper and lower "crease" was highlighted by using fineline tape alongside. Then a pencil was used on the outside of the paper pattern, which now showed the location. Better shown here: https://www.youtube.com/watch?v=miZW1aOWwXg The halves still need to be welded together using O/A. Two of the ball glove pounding pads were put into service for metalshaping, one using shot, the other using sand..  Peter showed lead loading method for aluminum...

__________________

Robert |

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

Started the evening off with some TIG practice, here tacking two panels together....

https://www.youtube.com/watch?v=aTqQJoecqCw Next, to use our fancy dancy paint rollers, getting epoxy inside the rocker panels and inner quarter in prep for installing the wheel wells... Had some SPI epoxy mixed up, poured a small amount in the inner quarter and used the long narrow roller to push paint all the way to the front of the rocker. Lather, rinse, repeat.     ...and used a brush to cover the bare metal that was above the quarter panel's baffle..  There was a bit of overflow, or dust control shall we say.  One rocker down, one to go..

__________________

Robert |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

With the rockers and inner quarters covered with some SPI epoxy primer, tonight we'll get the quarter panel baffles welded in place so we can install the wheel wells.

Here's our home-made baffles:  Primer cleaned off for the plug weld holes..   Kyle plug welding: https://www.youtube.com/watch?v=_AIDbEy_uLc Now plug welded in, we'll clean up these welds tomorrow evening, epoxy prime and seam seal around the top profile of the baffle inside the window extrusion area.

__________________

Robert |

|

|

|

|

|

#23 |

|

Registered User

Join Date: Dec 2011

Location: Mobile, Alabama

Posts: 996

|

Re: 55 Wagon Progress

Attention to detail never disappoints!

__________________

My Build - http://67-72chevytrucks.com/vboard/s...d.php?t=515876 |

|

|

|

|

|

#24 |

|

Registered User

Join Date: Apr 2011

Location: .

Posts: 3,104

|

Re: 55 Wagon Progress

So Im at a swap meet, here in Oregon, run into a forum member and we start shooting the breeze about builders we follow.

When we got to MP&C we talked for 20+ minutes on all the things we've learned from watching the '55 thread. Thanks for sharing and teaching. Level of quality always top notch. |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2013

Location: Leonardtown, MD

Posts: 1,647

|

Re: 55 Wagon Progress

I've always felt that if you could explain it to others, you would better understand yourself. So I try to explain what I'm doing...

......thought my ears were burning

__________________

Robert |

|

|

|

|

| Bookmarks |

|

|